Solid-liquid separator for superfine powder

A solid-liquid separator and ultra-fine powder technology, used in centrifuges, centrifuges with rotating drums, etc., can solve the problems of not easy to scrape clean, block liquid phase centrifugal effect, influence, etc., and achieve fast solid collection. Convenience and improved solid-liquid separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

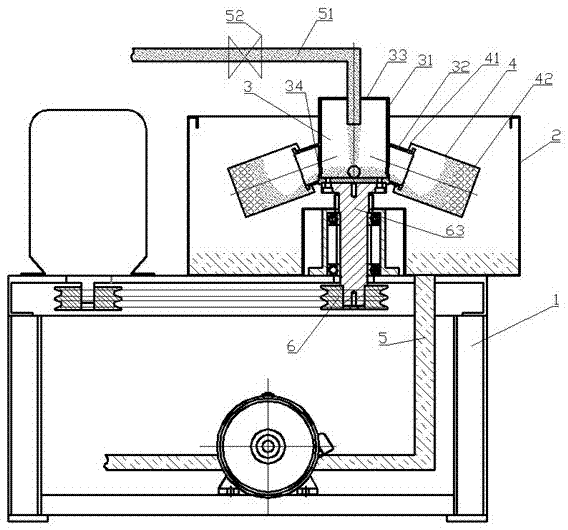

[0019] An ultra-fine powder solid-liquid separator, comprising: a base 1, a liquid container 2, a separation device 3, a solid receiving device 4, a liquid recovery device 5, a driving device 6, a control device; the liquid container 2 is set On the base 1, the separating device 3 is placed in the liquid container 2, and the bottom of the separating device 3 is fixed on the end surface of the output shaft 63 of the driving device 6, and is driven to rotate by the driving device 6; the receiving device 4 is installed and separated The lower part of the device 3; the separating device 3 includes a rotating slinger 31, a solid collection opening branch 32, the top of the rotating slinger 31 is provided with a liquid inlet 33, and a plurality of openings and branching outlet holes 34 are evenly distributed on the lower part of the side wall. When the ultrafine powder solid-liquid separation device proposed in this embodiment works, the solution is controlled to enter the liquid mixt...

Embodiment 2

[0021] A solid-liquid separation device for ultrafine powder, comprising a base 1, a liquid container 2, a separating device 3, a receiving device 4, a liquid recovery device 5, a driving device 6, and a control device; the separating device 3 includes a rotating spin bucket 31, The solid collection opening branch 32 is provided with a liquid inlet 33 on the top of the rotating spin bucket 31, a plurality of solid collection opening branch and discharge holes 34 are evenly distributed along the lower part of the side wall of the rotating spin bucket 31, and the solid collection opening branch 32 is 20 to the horizontal plane. °Including angle, the solid collection opening on the side wall of the rotating bucket 31 and the branch outlet hole 34 are tangent to the bottom surface of the rotating bucket 31. The bottom of the rotating bucket 31 is fixed on the end surface of the output shaft 63 of the driving device 6, and the driving device 6 drives The separation device 3 rotates a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com