Hybrid power transmission system of longitudinal flow cutting threshing device and harvesting machine

A technology of hybrid power and transmission system, applied in the field of hybrid power transmission system and harvester, to achieve the effect of maintaining smoothness, increasing continuous working ability, and less technical difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

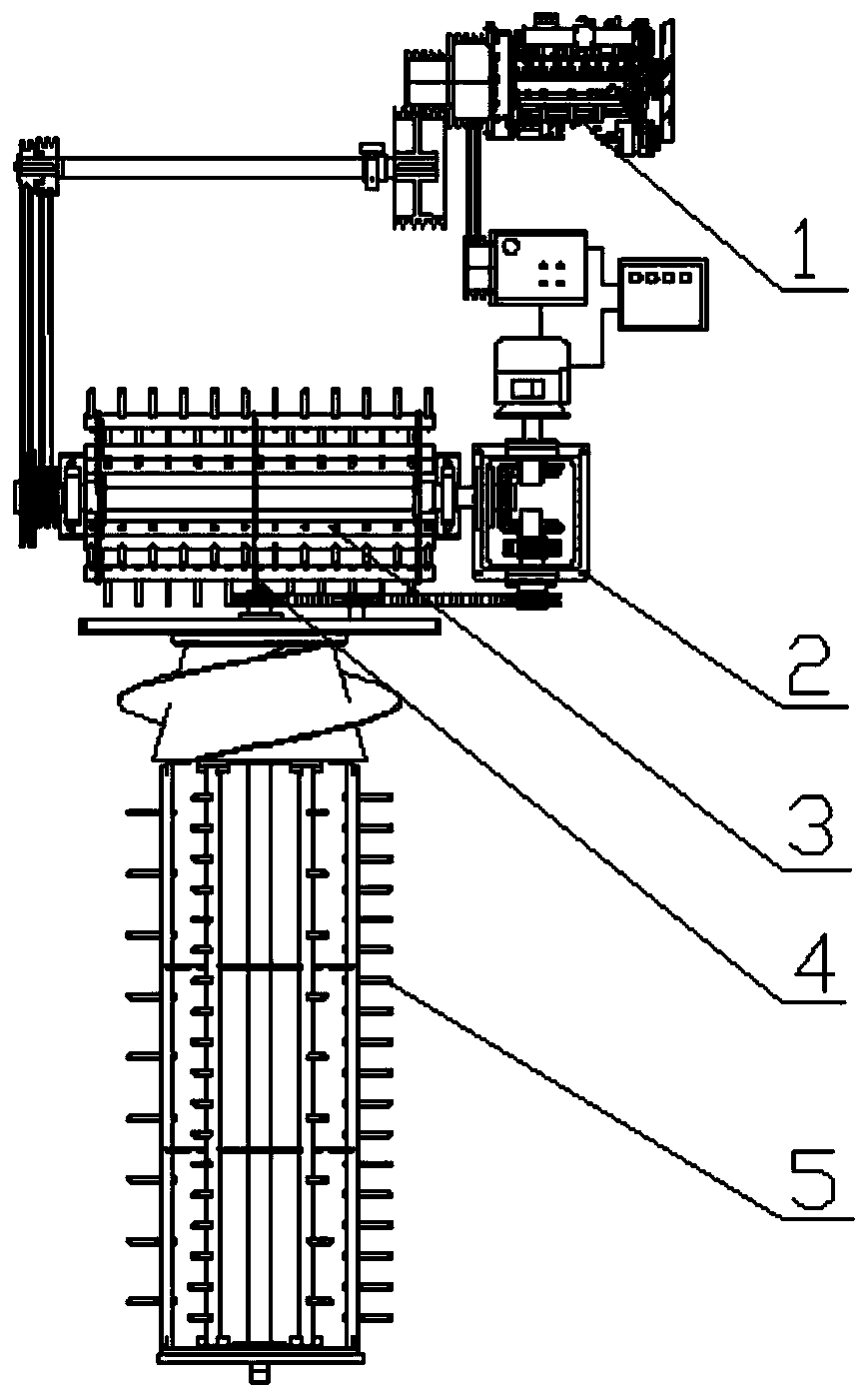

