Hearth push-pull type ash discharging device for biomass gasifying furnace

A gasifier, push-pull technology, applied in the field of push-pull ash extraction devices at the bottom of biomass gasifiers, can solve the problems of ash extraction, unclean ash and slag removal, affecting gasification effect, etc., and achieves simple and convenient operation and improved Operating conditions and environment, the effect of improving continuous working ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

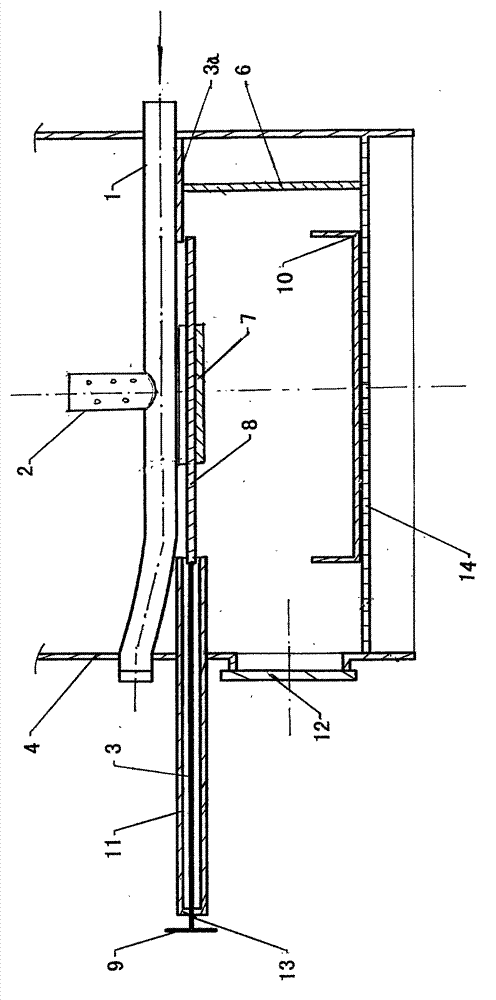

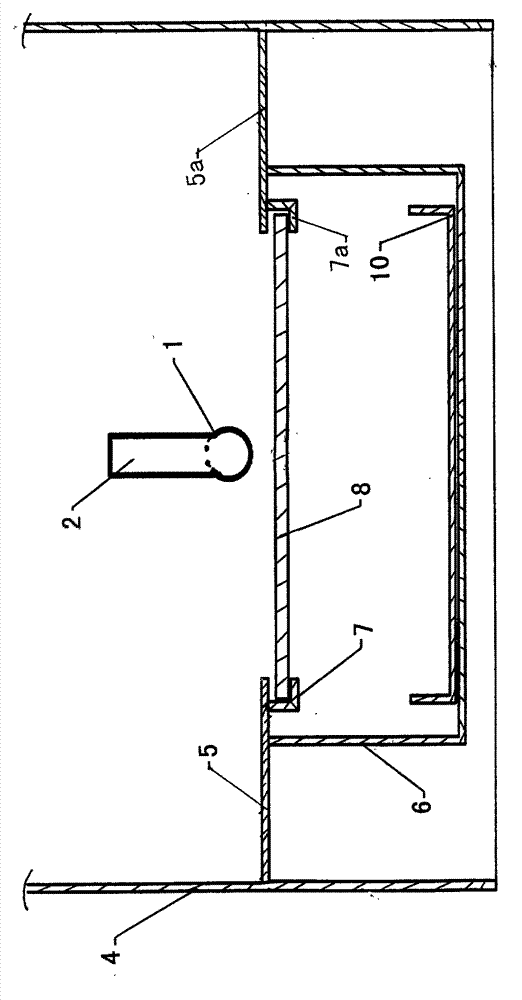

[0012] A push-pull type ash discharge device at the bottom of a biomass gasification furnace according to the present invention includes an air inlet pipe 1, an air nozzle 2, ash plate push-pull rod 3, a furnace body 4, a left support plate 5 and a right support plate 5a, a storage Ash box 6, front push-pull groove 7 and rear push-pull groove 7a, ash drop plate 8, handle 9, ash storage box 10, ash drop plate guide box 11, ash storage box door 12, rear support plate 3a, oil seal 13 and bottom solid plate 14. The sidewall of body of heater 4 lower ends is equipped with ash storage box door 12, opens ash storage box door 12 and can take out or put into ash storage box 10 from ash storage box 6. Close to the ash storage door 12, a bottom solid plate 14 is fixedly connected to the transverse inner cavity wall at the lower end of the furnace bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com