Patents

Literature

148results about How to "Improve the efficiency of solid-liquid separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

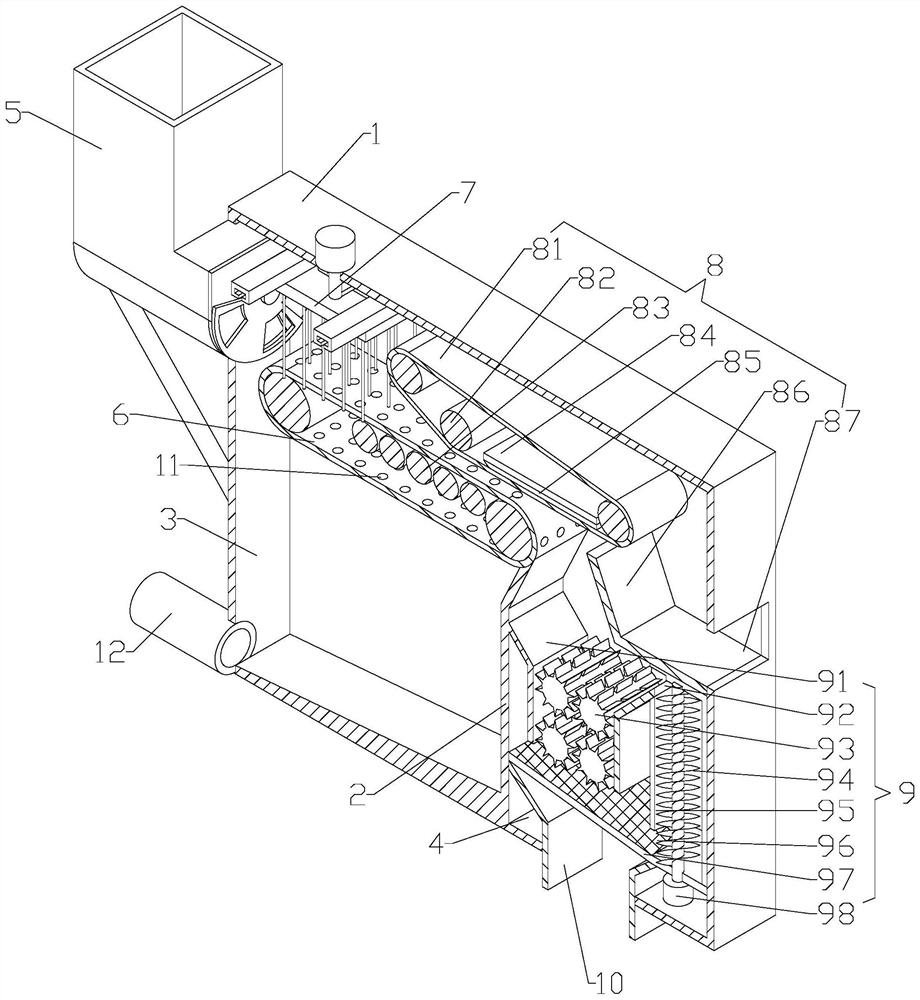

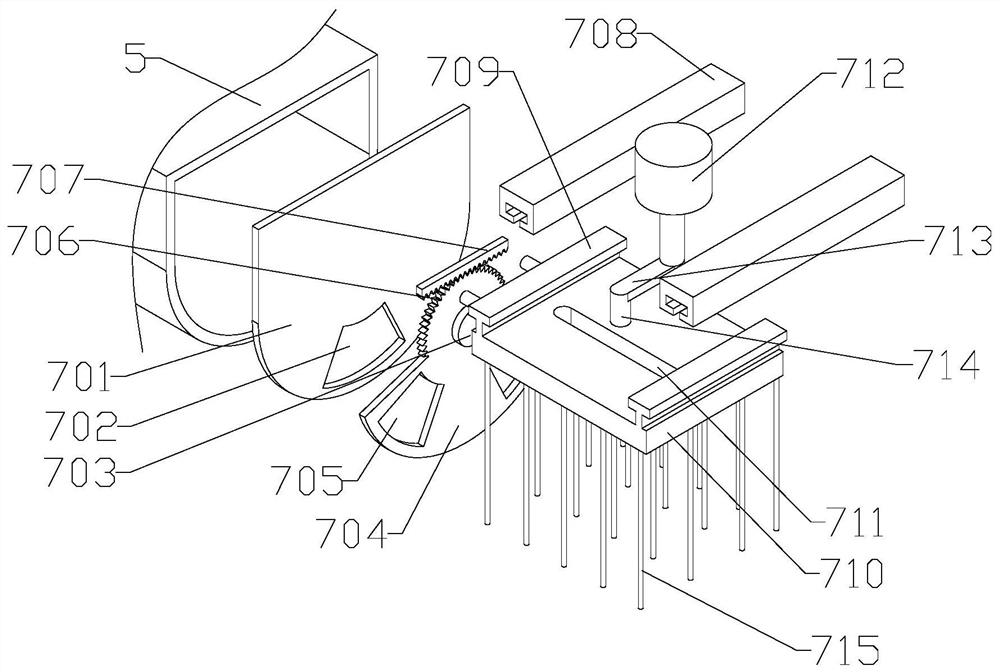

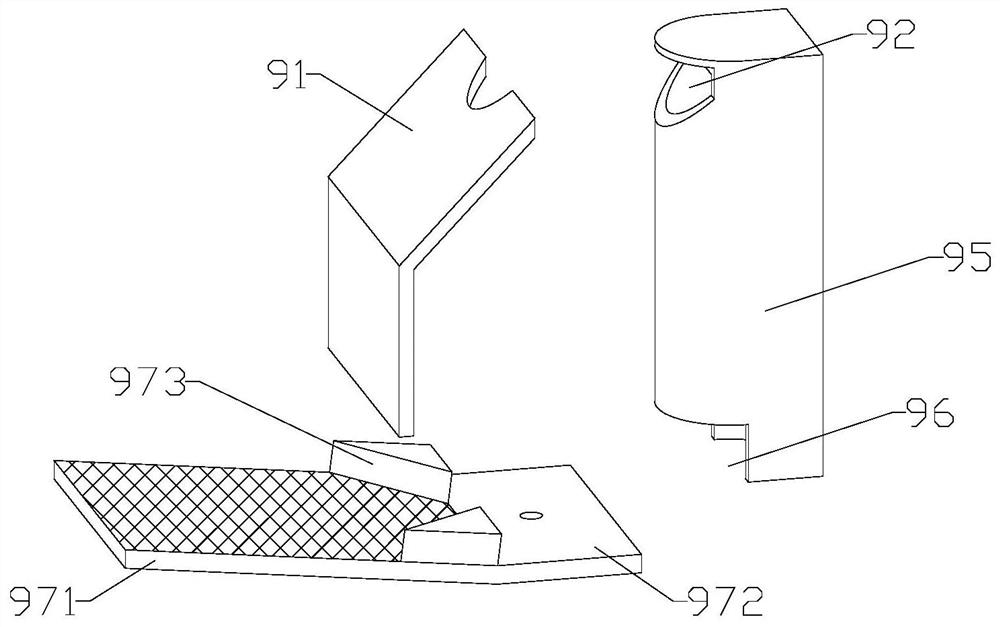

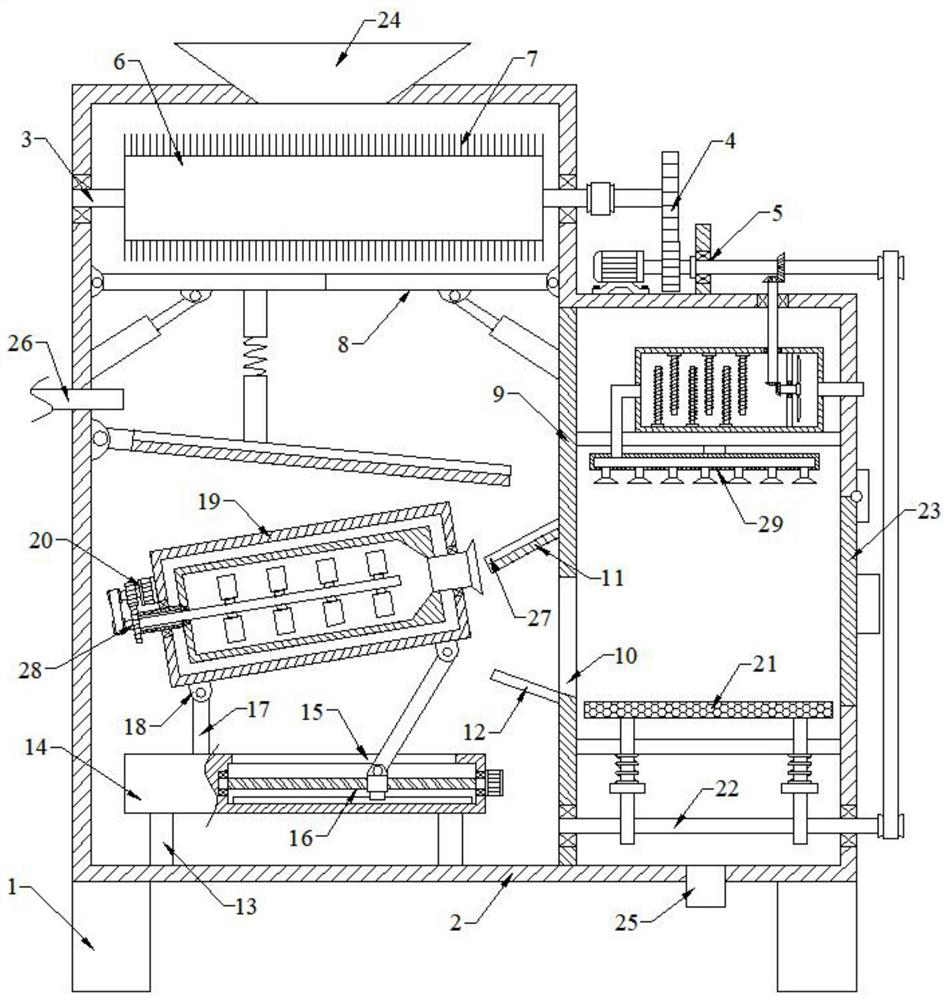

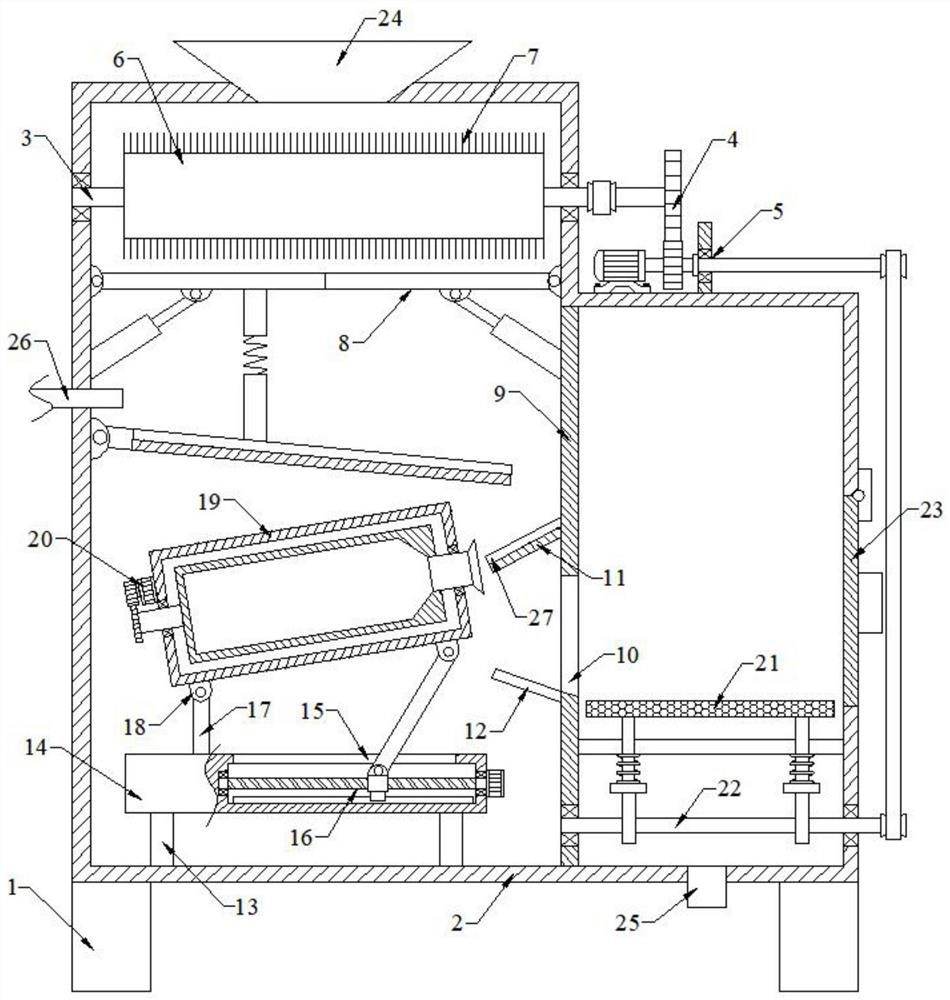

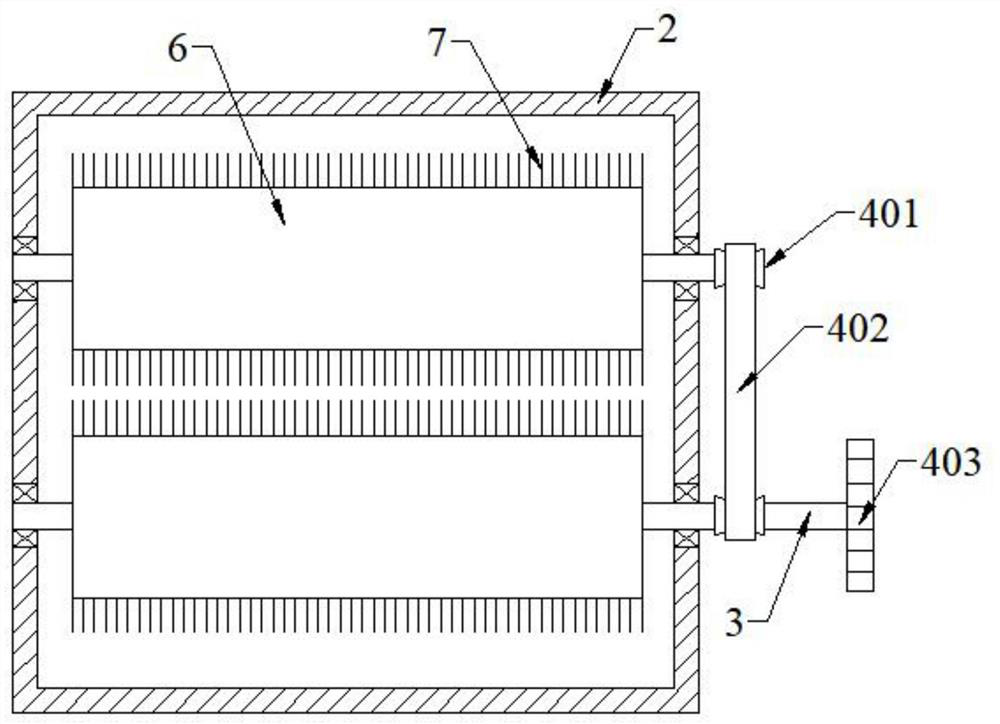

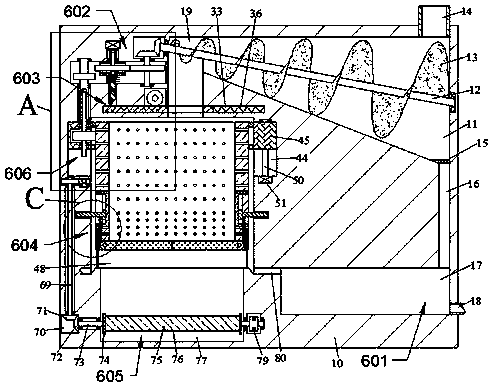

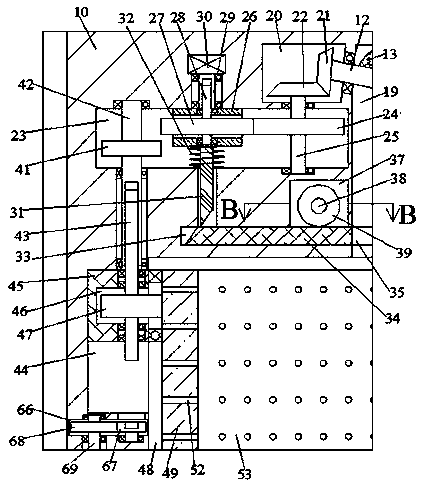

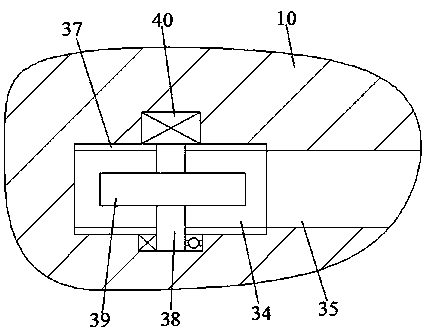

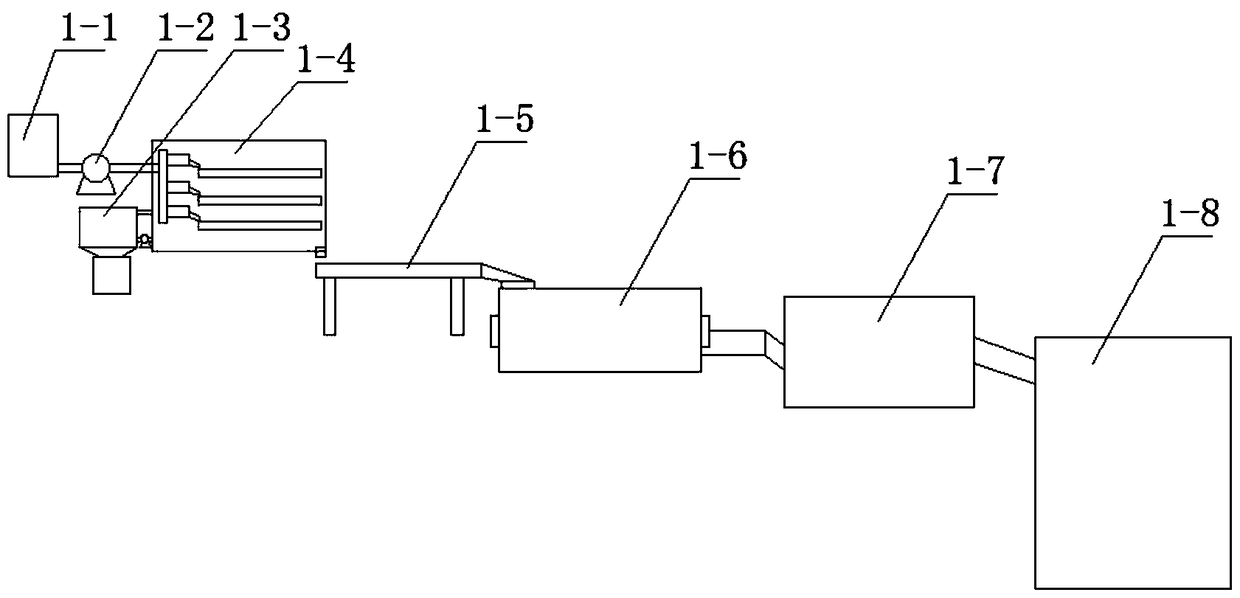

Kitchen waste pretreatment equipment and technology

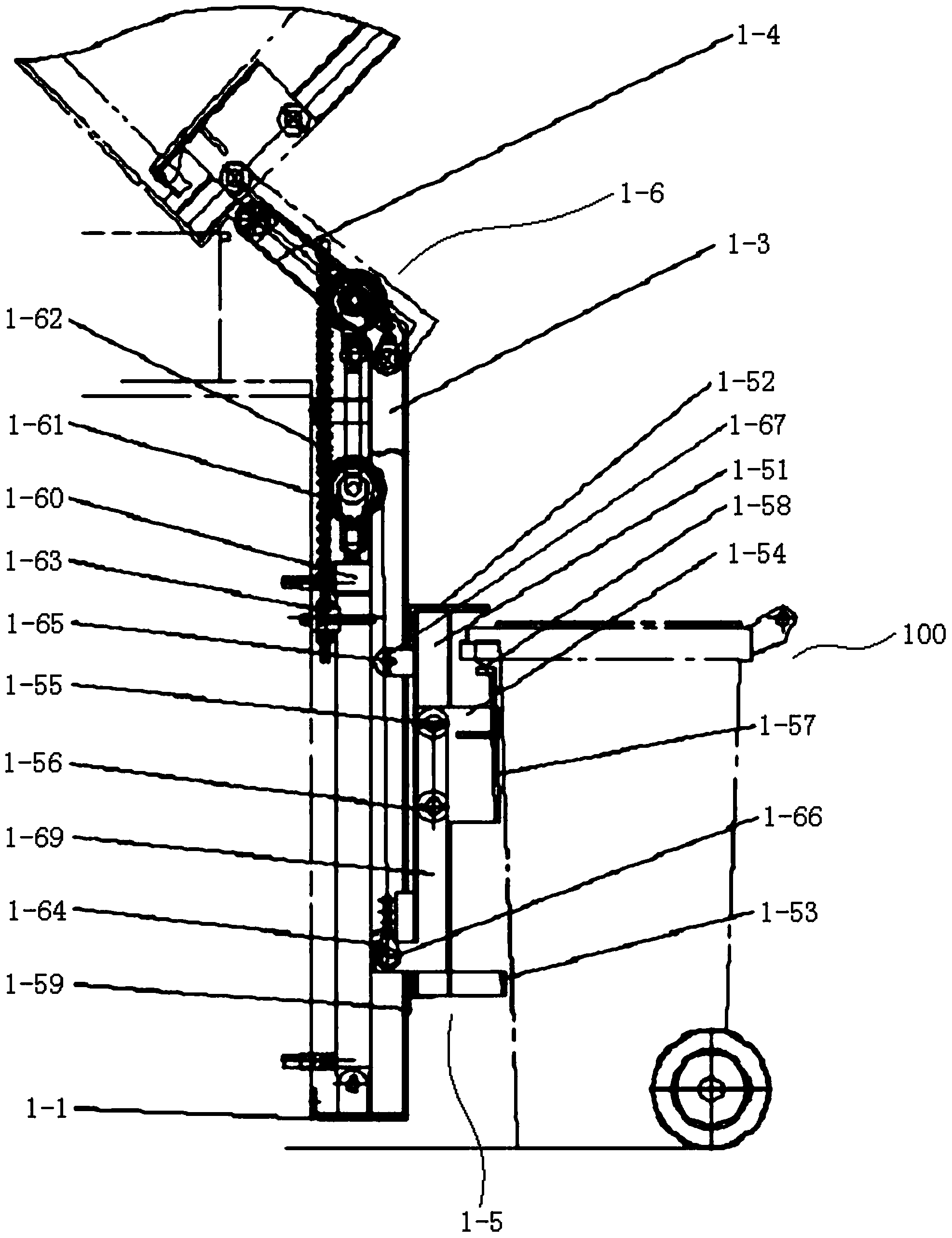

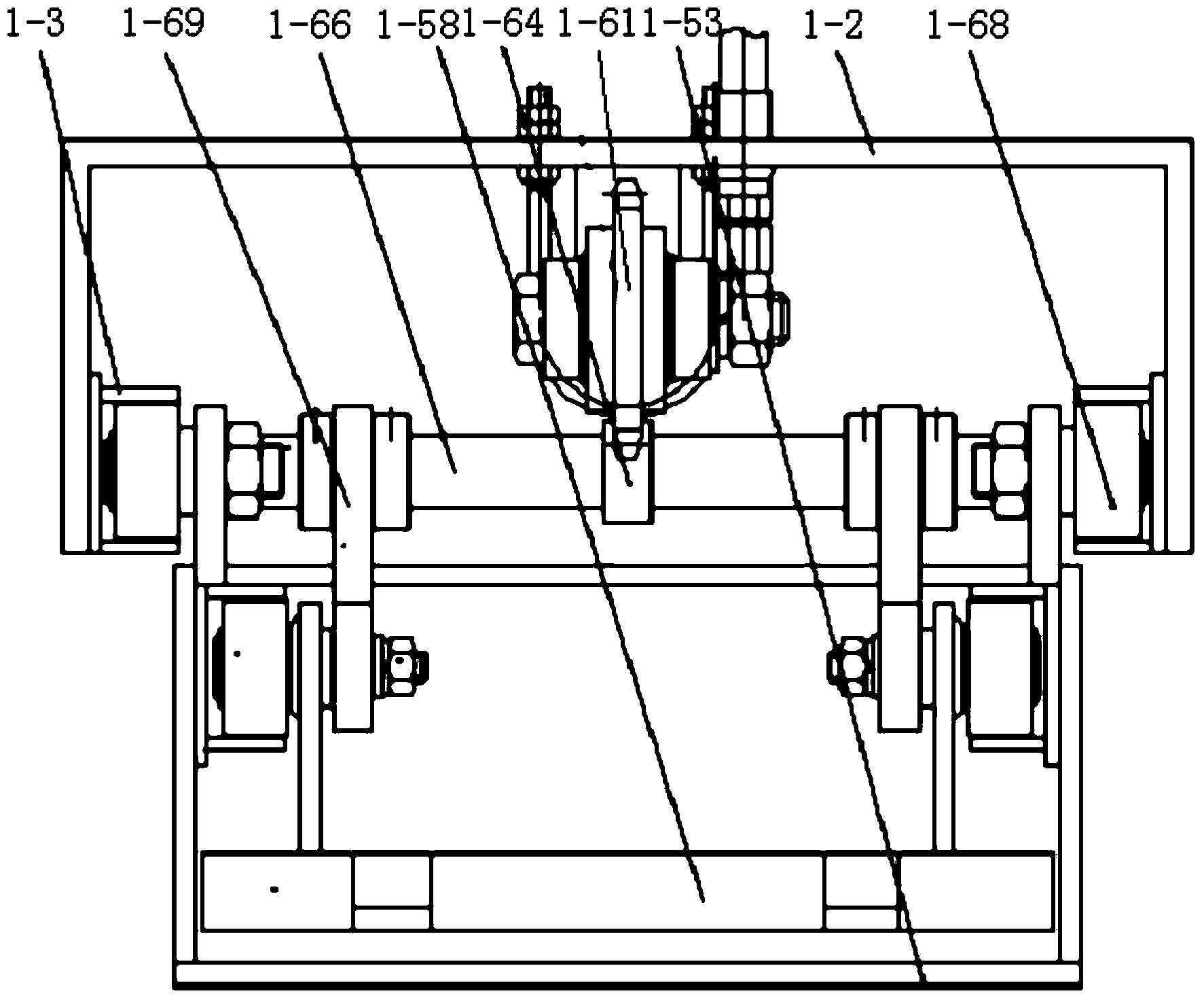

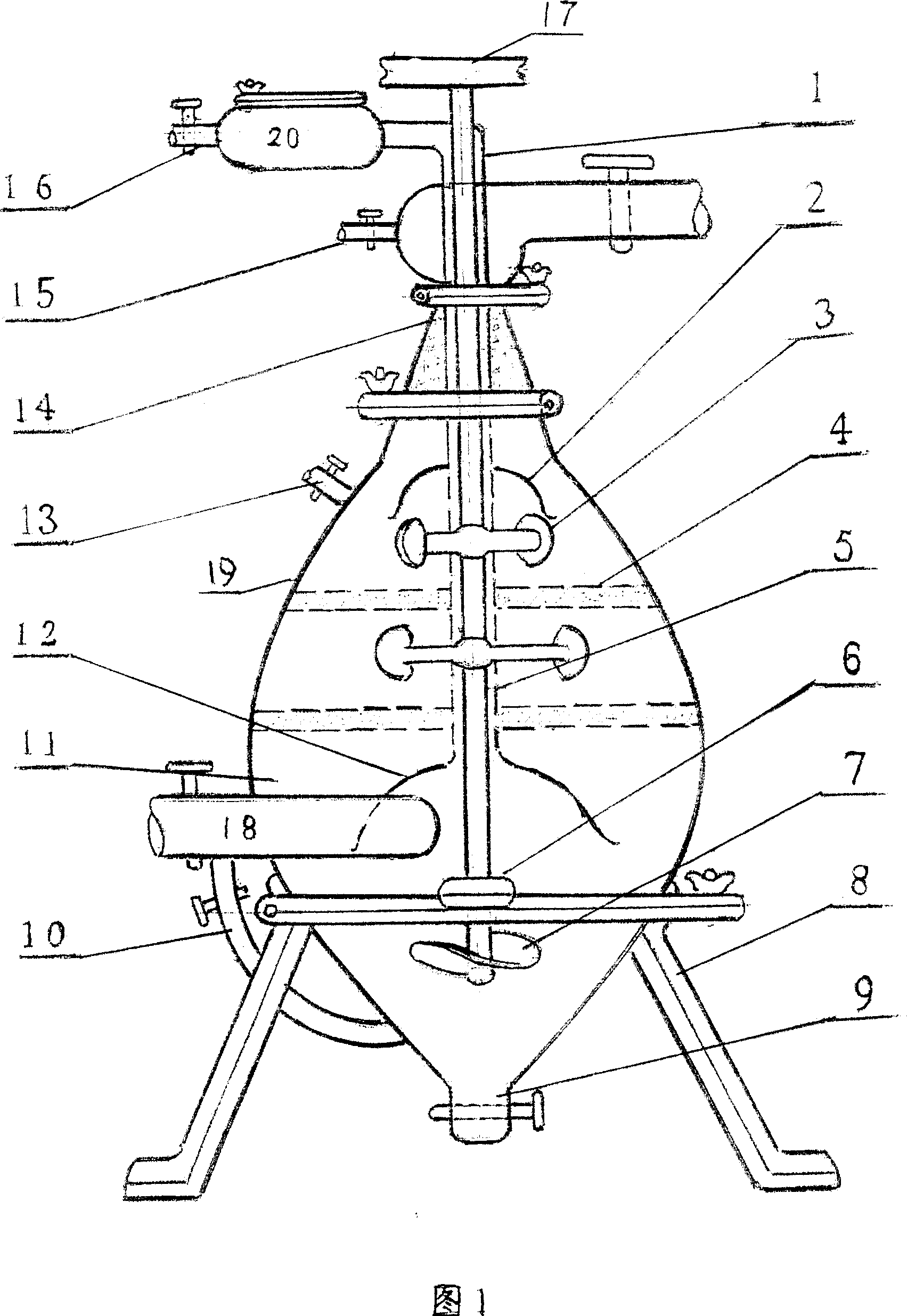

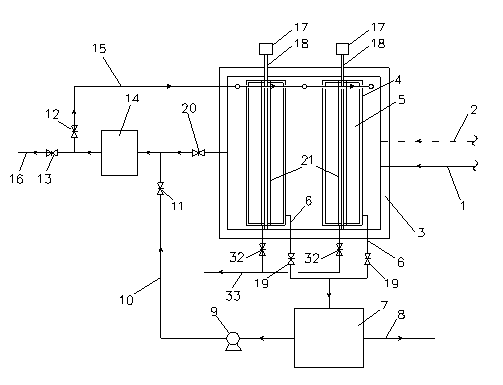

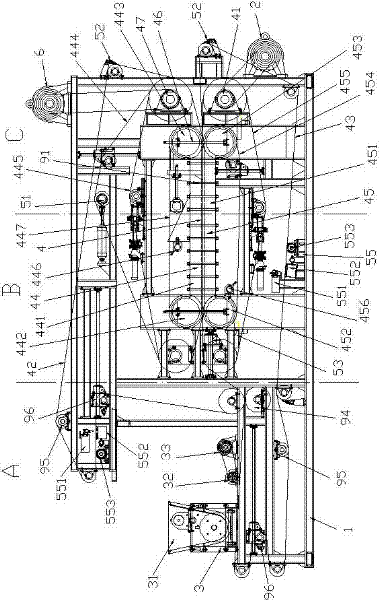

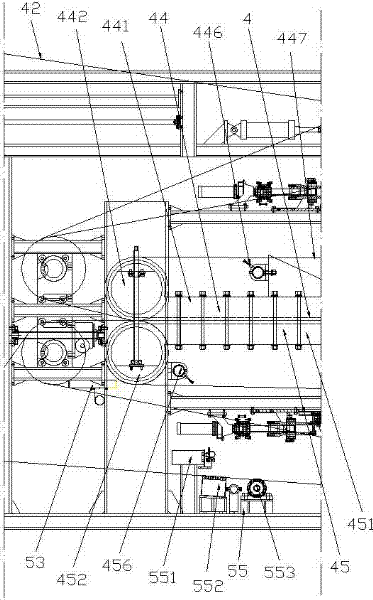

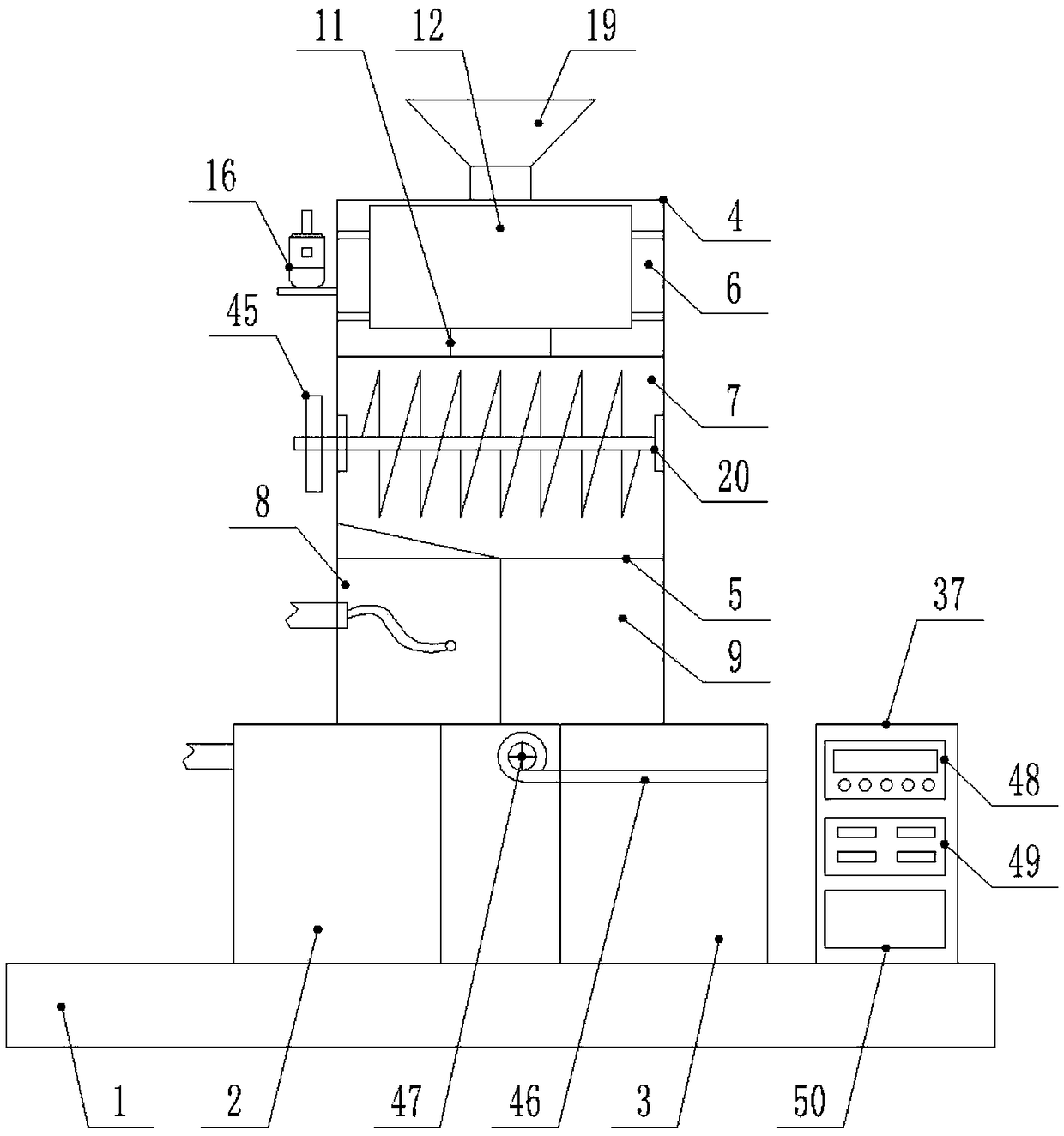

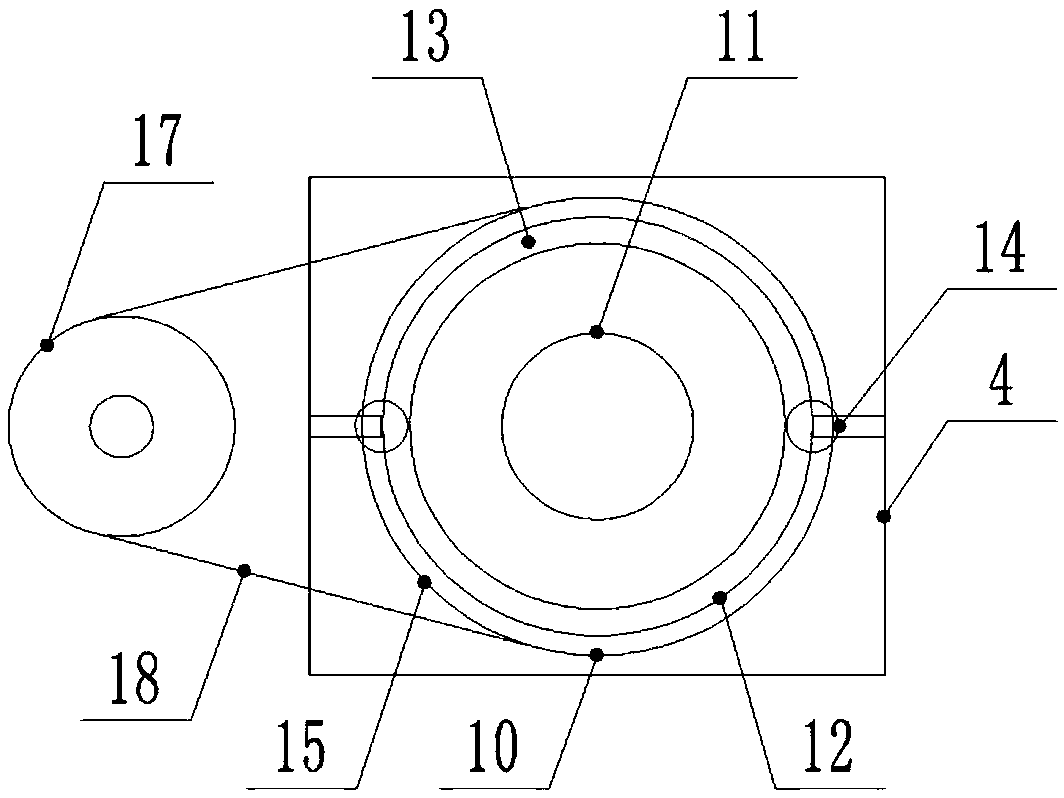

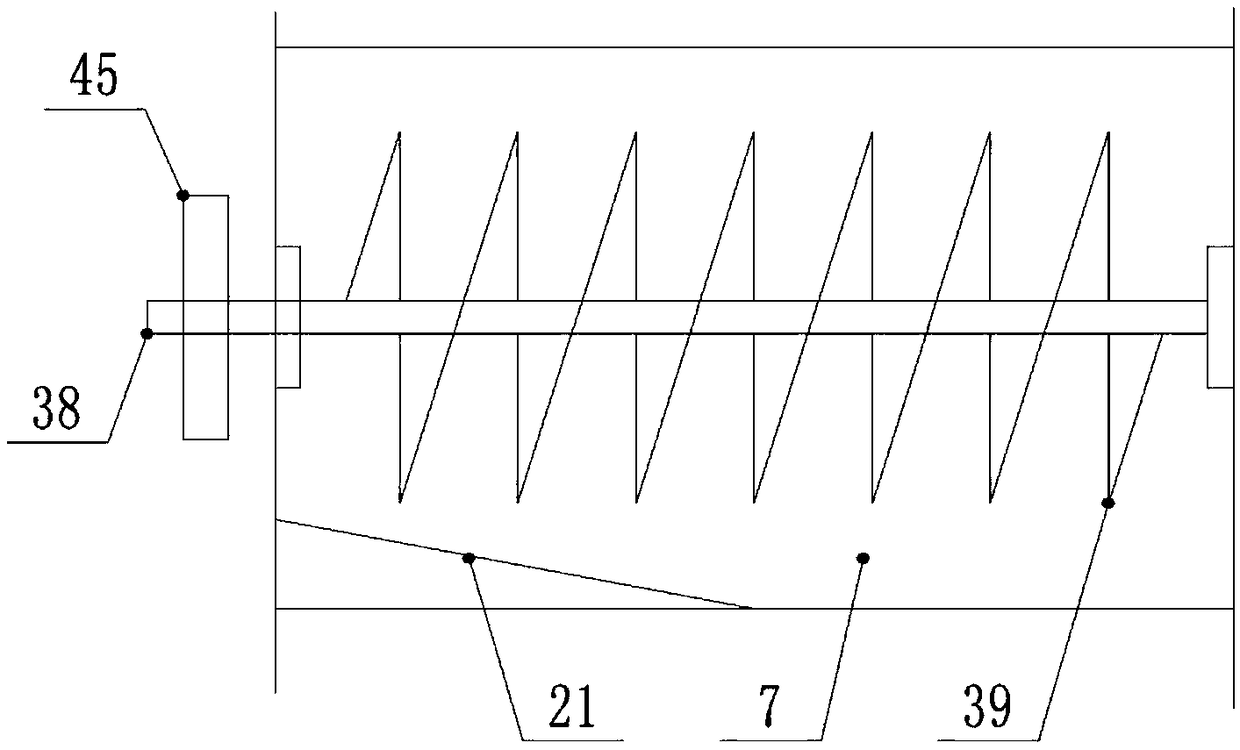

The invention relates to a kitchen waste pretreatment equipment and technology. The equipment is characterized by comprising a shell body, a garbage can lifting device mounted on one side of the shell body, a feeding device mounted on the upper portion of the shell body, an automatic separation device mounted in the shell body, an extrusion device mounted in the shell body, a smashing device mounted in the shell body, a fermenting and drying device mounted in the shell body and an ionization deodorization device mounted in the shell body. The kitchen waste pretreatment equipment and technology has the advantages of feeding and sorting automatically, being good in solid-liquid separation effect, high in efficiency, high in dehydration rate, high in fermentation treatment speed, even in fermentation, high in heating speed, capable of oxygenating automatically during fermentation, up to standard on gas deodorization, environmentally friendly, free of pollution and convenient to operate, saving manpower and the like, can process the kitchen waste generated by 300 to 500 people in 24 hours, and output 150kg to 200kg organic fertilizer with the moisture content not more than 25%.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

Method for preparing high-purity vanadium pentoxide by use of stone coal one-step method

