Oil spill cleaning ship on water and control method

An oil spill cleaning and controller technology, which is applied in the cleaning of open water surfaces, water conservancy projects, general water supply conservation, etc., can solve the problems of secondary pollution, such as the oil spill treatment effect and monitoring of the automatic oil spill recovery device on the sea, and achieve reduction The effects of safety threats, lower usage costs, and reduced round-trip transportation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

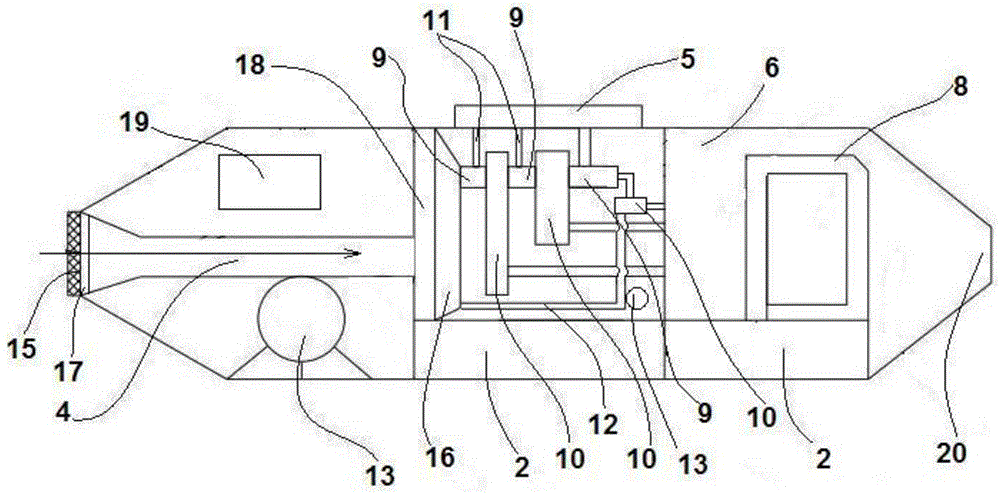

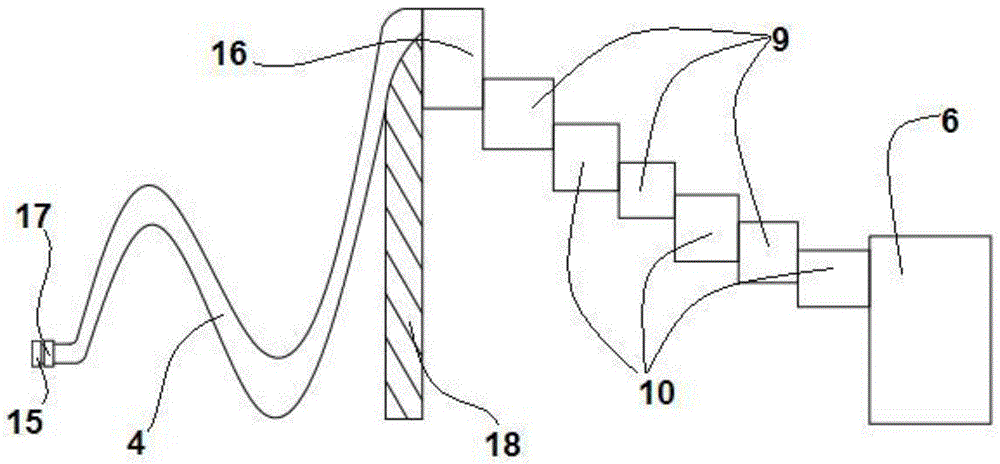

[0070] Such as figure 1 , figure 2 The shown embodiment is an oil spill cleaning ship on water, including a controller 1, two ballast tanks 2 arranged on the hull, a floating body 3 arranged on the lower surface of the hull, and a water inlet pipe 4 arranged at the head of the hull , the oil-water separation system connected with the water outlet of the water inlet pipe, the oil storage tank 5 connected with the oil-water separation system, the water storage tank 6 connected with the oil-water separation system, the wave generator located in the water storage tank and the Part of the power system 8;

[0071] The oil-water separation system includes three stages of oil-water separators 9 arranged in sequence from front to back, and liquid storage tanks 10 are arranged behind the oil-water separators at all levels, and electromagnetic valves are arranged between the water outlets of the liquid storage tanks and the oil-water separators. The oil-water separators of each stage ...

Embodiment 2

[0094] In Embodiment 2, a sewage volume regulating box 16 is provided between the first-stage oil-water separator and the water inlet pipe, a water level sensor 14 is arranged in the sewage volume regulating box, and an electromagnetic flow control valve 17 is provided at the front end of the water inlet pipe; The liquid tank is connected with the sewage volume regulating tank through the return water pipe; the electromagnetic flow control valve and the water level sensor are both electrically connected with the controller. Other structural parts in Embodiment 2 are the same as in Embodiment 1.

[0095] Step b in Example 1 is replaced by the following steps:

[0096] The standard range of water level is set in the controller, and the standard range of water level is 30% to 85% of the height of the sewage volume adjustment tank;

[0097] When the oil content is greater than or equal to W, the controller controls the electromagnetic valve on the return water pipe to open, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com