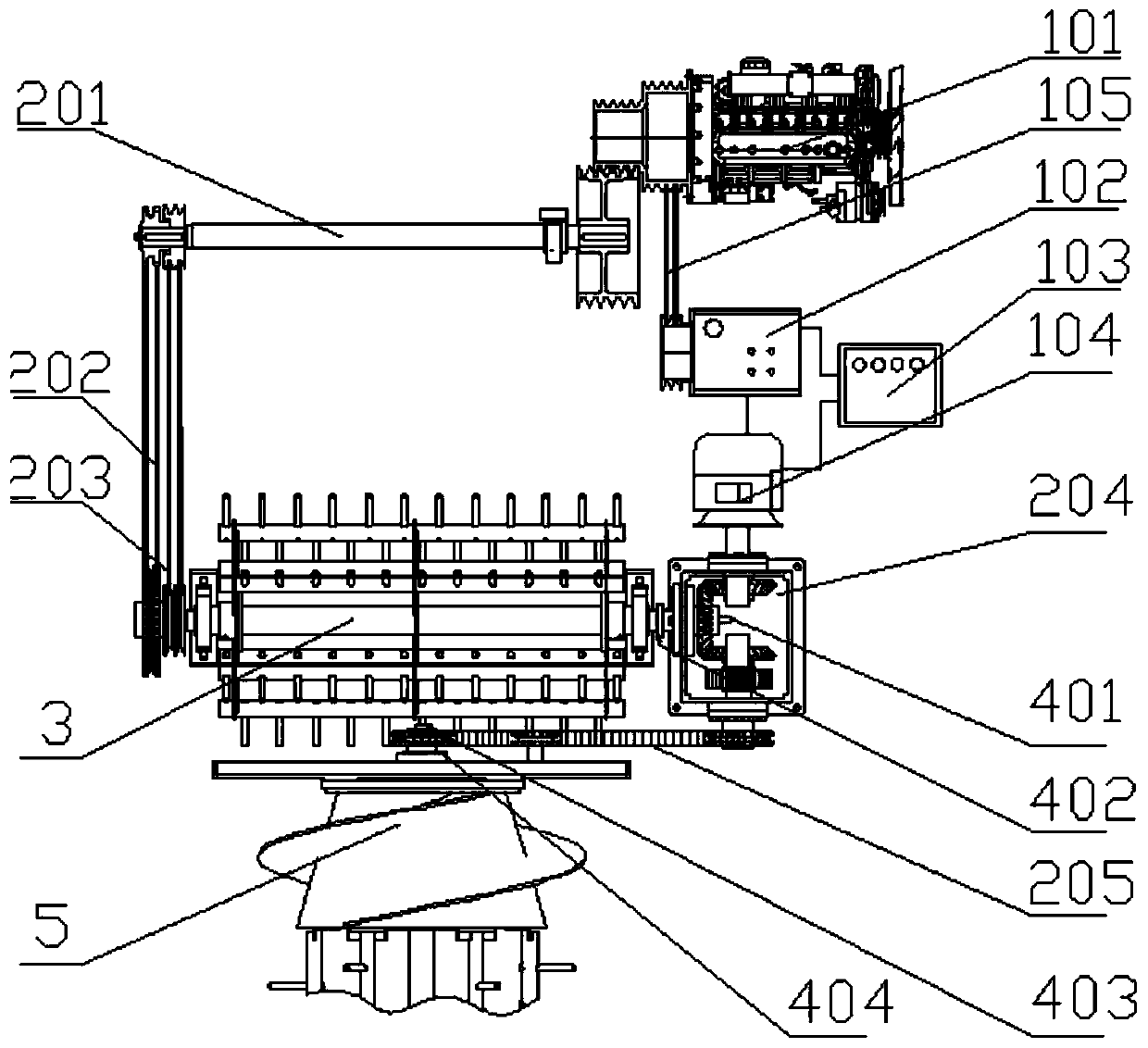

[0044] Such as figure 1 with figure 2 Shown is a preferred embodiment of the hybrid power transmission system of the cutting and longitudinal flow threshing device of the present invention, the hybrid power transmission system of the cutting and longitudinal flow threshing device includes a drive device 1, a transmission device 2, and a cutting flow drum 3 , sensing device 4, longitudinal axial flow drum 5 and control unit;