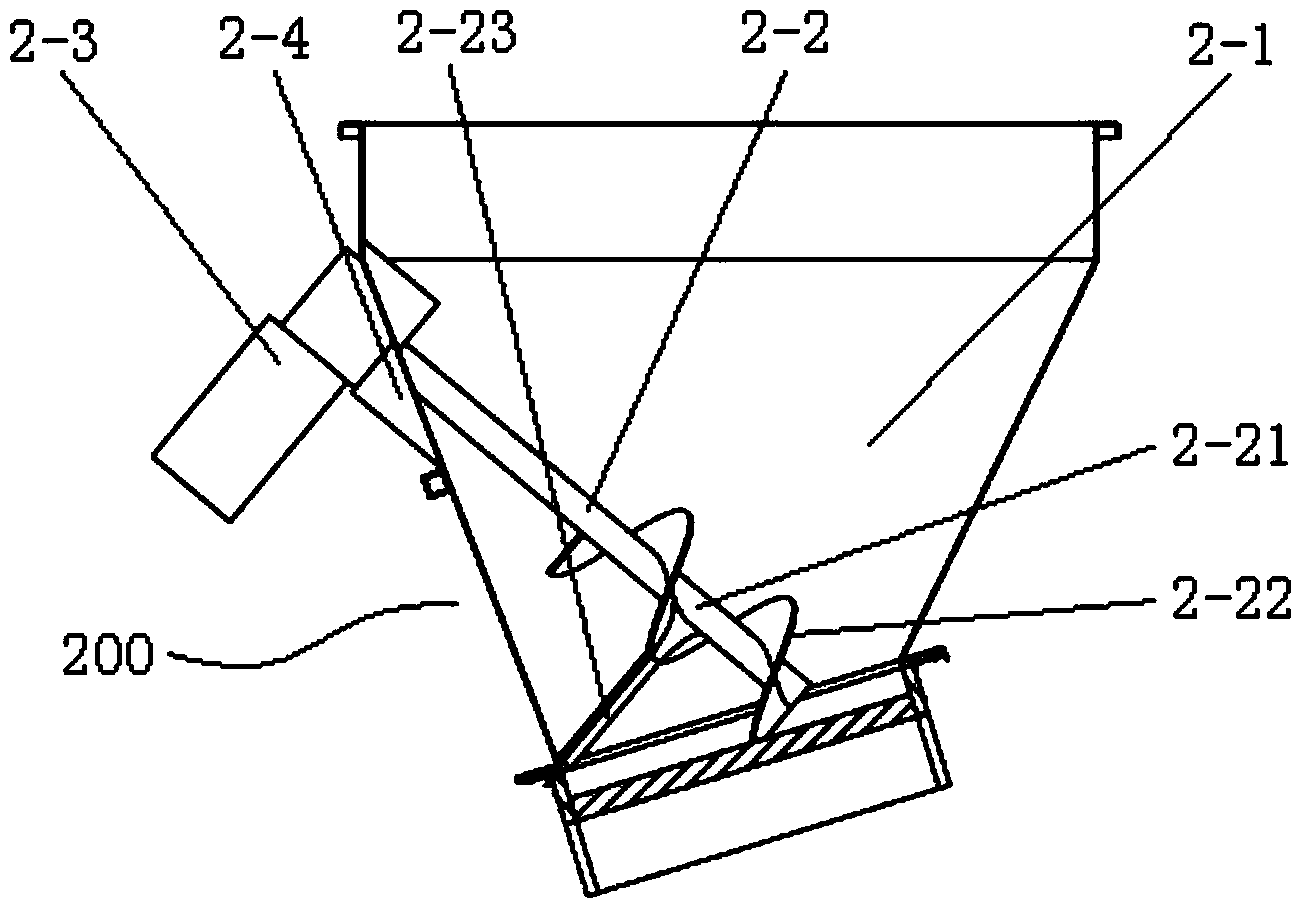

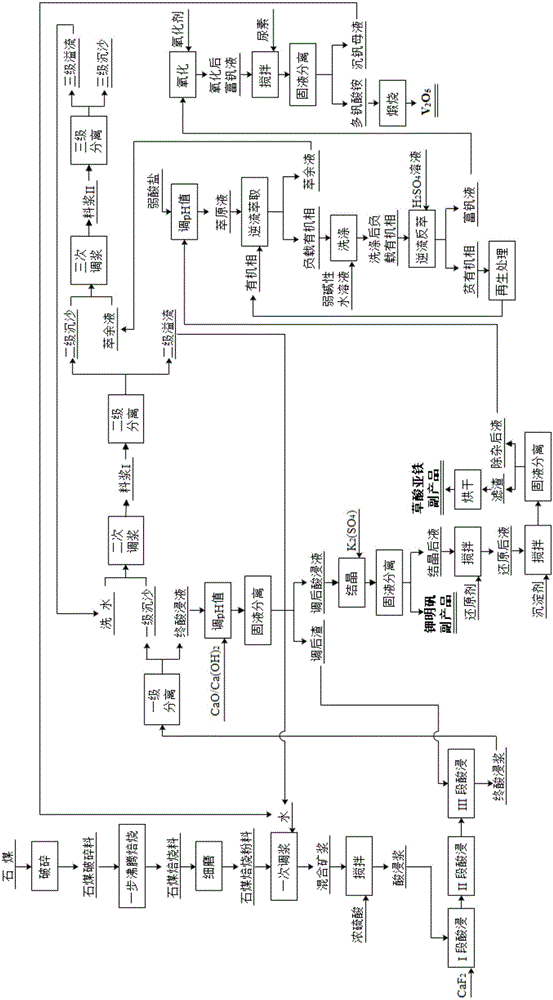

The invention relates to a method for preparing high-purity vanadium pentoxide by use of a stone coal one-step method. The technical solution is as follows: a fluidized bed furnace for one-step roasting of stone coal is adopted to perform one-step fluidized bed roasting on the stone coal; roasted materials are leached in three segments, final pickling slurry is subjected to primary separation so as to obtain final pickle liquor, secondary overflow is returned to be subjected to primary size mixing, and tertiary overflow is returned to be subjected to secondary size mixing; the pH value of the final pickle liquor is regulated, and slags obtained after regulation are returned to a segment III so as to be leached; the regulated pickle liquor is crystallized to obtain a potassium alum byproduct; after crystallization, the liquid is subjected to reduction and precipitation-based impurity removal, and filter residues are dried to obtained a ferrous oxalate byproduct; after impurity removal, pH value regulation is performed on the liquid by use of weak acid salt, then counter-current extraction is performed on the liquid, and extraction raffinate is returned to be subjected to tertiary size mixing; after being washed, the loaded organic phase is subjected to countercurrent reverse extraction; a lean organic phase is regenerated and then is returned to be extracted; after a vanadium-rich solution is oxidized, urea is added, stirring is performed, the obtained molybdenum precipitation mother solution is returned to be subjected to primary size mixing, and ammonium polyorthovanadate is calcinated to prepare vanadium pentoxide. The method has the characteristics of short process flow, less pollution, low energy consumption, less chemical usage, high vanadium recovery rate and high product purity.

Owner:WUHAN UNIV OF SCI & TECH

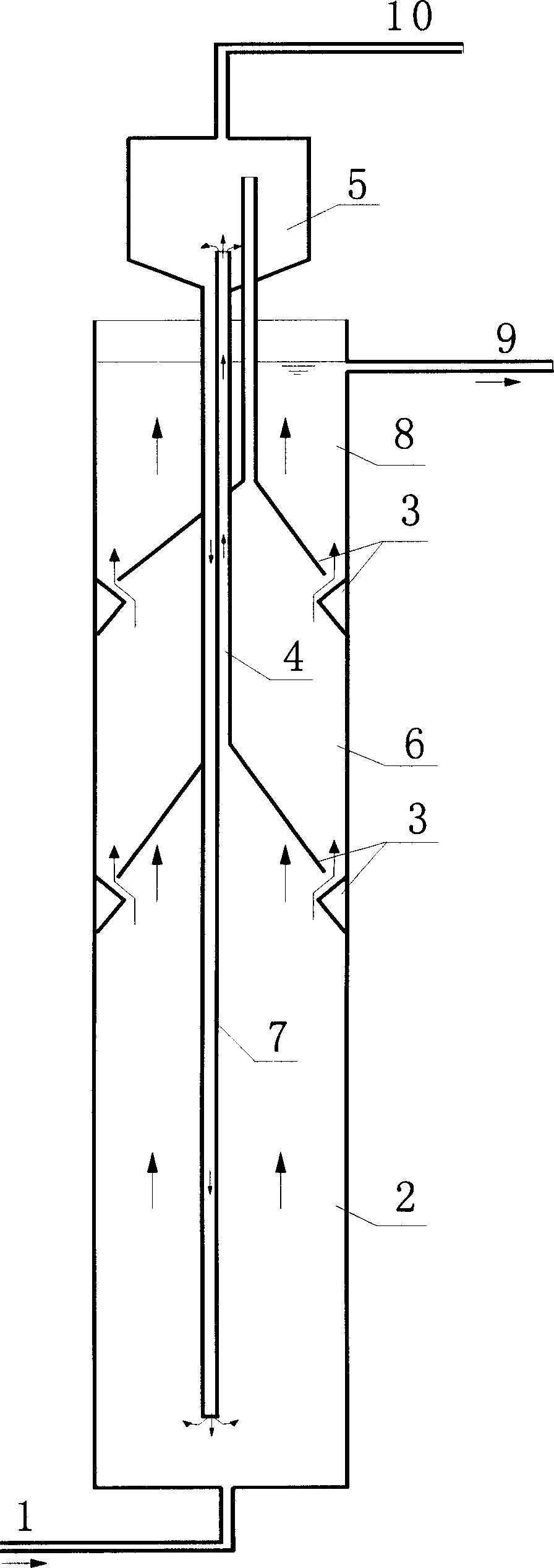

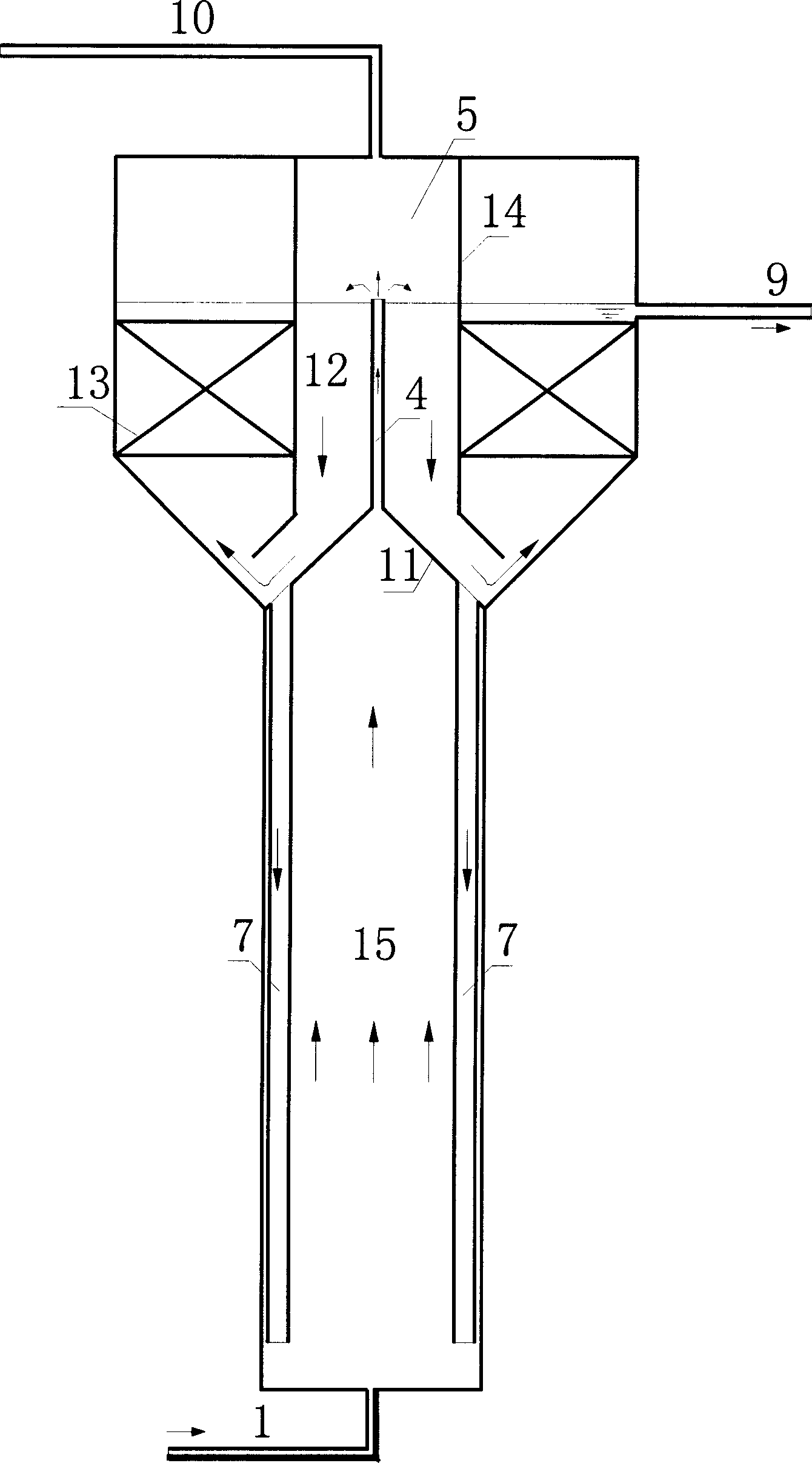

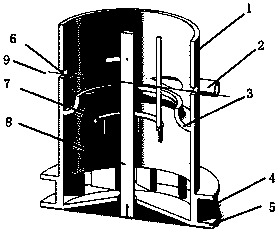

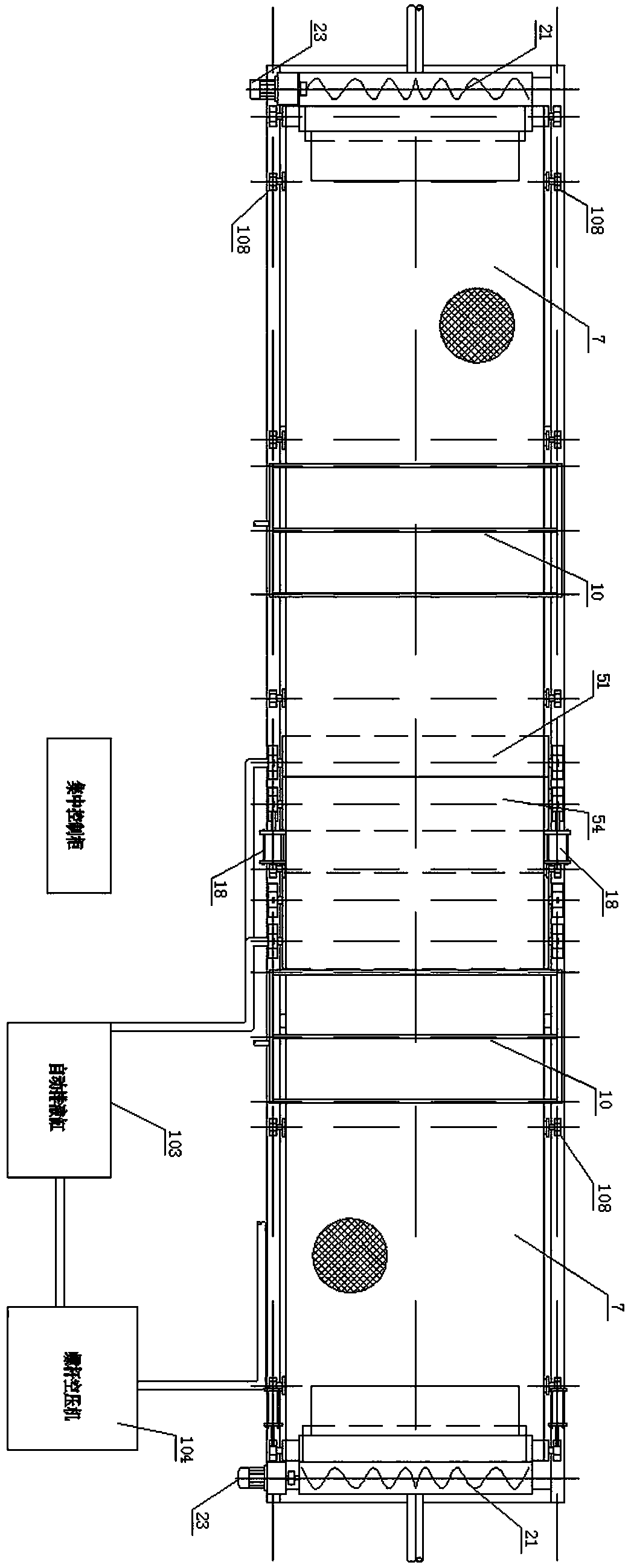

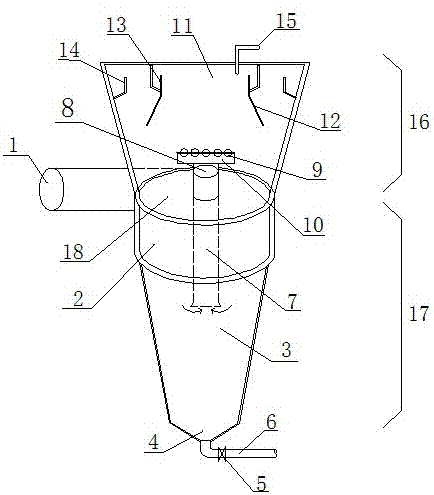

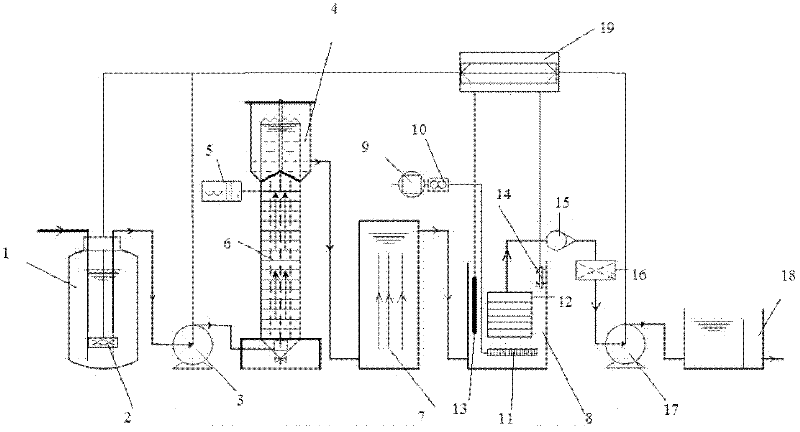

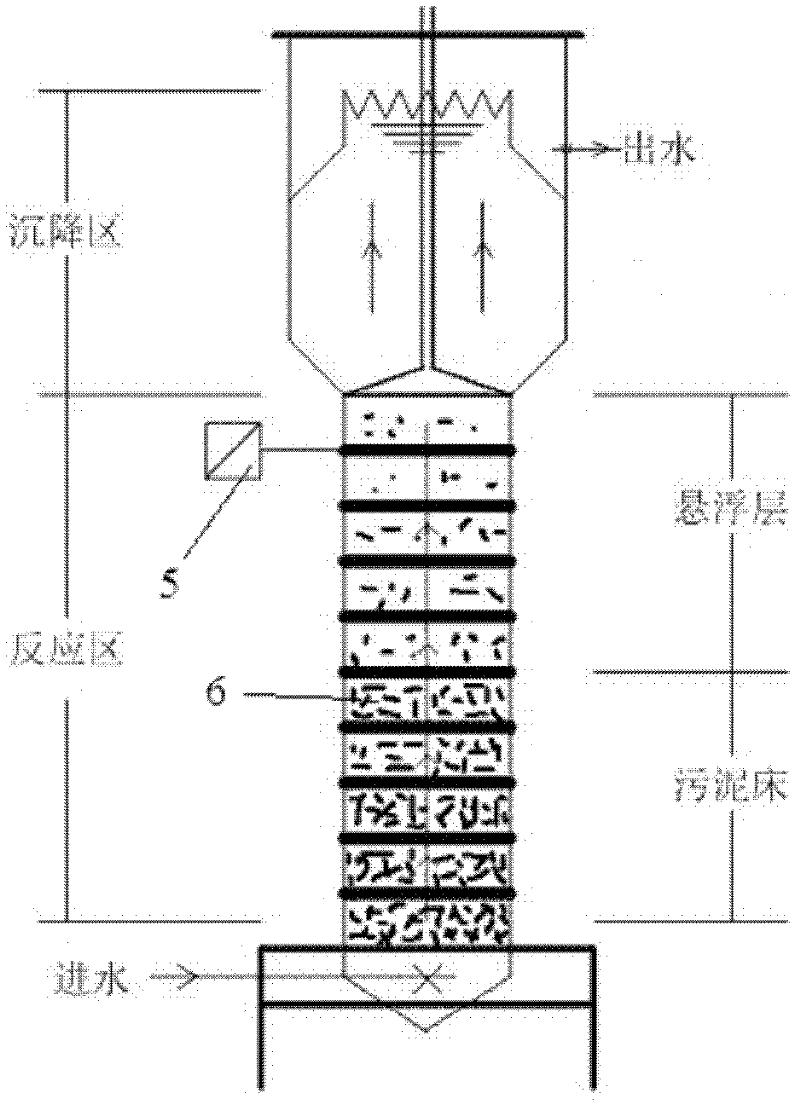

Composite anaerobic reactor with inner circulation

InactiveCN1915862AImprove volumetric efficiencyWell mixedWaste based fuelTreatment with anaerobic digestion processesFiltrationSmall footprint

This invention relates to an improved internal circulating anaerobic bioreactor. When the present internal circulating anaerobic bioreactors are used to treat low-concentration organic wastewater, the SS content in the outlet water is high, the internal circulating liquid ans the inlet water is not adequately mixed, and the utility of the second reaction zone is low. The improved internal circulating anaerobic bioreactor in this invention retains the upcast pipe, the downcast pipe and the gas-liquid separation zone, while uses a filtration zone to replace the precipitation zone, changes the single downcast pipe into 2-4 pipes with the equal space, and cancles the second reaction zone. The improved internal circulating anaerobic bioreactor has such advantages as simplified structure, high volume utility, low SS content in the outlet water, no sludge loss and high reaction efficiency. The volume load of the improved internal circulating anaerobic bioreactor is four times that of UASB reactor, with 20 kg COD / (m3 .d) when treating medium-concentration organic wastewater (such as beer wastewater), and 8 kg COD / (m3 .d) when treating low-concentration organic wastewater. Besides, the improved internal circulating anaerobic bioreactor also has such advantages as small space area, stable running and easy operation.

