Patents

Literature

557 results about "Dry cleaner" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

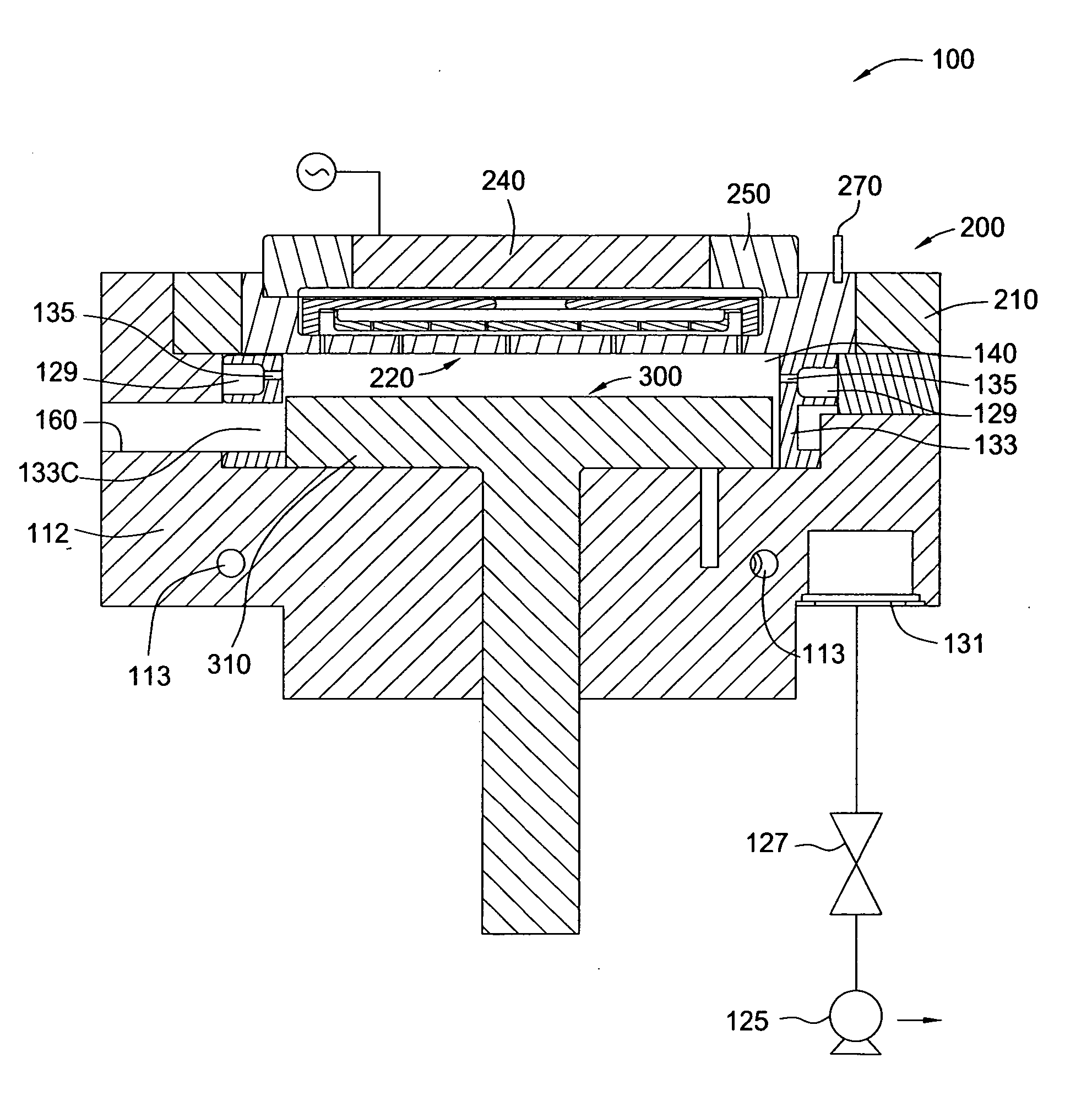

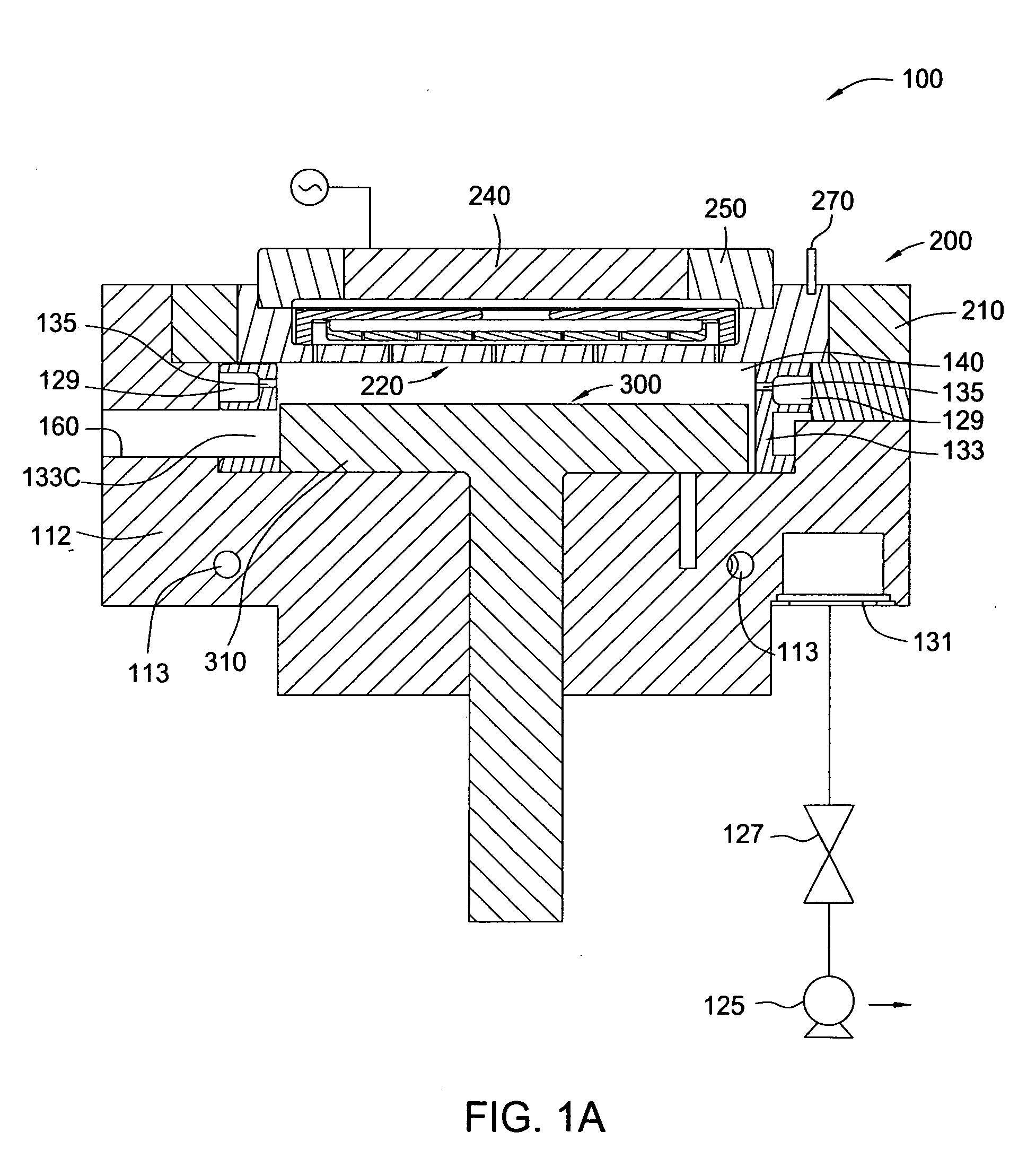

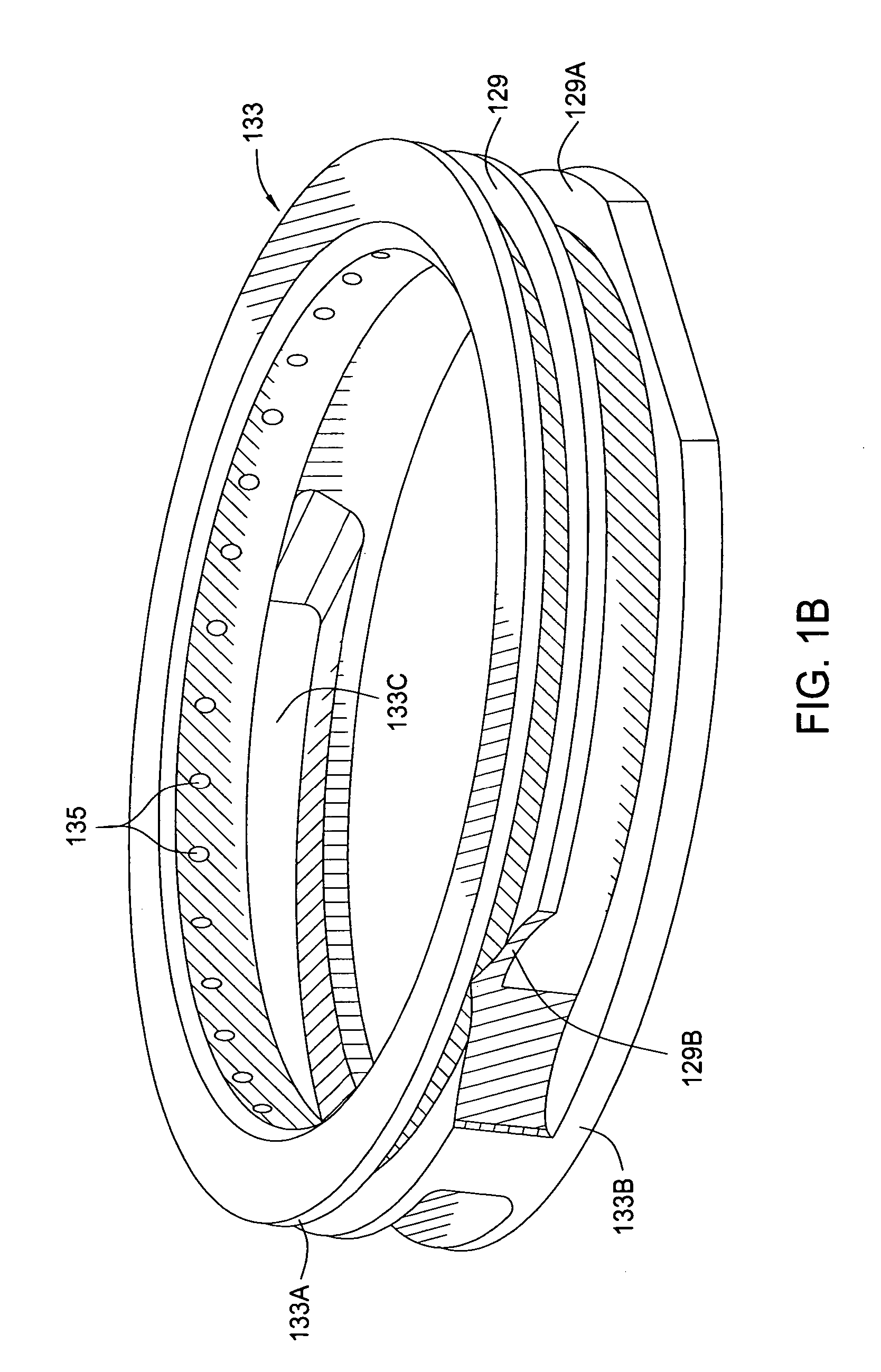

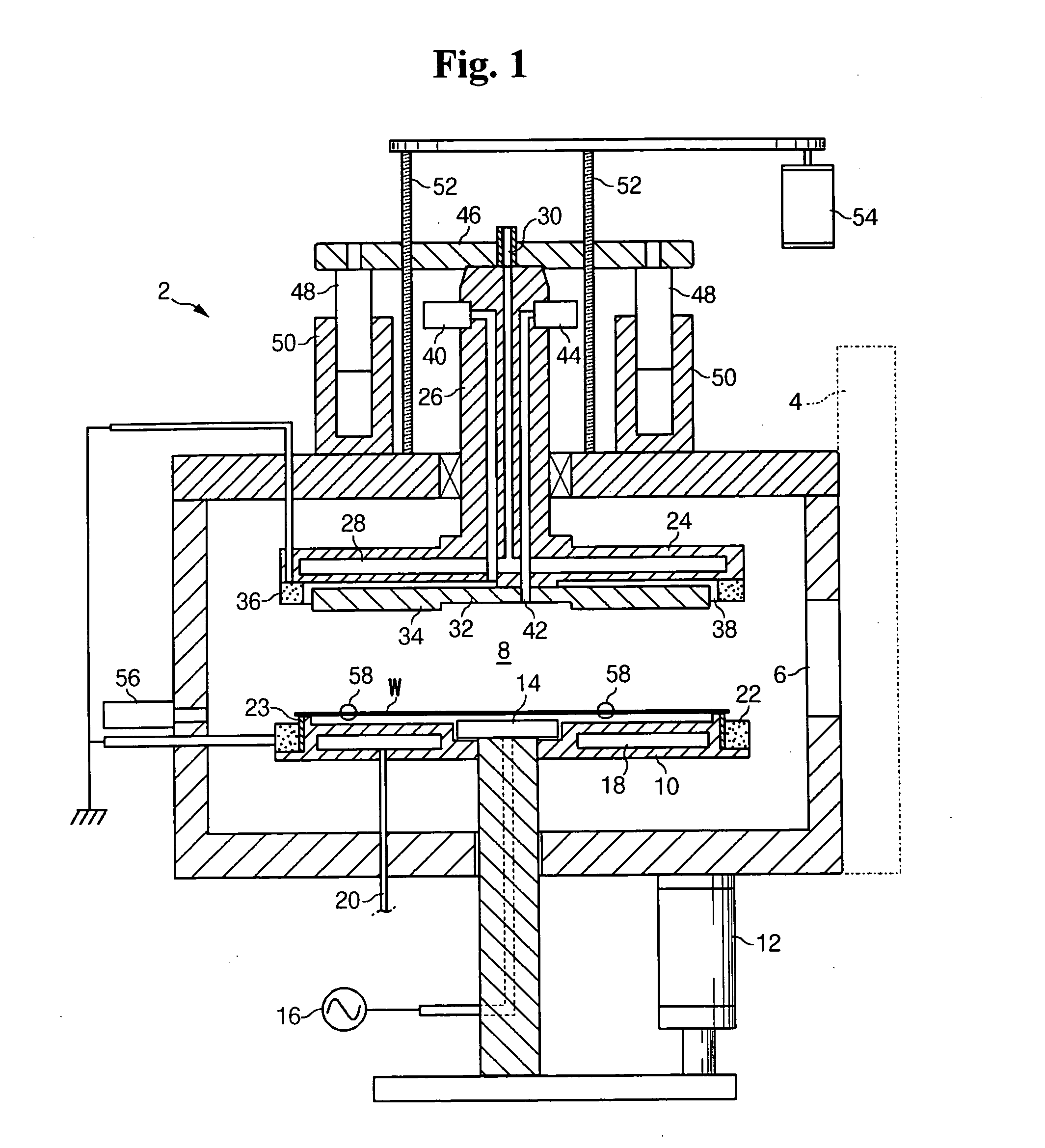