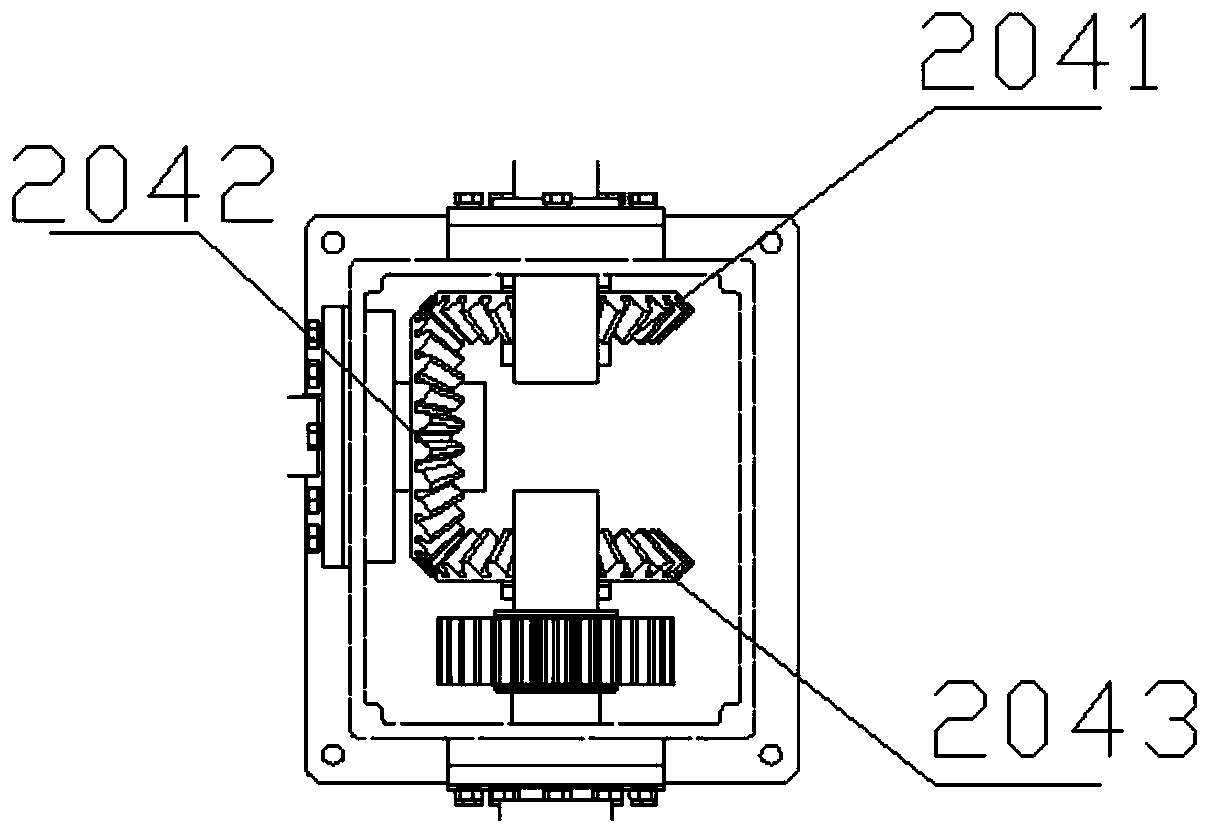

[0045] Described driving device 1 comprises motor 101, generator 102, supercapacitor 103 and motor 104; Described motor 101 and generator 102 are connected through transmission mechanism; Preferably, described transmission mechanism is and belt transmission 105, generator 102 and Engine 101 is connected by belt drive 105; Described motor 104 is connected with generator 102; Supercapacitor 103 is connected with described motor 104 and generator 102 respectively; Described generator 102, supercapacitor 103 and motor 104 form an electric drive The device ...

Embodiment 2

[0059] A harvester, comprising the hybrid power transmission system of the cutting and longitudinal flow threshing device described in the embodiment, therefore has the beneficial effects of the embodiment 1, and will not be repeated here.

Embodiment 3

[0061] A method for controlling the hybrid power transmission system of the tangential flow threshing device according to embodiment 1, comprising the following steps:

[0062] Such as Figure 5 As shown, the sensing device 4 collects and measures the rotational speed T of the flow cutting drum 3 respectively. 1 , the speed T of the vertical axial flow drum 5 2 , the SOC value of the state of charge of the supercapacitor 103, and transmit it to the control unit;

[0063] According to the speed T of the flow cutting drum 3, the control unit 1 and the rotational speed T of the vertical axial flow drum 5 2 The torque Trq required by the hybrid power transmission system is obtained, and the torque Trq and SOC values are used as the input variables of the fuzzy controller, and the output variable is calculated as the coefficient parameter K through the fuzzy logic control strategy, and the control unit controls the engine 101 and the generator according to the K value 102, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com