Semi-automatic paint spraying machine

A paint spraying machine and semi-automatic technology, applied in spray booths, spraying devices, coatings, etc., can solve the problems of low production efficiency, poor working environment, and low cost, and achieve the effects of reduced motor usage, low manufacturing cost, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

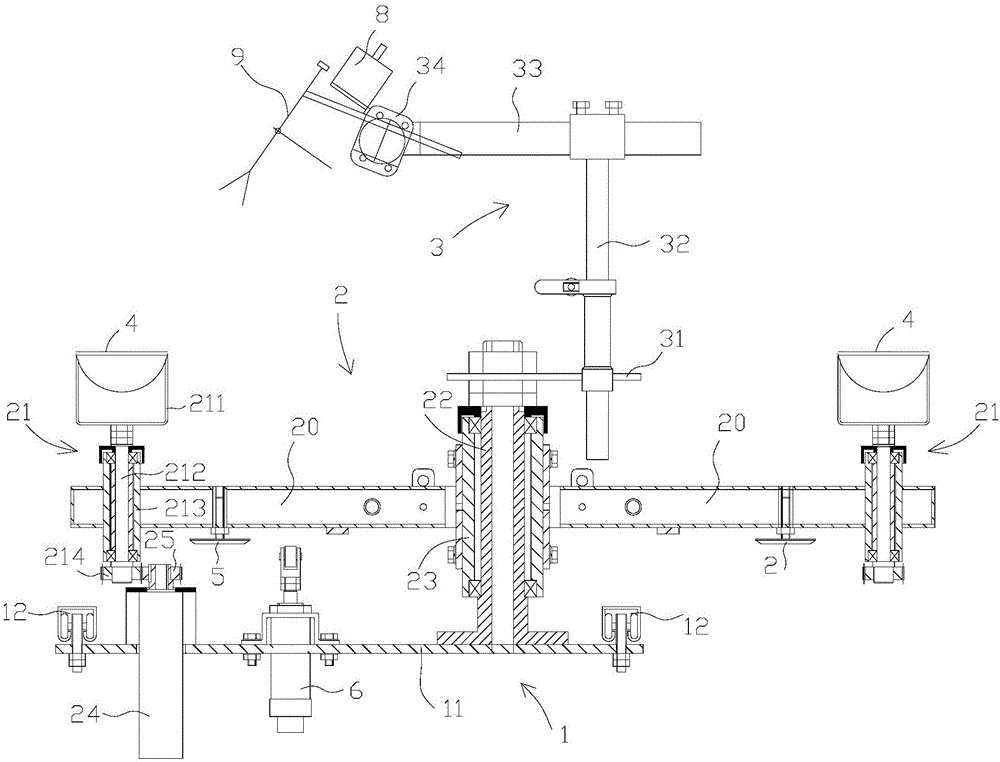

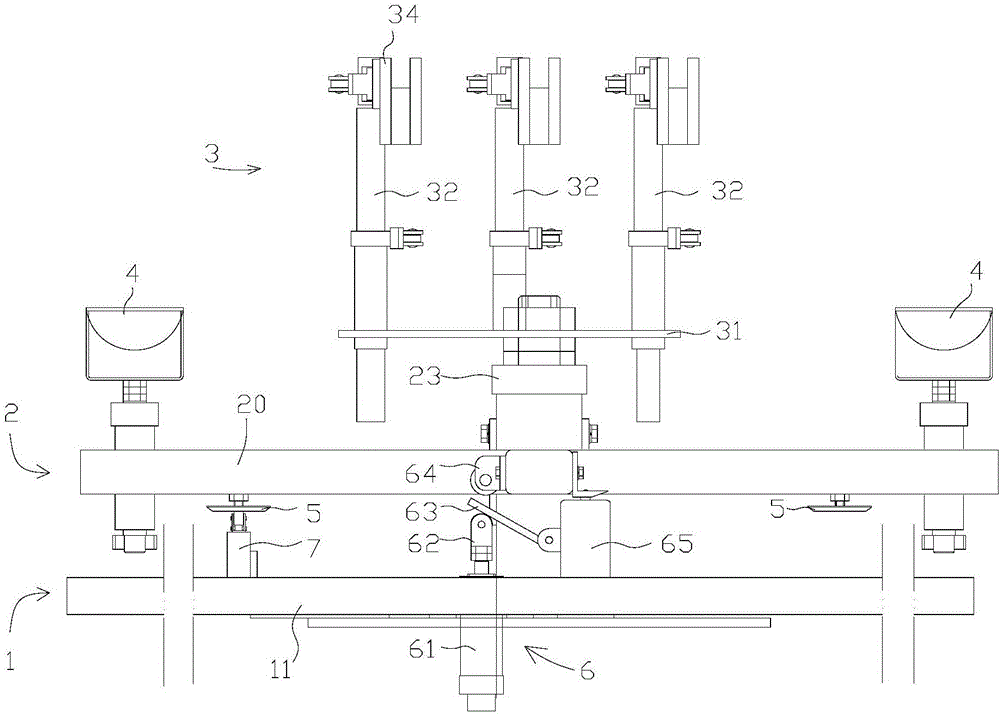

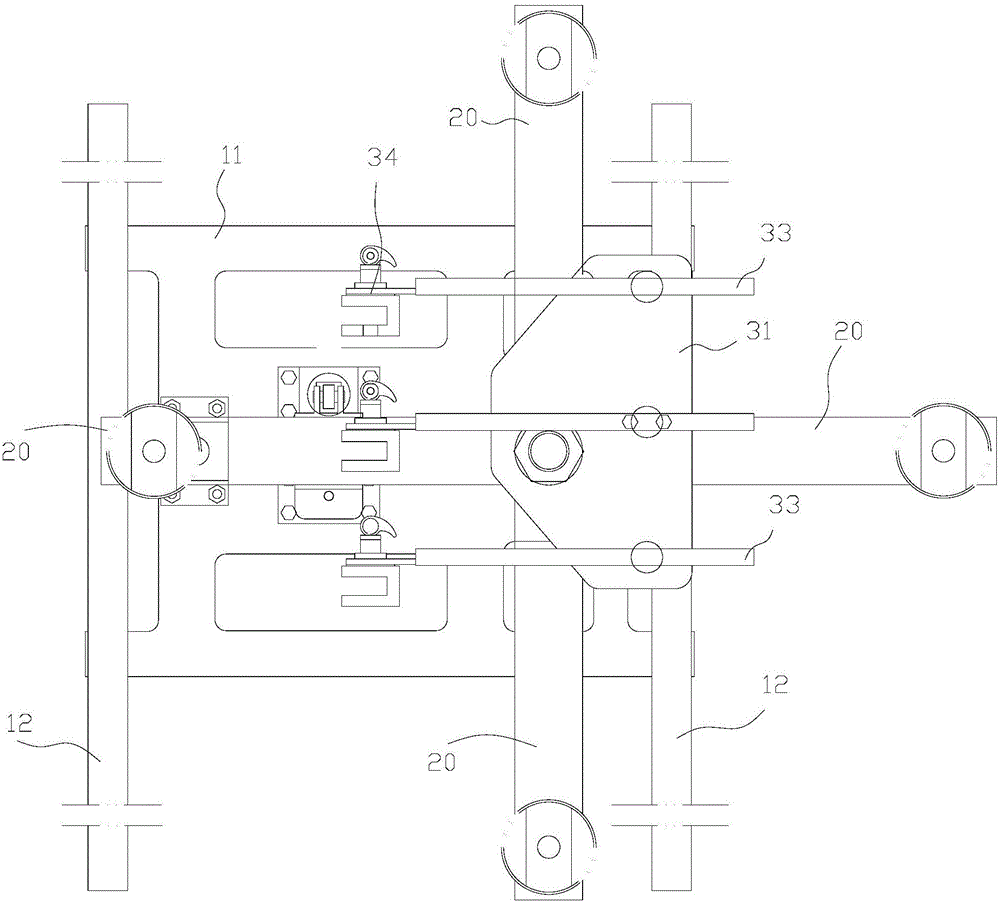

[0035] The invention discloses a semi-automatic paint spraying machine, comprising a base plate assembly 1, a rotary assembly 2, a spray rack assembly 3, a spray gun 9 assembly, an air supply device and a control box, the base plate assembly 1 includes a base plate 11 and a support rod 12, the The support rod 12 is horizontally fixed on the opposite sides of the bottom plate 11 by bolts, and the support rod 12 is detachably fixed on the ground or on a fixed platform; the rotary assembly 2 includes a cross swing frame 20, an air motor 24, a bracket assembly 21, Push the component 6 and the fixed seat 22; the fixed seat 22 is fixed on the upper surface of the bottom plate 11, the cross swing frame 20 is horizontally set on the fixed seat 22 and can rotate relative to the fixed seat 22; the air motor 24 is installed on the bottom plate 11 and located Below the swivel cross frame 20, the end of the swivel arm of the swivel cross frame 20 is provided with a bracket assembly 21, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com