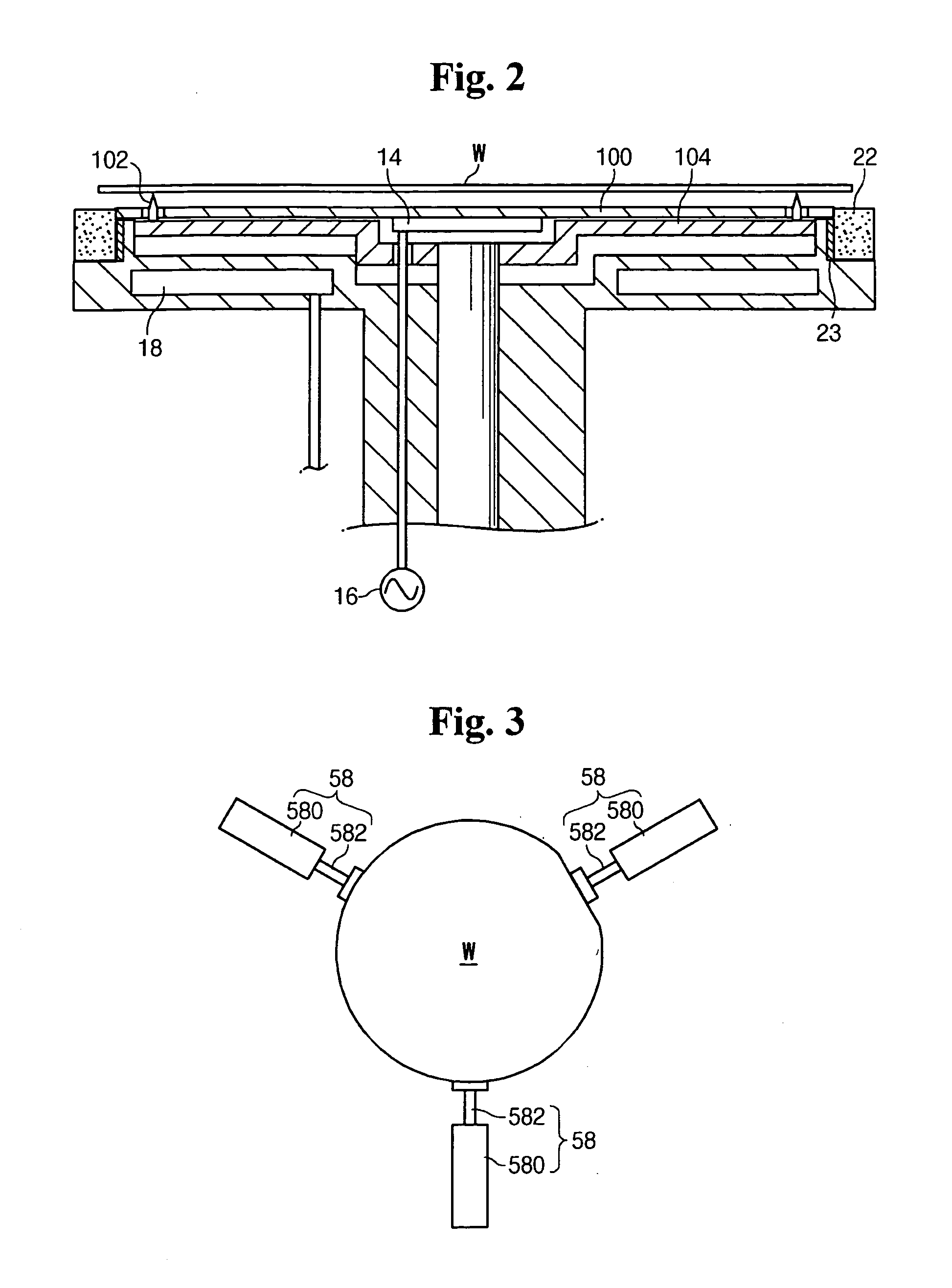

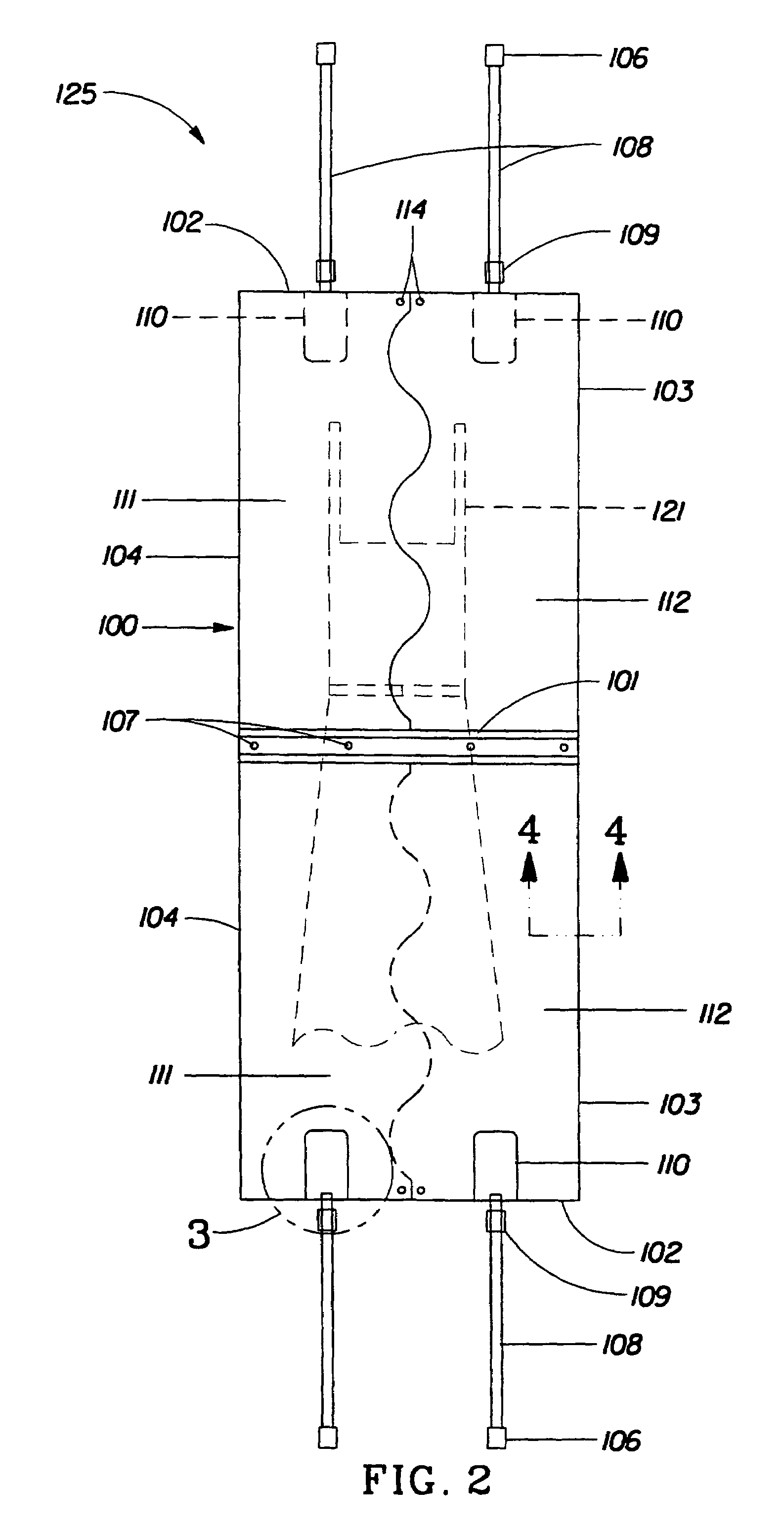

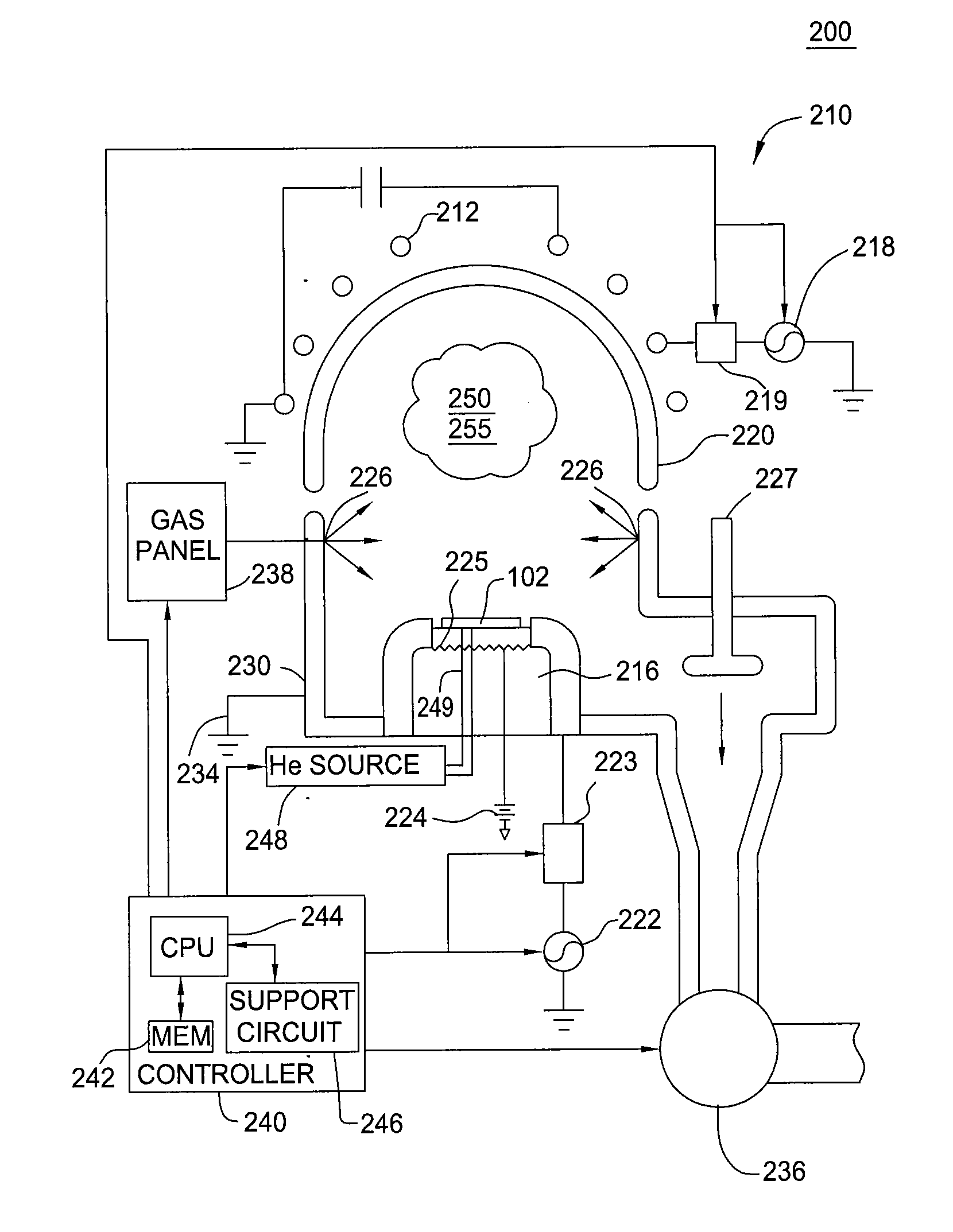

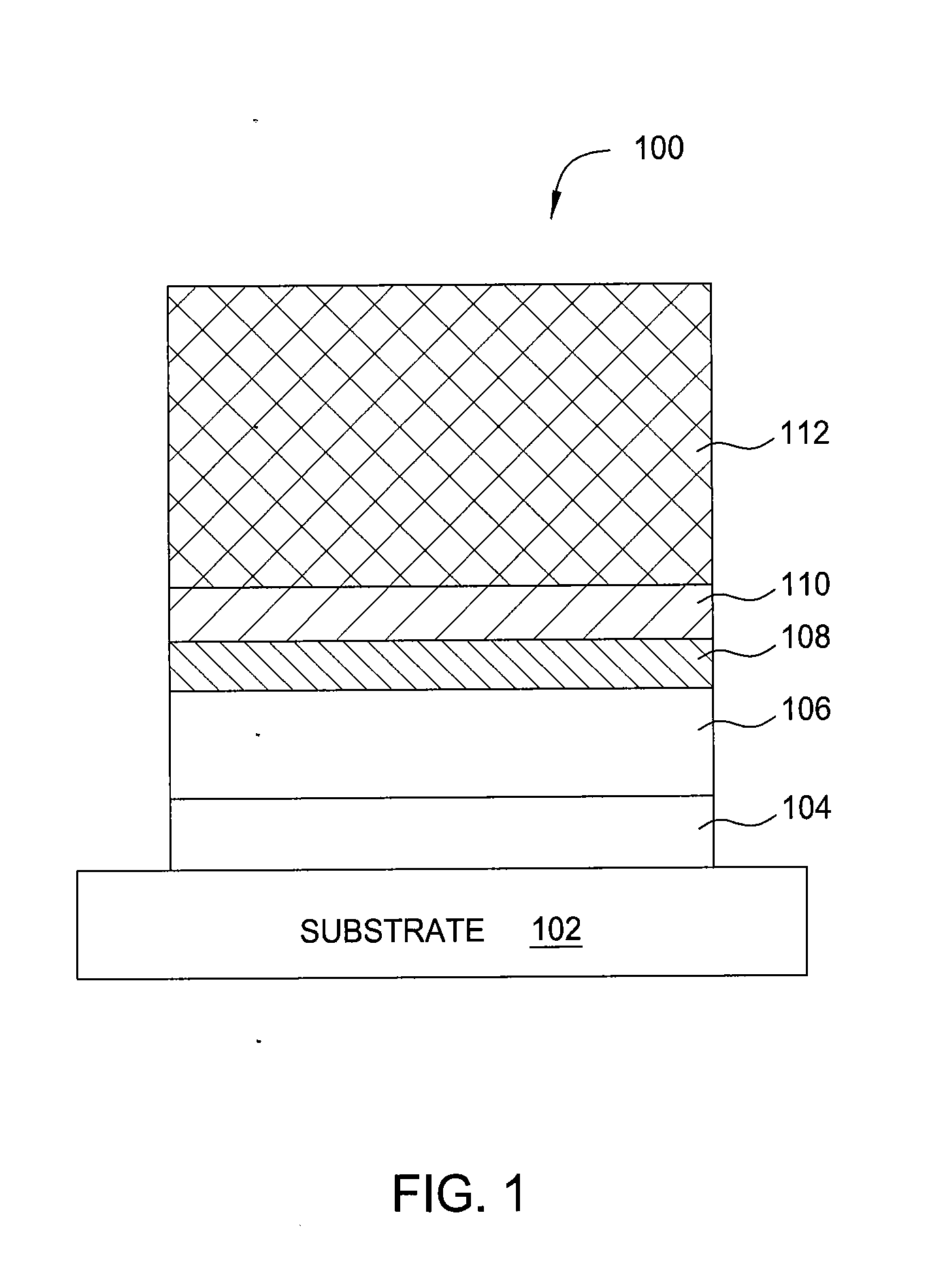

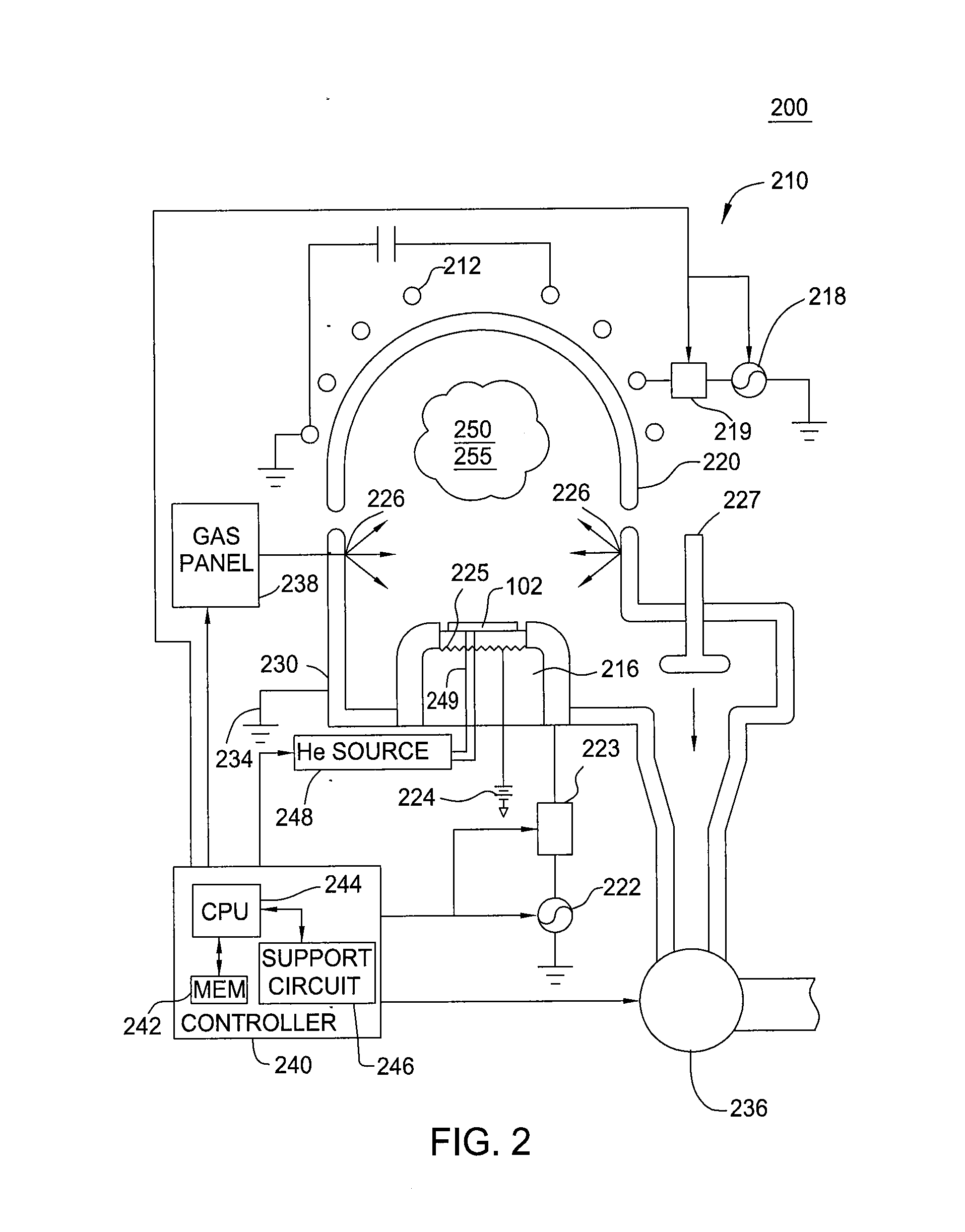

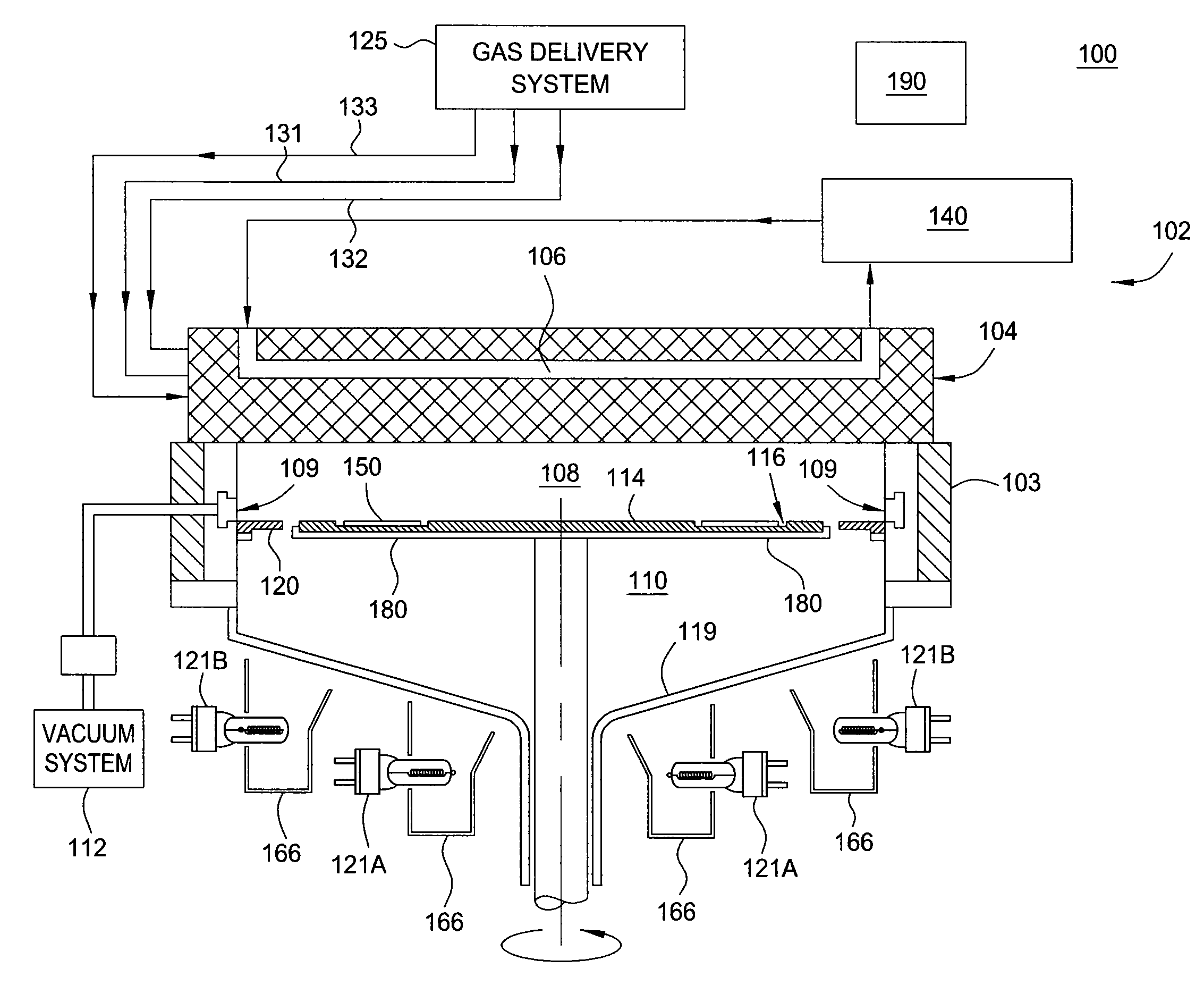

