Efficient sewage treatment device

A kind of sewage treatment device, high-efficiency technology, applied in the direction of filtration and separation, fixed filter element filter, chemical instrument and method, etc., can solve the problems of poor cleaning effect of impurities and ineffective discharge of impurities, so as to increase continuous working ability, Increase the effect of filter effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

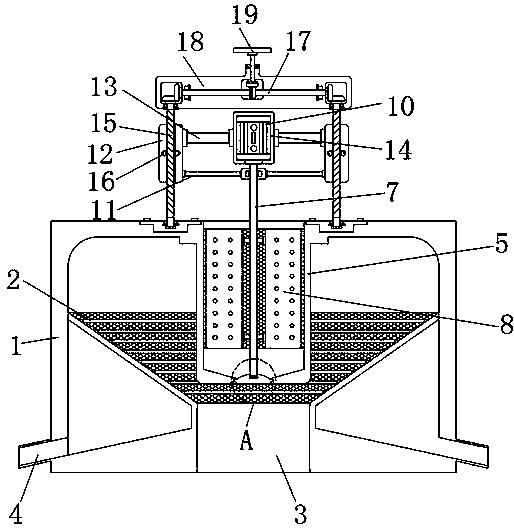

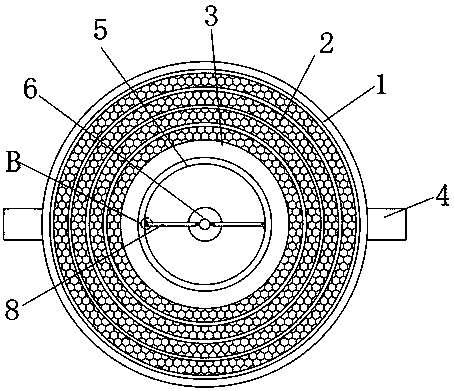

[0021] Embodiment 1, a high-efficiency sewage treatment device, including a device body 1 and a motor 10, a filter plate 2 is fixedly welded inside the device body 1, and the lower end opening of the filter plate 2 is seamlessly connected with the upper end opening of the sewage outlet 3, and the sewage is discharged The port 3 is fixedly set at the lower end of the device body 1, and the left and right ends of the device body 1 are symmetrically provided with drain ports 4, and the upper end of the device body 1 is fixedly welded with a filter cartridge 5, and the lower end of the filter cartridge 5 is provided with a bottom cover 6, and the bottom The cover 6 is installed on the lower end of the rotating shaft 7 through a bearing, and two sets of rotating plates 8 are welded symmetrically on the rotating shaft 7, and the end of the rotating plate 8 away from the rotating shaft 7 is fixedly equipped with bristles 9, and the upper end of the rotating shaft 7 is fixedly connected...

Embodiment 2

[0022] In Embodiment 2, the filter plate 2 is set in a rounded truncated shape, the filter hole diameter of the filter plate 2 is smaller than the filter hole diameter of the filter cartridge 5, the upper surface of the filter plate 2 is equidistantly provided with annular protrusions, and the bottom inner wall of the device body 1 It is set in the shape of a truncated cone. This structure makes when the sewage in the filter cartridge 5 flies out of the filter hole of the filter cartridge 5 by centrifugal force, the sewage will fall on the filter plate 2, and the filter hole of the filter plate 2 is larger than that of the filter cartridge 5. The filter holes are smaller, so the fine impurities in the sewage can be re-filtered, and the sewage will continue to slide down the slope of the filter plate 2, driving the impurities to permeate the filter plate 2 and fall into the bottom of the device body 1 while the filter plate The annular bump on the filter plate 2 can reduce the f...

Embodiment 3

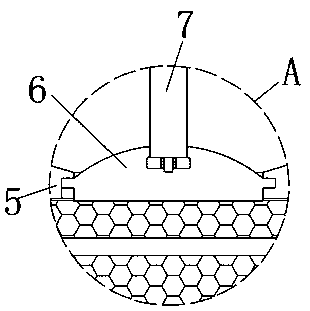

[0023] Embodiment three, such as image 3 The lower end of the filter cartridge 5 is provided with a circular hole, and the inner wall of the lower end of the filter cartridge 5 is set to be inclined. Block, the inner wall of the circular hole at the lower end of the filter cartridge 5 is provided with a slot that matches the insert, and the upper surface of the bottom cover 6 is set in a semicircle, this structure makes the bottom cover 6 cover the lower end of the filter cartridge 5 When the opening is at the opening, it can prevent the sewage in the filter cartridge 5 from being discharged, and when the bottom cover 6 opens the opening at the lower end of the filter cartridge 5, the impurities in the filter cartridge 5 can automatically slide along the inclined inner wall of the bottom end of the filter cartridge 5 by their own weight. out, and when it falls on the bottom cover 6, it will not be able to stay on the bottom cover 6 because of the arc-shaped surface of the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com