System and method for preparing organic fertilizer by electric dehydration of dry clean cow dung

An electro-dehydration and organic fertilizer technology, applied in the field of fertilizers and organic fertilizers manufactured by fertilizers, can solve the problems of poor separation effect, low separation efficiency, heavy metal pollution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

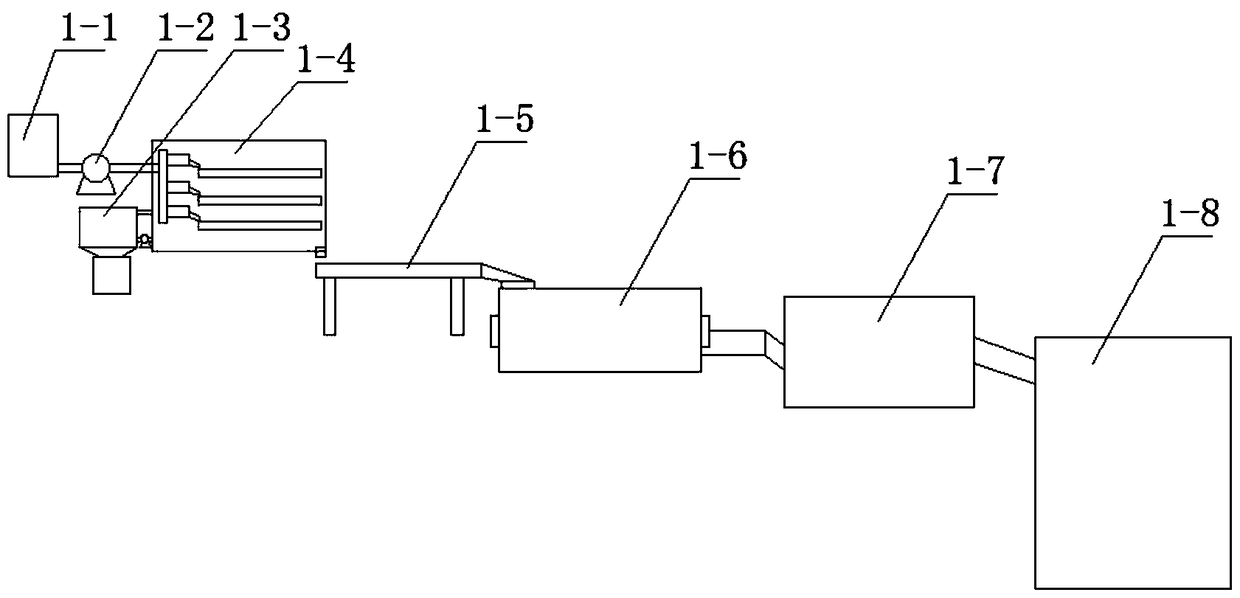

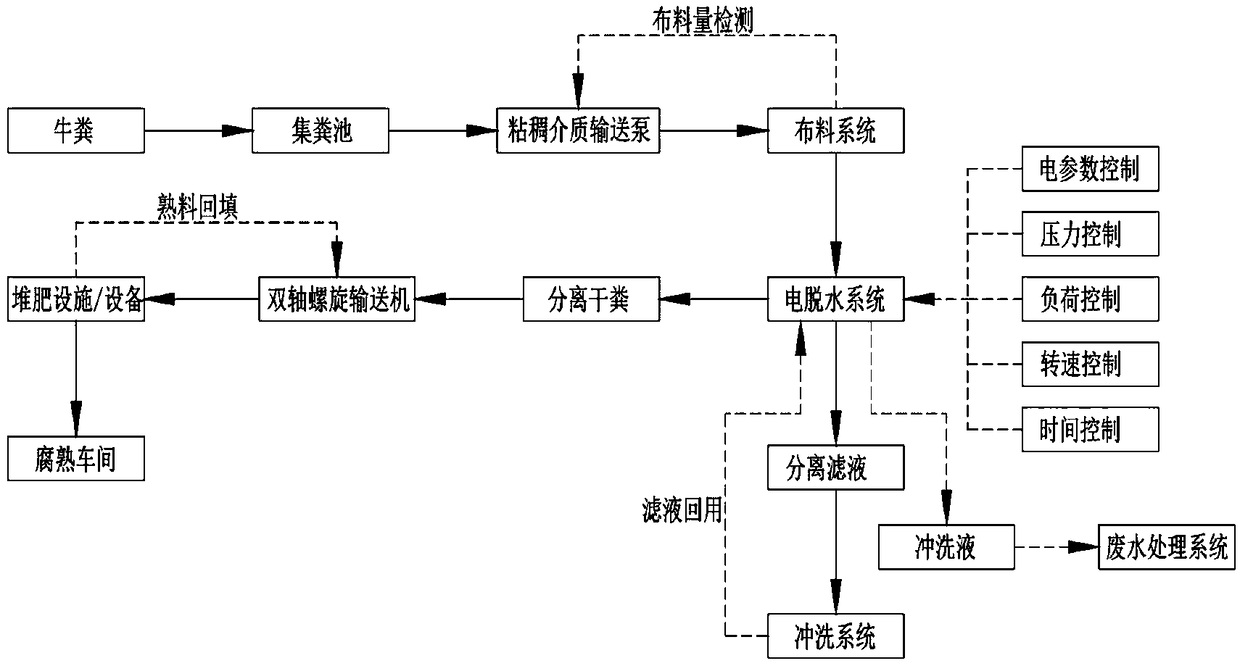

[0059] A method for preparing organic fertilizer by electric dehydration of dry and clear cow dung, as attached figure 1 shown, including the following steps:

[0060] (1) Scrape the cow dung to the manure collection tank on one side of the cowshed through the scraper machine, and the moisture content of the cow dung is about 80%.