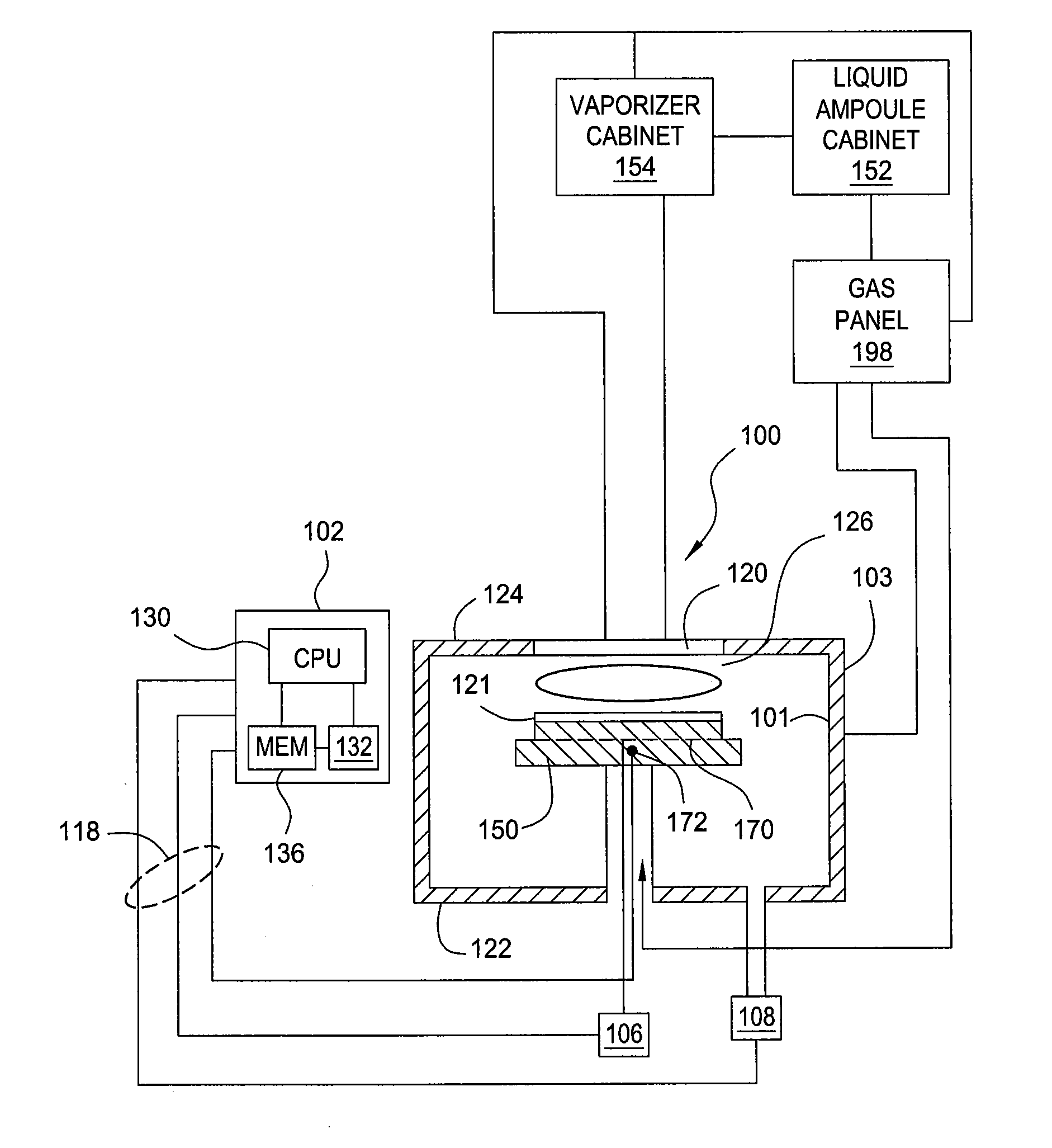

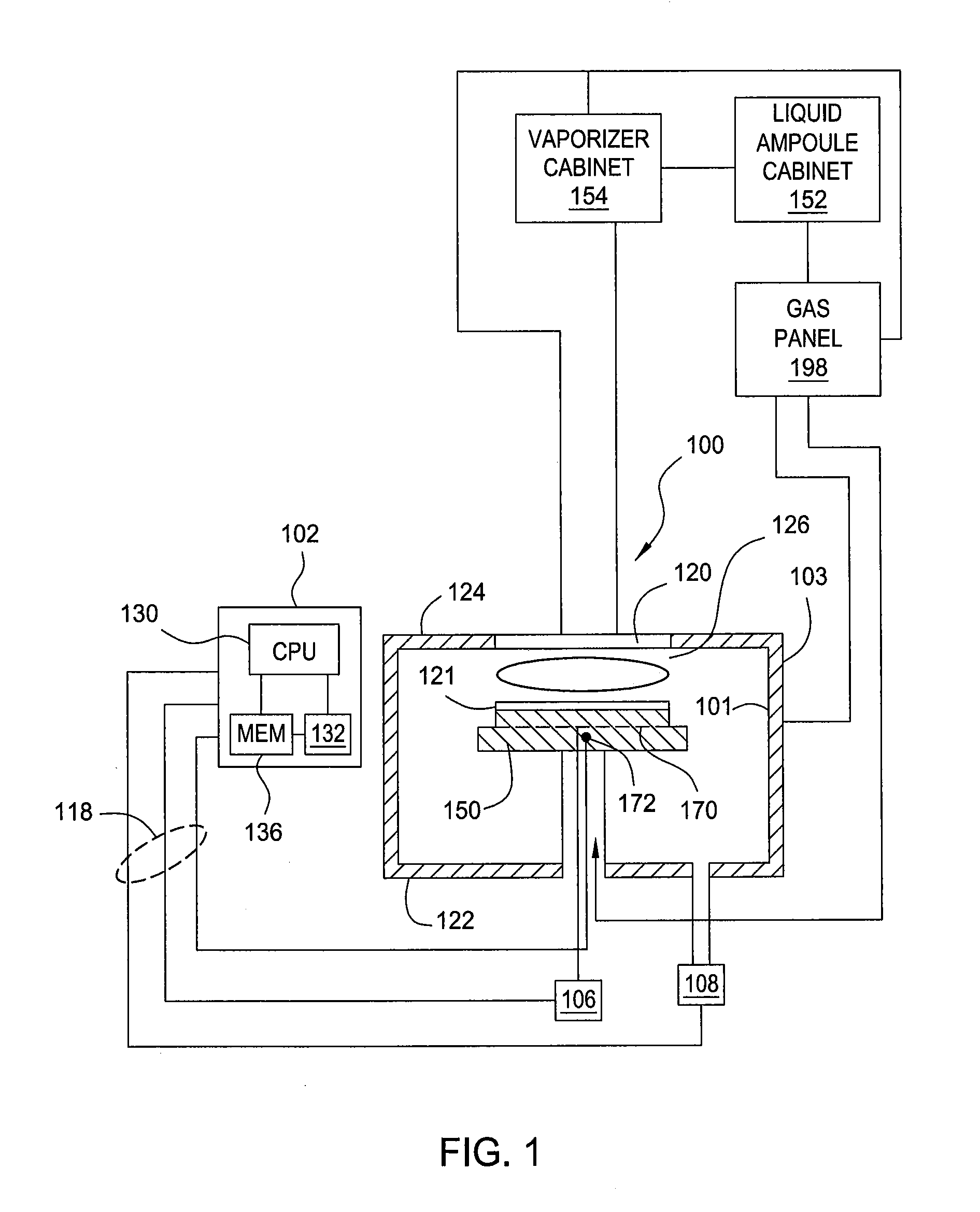

Substrate support for in-situ dry clean chamber for front end of line fabrication

InactiveUS20050221552A1Electric discharge tubesSemiconductor/solid-state device detailsFront end of lineBiomedical engineering