Owner:TSINGHUA UNIV

Medical waste recovering device provided with solid-liquid separation device and use method of medical waste recovering device

ActiveCN107900081ASimple structureEasy to separateSolid waste disposalTransportation and packagingMedical wasteMedical treatment

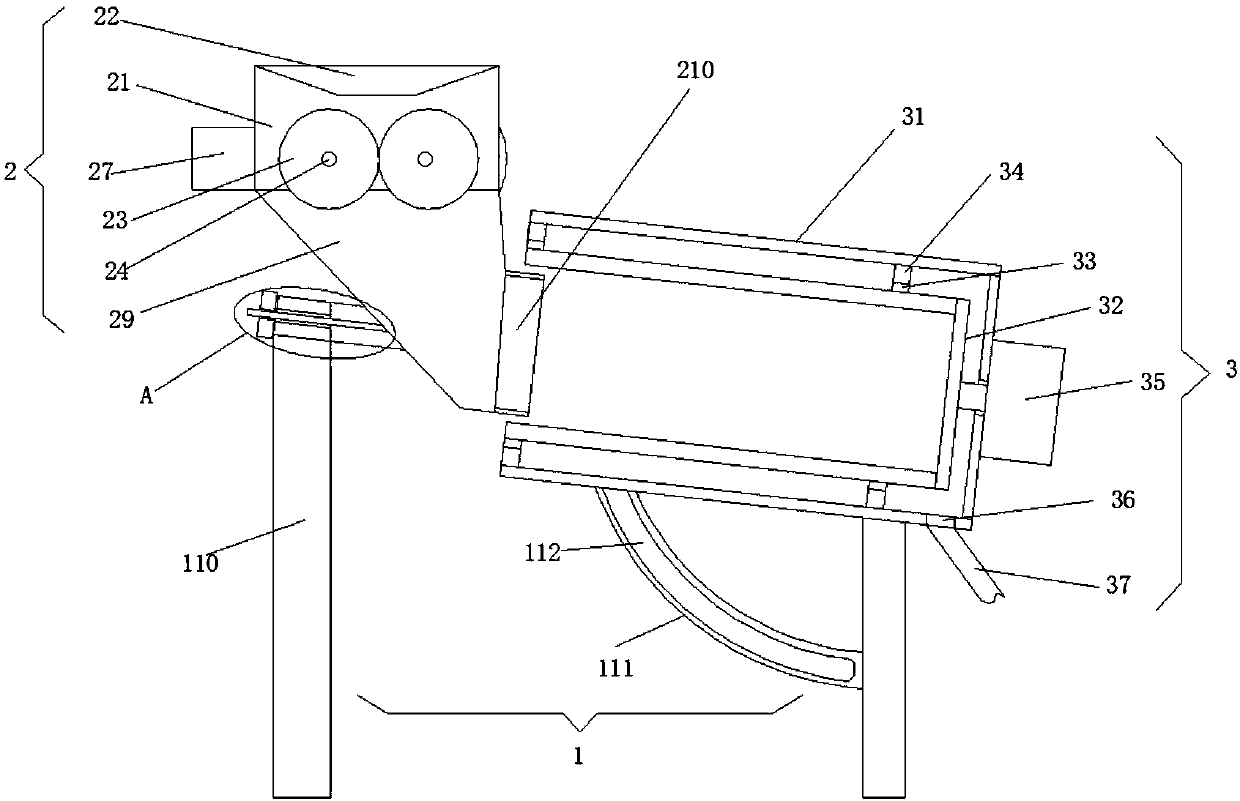

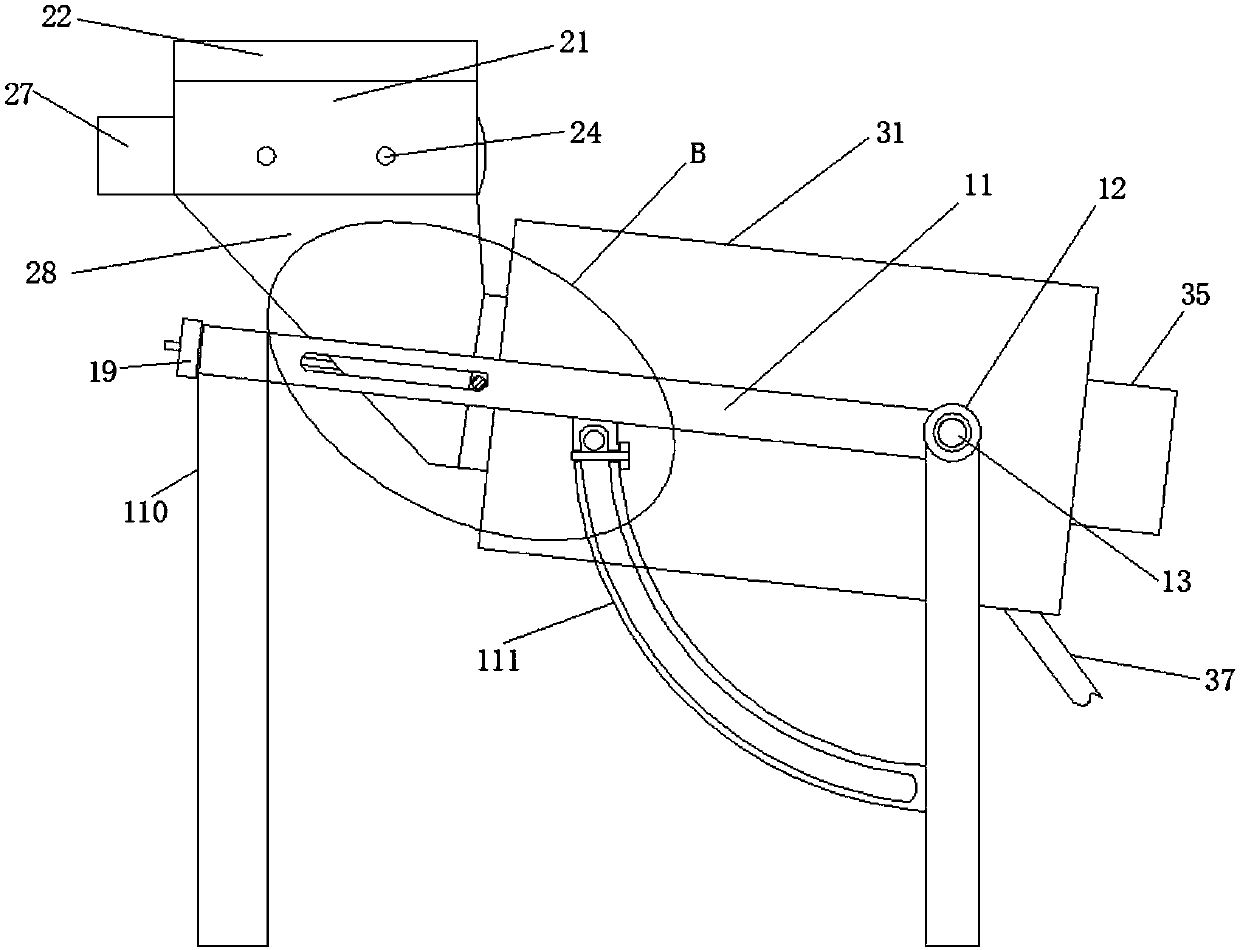

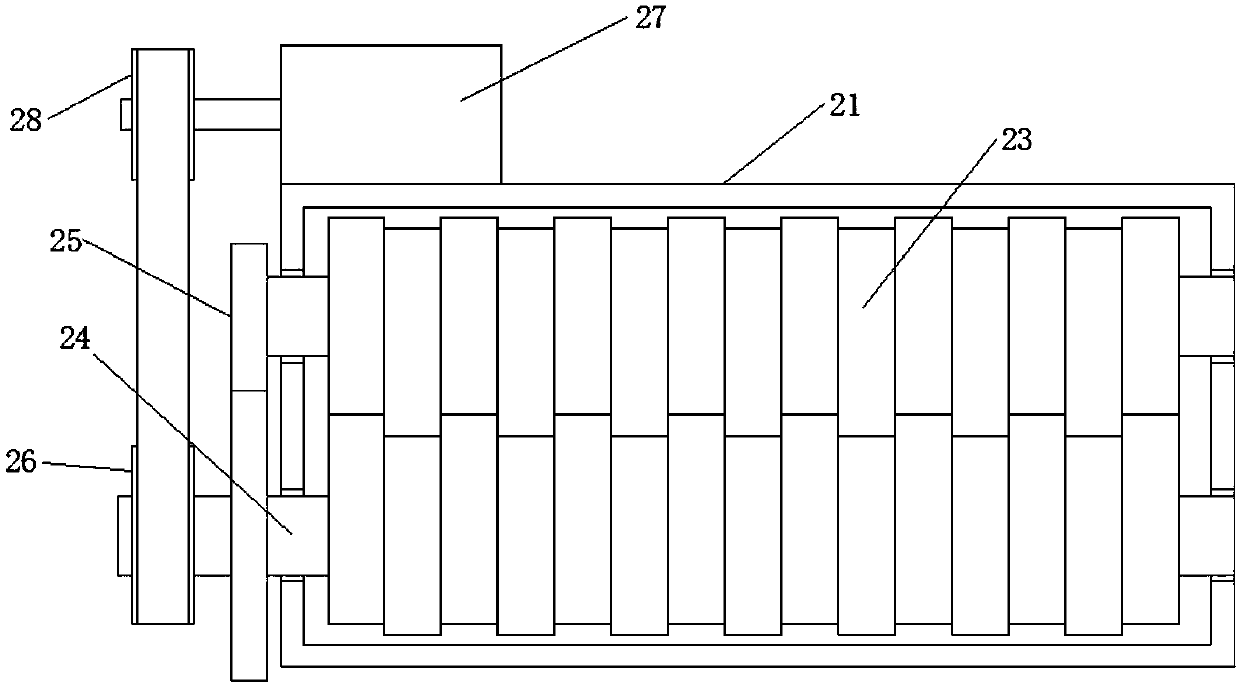

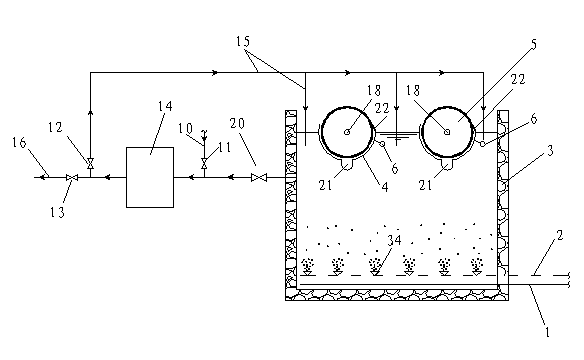

The invention discloses a medical waste recovering device provided with a solid-liquid separation device. The medical waste recovering device comprises a rack, a feeding device and the separation device; the feeding device and the separation device are mounted on the rack; the feeding device comprises a crushing bin; a hopper is fixedly connected at the top of the crushing bin; two tooth rollers are symmetrically arranged inside the crushing bin, mesh with each other and are tangent; rotating shafts are fixedly connected in centers of two ends of each of the two tooth rollers; the rotating shafts are movably connected with the bin wall of the crushing bin; the rotating shafts located on the same sides of the two tooth rollers penetrate through the bin wall of the crushing bin to extend outof the crushing bin; gears are fixedly connected onto the rotating shafts extending out of the crushing bin; the gears on the two rotating shafts mesh with each other; a delivery pipe is fixedly connected at the bottom of the crushing bin; and a connecting pipe is connected at one end, far away from the crushing bin, of the delivery pipe.

Owner:袁永春

Electric wastewater treating apparatus

InactiveCN101058048AShort processing timeReduce processing costsDispersed particle separationFiltration circuitsDrive shaftWater flow

The invention relates to an electronic sewage processor that comprises the shell, water inlet, water outlet, filter layer of the inner cavity of the container, water outlet installed on the outer shell of the container above the filter, water inlet installed on the outer shell under the filter layer, drive shaft set inside the shell of the container with assistant spinning machine above the filter, twister under the filter and connected with the drive shaft through the clutch. The swirl incurred after the running in of sewage deposits the thick contaminate to separate the solid and the liquid, with the gas and water rising up, under strong centrifugal force for better solid and liquid separation, making space for the center of the high speed swirling flow for the exhaust of the generated gas. Under the centrifugal force of the sewage processing, it has high efficiency in liquid and solid separation with short sewage processing period and low cost.

Owner:彭世英

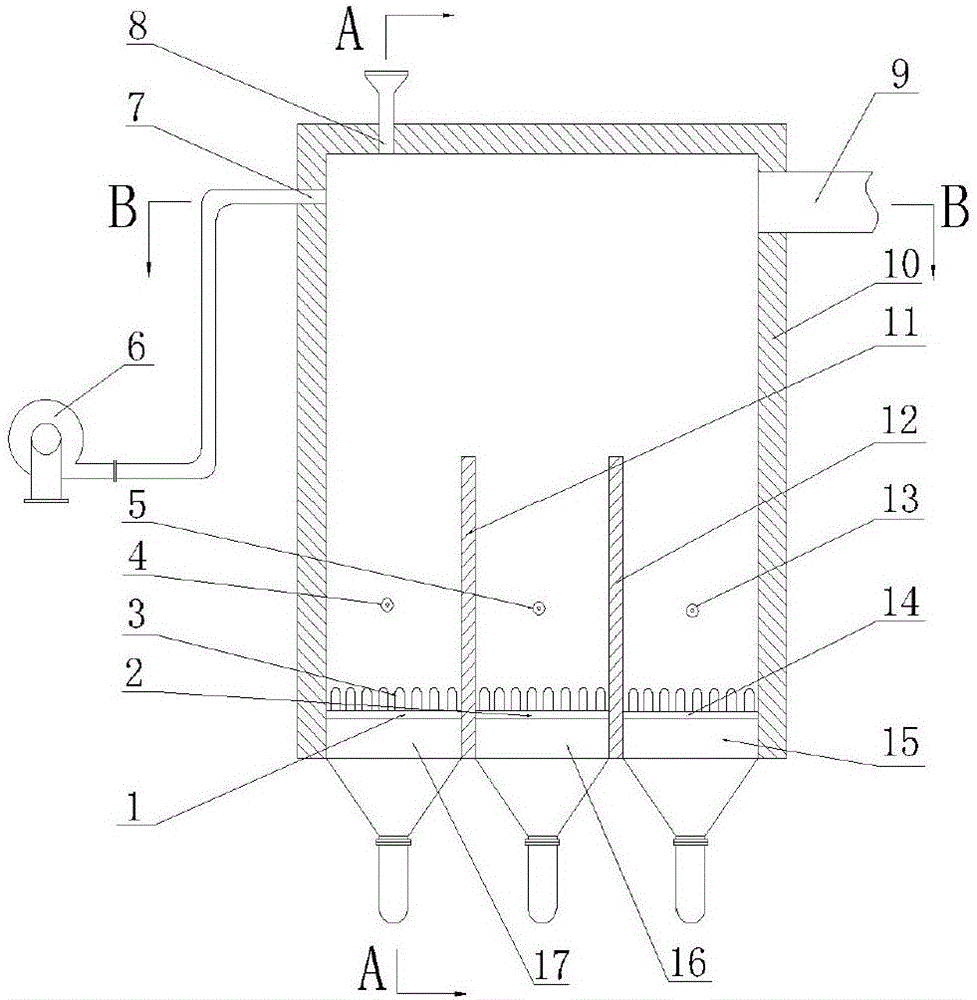

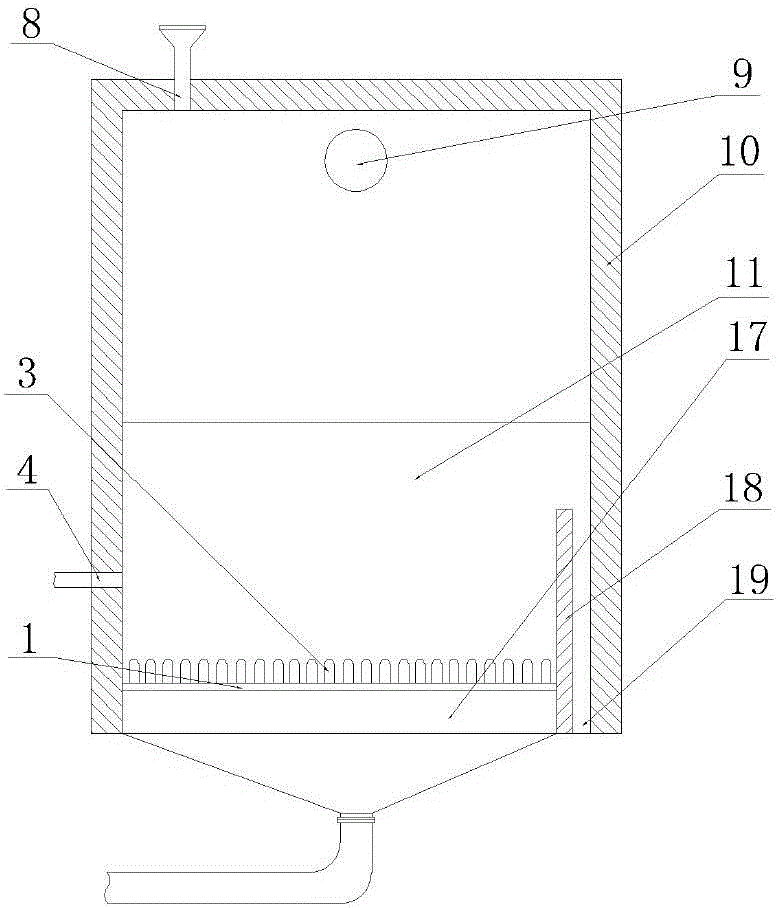

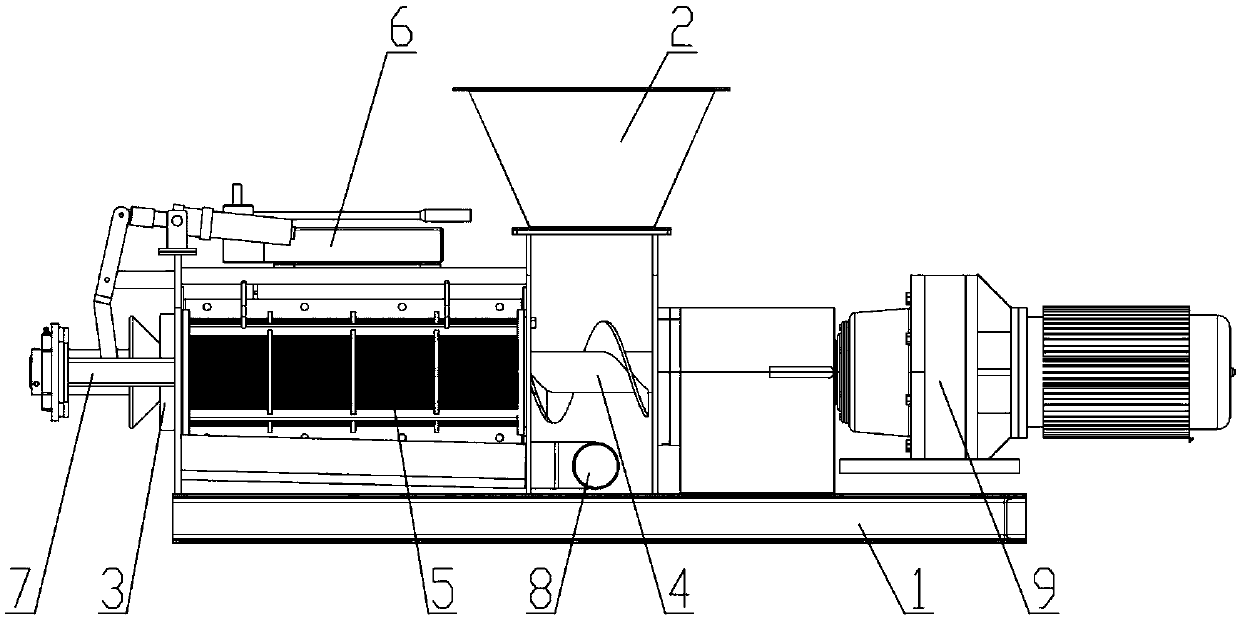

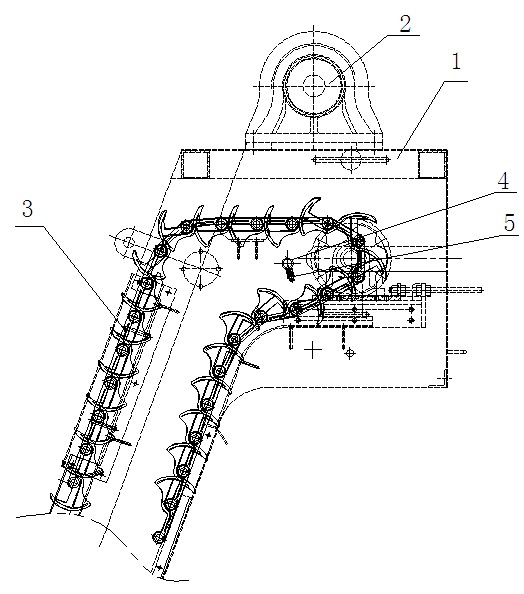

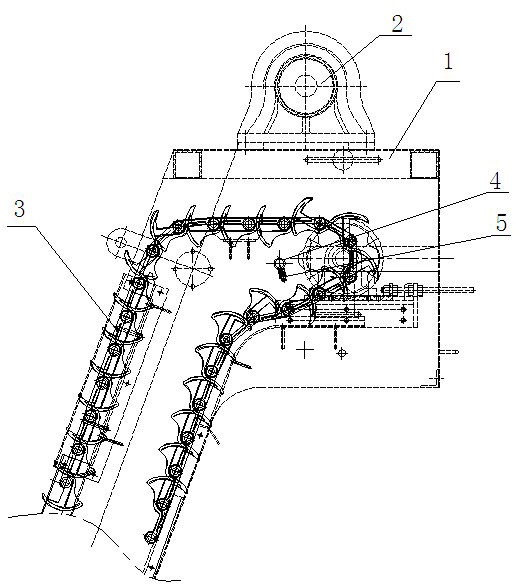

Industrial garbage solid-liquid crushing and separating device and operation method thereof

PendingCN112275771AConvey evenlyPrevent accumulation and cloggingSolid waste disposalTransportation and packagingWater filterMagnetic separator

The invention discloses an industrial garbage solid-liquid crushing and separating device and an operation method thereof. The industrial garbage solid-liquid crushing and separating device comprisesa treatment box, wherein the treatment box is divided into a water filtering cavity and a crushing cavity; a conveying belt is mounted at the top of the water filtering cavity; water filtering holes are formed in the conveying belt; a feeding hopper is mounted at the top of the side wall of the treatment box; a material spreading mechanism is mounted between the feeding hopper and the treatment box; a filter pressing magnetic separation mechanism is mounted between the conveying belt and the top of the crushing cavity; a crushing mechanism is mounted in the middle of an inner cavity of the crushing cavity; and a material falling opening is formed in the bottom of the crushing cavity. The material spreading mechanism enables garbage to be uniformly spread on the conveying belt, so that water in the garbage can be naturally filtered out through the water filtering holes, and the situation that a large amount of garbage is fed into the crushing mechanism at the same time to cause blockageis avoided; the filter pressing magnetic separation mechanism compacts the spread garbage to press out liquid in the garbage, so that a filter pressing effect is achieved; iron products in the garbage are removed through magnetic separation, so that the damage to the crushing mechanism by the iron products is avoided; the crushing mechanism performs cyclic crushing, so that the crushing is thorough; and solid-liquid separation and crushing are integrally designed, so that the efficiency is improved, and the cost is reduced.

