Semi-submersible type overwater overflow oil cleaning ship and control method thereof

An oil spill cleaning and semi-submersible technology, which is applied in the field of oil pollution treatment on water, can solve the problems that the automatic oil spill recovery device for secondary pollution can not deal with oil spills, monitor and other problems, so as to reduce safety threats, reduce use costs, and reduce work costs. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

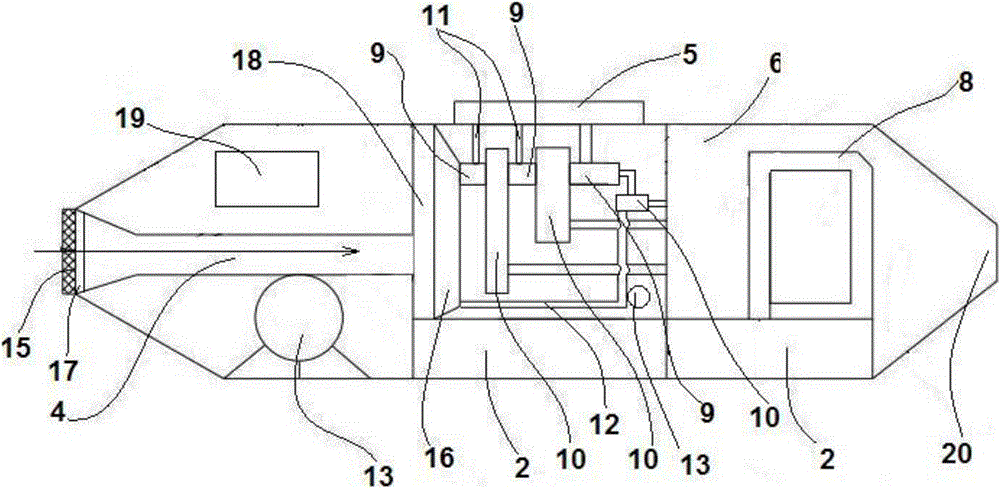

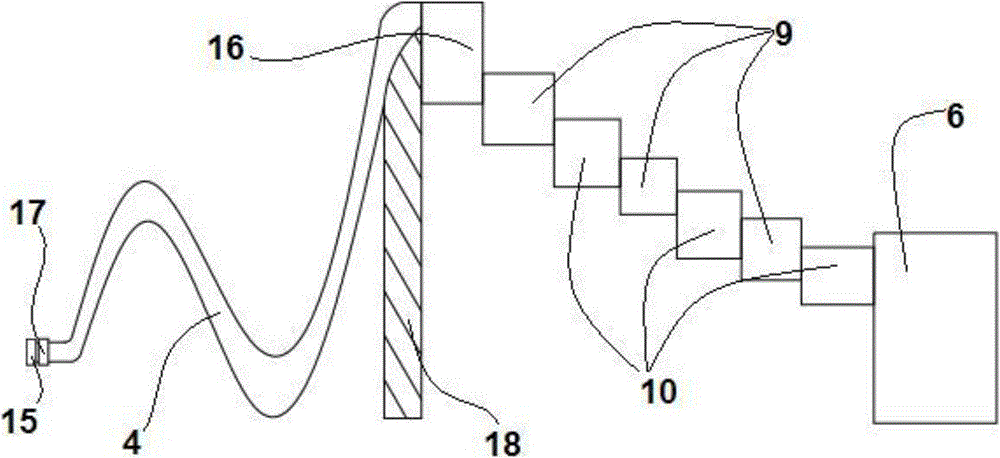

[0073] like figure 1 , figure 2 The illustrated embodiment is a semi-submersible oil spill cleaning ship, including a controller 1 arranged on the hull, a wireless transceiver 21, two ballast tanks 2 and a floating body 3 for adjusting the diving depth of the hull, The water inlet pipe 4, the oil-water separation system connected with the water outlet of the water inlet pipe, the oil storage tank 5 connected with the oil-water separation system, the water storage well 6 and the power system 8 connected with the oil-water separation system; Generator 7; The floating body is located on the lower surface of the hull; The ballast tank is connected with the water inlet and outlet pipes, and the water pumps are arranged on the water inlet and outlet pipes, and a water level sensor 14 is arranged in the ballast tank;

[0074] The oil-water separation system includes 3 oil-water separators 9 and 3 liquid storage tanks 10. Solenoid valves are installed between the water outlets of th...

Embodiment 2

[0098]In Embodiment 2, a sewage volume regulating box 16 is provided between the first-stage oil-water separator and the water outlet of the water inlet pipe, a water level sensor 14 is provided in the sewage volume regulating box, and an electromagnetic flow control valve 17 is provided at the front end of the water inlet pipe; finally The primary liquid storage tank is connected with the sewage volume regulating tank through the return water pipe; the electromagnetic flow control valve and the water level sensor are both electrically connected with the controller. Other structural parts in Embodiment 2 are the same as in Embodiment 1.

[0099] Step b in Example 1 is replaced by the following steps, and other steps in Example 2 are the same as in Example 1.

[0100] The standard range of water level is set in the controller, and the standard range of water level is 30% to 85% of the height of the sewage volume adjustment tank;

[0101] When the oil content is greater than or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com