Owner:APPLIED MATERIALS INC

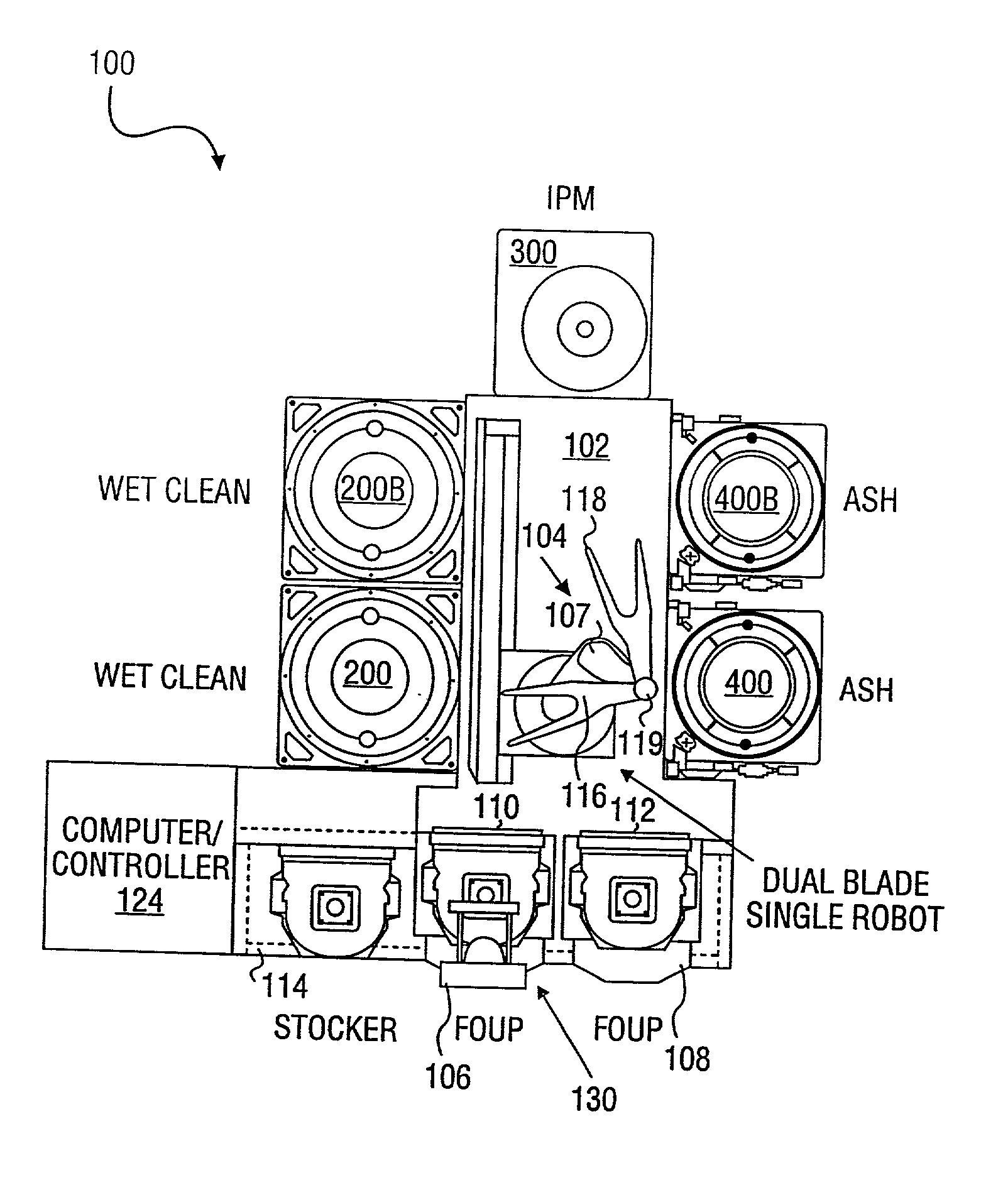

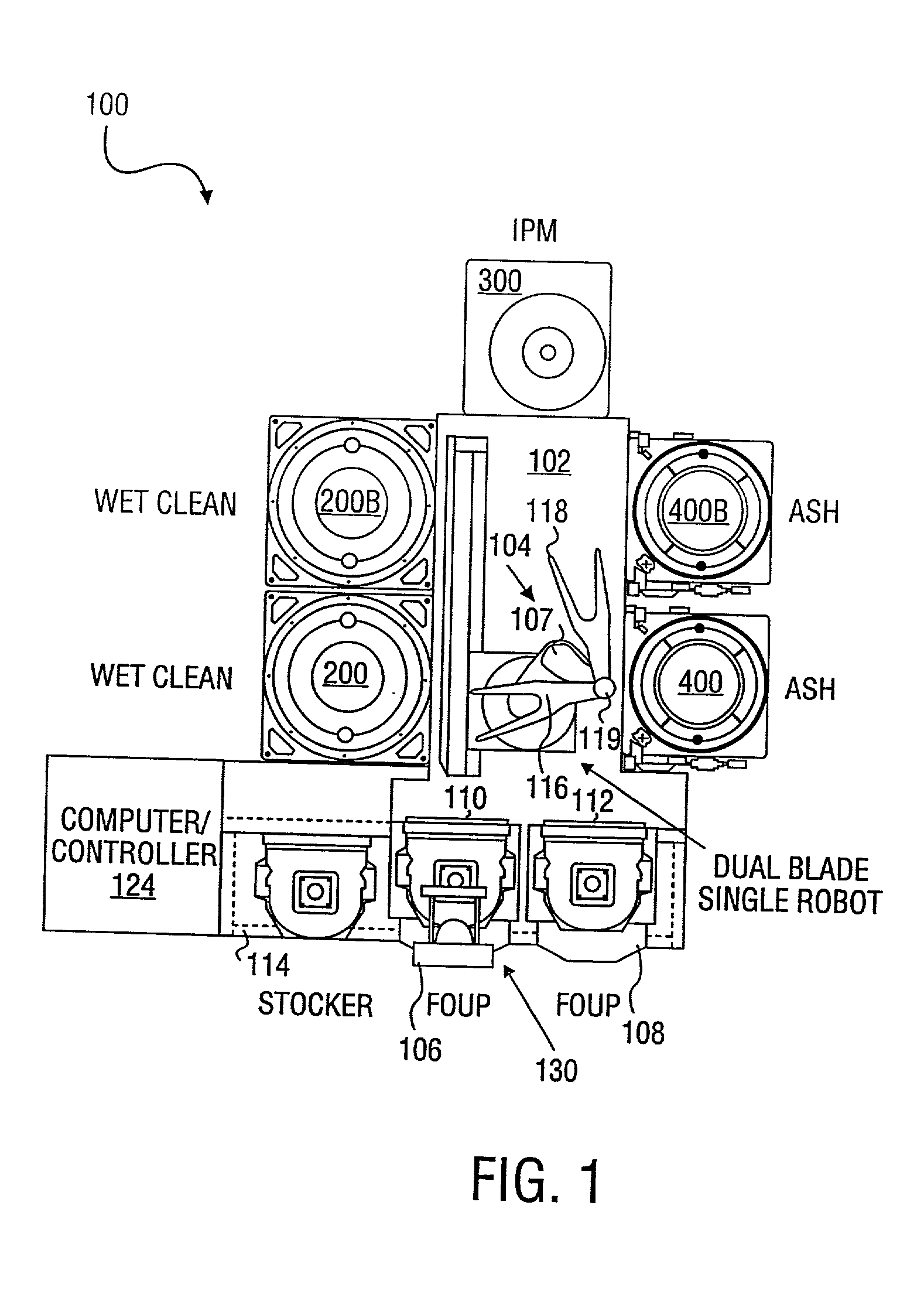

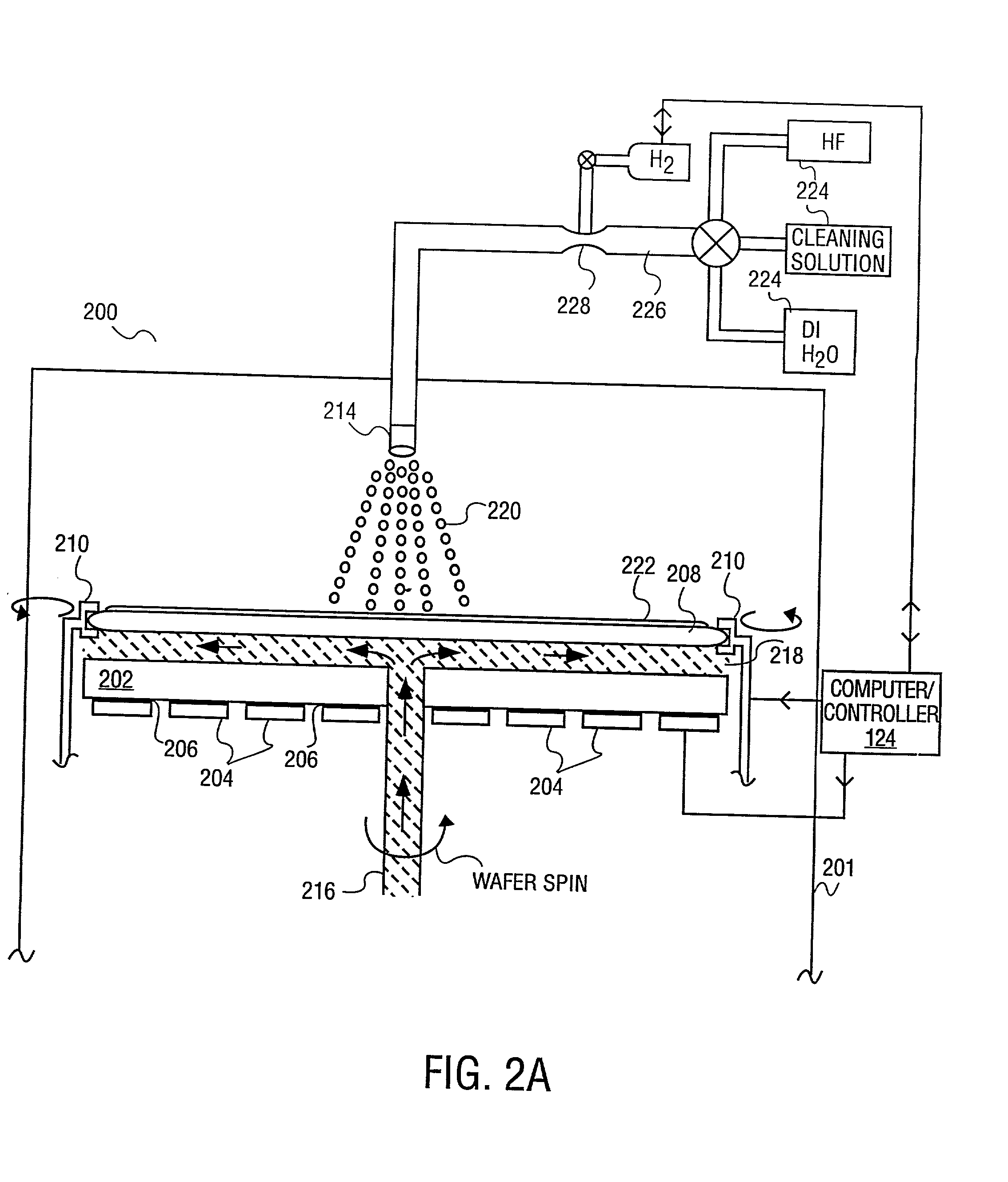

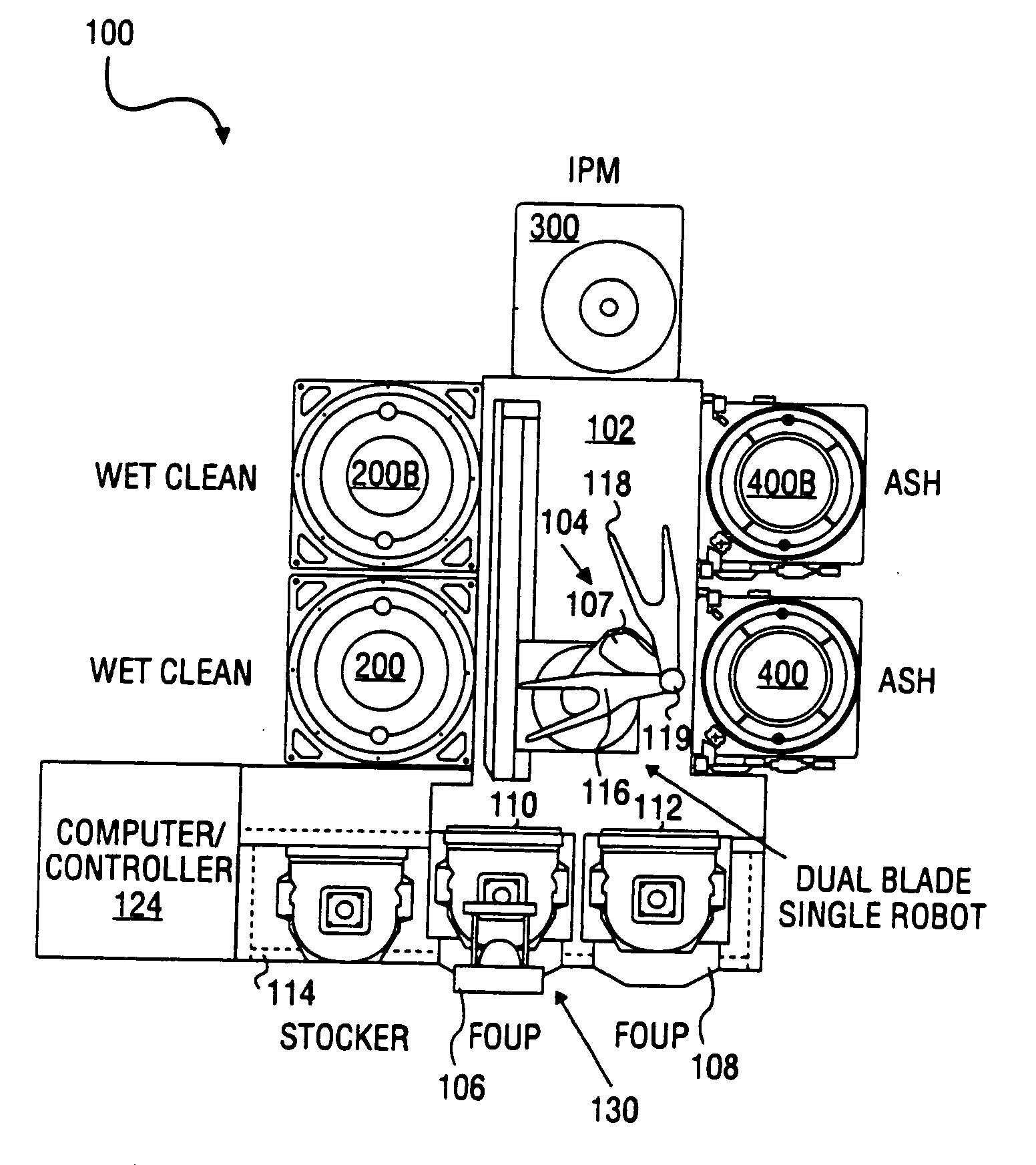

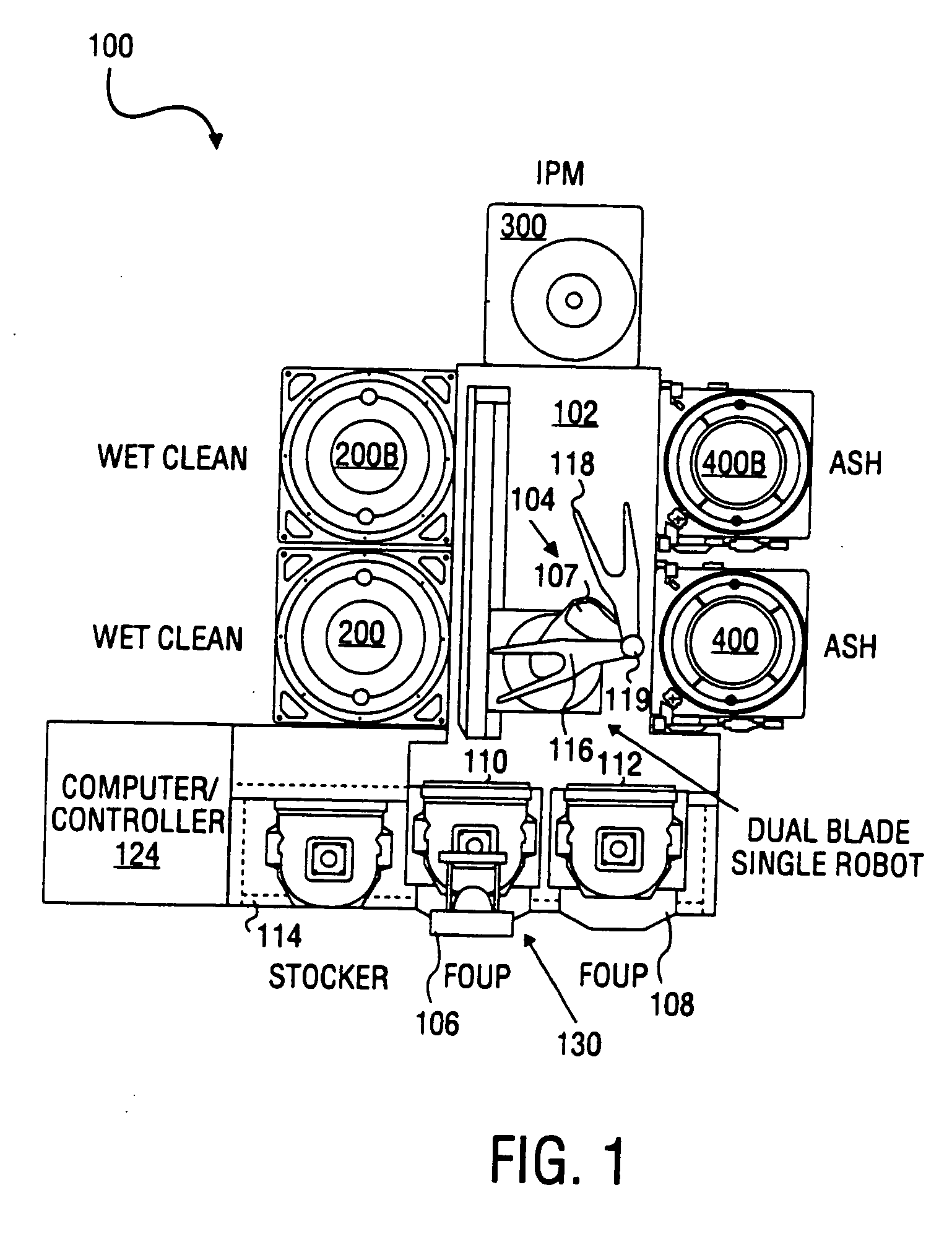

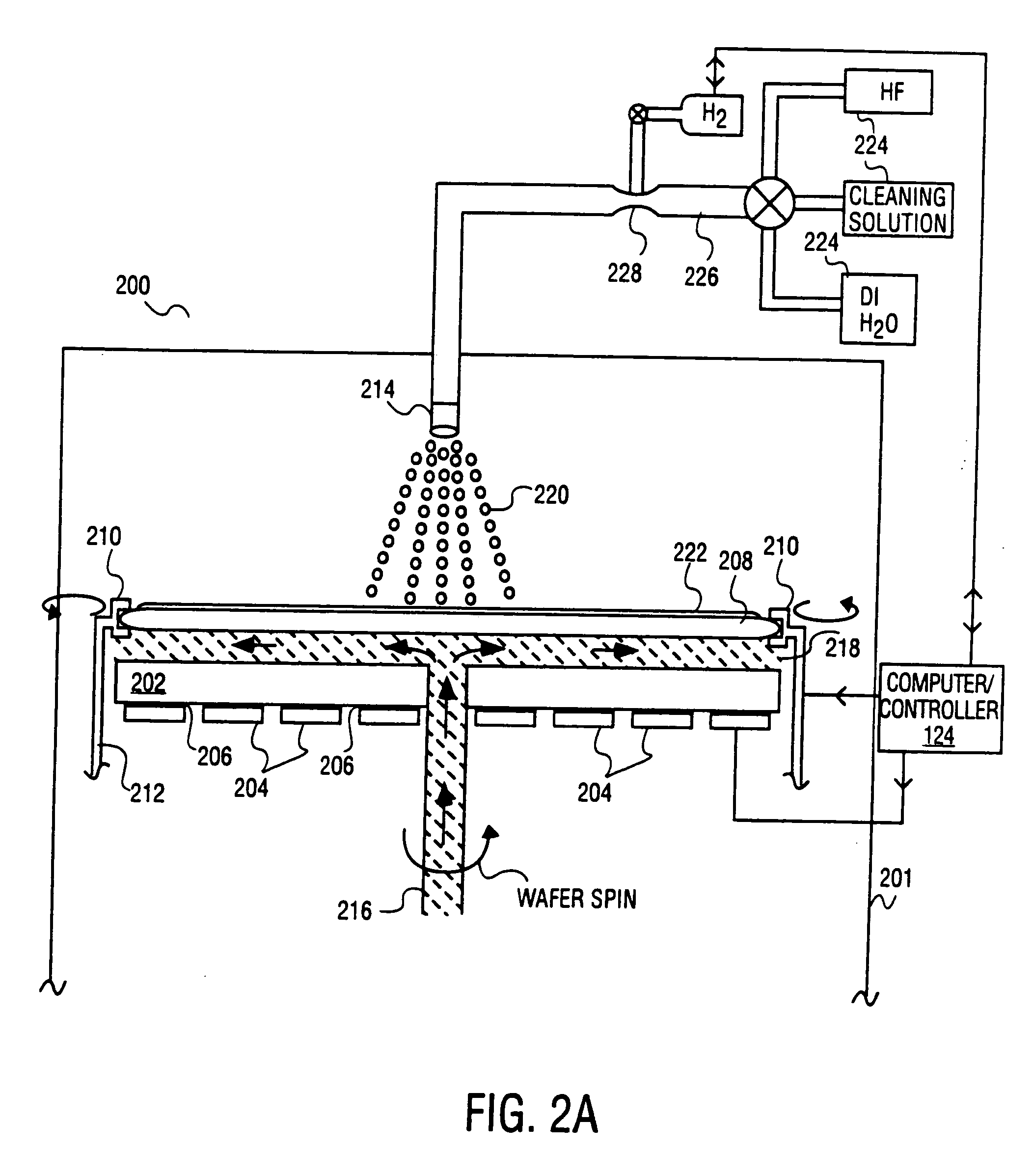

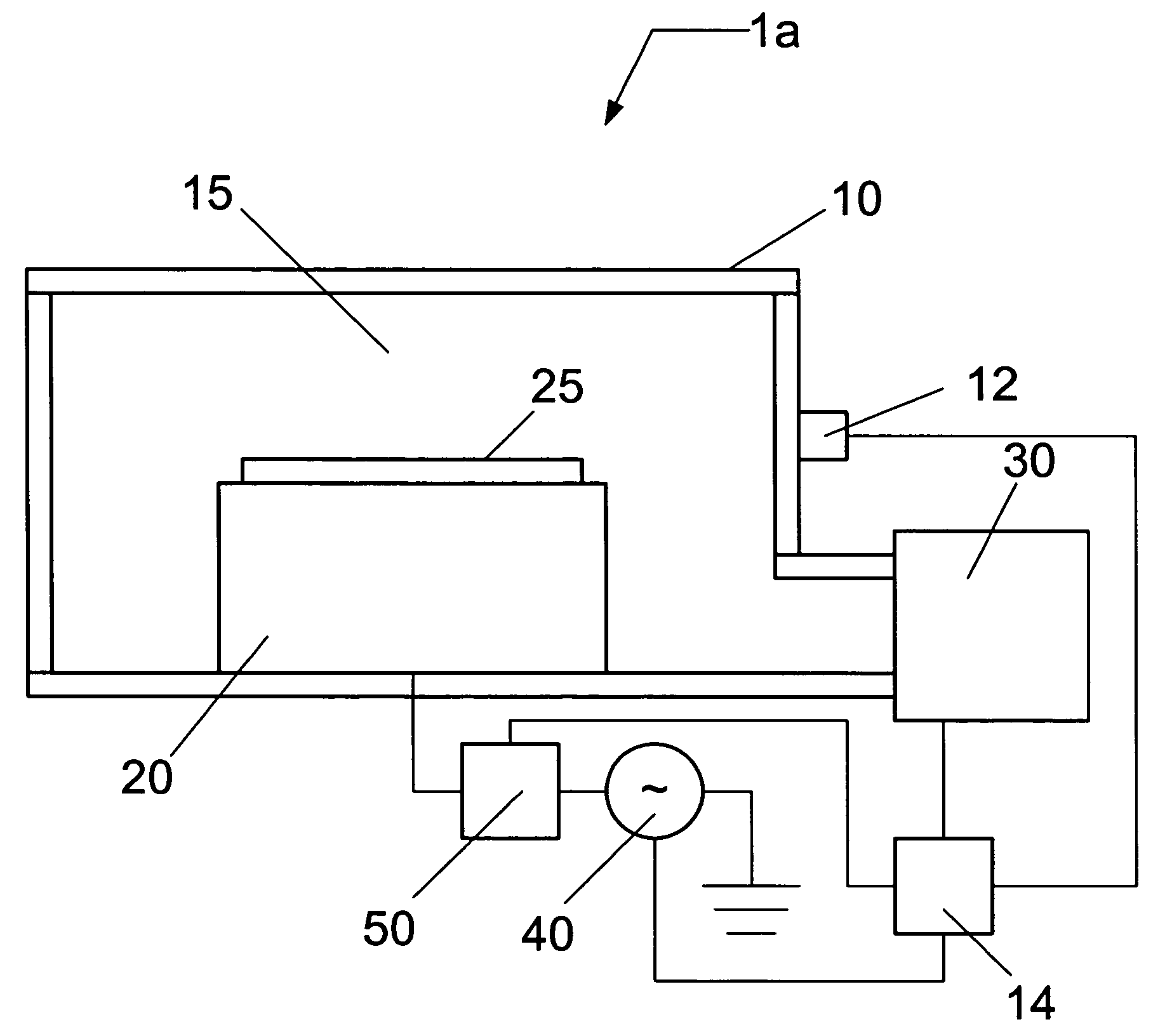

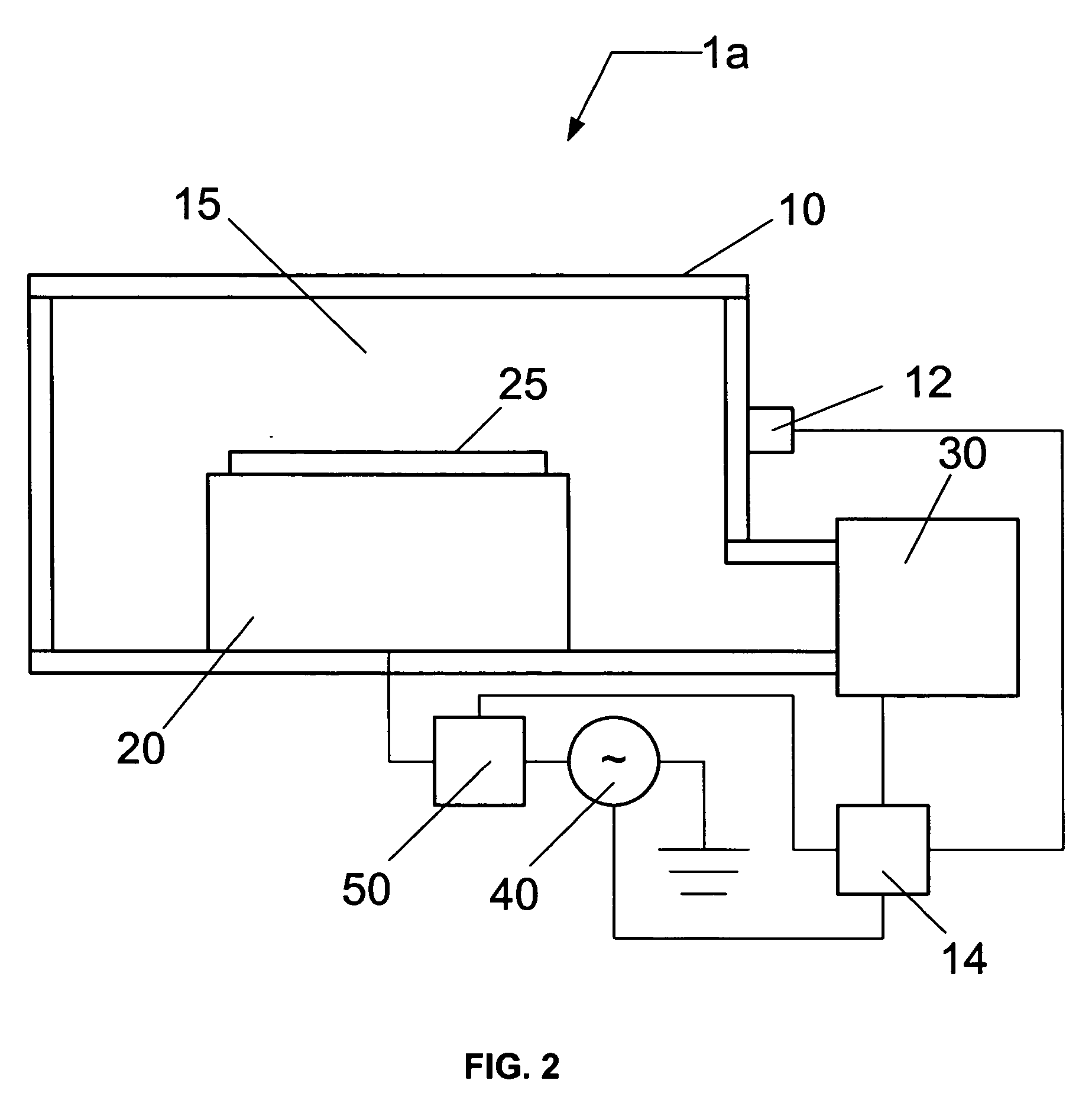

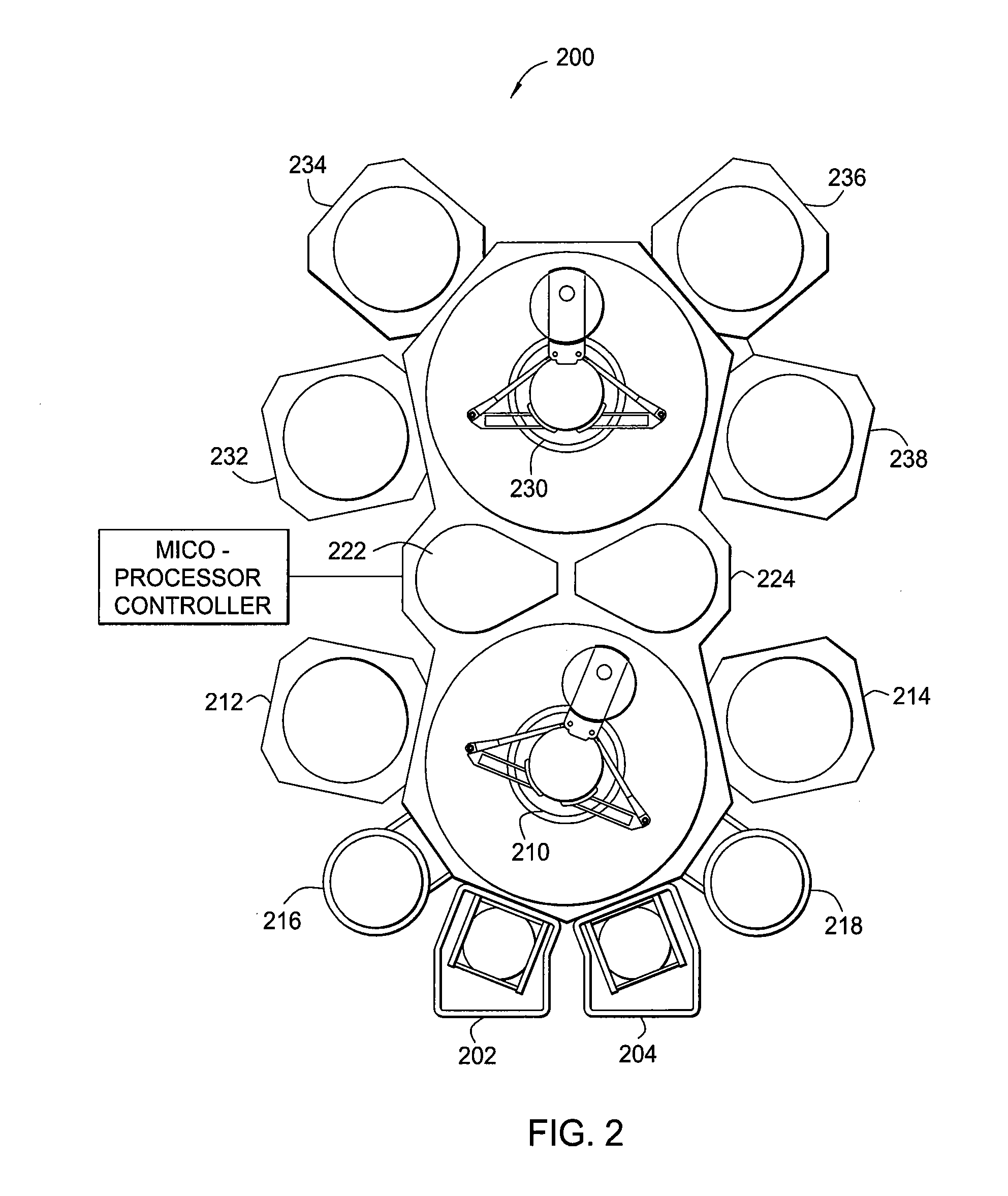

Method and apparatus for processing a wafer

InactiveUS20030045098A1Vacuum evaporation coatingPhotomechanical apparatusEngineeringMechanical engineering

A method of a single wafer wet / dry cleaning apparatus comprising: a transfer chamber having a wafer handler contained therein; a first single wafer wet cleaning chamber directly coupled to the transfer chamber; and a first single wafer ashing chamber directly coupled to the transfer chamber.