Owner:沈洁

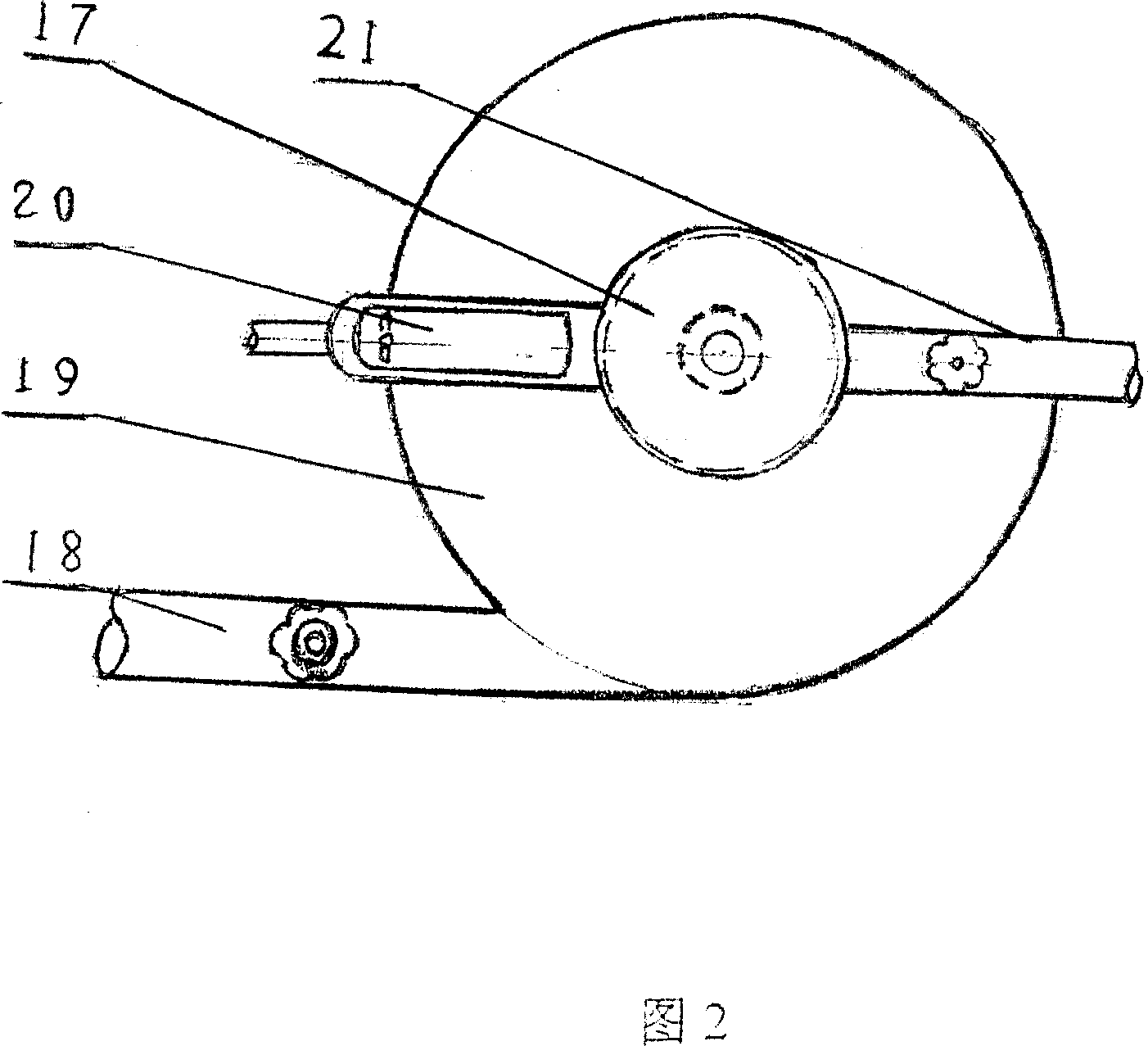

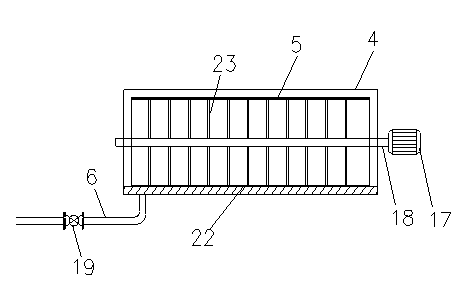

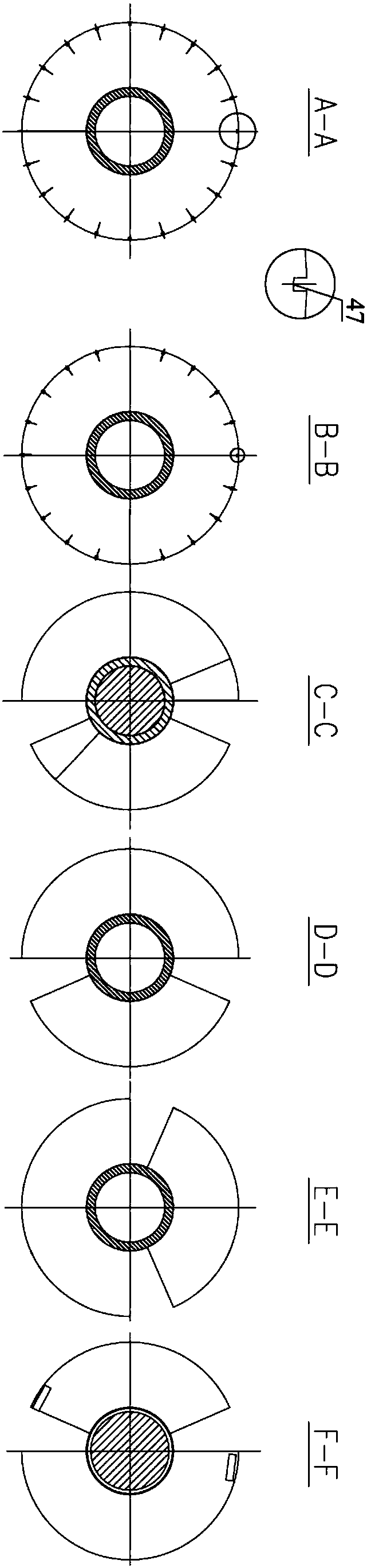

Vacuum filtering machine for indissoluble sulfur solid and liquid separation

PendingCN108176118AFiltration GuaranteeReduce the cost of large-scale investmentMoving filtering element filtersSulfurProduct gas

The invention provides a vacuum filtering machine for indissoluble sulfur solid and liquid separation. The vacuum filtering machine can improve the suction filtration effect and the solid and liquid separation efficiency, can reduce the integrated large-scale investment cost and the generation cost of the insoluble sulfur, and can guarantee the suction filtration and separation effects of the soluble sulfur. The vacuum filtering machine comprises a shell, a discharging scraping plate, a driving mechanism and a suction filtration mechanism; a slurry inlet, a washing liquid inlet, a balance gasinlet, a solid outlet and a mother liquid suction filtration port are formed in the shell; the suction filtration mechanism comprises a suction filtration pipe, a filtering disk and a cover shell; thefiltering disk hermetically covers the opening at the upper end of the cover shell to form a separation chamber; the separation chamber is integrally sealed in the shell; and one end of the suction filtration pipe stretches into the separation chamber and the other end of the suction filtration pipe is connected with the mother liquid suction filtration port. The vacuum filtering machine is characterized in that the filtering disk can be driven by the driving mechanism to rotate; a slurry distributing tank, a washing liquid distributing tank and the discharging scraping plate are arranged above the filtering disk; and the slurry distributing tank and the washing liquid distributing tank are communicated with the corresponding slurry inlet and the washing liquid inlet.

Owner:WUXI HUASHENG RUBBER TECHN

Cleaning equipment for automobile parts

InactiveCN111804635AFor subsequent cleaningReasonable structural designDrying gas arrangementsCleaning using toolsStructural engineeringMechanical engineering

The invention discloses cleaning equipment for automobile parts. The cleaning equipment comprises two supports, wherein a cleaning box is fixedly connected to the upper ends of the supports, a rotating assembly is connected to the right ends of first rotating shafts, a linkage assembly is connected to the rotating assembly, sweeping rollers are arranged on the two first rotating shafts, a discharging assembly is arranged in the middle of an inner cavity of the cleaning box, a lifting assembly is arranged in a supporting table, an overturning assembly is arranged in an outer cylinder, and a vibration assembly is arranged at the lower end of a filter plate; and parts are swept and brushed through sweeping brushes, a large amount of sweeps and dirt adhering to the parts can be brushed away, the parts, cleaning liquid and water in an inner barrel are driven by the overturning assembly to be overturned and cleaned, the cleaning efficiency is high, solid-liquid separation of the parts and waste liquid is achieved through the filter plate, the vibration assembly drives the filter plate to vibrate up and down in a reciprocating mode, the solid-liquid separation efficiency can be improved,parts on the filter plate are dried through a drying assembly, follow-up part treatment and use are facilitated, the cost is reduced, and the machining efficiency is improved.

Owner:杭州巾成科技有限公司

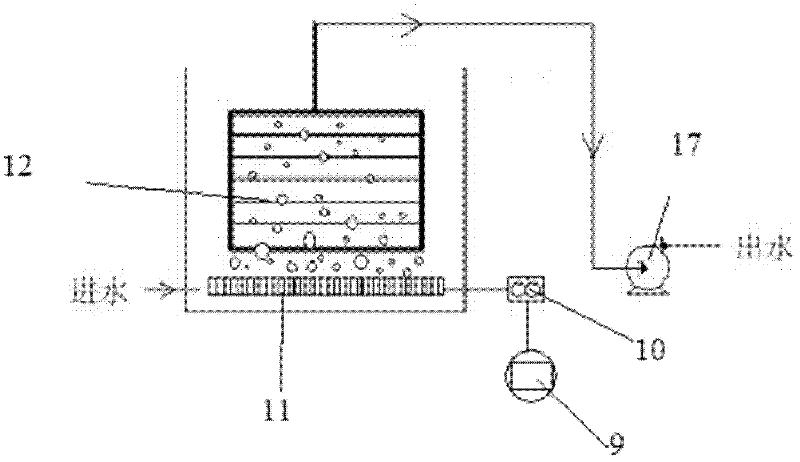

Method for treating degradation-resistant organic wastewater by membrane potential biological coupling process

InactiveCN104261628ASimple processImprove the effect of sewage treatmentTreatment by combined electrochemical biological processesWater contaminantsChemistrySewage treatment

The invention relates to a method for treating degradation-resistant organic wastewater by a membrane potential biological coupling process. The method is characterized in that membrane potential biological coupling process comprises two zones, namely the anaerobic zone and the aerobic zone; a cathode plate is placed in the anaerobic zone; a filtering membrane and an anode plate are placed in the aerobic zone; the average pore size of the membrane is 0.1-0.4 microns; during membrane filtration, negative pressure suction is used for filtering the wastewater. The method is provided on the basis of adoption of electrically-assisted reinforcing microorganisms for reduction and oxydative degradation of degradation-resistant biological wastewater and a coupling membrane filtration technology, complete separation of anaerobic and aerobic microorganisms is achieved, the membrane filtration outlet water is used, and a process flow is simplified; by the method, CODCr removing rate in the degradation-resistant organic wastewater is more than 90%, and the removal rate of chroma is more than 95%; through electrobiological enhanced degradation, the wastewater treatment effect is good and membrane pollution is controlled relatively better; through membrane outlet water, the solid-liquid separating efficiency is improved and the water quality of the outlet water is stable.

Owner:TIANJIN POLYTECHNIC UNIV

Process, device and system for biological treatment for internal reflux sewage by magnetic-loading magnetic sludge

ActiveCN102992476AImprove adsorption capacityEvenly arrangedSustainable biological treatmentBiological water/sewage treatmentRefluxSludge

The invention discloses a process, a device and a system for biological treatment for internal reflux sewage by magnetic-loading magnetic sludge, wherein the process, the device and the system for the biological treatment adopt a completely-mixed type active sludge aeration basin, common active sludge is inoculated and a certain amount of magnetic powder is poured in the basin before running, and the common active sludge and the magnetic powder are gradually cultured to be magnetic active sludge during running. A weakly-magnetic solid-liquid separator is arranged on the upper part of a magnetic active sludge biological reaction basin and close to a liquid level, the separator has a main function of performing separation for magnetic active sludge and water on a sludge-water mixture in the reaction basin, the separated magnetic active sludge directly returns into the magnetic active sludge biological reaction basin to increase sludge concentration and treatment efficiency, and the treated clean water which reaches the standard is directly drained. Via the process, the device and the system disclosed by the invention, the efficiency of degrading pollutants and the capacity of resisting an impact load of the treatment system are improved; and moreover, a secondary sedimentation basin, a sludge reflux system and a sludge concentration basin which need to be arranged in the conventional active sludge process are omitted, so that the process is small in floor area, high in treatment efficiency, simple in structure and low in construction cost.

Owner:HUAQI ENVIRONMENT PROTECTION SCI & TECH

Efficient sludge resource utilization method

ActiveCN107434341AImprove dehydration effectImprove the efficiency of solid-liquid separationSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisResource utilizationSorbent

The invention belongs to the field of sewage treatment and specifically relates to an efficient sludge resource utilization method. The method mainly comprises links of sludge concentration, pretreatment, solid-liquid separation, anaerobic digestion, preparation of a sludge adsorbent and the like. The operation method comprises the following steps: sludge from a sewage treatment plant is firstly concentrated to a proper concentration; pretreatment of calcium and alkaline agents mixing combined with other methods is then carried out; and solid-liquid separation is conducted, the liquid part undergoes anaerobic digestion for production of methane, and the solid part undergoes anhydration or pyrolysis to prepare sludge charcoal. By the pretreatment including the calcium and alkali mixing treatment process, organic substances in the sludge can be released, and those organic substances can be subjected to anaerobic digestion through an effective anaerobic reactor for production of methane. By calcium and alkali mixing, on one hand, most of phosphorus in the sludge can be maintained in sludge solids to reduce release of phosphorus during the pretreatment process, and the content of phosphorus in the prepared sludge charcoal is high. On the other hand, the sludge solids can be activated and modified, and the prepared sludge charcoal has good adsorption characteristic.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

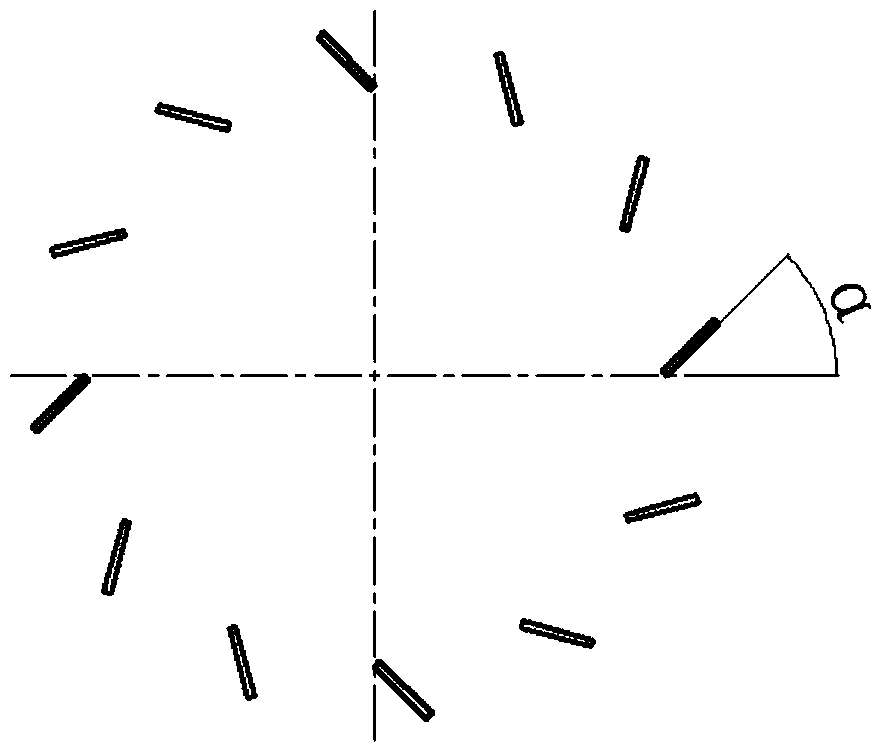

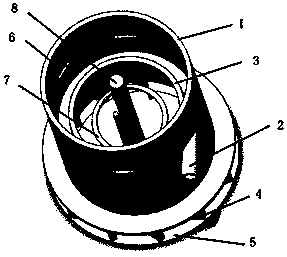

Feeding well device for thickener

ActiveCN104208923AExtension of timeRealize automatic dilutionSettling tanks feed/dischargeEngineeringEnergy consumption

The invention discloses a feeding well device for a centre drive thickener. A feeding well wall is cylindrical; an annular horizontal outer edge is formed in the lower edge of the feeding well wall; a feeding pipe is connected with the outer side of the feeding well wall; a feeding pipe orifice is positioned below the overflow liquid level of the thickener; an overflow tank is arranged below the feeding pipe orifice; the overflow tank is horizontally distributed in a circle along the inner side of the feeding well wall, and the edges of the overflow tank are equal in heights; a conical guide plate is arranged at a lower outlet of the feeding well wall, the edge of the conical guide plate is connected with the outer edge of the lower edge of the feeding well wall through guide vanes, and the guide vanes are uniformly distributed; a flocculating agent addition tube is arranged on the inner side of the overflow tank; and dilution openings are uniformly formed in the feeding well wall. According to the feeding well, any extra power is not needed, and the energy consumption is reduced; ore pulp is uniformly distributed in the feeding well and flows out of the feeding well from all directions, and the utilization rate of settling area is improved; and moreover, the ore pulp flows out of channels between the guide vanes which form an included angle of 40-50 degrees with the radial direction, so that a settled layer in the thickener is prevented from being impacted, the underflow concentration is high, and the feeding well device is convenient to popularize.

