Rolling harrow-based, material-turnover, material-charging and high-efficiency loader and loading method therefor

A technology of loader and rolling rake, which is applied in the fields of excavation, material loading, mining, and tunnel excavation. It can solve the problems that the rake teeth are easy to be lifted by bulk materials, use restrictions, and easy to be picked up, so as to achieve continuous operation of the equipment Improved performance, improved loading efficiency, and low raking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

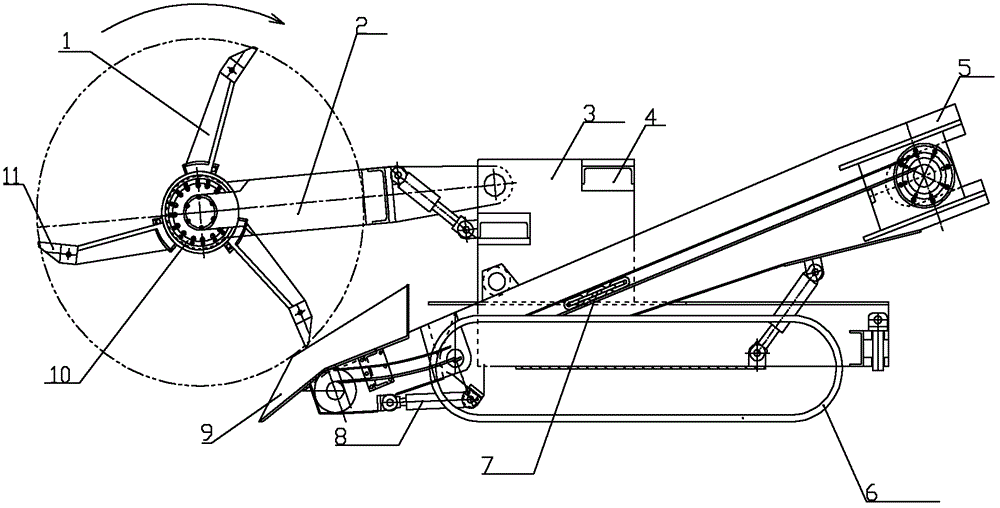

[0032] figure 1 It is the high-efficiency loader and loading method for rolling rake turning material described in this embodiment. The high-efficiency roller rake turning material loading machine includes a fuselage 4, a roller rake 1, a transport mechanism 5 and a drive mechanism 3, the transport mechanism 5 and the drive mechanism 3 are both arranged on the fuselage 4, and the transport mechanism 5 includes a scraper conveyor 7 And the traveling device, the scraper conveyor 7 is used to convey materials, and the roller rake includes a support arm 2 , rake teeth 11 and a rake cylinder 10 , and the rake teeth 11 are arranged at intervals along the outer surface of the rake cylinder 10 . One end of the support arm 2 is connected with the transport mechanism, and the rake teeth 11 rotate clockwise relative to the transport mechanism 5, which is opposite to the flow direction of the material, that is, picks up the material in the direction in which the material falls. The rake ...

