Method for making GaN-based LED with back hole structure

A light-emitting diode, gallium nitride-based technology, applied in the field of semiconductors, can solve problems such as hindering high-power light-emitting diodes and large thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

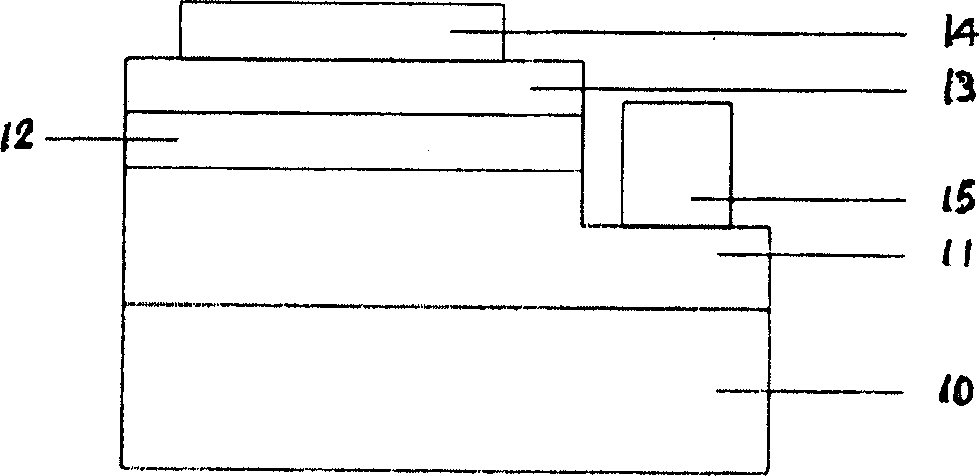

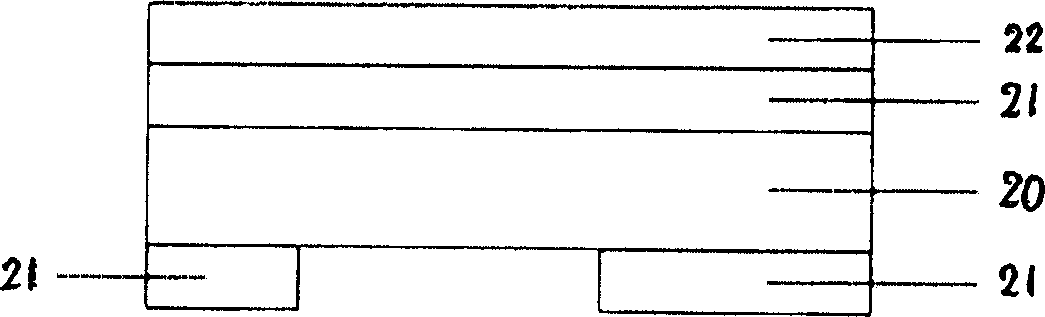

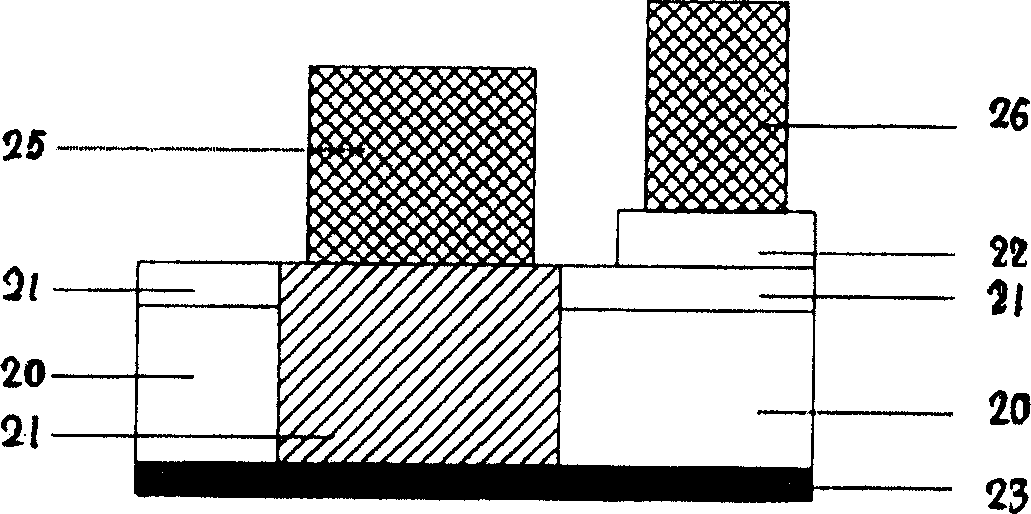

[0041] first as figure 1 As shown, this is a cross-sectional view of the die structure of a GaN-based light-emitting diode. The manufacturing process is to epitaxially grow a GaN N-type contact layer 11 on a sapphire substrate 10 using MOCVD method, a light-emitting active region 12 and a P-type GaN contact layer 13; the shape of the die is designed to be a square, with a size of 1mm×1mm, and then an N-type mesa (N-type contact layer 11) is etched according to the designed die pattern and dry-etched by an ICP system. Ni / Au / Ag / Ni / Au (50 Å / 50 Å / 1500 Å / 200 Å / 1200 Å) was prepared by electron beam evaporation (or sputtering) on the P-type GaN contact layer 13, and annealed at 500 degrees Celsius For 5 minutes, an ohmic contact electrode 14 of P-type GaN with low ohmic contact and high reflectivity is formed. Ti / Al / Ni / Au (150 Å / 2200 Å / 400 Å / 500 Å) was prepared on the N-type GaN layer 11 by electron beam evaporation (or sputtering), and annealed at 900 degrees Celsius for 30 secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com