[0061] (2) Control the rotation speed of the single screw pump at the bottom of the manure collection tank to 70 rpm, without setting the anti-bridging reamer, and transport the cow dung to the cloth mud bucket of the electric dehydration equipment.

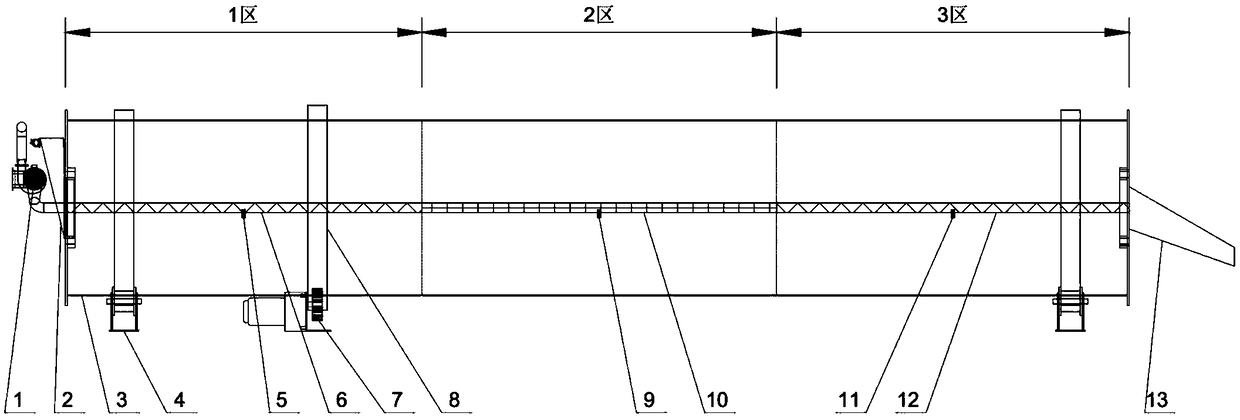

[0062] (3) A flat membrane pressure sensor is installed on the top of the mud hopper of the electric dehydration equipment. After detecting a sudden change in pressure, the single screw pump is stopped, and the filter belt rotation process of the electric dehydration equipment is started at the same time. The thickness of the fabric is limited to 1.5cm. Electrodehydration is performed after the cow ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com