Owner:TIANJIN UNIV

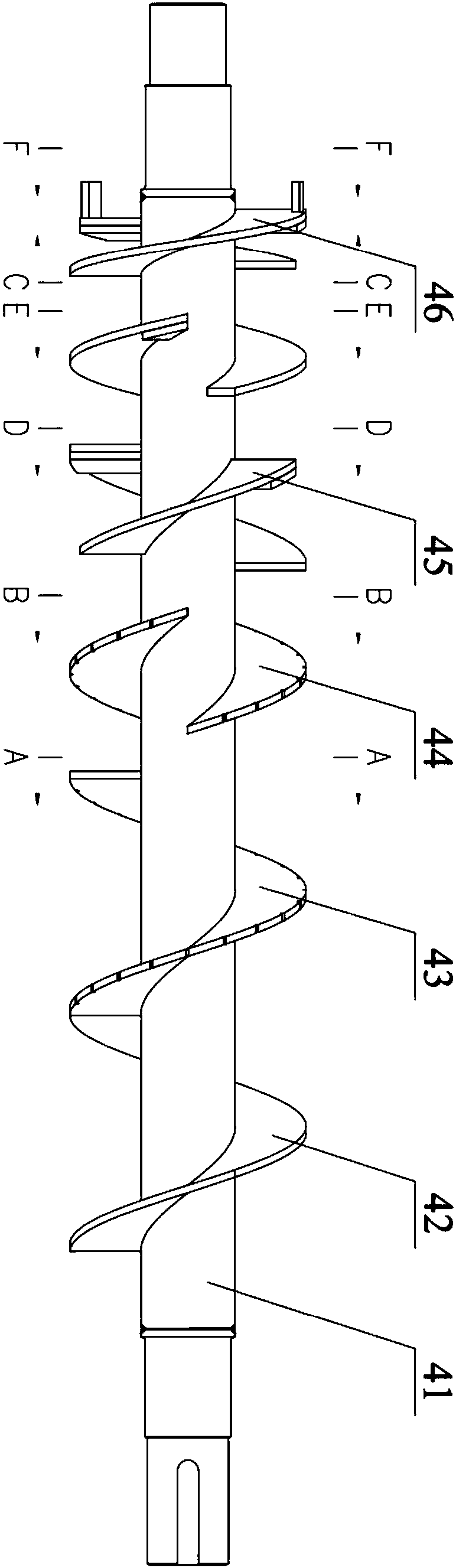

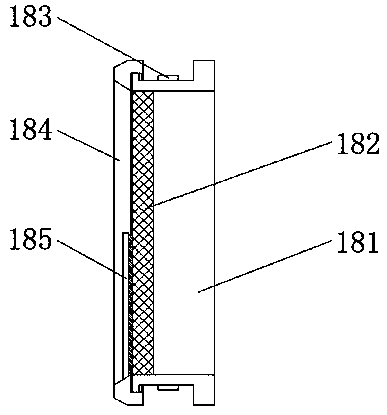

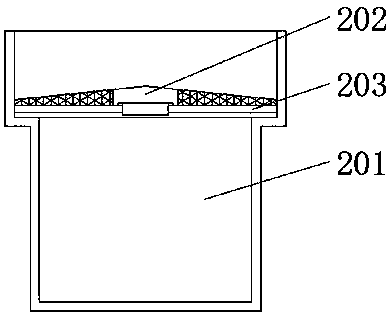

Soft extrusion spiral solid-liquid separation device

Owner:MAE WELLFUL IND

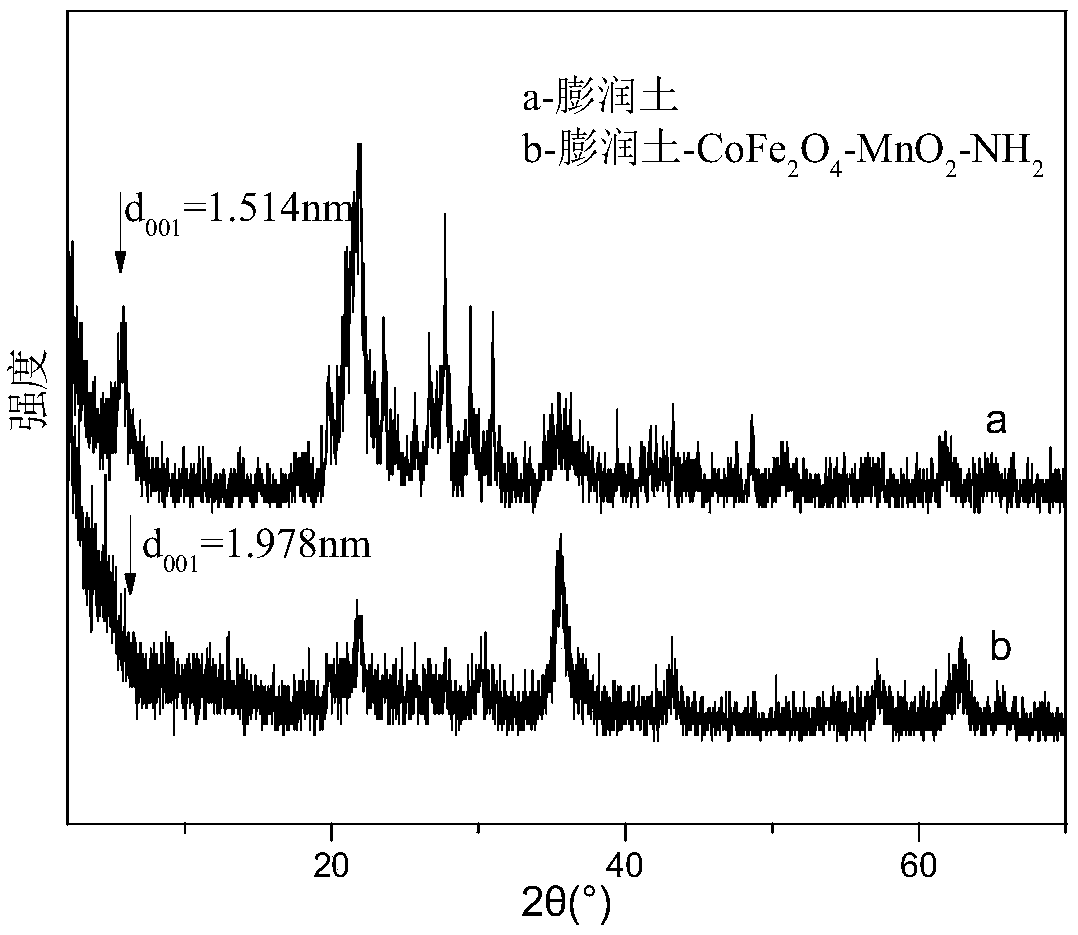

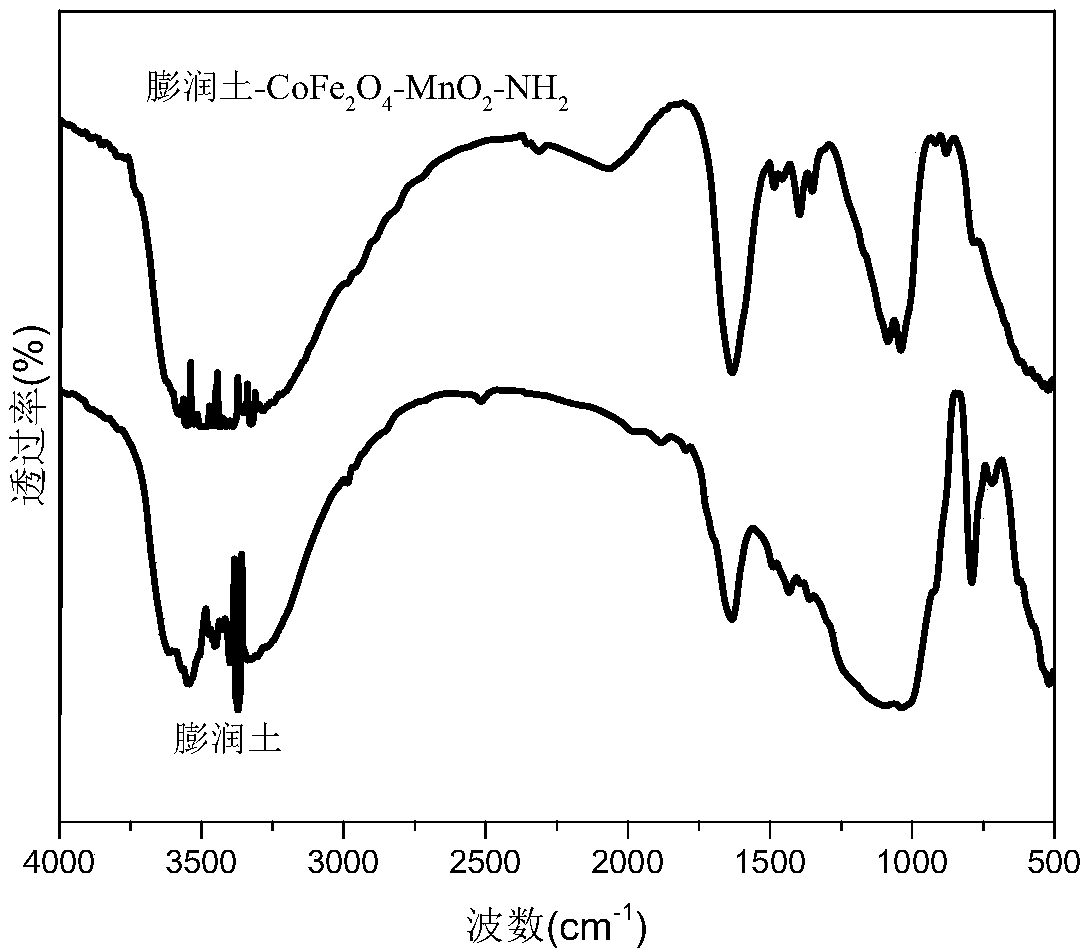

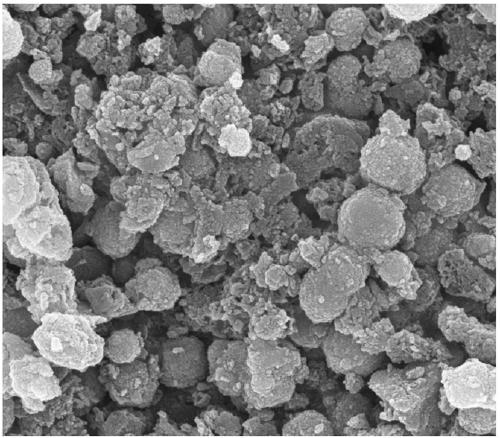

Preparation method and application of amino-functionalized manganese dioxide-loaded nano-magnetic bentonite

ActiveCN109499520AMaintain paramagnetic propertiesHigh selectivityOther chemical processesWater contaminantsSodium acetateSodium Bentonite

The invention discloses a preparation method of amino-functionalized manganese dioxide-loaded nano-magnetic bentonite. The preparation method comprises the following steps: selecting sodium bentonite,ferric chloride, cobalt chloride, sodium acetate and ethylene glycol as raw materials, mixing uniformly, and then performing hydrothermal reaction to prepare nano-magnetic bentonite A; then mixing the nano-magnetic bentonite A with manganese chloride and a sodium permanganate solution, in which potassium permanganate is dissolved, so as to react to obtain manganese dioxide-loaded nano-magnetic bentonite B; then reacting the manganese dioxide-loaded nano-magnetic bentonite B with an organic solvent, a silane coupling agent and the like to obtain novel amino-functionalized manganese dioxide-loaded nano-magnetic bentonite. According to the novel nano-magnetic bentonite disclosed by the invention, an iron and cobalt-containing magnetic nanomaterial is loaded on the bentonite, active manganesedioxide and amino functional groups are introduced, the selectivity and removal effect of cadmium ions can be effectively strengthened when the paramagnetic property of a material is simultaneously maintained, and the adsorption efficiency of Cd<2+> is as high as 99% or above.

Owner:SHANDONG UNIV OF SCI & TECH

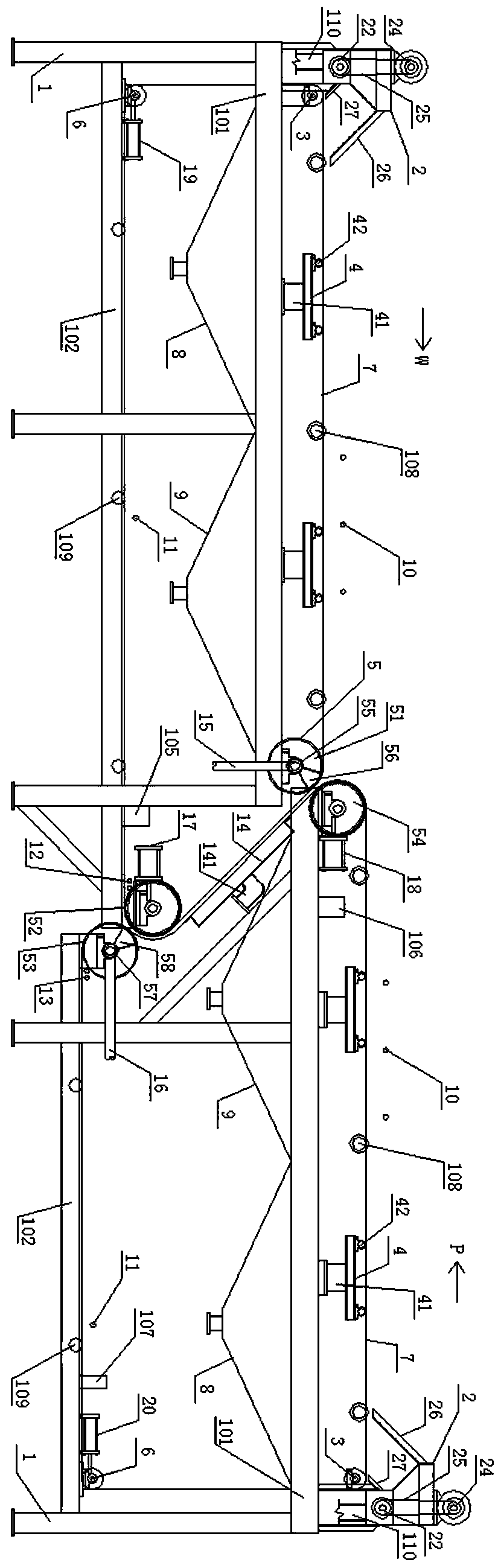

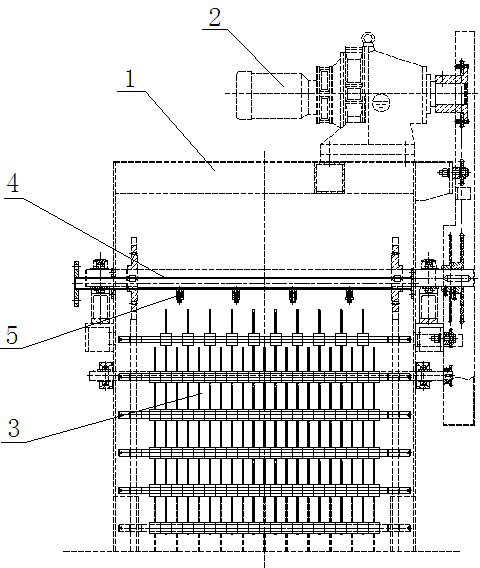

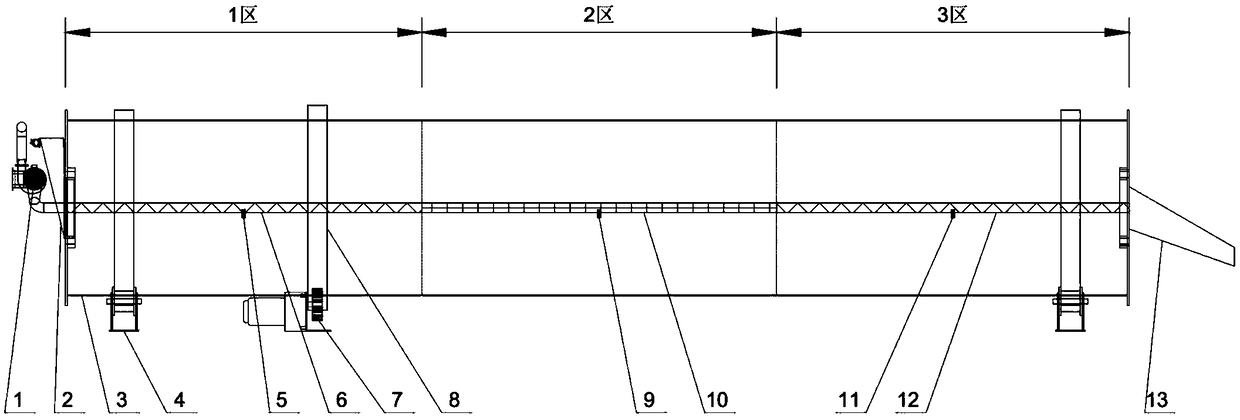

Novel belt type vibratory rolling filtering device

ActiveCN108211478AExtended service lifePrevent extrusionMoving filtering element filtersMechanical engineeringLiquid content

The invention provides a novel belt type vibratory rolling filtering device. The novel belt type vibratory rolling filtering device comprises belt type vibratory rolling filtering machines which are oppositely arranged, wherein each filtering machine comprises a rack; the rack comprises an upper supporting frame and a lower supporting frame; a layering distribution device is arranged at the upstream end of the upper supporting frame; in the material flowing direction, the rack is provided with a guiding roll, a vibrating part, a driving rolling part and a tensioning roll in sequence; a ring-shaped filtering belt is arranged around the guiding roll, the vibrating part, the driving rolling part and the tensioning roll; the left driving rolling part comprises a first extruding and dewateringroller positioned on the upper supporting frame and a second driving electric roller positioned on the lower supporting frame; the right driving rolling part comprises a second extruding and dewatering roller positioned on the lower supporting frame and a first driving electric roller positioned on the upper supporting frame; extruding gaps are respectively formed between the first extruding and dewatering roller and the first driving electric roller, between the two filtering belts surrounding the left driving rolling part and the right driving rolling part and between the second extruding and dewatering roller and the second driving electric roller. The novel belt type vibratory rolling filtering device provided by the invention has the advantages that the liquid content of filter cakesis low and the productivity is improved.

Owner:贾守民 +1

Household garbage can with pressing device and solid-liquid separation function and using method

InactiveCN111907976AReduce volumeImprove efficiencyRefuse receptaclesFiltration circuitsDrive motorPulley

The invention discloses a household garbage can with a pressing device and a solid-liquid separation function and a using method, and belongs to the technical field of living goods. The household garbage can comprises a can body, wherein a fixing cover is arranged at the bottom of the inner wall of the can body, a servo motor is arranged inside the fixing cover, a power rotating shaft of the servomotor penetrates the fixing cover to be connected to a mounting shell, a placing barrel is movably connected to the mounting shell, a power rotating shaft of the servo motor is in sleeve connection to a driving pulley, the driving pulley is connected to a driven pulley through a belt, the driven pulley is in sleeve connection to a lead screw, through arrangement of a liquid discharging box, small-particle garbage can be filtered out, so that solid-liquid separation of the garbage is thorough, a rotary disc rotates through a driving motor, then a hinge rod is driven to rotate around the centerof the rotary disc, through rotation of the hinge rod, a discharging rod can drive a discharging plate in a reciprocating mode to push the small-particle garbage on a filter plate to be discharged, manual cleaning is not needed, and time and labor are saved.

Owner:浙江望森家居科技有限公司

Sliding compression continuous solid-liquid separator

InactiveCN102179092ASlide to achieveReasonable structural designPressesMoving filtering element filtersCompression deviceEngineering

The invention relates to a sliding compression continuous solid-liquid separator. Solid-liquid separation equipment capable of adapting to dehydrating adhesive and slippery materials and running continuously is absent at present. The sliding compression continuous solid-liquid separator comprises a frame, a feeding device, a lower filter belt, a squeezing area and a driving device, and is characterized in that: the squeezing area comprises an upper compression device and a lower compression device; the upper compression device comprises at least one upper compression unit comprising an upper compression block, an upper left compression roller, an upper right compression roller and an upper sliding rubber belt; the upper sliding rubber belt coats and winds the upper left compression roller, the upper compression block and the upper right compression roller; the lower compression device comprises a lower compression block, a lower left compression roller, a lower right compression roller and a lower sliding rubber belt; the lower sliding rubber belt coats and winds the lower left compression roller, the lower compression block and the lower right compression roller; the upper compression device is positioned over the lower compression device; a gap is formed between the upper compression device and the lower compression device; and the height of the gap is gradually reduced froman inlet to an outlet. The sliding compression continuous solid-liquid separator is reasonable in structural design and high in solid-liquid separation efficiency, and can adapt to dehydrating the adhesive and slippery materials and continuously operates.

Owner:ZHEJIANG HUAZHANG TECH

Tooth harrow sewage cleaning machine with back flushing function

InactiveCN102424433AImprove the efficiency of solid-liquid separationEffective flushingWater/sewage treatmentSpray nozzlePiping

The invention provides a tooth harrow sewage cleaning machine with a back flushing function, which relates to the technical field of sewage purification treatment. A transmission motor and a guide wheel are fixedly arranged on a machine frame, and a tooth harrow type grating chain is in transmission connection between the transmission motor and the guide wheel. The tooth harrow sewage cleaning machine is characterized in that a water inlet pipe is arranged on the machine frame, and spray nozzles with water outlets facing the tooth harrow type grating chain are uniformly distributed on the water inlet pipe. Pressing-back water can be introduced into a water inlet of the water inlet pipe, and the powerful flushing force can be formed through the spray nozzles, so each tooth harrow on the tooth harrow type grating chain in the spray nozzle flushing region can be powerfully flushed, and dregs salved by the sewage cleaning machine can be effectively flushed. The tooth harrow sewage cleaning machine has the advantages that the solid-liquid separation efficiency can be enhanced, and the groundwork is laid for the subsequent work procedure circulation.

Owner:YANGZHOU TIANLONG ENVIRONMENTAL PROTECTION EQUIP

Environment-friendly waste gas treatment device for factory production and processing

InactiveCN109200809AAvoid cloggingImprove continuous working abilityHuman health protectionGas treatmentSlagFixed frame

The invention discloses an environment-friendly waste gas treatment device for factory production and processing, and relates to the technical field of waste gas treatment. The environment-friendly waste gas treatment device comprises a reaction chamber, a slag discharge pipe, a flow guide cover, a fixed pipe, a filter funnel, a nozzle, a conveying device, a fixed frame, a storage bin, a gas guiding pipe, a first fixed rod, a filter tank, an intake pipe, a second fixed rod, a transmission rod, a motor, a snap ring, a filter device, a dust collecting pipe and a collecting device. In the environment-friendly exhaust treatment device, a driving lever can be moved to drive a second blade to rotate to block a gap of a first blade, and the driving lever can be moved to drive the second blade andthe first blade to effectively prevent flying dust from being generated when dust inside the collecting device is cleaned, thereby solving the problem that when an existing exhaust treatment device is used for treating filtered dust, the flying dust is likely to generate and secondary pollution is caused to air.