Owner:APPLIED MATERIALS INC

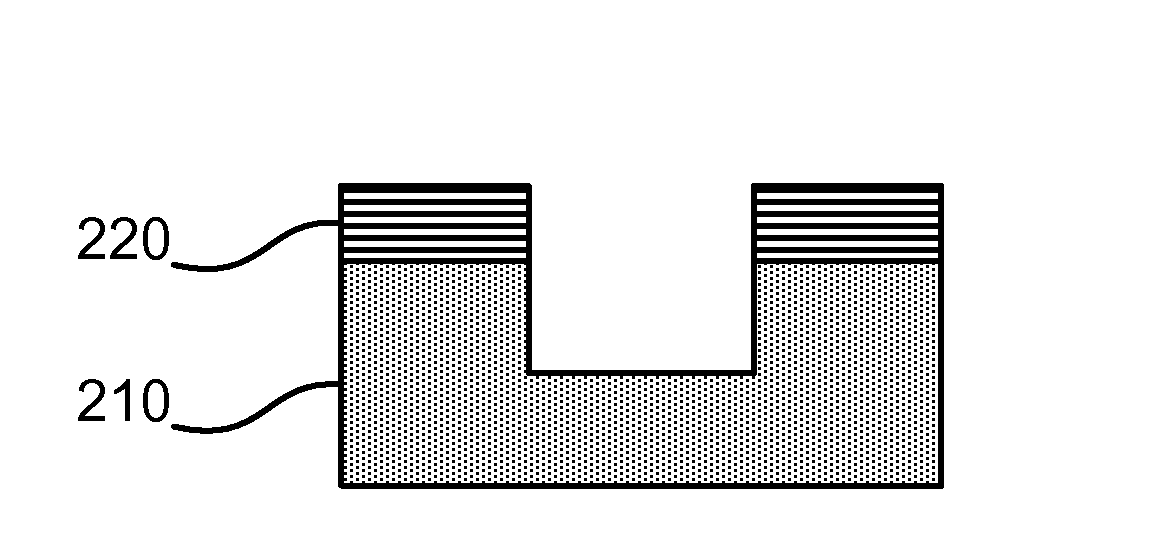

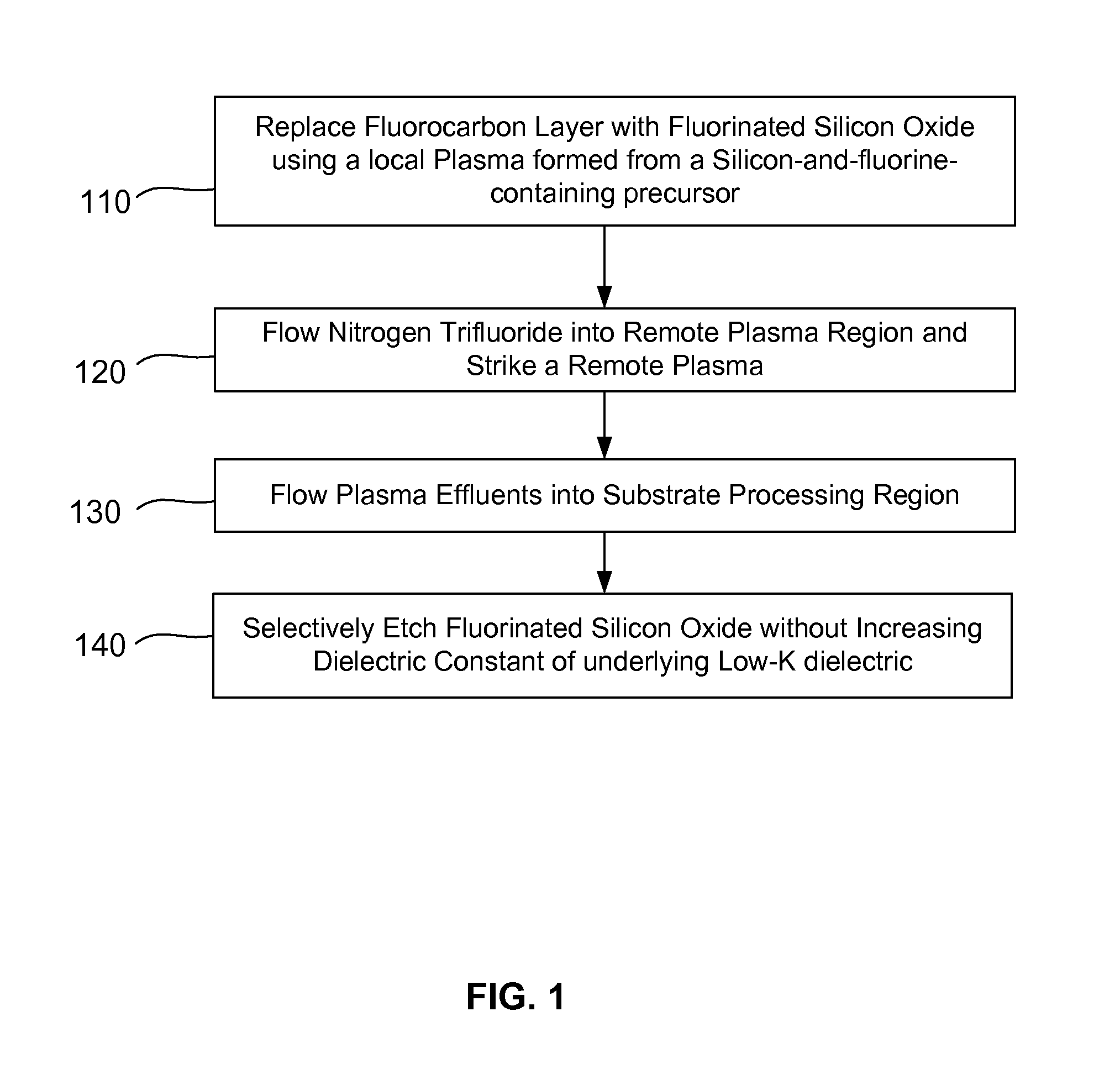

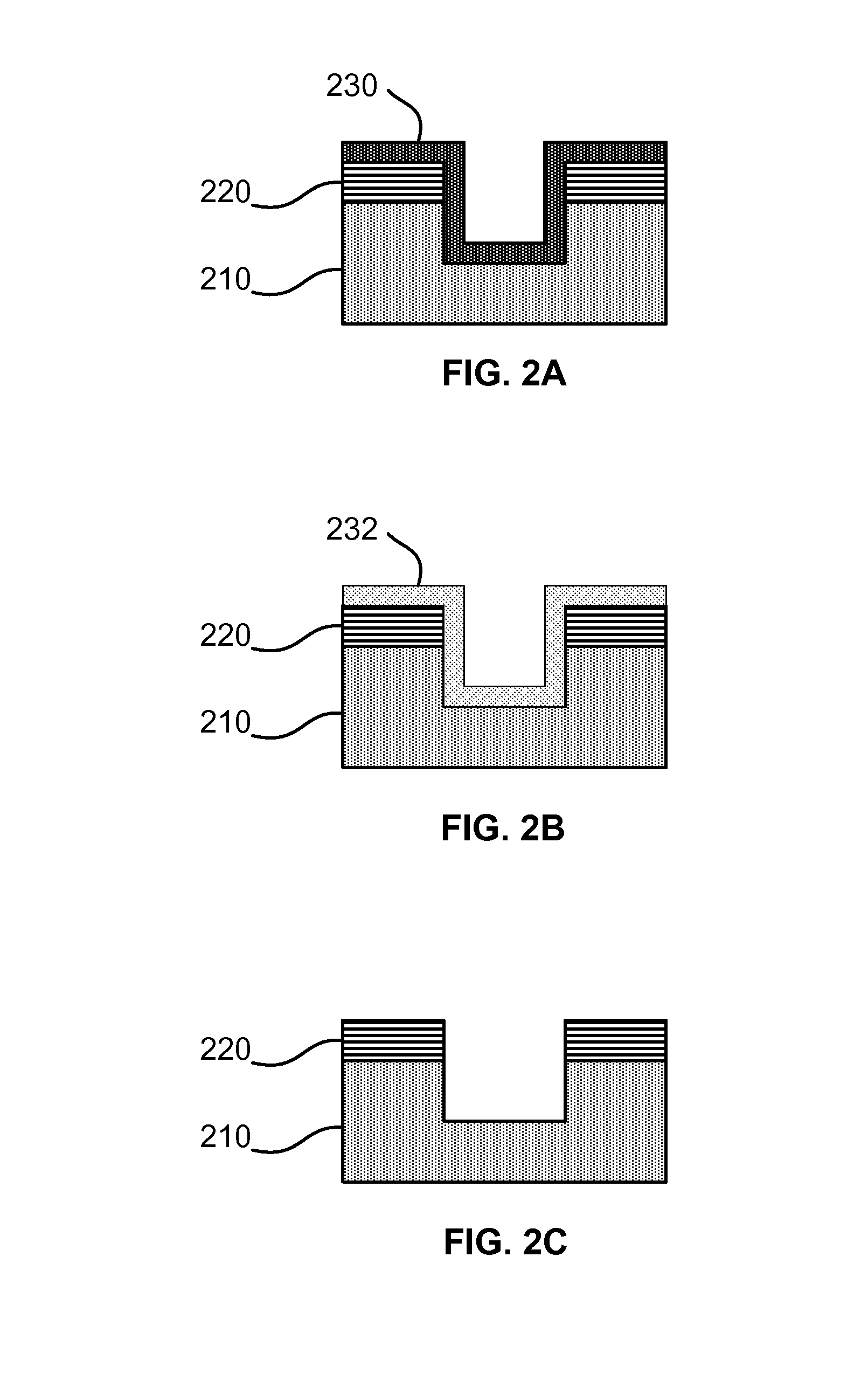

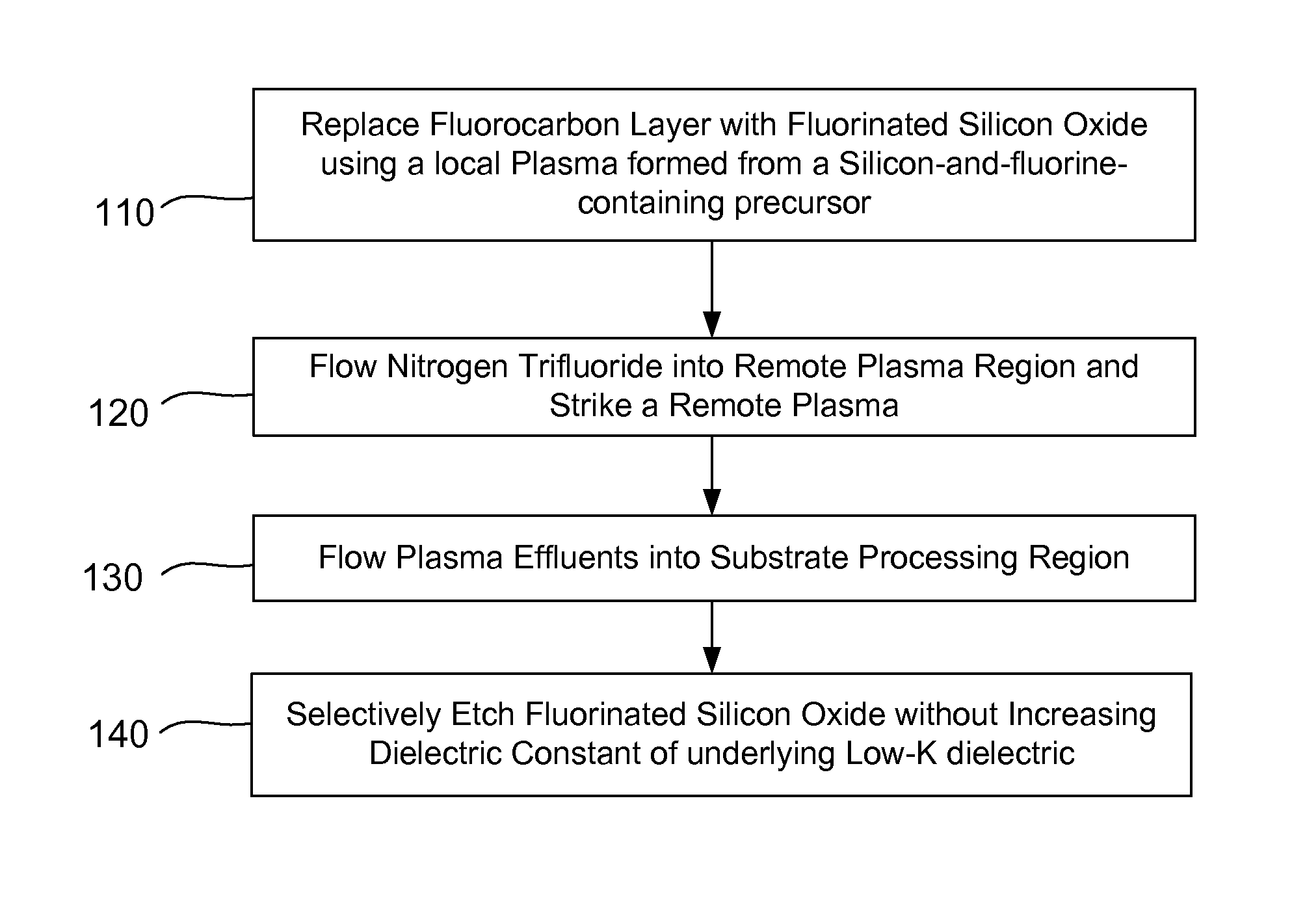

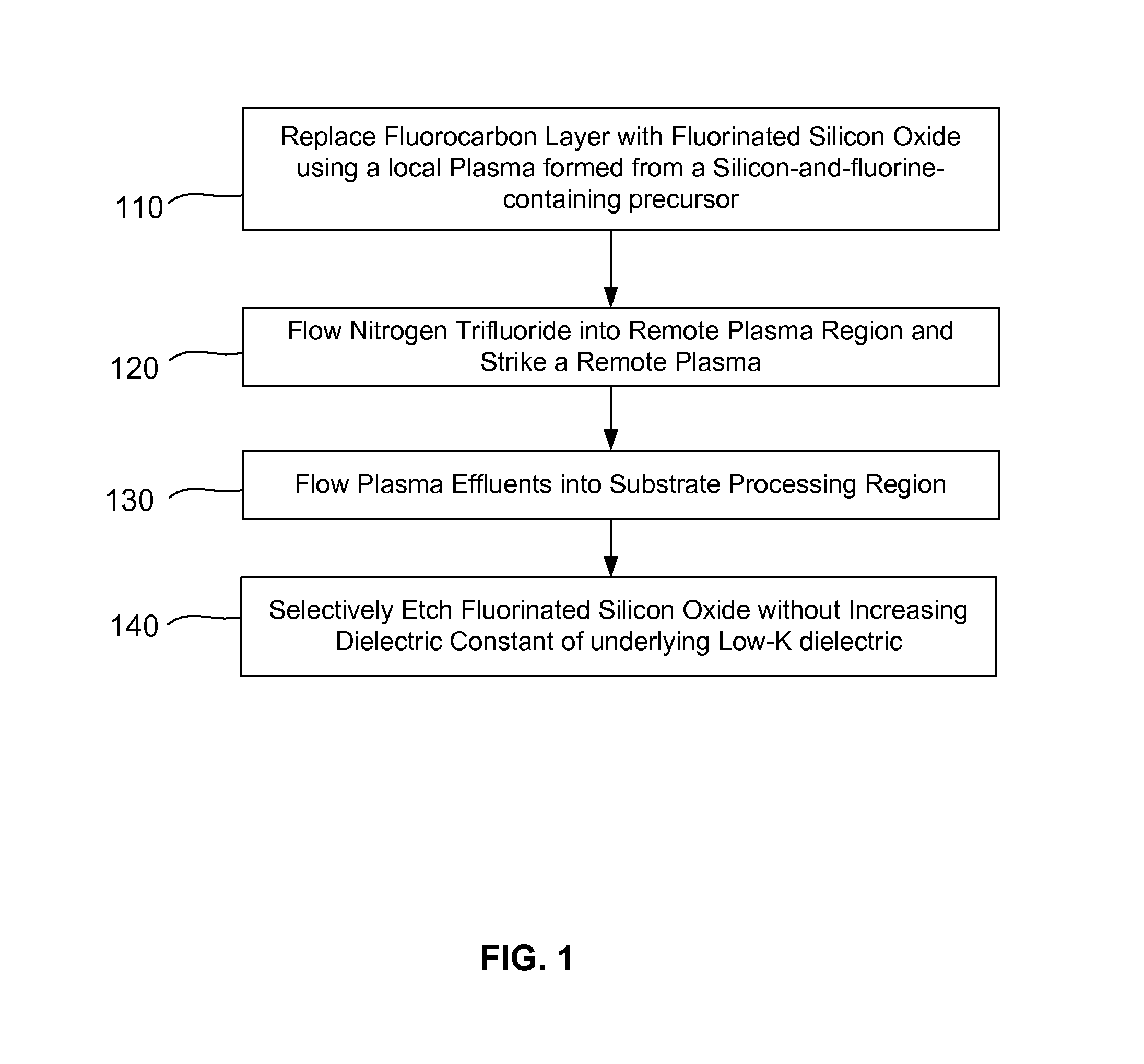

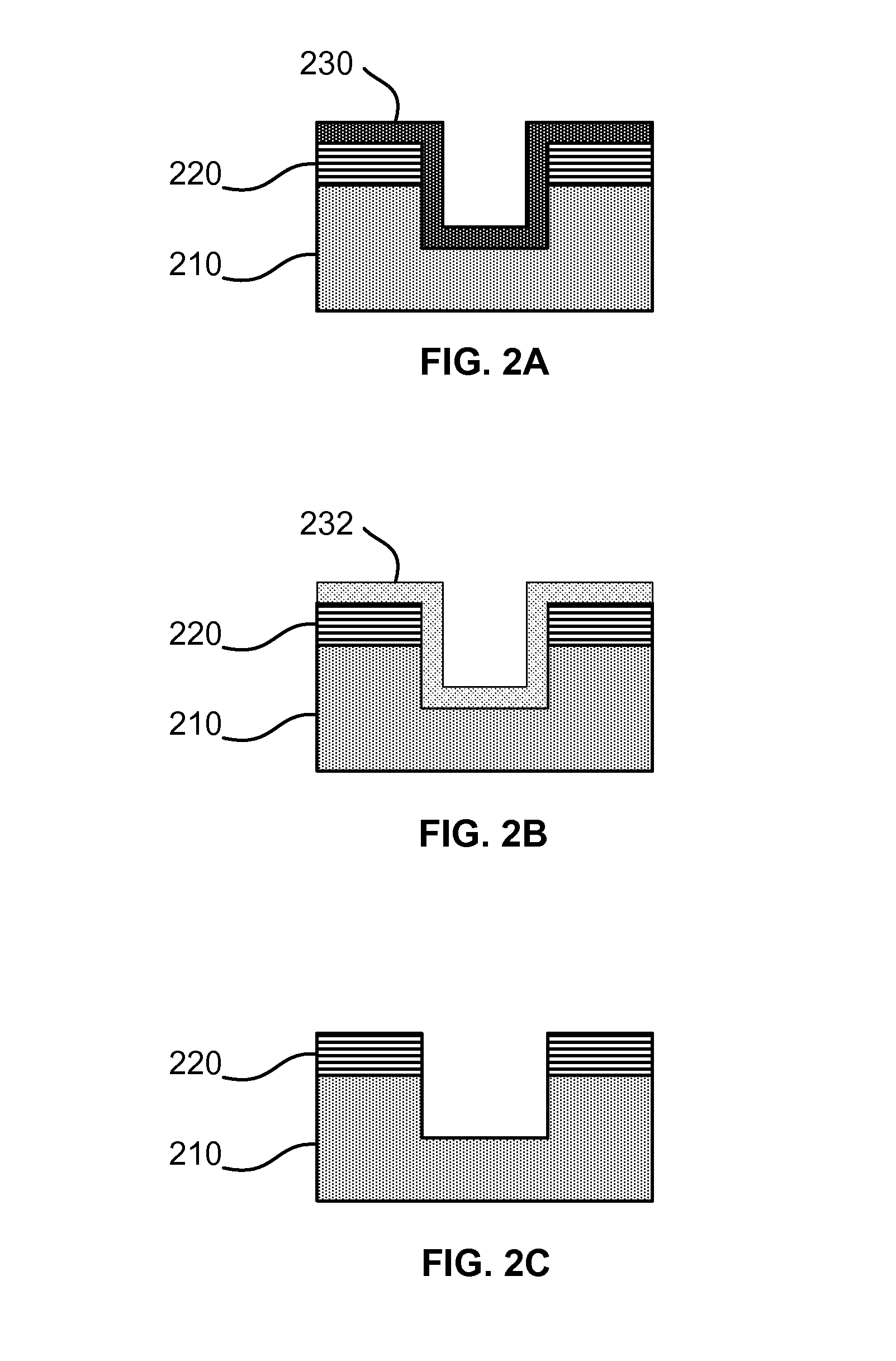

Delicate dry clean

ActiveUS20140342532A1High selectivityAvoid exposureSemiconductor/solid-state device manufacturingOxygenCompanion animal

A method of selectively removing fluorocarbon layers from overlying low-k dielectric material is described. These protective plasma treatments (PPT) are delicate alternatives to traditional post-etch treatments (PET). The method includes sequential exposure to (1) a local plasma formed from a silicon-fluorine precursor followed by (2) an exposure to plasma effluents formed in a remote plasma from a fluorine-containing precursor. The remote plasma etch (2) has been found to be highly selective of the residual material following the local plasma silicon-fluorine exposure. The sequential process (1)-(2) avoids exposing the low-k dielectric material to oxygen which would undesirably increase its dielectric constant.

Owner:APPLIED MATERIALS INC

Delicate dry clean

ActiveUS8895449B1High selectivityAvoid exposureDecorative surface effectsSemiconductor/solid-state device manufacturingOxygenCompanion animal

