Vacuum hotpressing machine

A technology of vacuum hot pressing and vacuum pumping system, applied in the field of powder metallurgy, can solve the problems of unsuitability, long time, long time, etc., and achieve the effect of reducing waiting time and improving continuous working ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

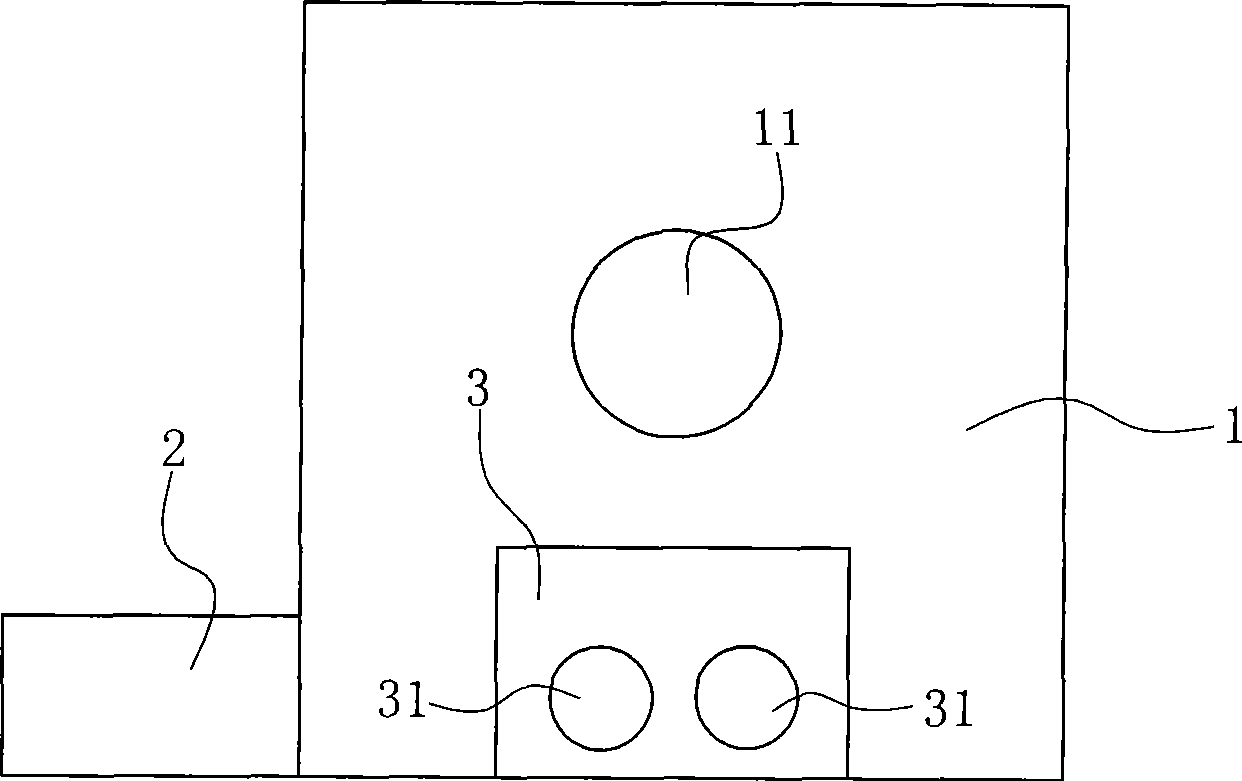

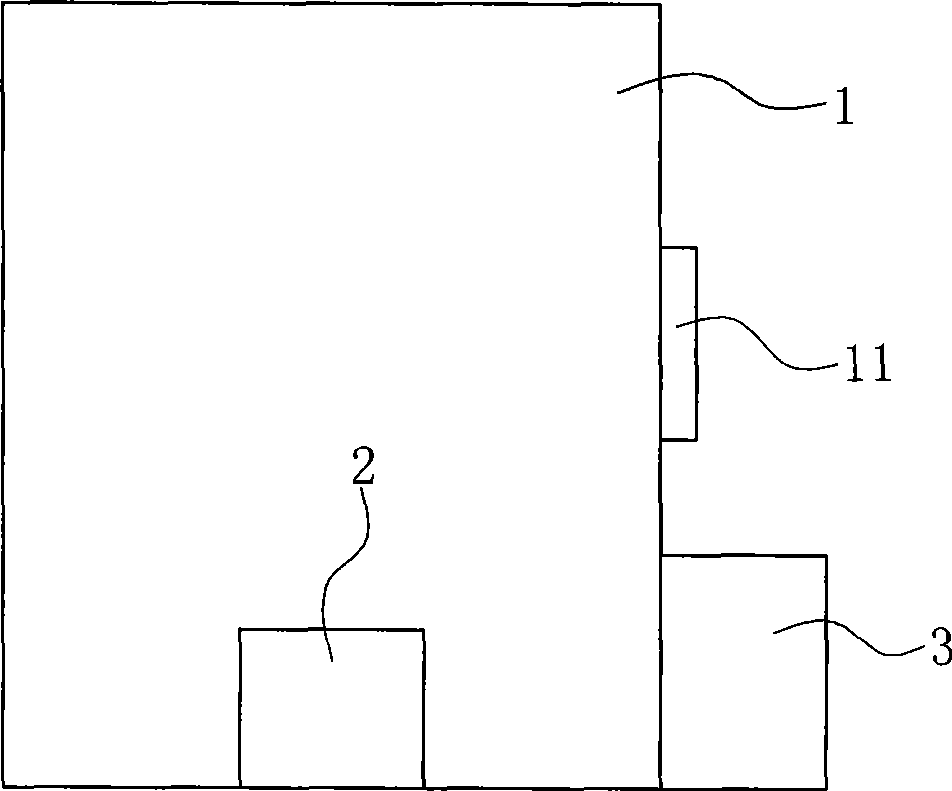

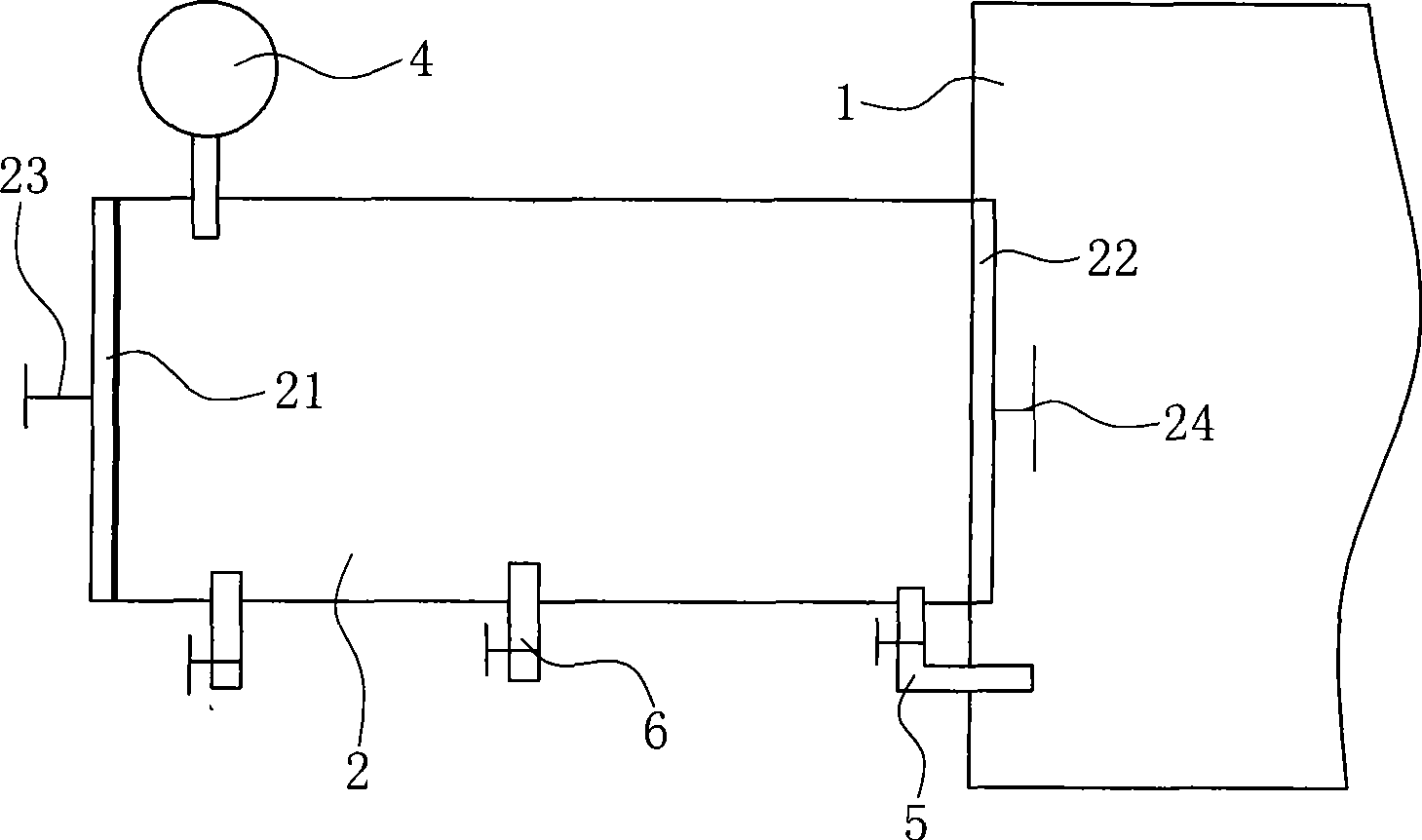

[0019] Such as Figure 1~4 Shown is a preferred embodiment of the present invention.

[0020] A vacuum hot press, comprising a main working chamber 1 with an observation window 11, the main working chamber 1 is provided with a vacuum system, a heating source, and a hydraulic forming system, and the inflation adjustment pressure in the hot press system adopts The gas source is pure (99.9%) or high-purity nitrogen (99.99%), argon, helium or a mixture of at least two of these three. The observation window 11 is arranged on the front panel of the main working room 1, and the various devices in the main working room 1 and their connection methods are all prior art, and will not be described in detail here.

[0021] It also includes a highly airtight transition chamber 2 and a glove box 3 that are smaller in volume than the main working chamber. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com