Owner:杭州富阳锦丰纸业有限公司

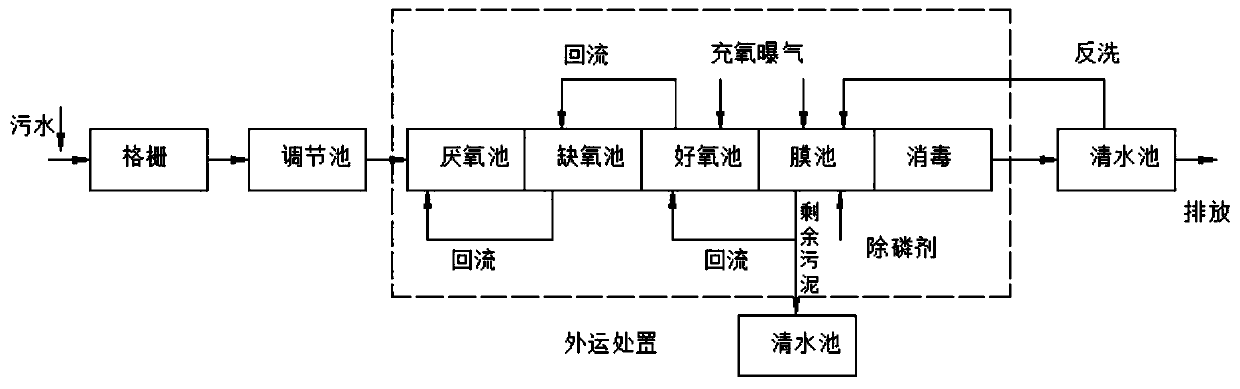

Enhanced type efficient nitrogen and phosphorus-removing sewage treatment system and treatment technology

PendingCN110040906AAvoid enteringLarge doseWater treatment parameter controlTreatment using aerobic processesWater treatment systemReaction rate

The invention relates to an enhanced type efficient nitrogen and phosphorus-removing sewage treatment system. A structure thereof comprises the following units: 1) a biochemical treatment unit, 2) a membrane treatment unit, 3) a backflow unit, 4) filling units and 5) a control unit, wherein the membrane treatment unit is connected with a water outlet end of the biochemical treatment unit; backflowsludge of the membrane treatment unit is connected with a water inlet end of an aerobiotic tank of the biochemical treatment unit, and the backflow rate is 300%-400%; the water outlet end of the aerobiotic tank flows back to the water inlet end of an anoxic tank through a backflow pipeline and a backflow device, the water outlet end of the aerobiotic tank and the water outlet end of an anaerobictank are jointly connected with the anoxic tank, and the backflow rate is 100%-200%; the water outlet end of the anoxic tank flows back to the water inlet end of the anaerobic tank through the backflow pipeline and the backflow device, the water outlet end of the anoxic tank and a pretreated water outlet end are jointly connected with the anaerobic tank, and the backflow rate is 100%-200%; the filling units are arranged in the anoxic tank and the aerobiotic tank. In the invention, a filler is added in a traditional A / A / O technical reactor, the backflow position and the backflow rate are adjusted, the carbon source is efficiently utilized, the nitrogen and phosphorus removal effect is enhanced, the reaction rate is effectively increased and the effluent index can be guaranteed.

Owner:新权诚工程建设项目咨询管理有限公司

Solid-liquid separation device based on sewage treatment

InactiveCN110078246AEasy to separateReduce moisture contentWater/sewage treatment by centrifugal separationTreatment involving filtrationSewage treatmentExternal drainage

The invention discloses a solid-liquid separation device based on sewage treatment. The device comprises a device body, wherein a solid-liquid separation cavity is formed in the device body, a water inlet pipe is fixed on the upper side of the solid-liquid separation cavity, the lower end of the water inlet pipe is communicated with the solid-liquid separation cavity, and the upper end of the water inlet pipe is connected with an external drainage pipe; a filter screen is fixed in the solid-liquid separation cavity, and a water treatment device is arranged on the lower side of the solid-liquidseparation cavity. The separation cavity in the solid-liquid separation device is obliquely arranged, solid waste is mutually squeezed and dewatered through a push plate when being conveyed, so thatsolids and liquid can be completely separated initially. Separated water can be deodorized and drained, environmental water pollution is reduced, the separated solids are centrifugally dewatered, so that the lowest water content of the solids is reached, and subsequent waste classification and recovery treatment is facilitated. The device has high solid-liquid separation efficiency, and is convenient to install and use.

Owner:新昌县韵母电子有限公司

Kitchen waste recycling equipment

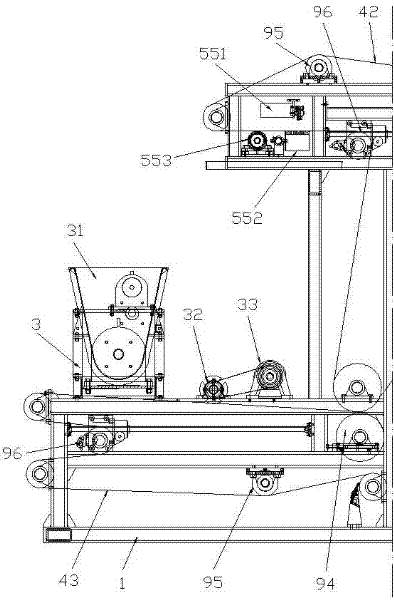

InactiveCN109127659AImprove separation rateAvoid breedingSolid waste disposalGrain treatmentsOil waterAir blower

The invention discloses kitchen waste recycling equipment. The equipment comprises a basic mounting base, an oil collection box body, a material collection box body and a feeding box body are arrangedat the upper end of the basic mounting base, and an inner cavity of the feeding box body is provided with several partition layers to be partitioned into a solid-liquid separation chamber, a twistingcutting chamber, a left oil-water separation chamber and a right material collection chamber from top to bottom in sequence; the solid-liquid separation chamber is internally provided with a solid-liquid separation device, the twisting cutting chamber is internally provided with a twisting cutting device, and a first heating sheet, a temperature sensor and a liquid level sensor are arranged on the inner side wall of the left oil-water separation chamber separately; a first air blower is arranged on the outer wall of the feeding box body and communicated with the bottom of an inner cavity of the left oil-water separation chamber through an air inlet pipe, an oil pumping pipe is arranged between the left oil-water separation chamber and the oil collection box body, and a drying and stirringdevice is arranged in the right material collection chamber. The kitchen waste recycling equipment has the advantages of being simple in structure and high in practicability.

Owner:SHANGHAI ZHENGYU MACHINERY CO LTD

Integrated device and method for treating sewage through cooperation between hydraulic action and flotation

ActiveCN107445327AImprove the process of primary solid-liquid separationWell mixedWater/sewage treatment by centrifugal separationMultistage water/sewage treatmentHydraulic actionTurbidity

The invention discloses an integrated device and method for treating sewage through cooperation between hydraulic action and flotation. The device consists of a hydraulic separation zone and a flotation zone. The hydraulic separation zone mainly comprises a tangential-inlet water inlet pipe, a swirl chamber, an overflow pipe, a swirl barrel, a sand collecting zone and a solid-rich phase outlet pipe from top to bottom; and large-grain solid matters are separated from water through hydraulic action. The flotation zone is located above the hydraulic separation zone and is mainly composed of, from bottom to top, a supporting tray, a releaser, a scum zone and the like, wherein the scum zone is provided with a deflector and an oil overflow weir and is used for collecting scum, and the periphery of the scum zone is an effluent weir for discharging purified water. The integrated device for treating sewage through cooperation between hydraulic action and flotation in the invention has the obvious effects of removing sand, lowering turbidity, separating solid and liquid and the like in the field of water treatment. The device is high in integration level, compact in structure, small in an occupied land area, high in the degree of automation, easy to operate, convenient to transport, fast in processing speed and low in energy consumption.

Owner:上海京明环境科技有限公司

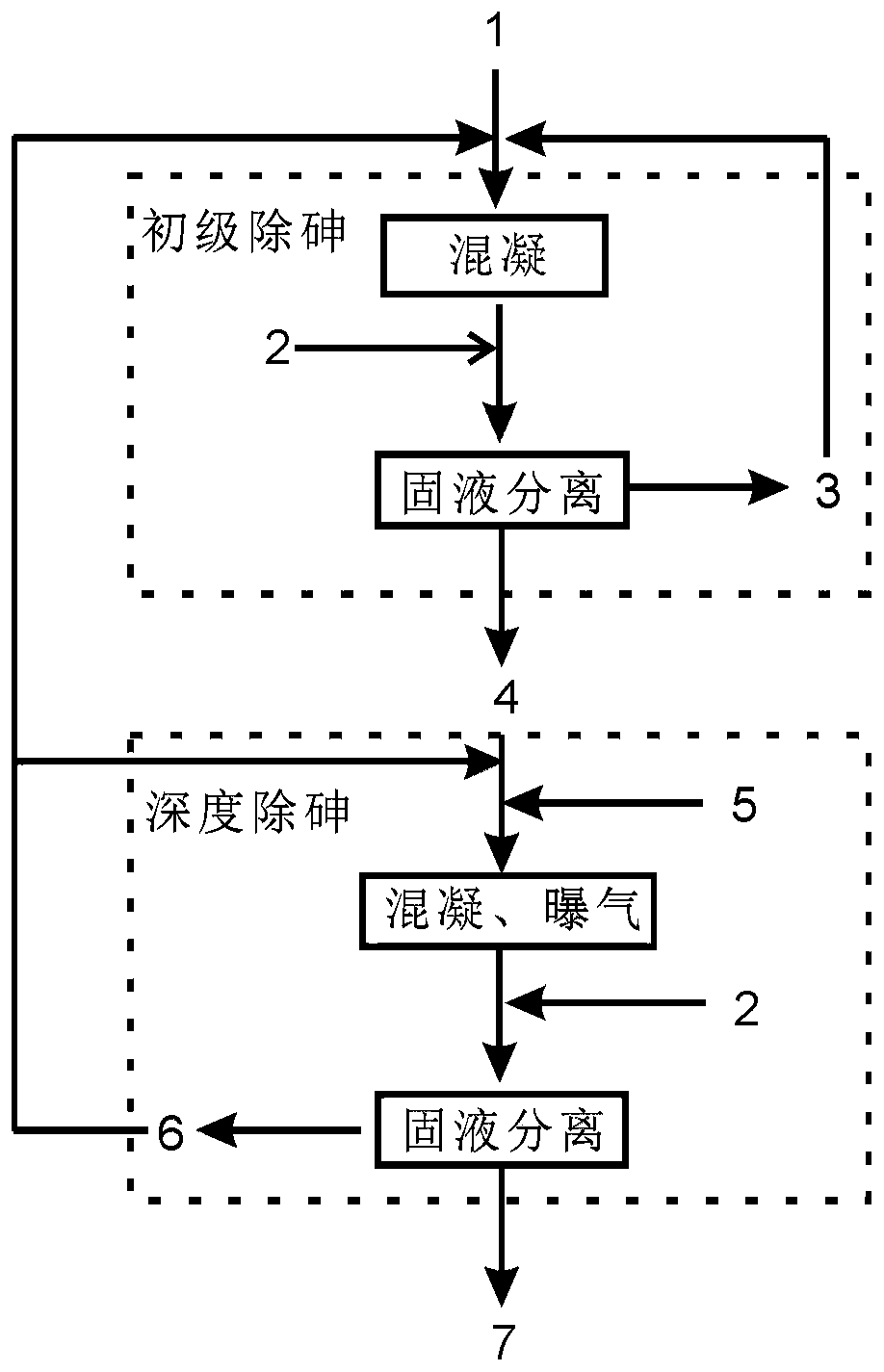

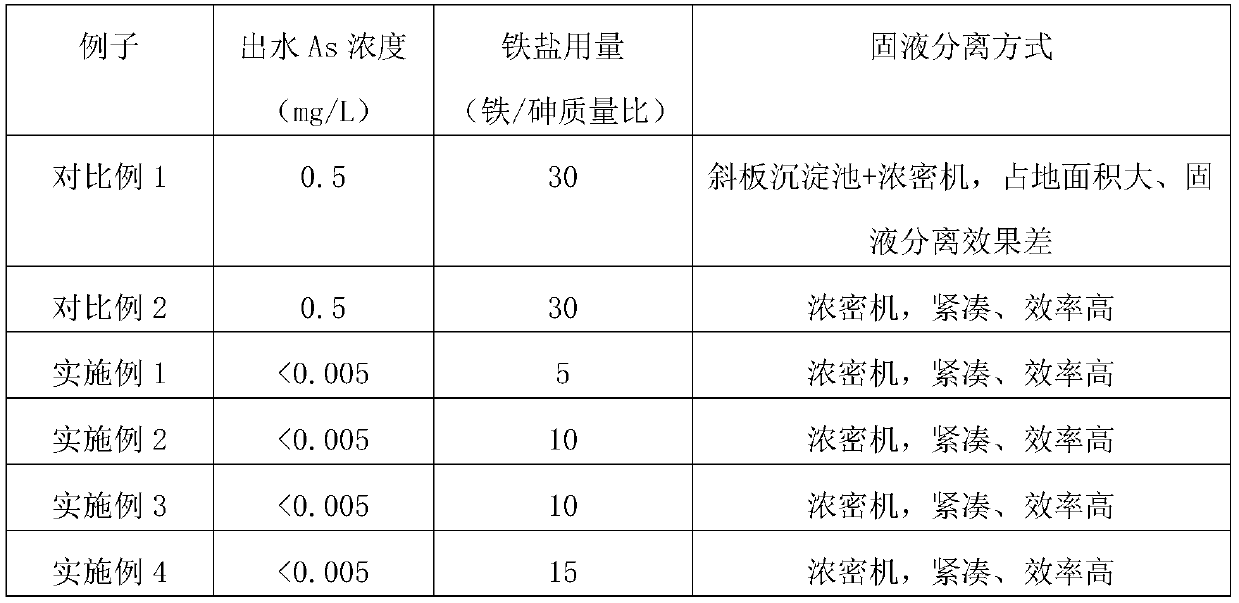

Stepped deep purification method of low-concentration arsenic waste water

ActiveCN110590011AReduce total arsenicReduce consumptionWater contaminantsWater/sewage treatmentPurification methodsIron salts

The invention relates to a stepped deep purification method of low-concentration arsenic waste water. The low-concentration arsenic waste water (1) is subjected to a primary arsenic removing and deeparsenic removing stepped treatment mode; at the initial stage of primary arsenic removal, a coagulant (8) is added to perform coagulation and then solid and liquid separation is conducted to obtain primary arsenic-removing bottom flow (3) and primary arsenic-removing overflow (4); during deep arsenic removal, iron salt (5) is added into the primary arsenic-removing overflow (4) to perform coagulation aeration and solid-liquid separation to obtain deep arsenic-removing bottom flow (6) and deep arsenic-removing overflow (7), the deep arsenic-removing overflow (7) is subjected to up-to-standard discharge; subsequently, the primary arsenic-removing bottom flow (3) and the deep arsenic-removing bottom flow (6) return to the primary arsenic removal to replace the coagulant (8); and the stepped deep purification method of the low-concentration arsenic waste water has the advantages that the arsenic concentration of the aqueous solution after treatment can be as low as 0.005 mg / L or below, themedicament consumption is low, the slag amount is small and the medicament efficacy is high, and is suitable for being applied to environmental protection and mine resource comprehensive utilizationindustry.

Owner:ZIJIN MINING GROUP

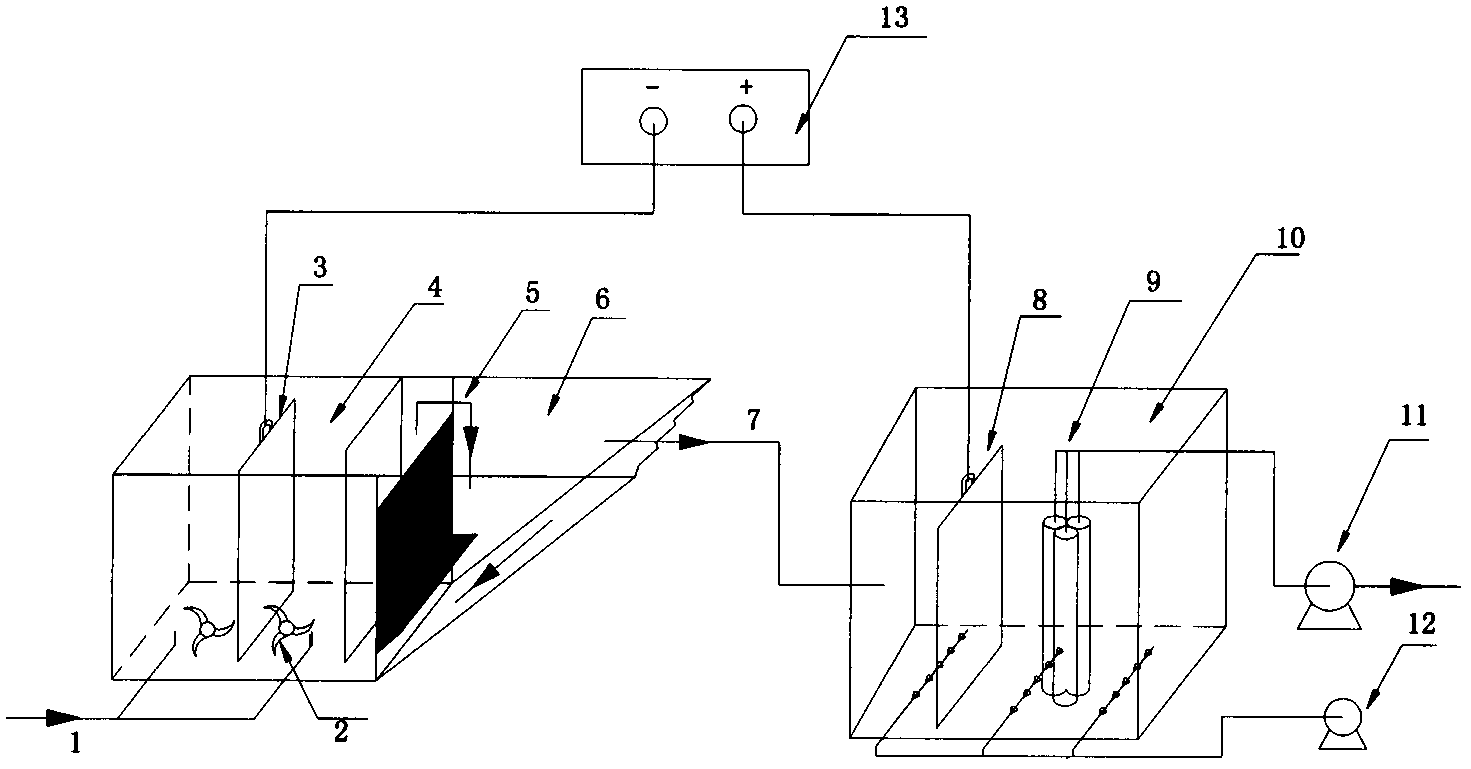

Experimental device for treating emulsified oil wastewater by UASB/MBR technology

InactiveCN102417276AInhibit swellingAvoid timeMultistage water/sewage treatmentChemical LinkageFiber

The invention discloses an experimental device for treating emulsified oil wastewater by UASB / MBR technology, which belongs to the technical field of wastewater treatment. The experimental device of the invention comprises four parts of a water intake system, an anaerobic digestion part, a membrane bioreactor, and a penetration water outlet part. The membrane bioreactor adopted by the invention combines the biodegradation function of a traditional activated sludge process with a high-efficient retention and separation effect of novel membrane separation technology, has the characteristics of high solid-liquid separation efficiency, less land occupation, convenient operation management, and the like, and avoids the disadvantages of sludge expansion, short solid retention time, and the like; the membrane surface of the polytetrafluoroethylene hollow fiber microfiltration membrane adopts chemical bond hydrophilic modification technology, and has the advantages of high flux, pollution resistance, and oil stain resistance. The whole device is controlled automatically, is very convenient for operation management, and is applicable to experiment teaching and scientific research.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