A method of selectively removing fluorocarbon layers from overlying low-k dielectric material is described. These protective plasma treatments (PPT) are delicate alternatives to traditional post-etch treatments (PET). The method includes sequential exposure to (1) a local plasma formed from a silicon-fluorine precursor followed by (2) an exposure to plasma effluents formed in a remote plasma from a fluorine-containing precursor. The remote plasma etch (2) has been found to be highly selective of the residual material following the local plasma silicon-fluorine exposure. The sequential process (1)-(2) avoids exposing the low-k dielectric material to oxygen which would undesirably increase its dielectric constant.

Owner:APPLIED MATERIALS INC

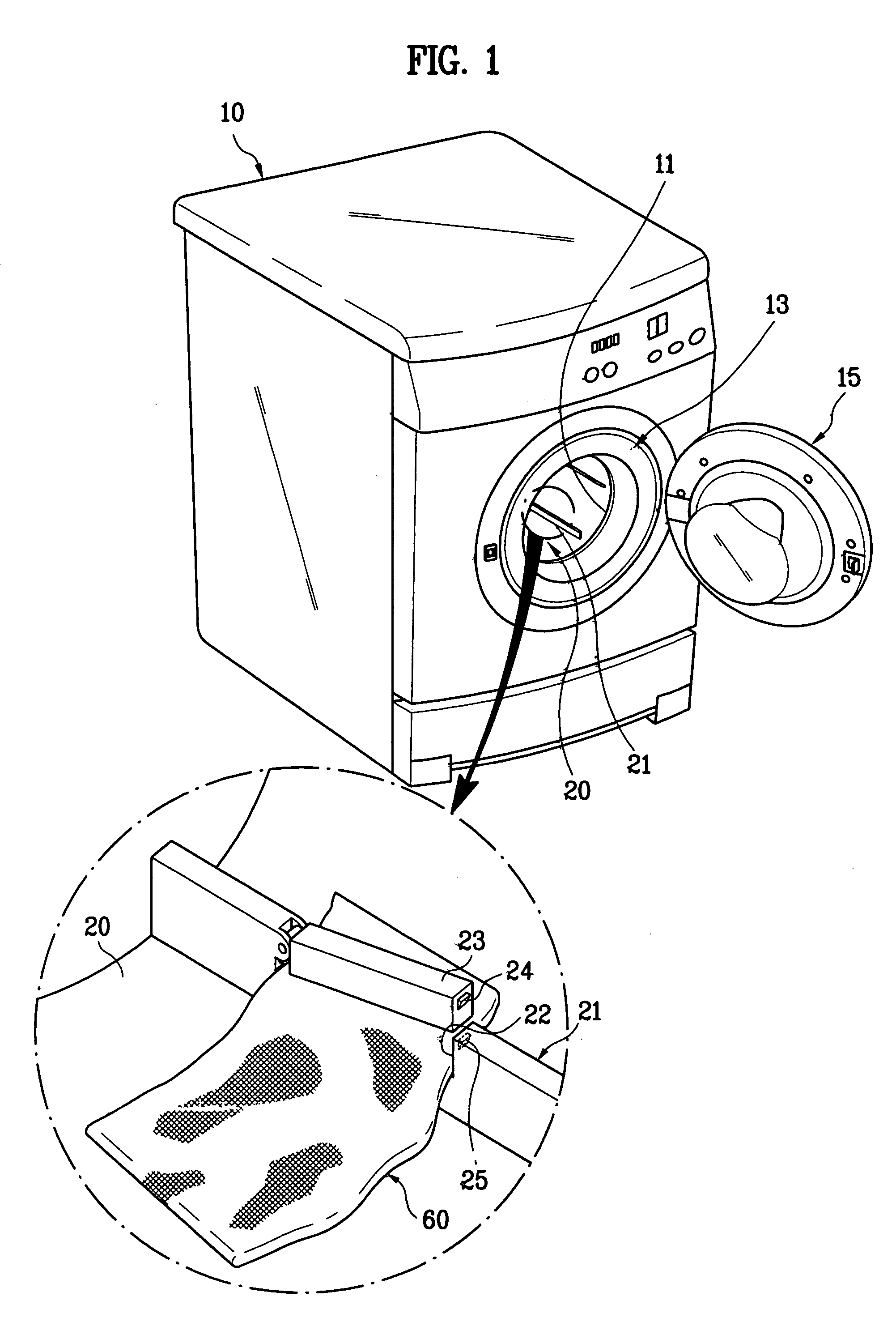

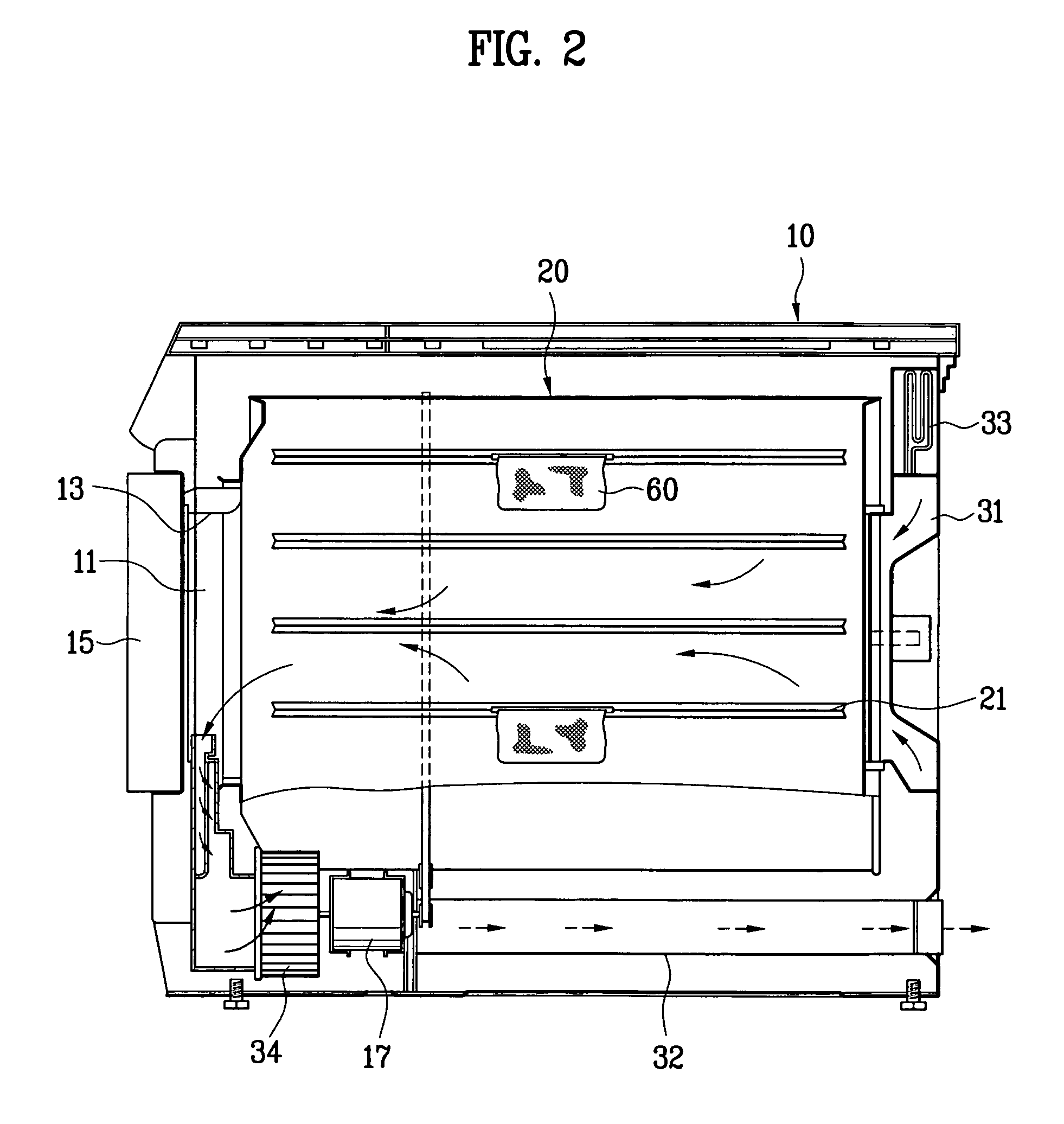

Washing apparatus and control method thereof

ActiveUS20050092035A1Reduce power consumptionReduce water consumptionWringing machinesDry-cleaning apparatusEngineeringMechanical engineering

The present invention provides a washing apparatus and control method thereof, by which laundry can be dry-cleaned through the loaded configurations of the wet pad cloth, the filth transfer cloth, the steam providing unit, the fragrance spraying unit, and the detergent supplying unit using either the wet pad cloth or the filth transfer cloth or without using both of the wet pad cloth and the filth transfer cloth.