Embodiment 2

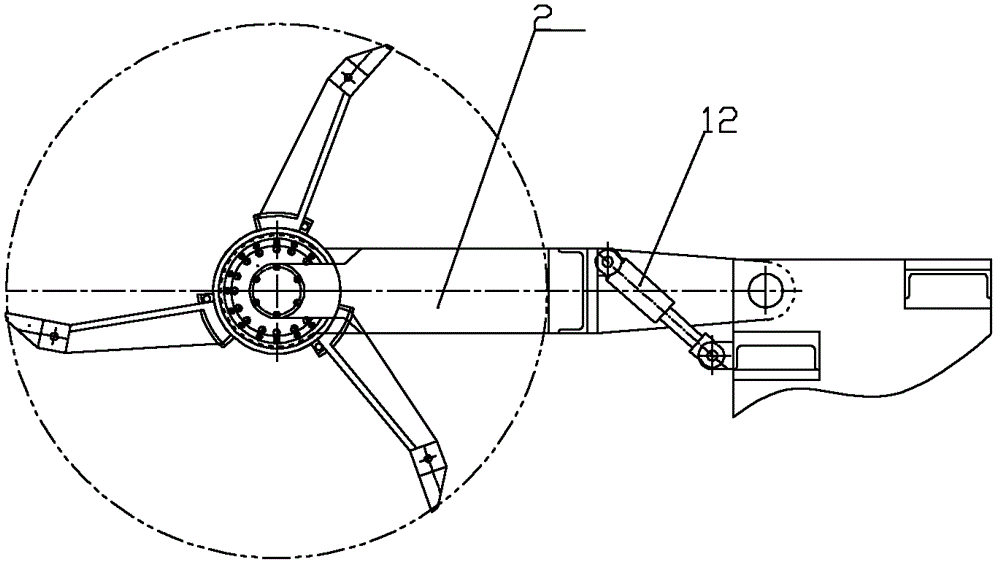

[0041] figure 2 It is the high-efficiency loader for rolling rake turning and charging described in this embodiment. In this embodiment, the support arm 2 includes a position adjustment device 12, figure 2 The position adjusting device 12 is a hydraulic cylinder, and it can also be realized by adjusting a screw, a rope reel, or adjusting a hydraulic push rod.

[0042] Others are with embodiment 1.

Embodiment 3

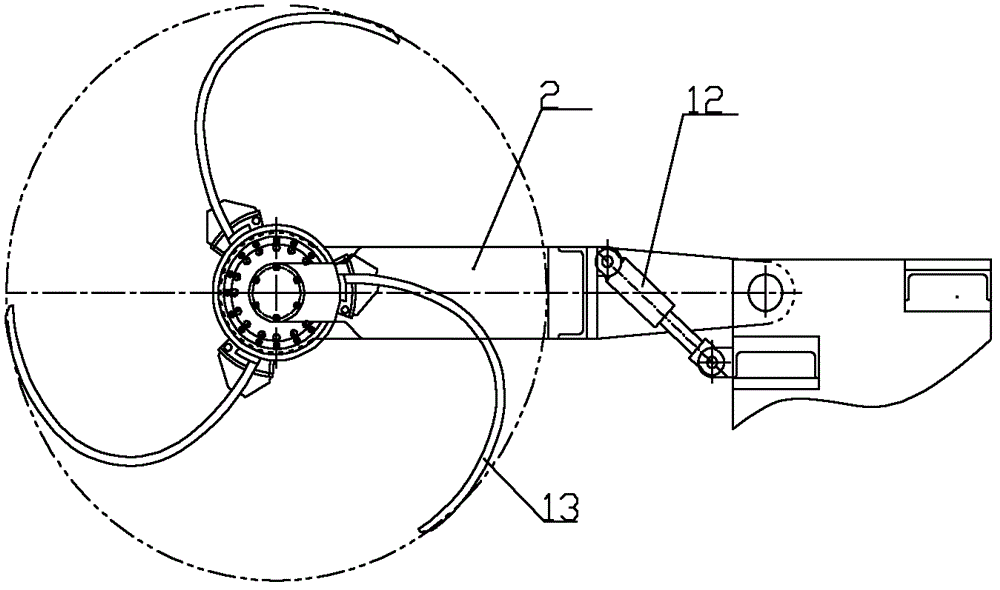

[0044] image 3 It is the high-efficiency loader for rolling rake turning and charging described in this embodiment. In this embodiment, the support arm 2 includes a position adjustment device 12, figure 2 The position adjusting device 12 in the middle is a hydraulic cylinder, and an adjusting screw, a rope reel or an adjusting hydraulic push rod can also be used. Meanwhile, the rake teeth adopted in this embodiment are arc-shaped rake teeth 13 .

[0045] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com