Wireless transmission module and manufacturing method thereof

A wireless transmission and module technology, which is applied in transmission systems, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the disadvantages of miniaturization and thinning of electronic equipment, low integration of wireless transmission modules, and reduction of module power density and other issues, to achieve the effect of improving continuous normal working ability, facilitating heat dissipation, and improving miniaturization and thinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Based on the background technology part, it can be seen that the existing wireless transmission module has the problem of low integration, and further has the following problems:

[0059] 1) It is not conducive to the miniaturization and thinning of electronic equipment assembled with wireless transmission modules;

[0060] 2) The sensitive components in the wireless transmission module are easily damaged, and the product reliability is low;

[0061] 3) There is a large family planning impedance, which makes the power density of the module low.

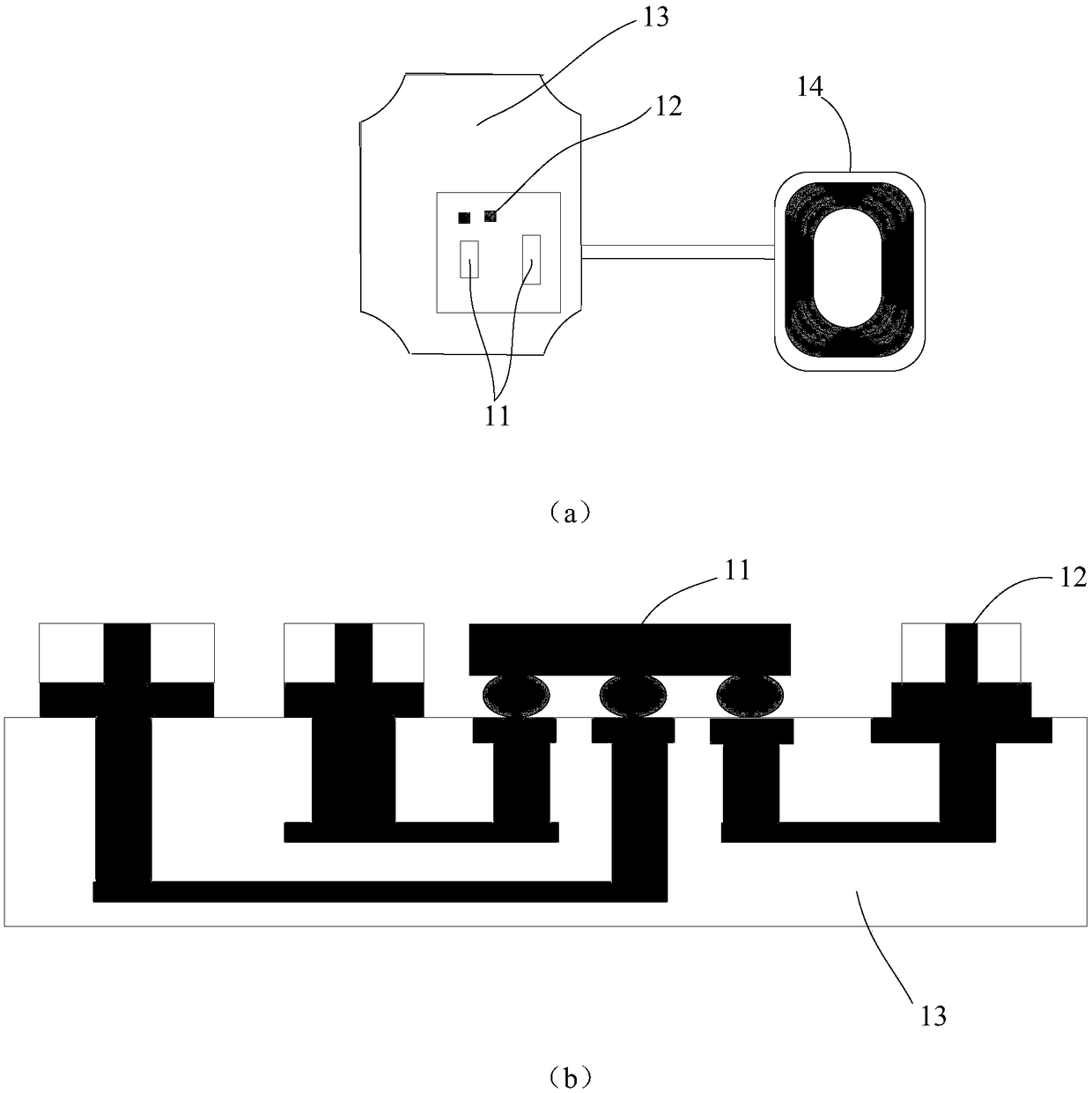

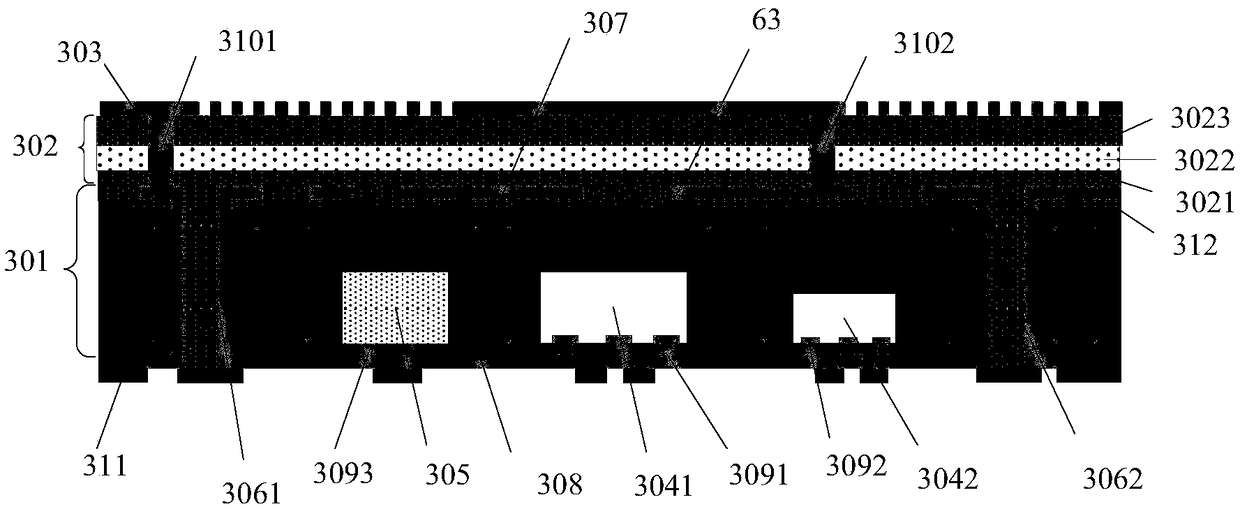

[0062] In order to solve the above technical problems, the embodiment of the present application integrates the chip, passive components, magnetic materials and coils to form a wireless transmission module with an integrated structure, so as to improve the integration degree of the wireless transmission module. The wireless transmission module with integrated structure can be flexibly arranged inside the whole electronic devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com