Flood drainage robot

A technology of a robot and a walking mechanism, applied in the field of emergency rescue and disaster relief equipment, can solve the problems of the overturning of the drainage robot, the heavy weight of the flood drainage robot, the inconvenience of setting up remote control electrical devices, etc., so as to achieve the effect of not easy to roll over.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

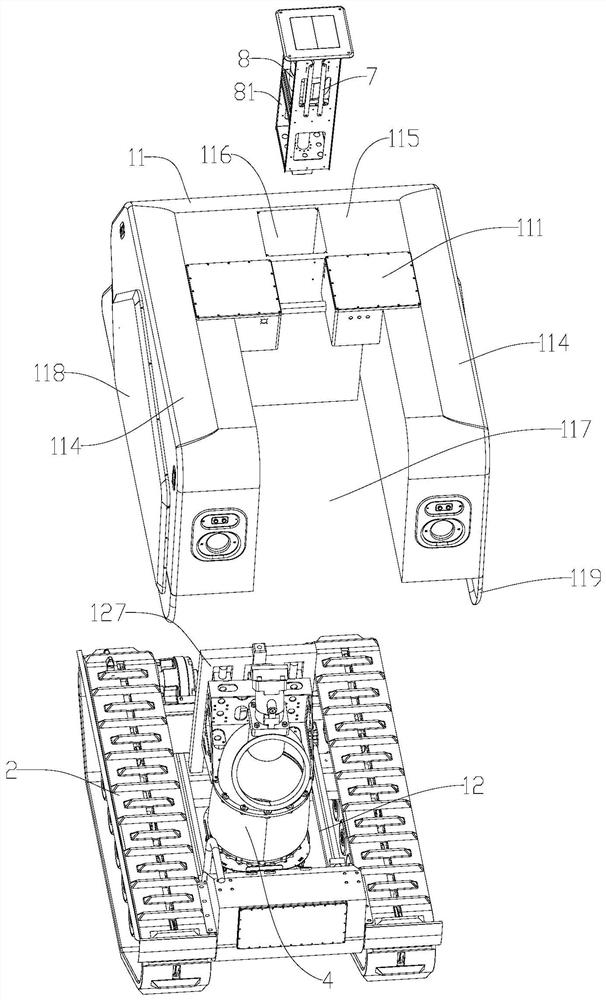

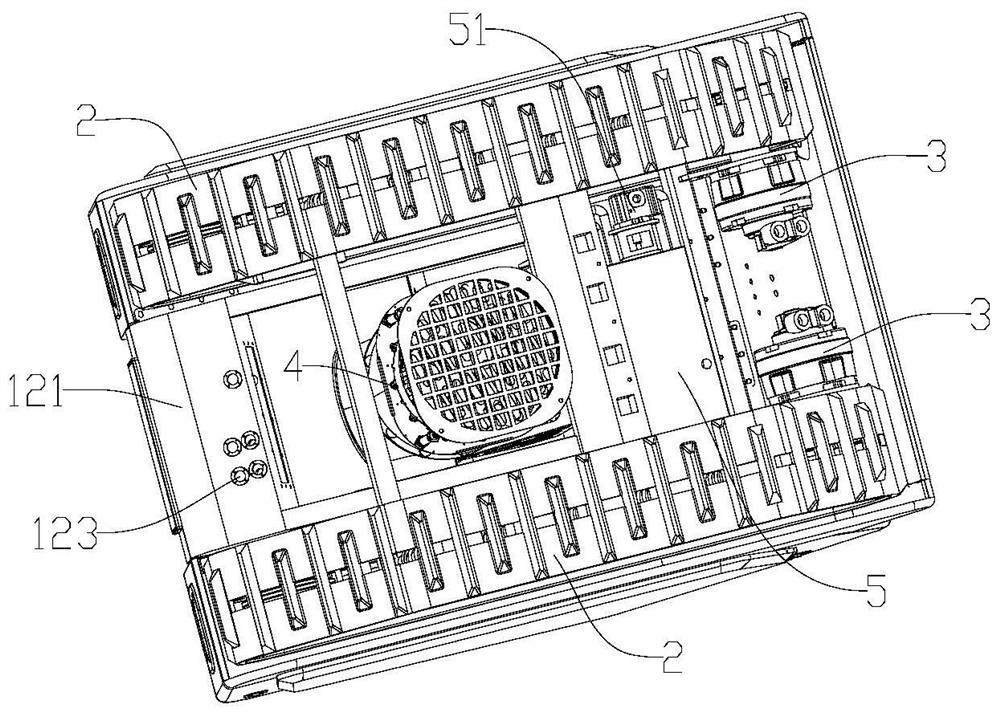

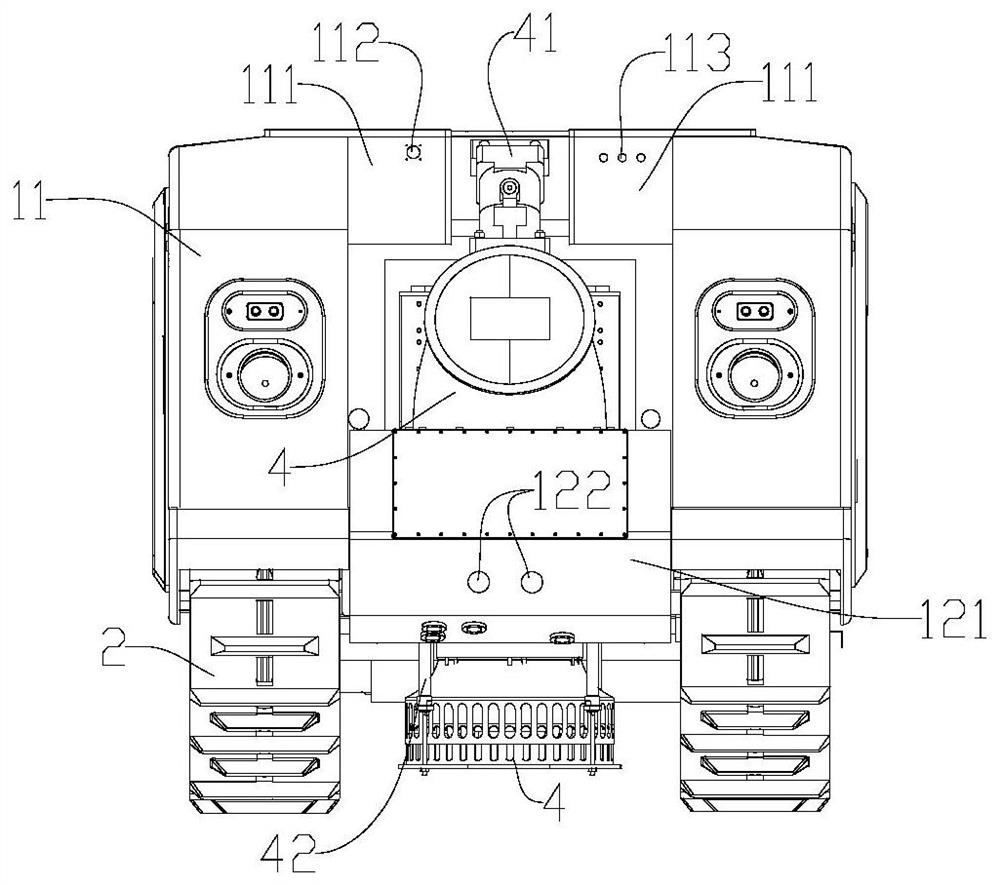

[0024] combined with Figures 1 to 8 Describe a kind of flood discharge robot of the present invention.

[0025] like Figure 1 to Figure 8 The flood discharge robot shown includes a main body 1 of the flood discharge robot, a hydraulic actuator, a water pump 4, a hydraulic pipeline, and a hydraulic power station. The hydraulic power station is placed outside the main body 1, and the hydraulic power The station is connected to the hydraulic pipeline on the main body 1 through the oil inlet pipe and the first oil return pipe, through which hydraulic power is provided for the hydraulic actuators on the main body 1, and the hydraulic pipeline includes the second oil return pipe and an overflow system, the second oil return pipe communicates with the first oil return pipe, and the overflow system is used to connect the overflow valve of the hydraulic actuator that needs to overflow to the second oil return pipe; the main body 1 includes Buoyancy cabin 11, base 12 and running gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com