Environment-friendly waste gas treatment device for factory production and processing

A waste gas treatment device and factory-produced technology, applied in gas treatment, transportation and packaging, climate change adaptation, etc., can solve problems such as easy generation of dust, secondary air pollution, filter blockage, etc., to improve convenience and enhance sustainability The effect on the ability to work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

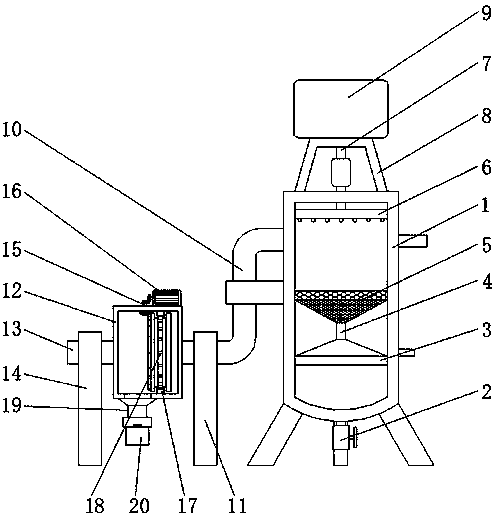

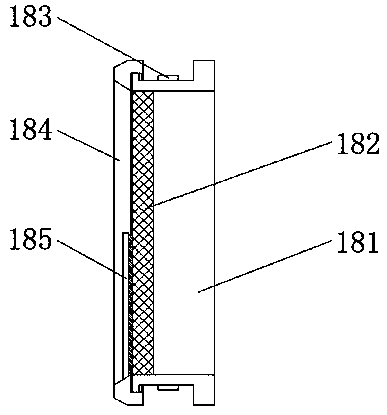

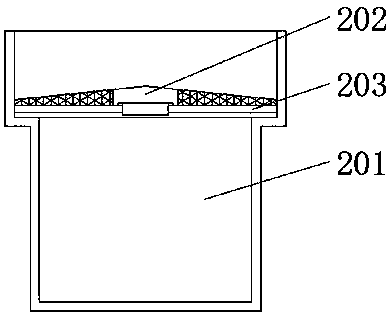

[0025] see Figure 1 to Figure 4 , the present invention provides a technical solution: an environmentally friendly waste gas treatment device for factory production and processing, including a reaction chamber 1, a slag discharge pipe 2, a diversion cover 3, a fixed pipe 4, a filter funnel 5, a nozzle 6, and a conveying device 7. Fixed frame 8, storage bin 9, air duct 10, first fixed rod 11, filter bin 12, air intake pipe 13, second fixed rod 14, transmission rod 15, motor 16, snap ring 17, filter device 18, set Dust pipe 19 and collecting device 20;

[0026]A slag discharge pipe 2 is fixedly installed in the middle of the bottom of the reaction chamber 1. Opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com