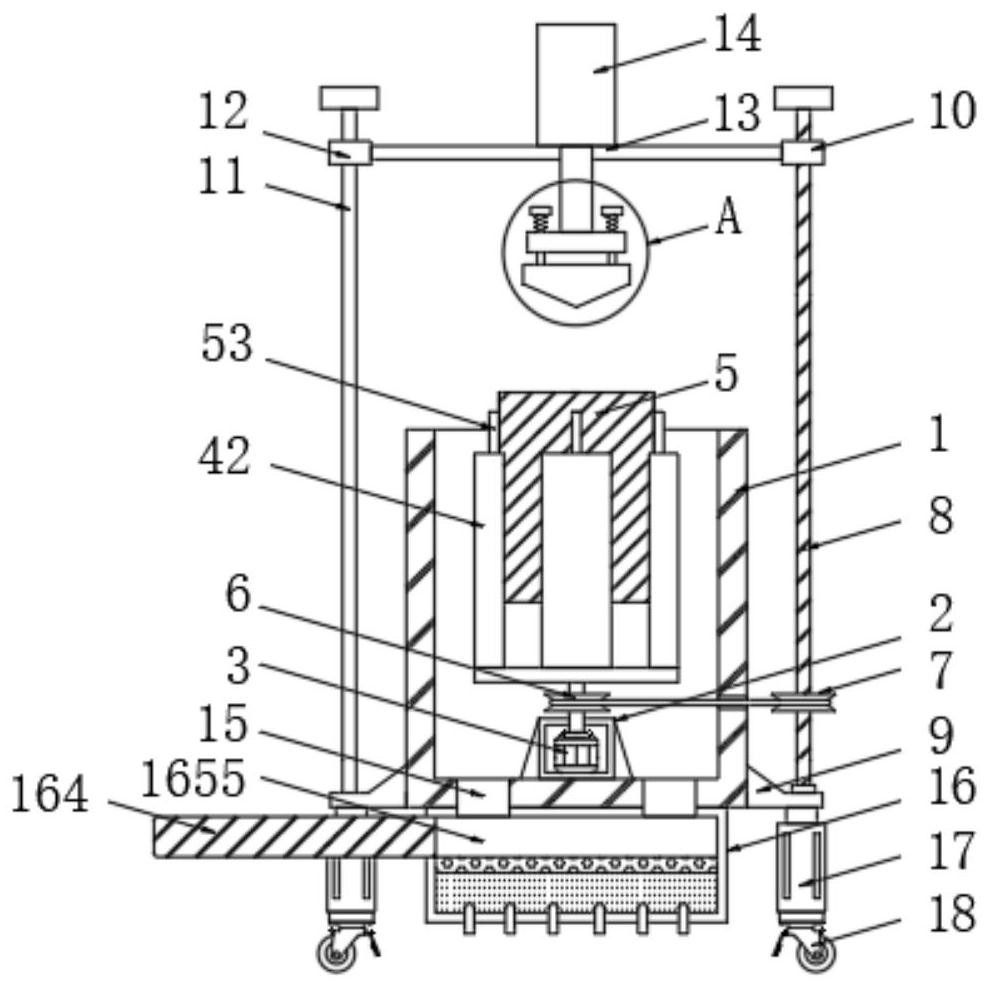

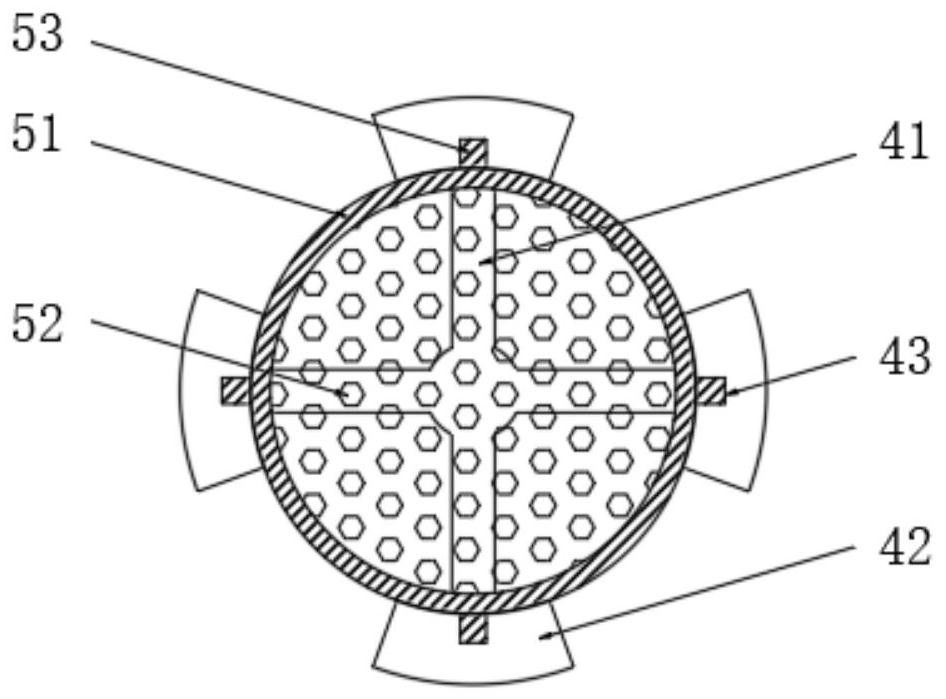

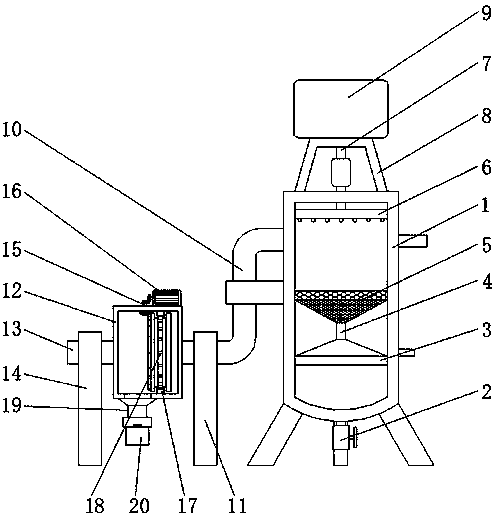

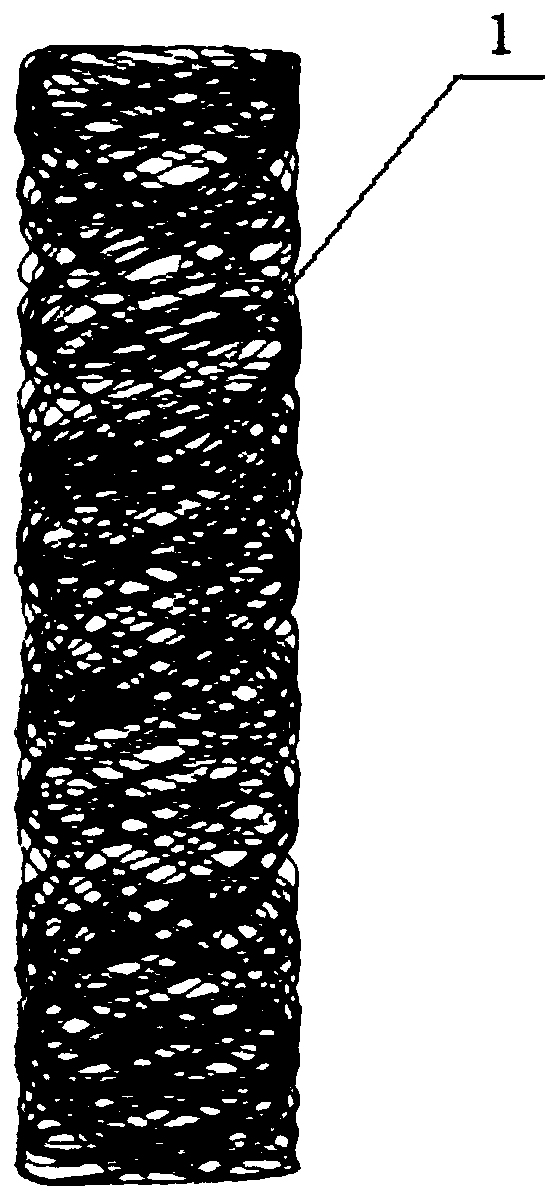

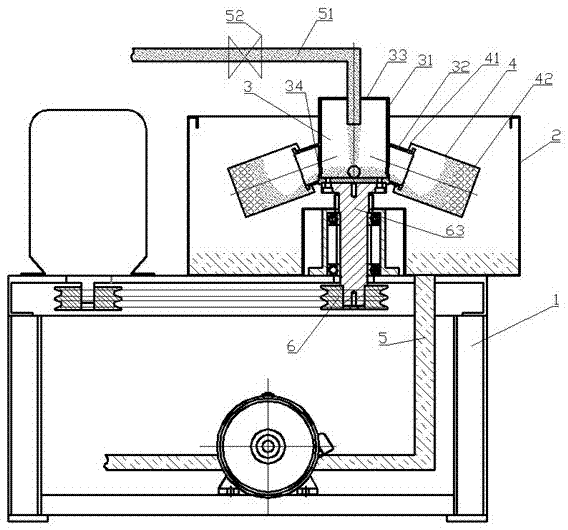

Solid-liquid separator for superfine powder

ActiveCN105435971AEasy to collectImprove the efficiency of solid-liquid separationRotary centrifugesEngineering

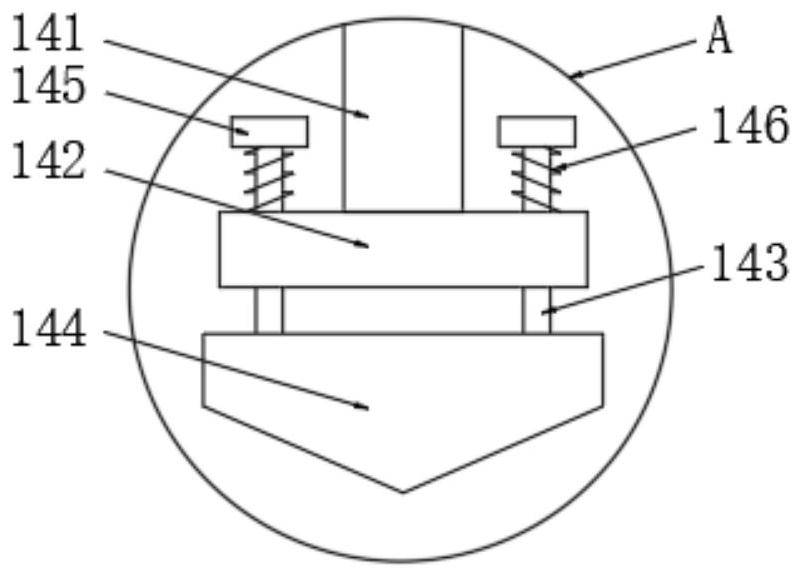

A solid-liquid separator for superfine powder comprises a base (1), a liquid containing bucket (2), a separating device (3), solid receiving devices (4), a liquid recovering device (5), a driving device (6) and a control device, wherein the liquid containing bucket (2) is arranged on the base (1); the separating device (3) is arranged in the liquid containing bucket (2); the bottom of the separating device (3) is fixed on the end surface of an output shaft (63) of the driving device (6), and is driven by the driving device to rotate; and the solid receiving devices (4) are mounted at the lower part of the separating device (3). The solid-liquid separator is characterized in that the separating device (3) comprises a rotating throwing-off bucket (31) and solid collecting opening branches (32); a liquid inlet (33) is formed in the top of the rotating throwing-off bucket (31); and a plurality of opening branch discharge holes (34) are uniformly distributed in the lower part of the rotating throwing-off bucket. The solid-liquid separator is simple in structural design and convenient to maintain, improves the solid-liquid separation efficiency, and is capable of collecting solids fast and conveniently.

Owner:长沙天创粉末技术有限公司

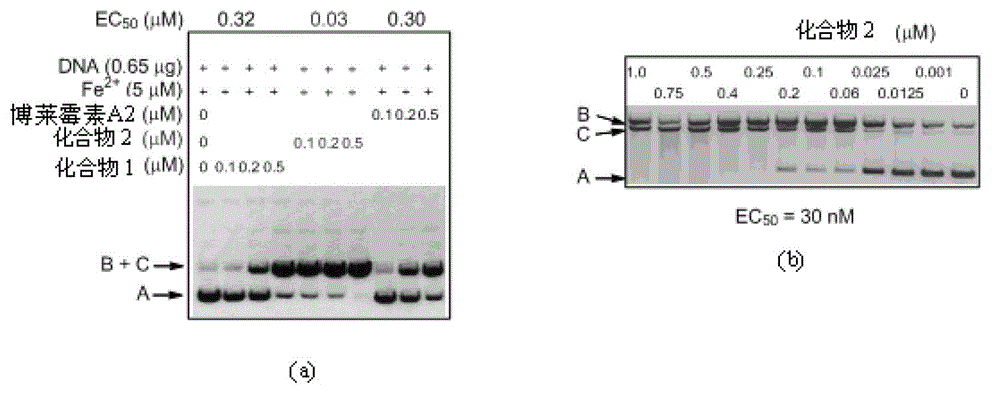

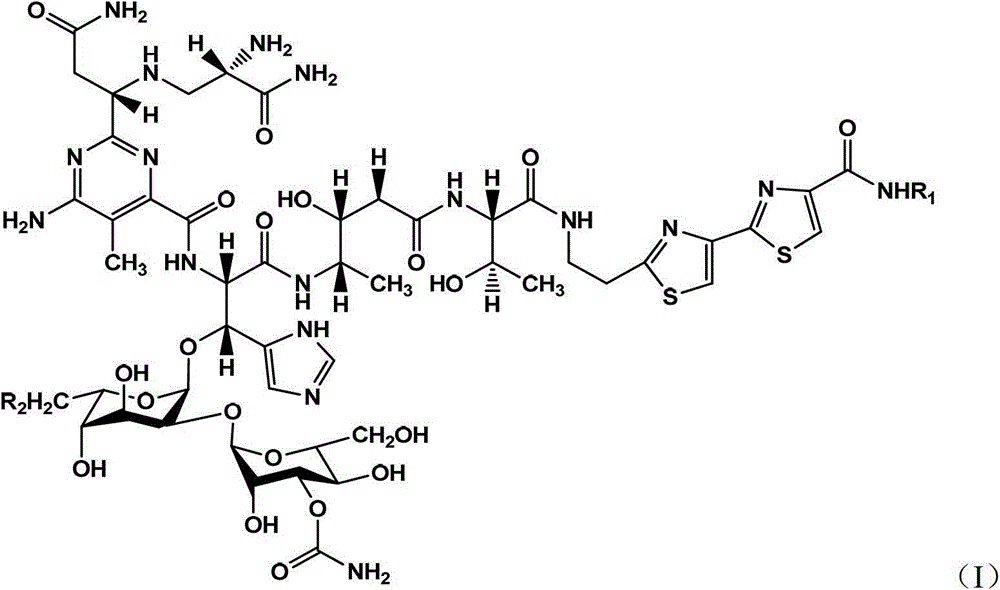

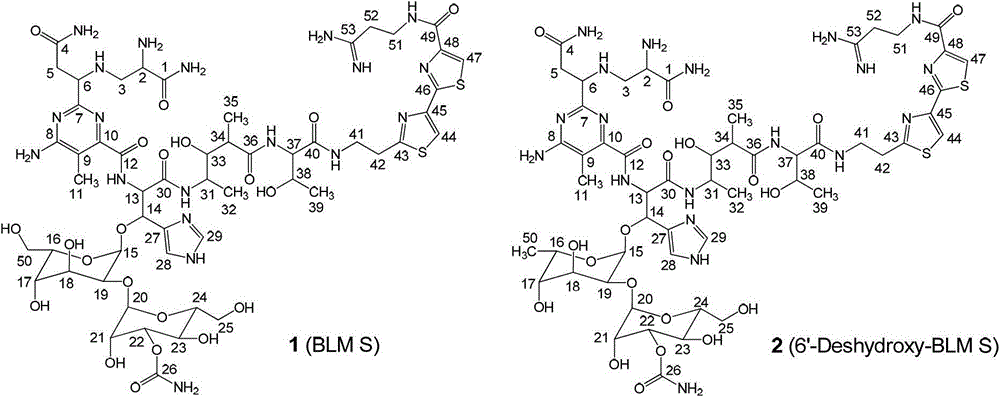

Bleomycin derivative separating and purifying method

ActiveCN104004065AImprove the efficiency of solid-liquid separationImprove serum qualityPeptide preparation methodsChemical structurePurification methods

The invention relates to the technical field of biomedicines, and concretely relates to a method for separating and purifying bleomycin (BLM) derivatives 6'-dehydroxy-BLMs from a recombinant engineering bacterium Streptomyces flavovirens SB9026 (with the preservation number of CCTCC M2011292) fermentation liquid. The method comprises the steps of deposition separation pretreatment, D-113 and Diaion HP-20 resin adsorption elution, Silica Flash column isogradient elution, copper removing refining and the like. The method has the advantages of simplification and reduction of the separating and purifying steps, production cost reduction and recovery rate increase. The chemical structure of the bleomycin derivatives is represented by a general formula shown in the specification.

Owner:CHANGSHA CHARISM BIOSCIENCES CO LTD +2

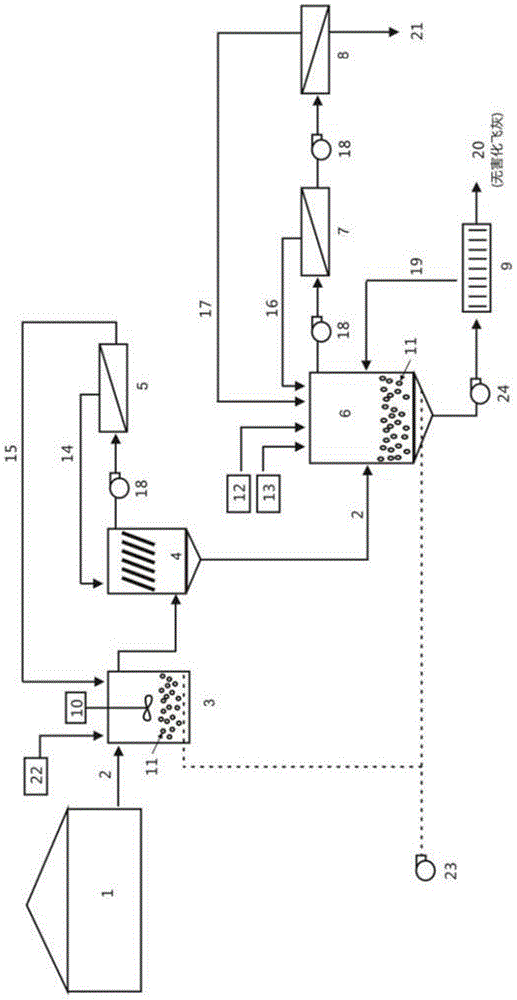

Film separation and concentration system for removing heavy metals in garbage incineration fly ash

ActiveCN105080946AImprove cleaning efficiencyImprove extraction efficiencySolid waste disposalAeration systemLitter

The invention relates to a film separation and concentration system for removing heavy metals in garbage incineration fly ash. The system comprises a cleaning tank (3), a settling tank (4), a leaching tank (6) and a press filter (9), wherein a stirring device (10) and a fine aeration system (11) are arranged in the cleaning tank (3); the cleaning tank (3) is connected with the settling tank (4); the settling tank (4) is connected with a first-grade film filter system (5), and is connected with the leaching tank (6); the fine aeration system (11) is arranged in the leaching tank (6); the leaching tank (6) is provided with an acid pouring port and a surface active agent pouring port, and is connected with a second-grade film filter system (7); the second-grade film filter system (7) is connected with a three-grade film concentration system (8); and a fly ash outlet of the leaching tank (6) is connected with the press filter (9). The system can realize the recycling of waste water and leaching liquid in the film system, and generates no secondary waste water and waste liquid; and the fly ash and the leaching liquid achieve high-efficiency separation through a film technology.

Owner:JOJOTECH ENVIRONMENTAL TECH LTD

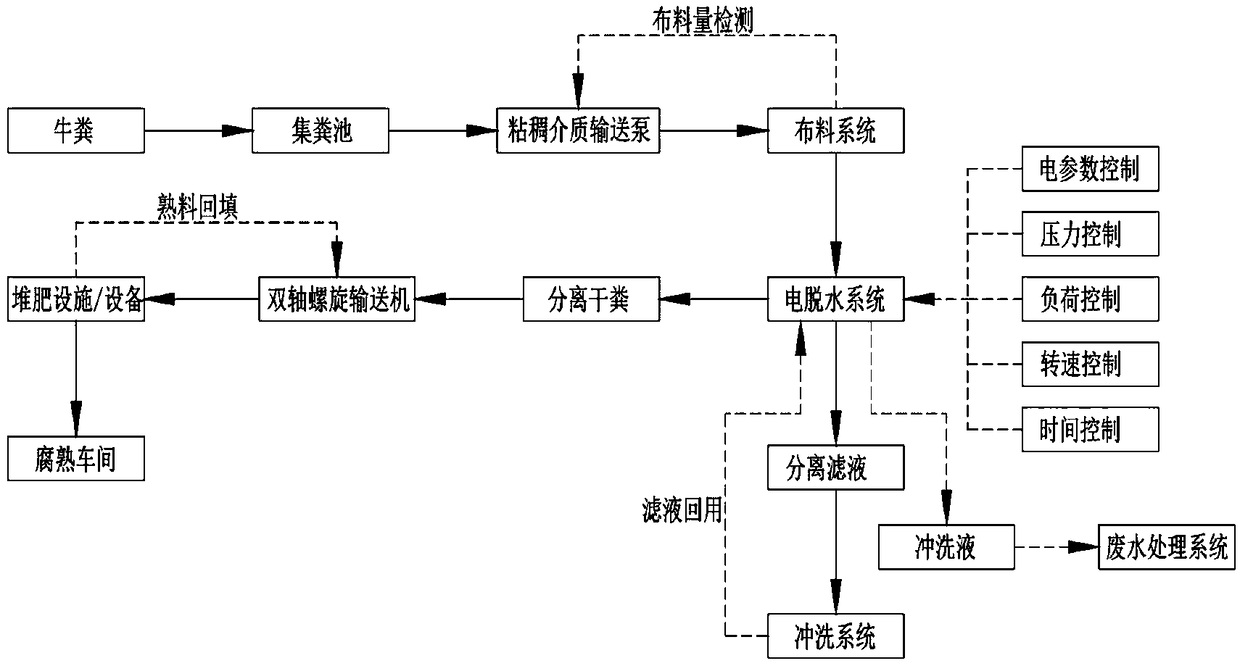

System and method for preparing organic fertilizer by electric dehydration of dry clean cow dung

PendingCN109369222ALow costReduce pollutionClimate change adaptationExcrement fertilisersEngineeringElectric field

The invention relates to a system and a method for preparing an organic fertilizer by electric dehydration of dry clean cow dung. The system comprises a dung collection tank, a conveying pump, an electric dehydration device, a double-screw conveyor and a rotary composting barrel, a discharging port of a composting tank is connected with a feeding port of the conveying pump, a discharging port of the conveying pump is connected with a mud distribution bucket, so that materials are fed into the electric dehydration device, a dry dung outlet of the electric dehydration device corresponds to a feeding port of the double-screw conveyor, a discharging port of the double-screw conveyor corresponds to a feeding port of the rotary composting barrel, and a discharging port of the rotary composting barrel is correspondingly connected with a rotten workshop through a conveying track. The solid water content of the dehydrated dry clean dung can be lower than 55%, the dry clean dung can be compostedwithout adding accessories, and accessory cost is reduced. Ionic heavy metal can be transferred from the dry dung under an electric field in the dehydrating process, the heavy metal content of a subsequent fertilizer is reduced, and environmental non-point source pollution is reduced.

Owner:天津市农业科学院

Environmental-friendly and energy-saving solid-liquid separation device

ActiveCN103752048AAffect the service lifeEasy to assemble and disassembleSettling tanks feed/dischargeDrive wheelCoupling

The invention discloses an environmental-friendly and energy-saving solid-liquid separation device which comprises a tank body, a driving device, a driving wheel device, a riding wheel device, a scraper blade device, a bend wheel device, a strut and a safety rack, wherein the tank body comprises a sliding chute, a guide tank, a front tank body and a rear tank body which are sequentially connected, the driving device is connected with the driving wheel device through a coupling, the driving wheel device is supported at the tail end of the guide tank through a driving wheel bracket, the scraper blade device is divided into an underwater part and an overwater part, the overwater part is supported on the water surface trough the riding wheel device, and a chain ring hook of the scraper blade device is connected with the riding wheel device and the bend wheel device and realizes transmission through the riding wheel device and the driving wheel device. The solid-liquid separation device disclosed by the invention is low in power consumption for processing, and high in solid-liquid separation efficiency; the solid content of effluents is over 60%; the manufacturing cost is low; and the solid-liquid separation device can replace filter presses, spiral classifiers, hydrocyclones, high-frequency vibrating undersize-sieves, dewatering screens, settling ponds and the like and is not equipped with a tailings pond (dam) which occupies a large space land and needs high investment, and tailings can be drily piled and backfilled or can level up land.

Owner:樊日宏 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com