Owner:LG ELECTRONICS INC

Plasma etching chamber and plasma etching system using same

ActiveUS20050173067A1Limited spaceImprove throughputElectric discharge tubesSemiconductor/solid-state device manufacturingRadio frequencyFilm material

Disclosed is a plasma etching chamber for completely dry-cleaning a film material and particles deposited at the periphery of a wafer through plasma etching while generating plasma at the top to the bottom sides of the periphery of the wafer. A pair of top and bottom anodes facing each other is placed around the periphery of the wafer under the application of radio frequency through a cathode. Alternatively, a top cathode and a bottom anode are placed around the periphery of the wafer while facing each other and a view-ring shields the area of the cathode, the anode and the wafer from the outside. A plasma etching system includes a plurality of the above-structured etching chambers. A handler takes wafers from a plurality of cassette stands or load ports, and posture-corrects the orientation frat locations of the wafers by a wafer alignment unit. The wafers are charged into the plasma etching chambers directly or via load lock chambers. The handler takes the etched wafers from the chambers, and returns the wafers to the cassettes or the load ports directly or via the load lock chambers.

Owner:SOSUL

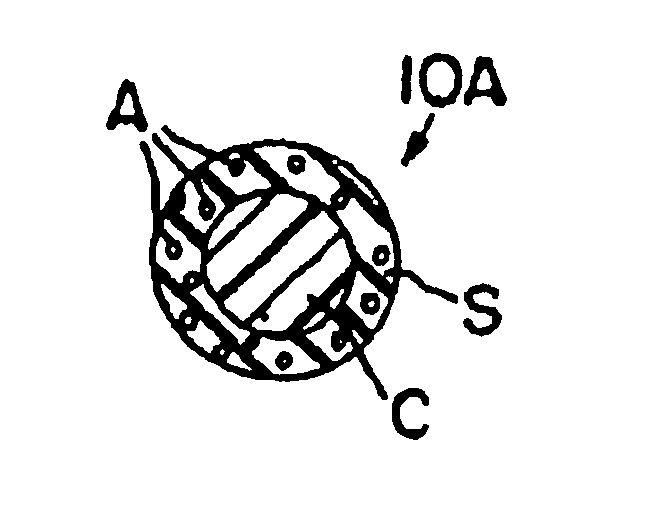

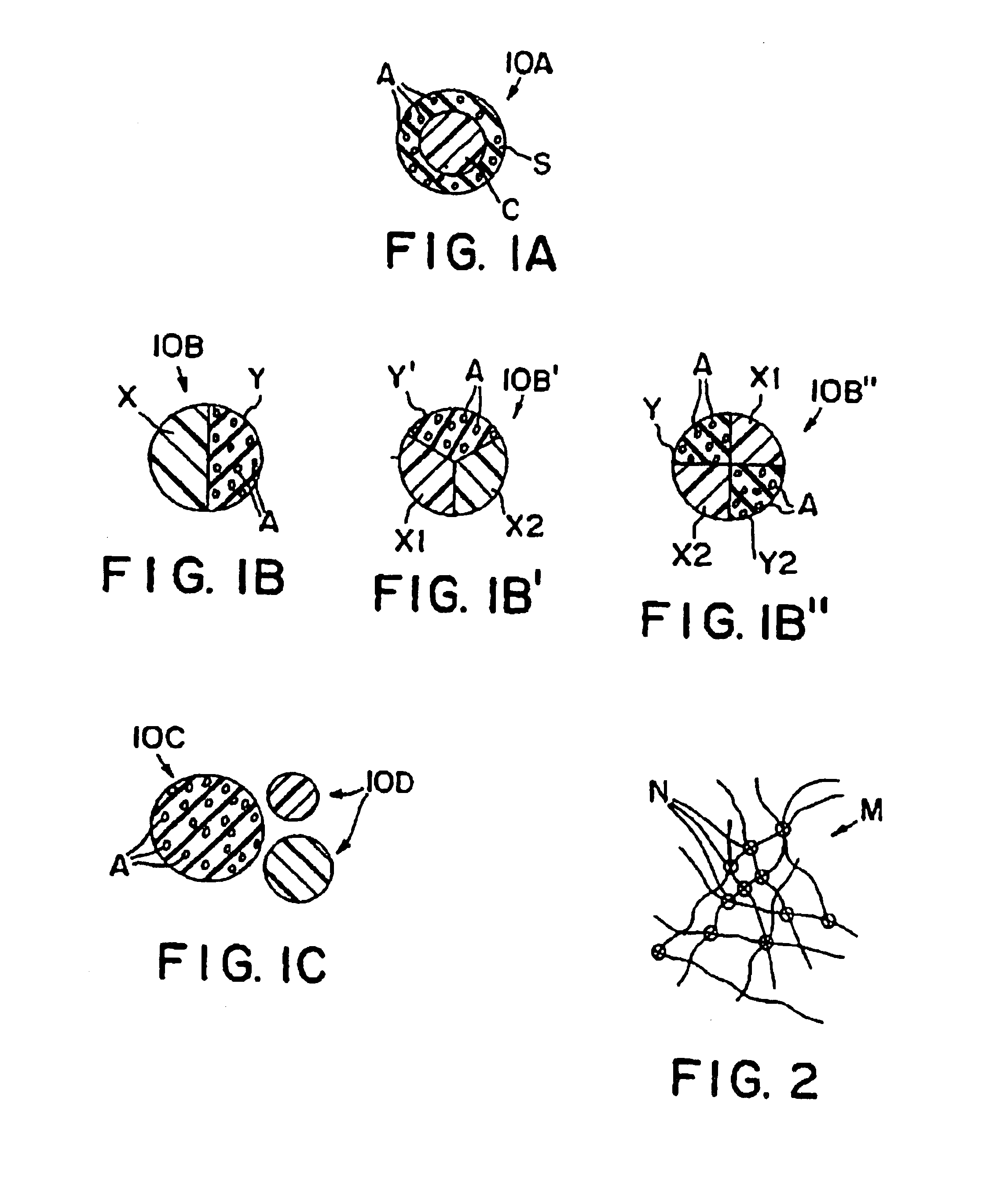

Anti-microbial fiber and fibrous products

InactiveUS6841244B2Resistant to washing off and wearing offLow costGarment special featuresDispersed particle filtrationPolyesterMicroorganism

An anti-microbial and / or anti-fungal synthetic fiber that comprises various thermoplastic polymers and additives in a bi-component form in either a core-sheath or side-by-side configurations. The anti-microbial synthetic fibers comprise inorganic anti-microbial additives, distributed in certain areas to reduce the amount of the anti-microbial agents being used, and therefore the cost of such fibers. The fibers can incorporate anti-microbial additives so that they are not removed by repeating washing in boiling water and in dry clean cycles and become ineffective and conversely enhance access to the additives by washing or the like. The fibers comprise high tenacity polymers (e.g. PET) in one portion and hydrolysis resistance polymers (e.g. PCT) in another portion with the additives. The fibers can further be blended with non-anti-microbial fibers such as cotton, wool, polyester, acrylic, nylon etc. to provide anti-microbial finished fabrics. In one such embodiment, binder fibers are used which are mixed with other fibers.

Owner:FOSS PERFORMANCE MATERIALS LLC

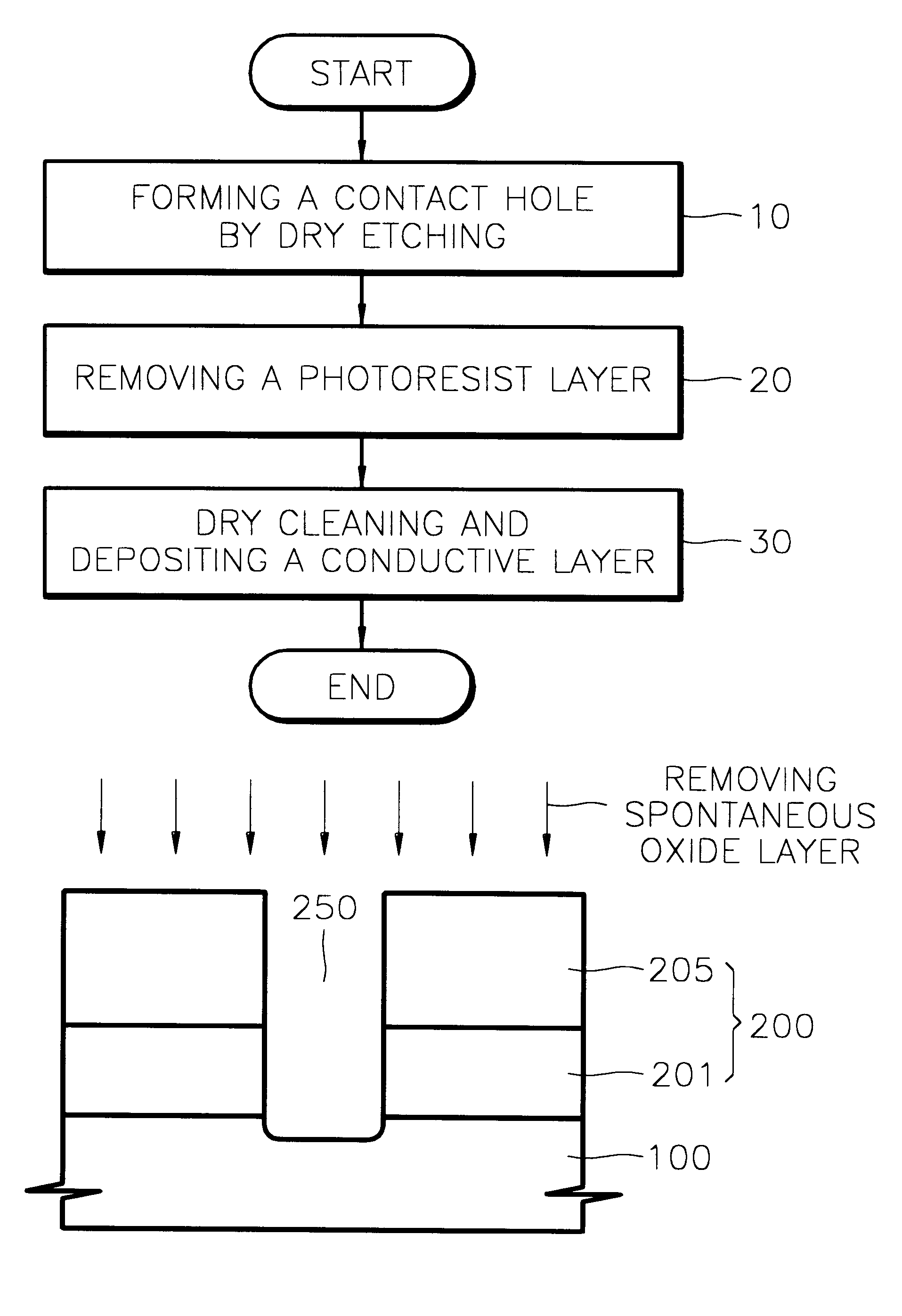

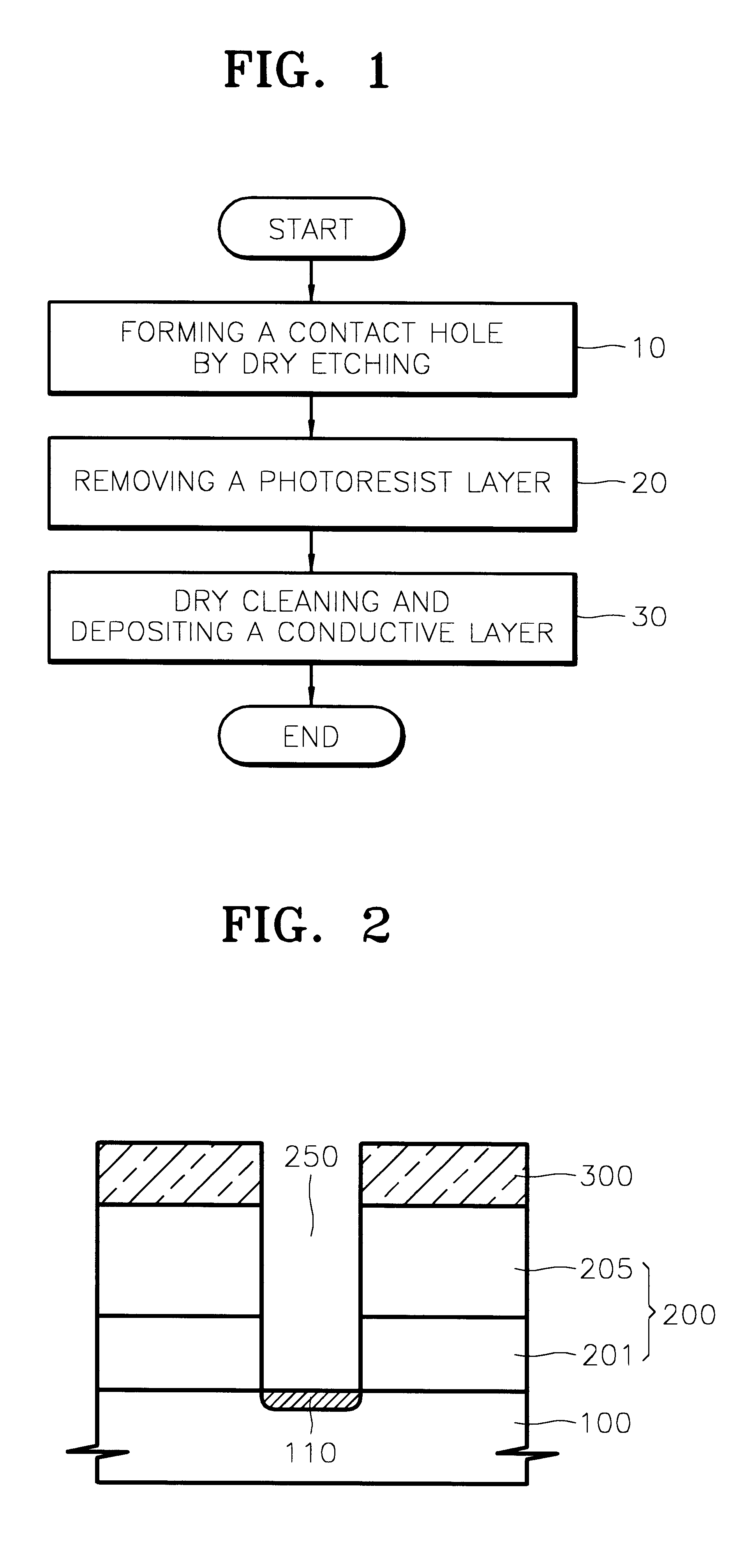

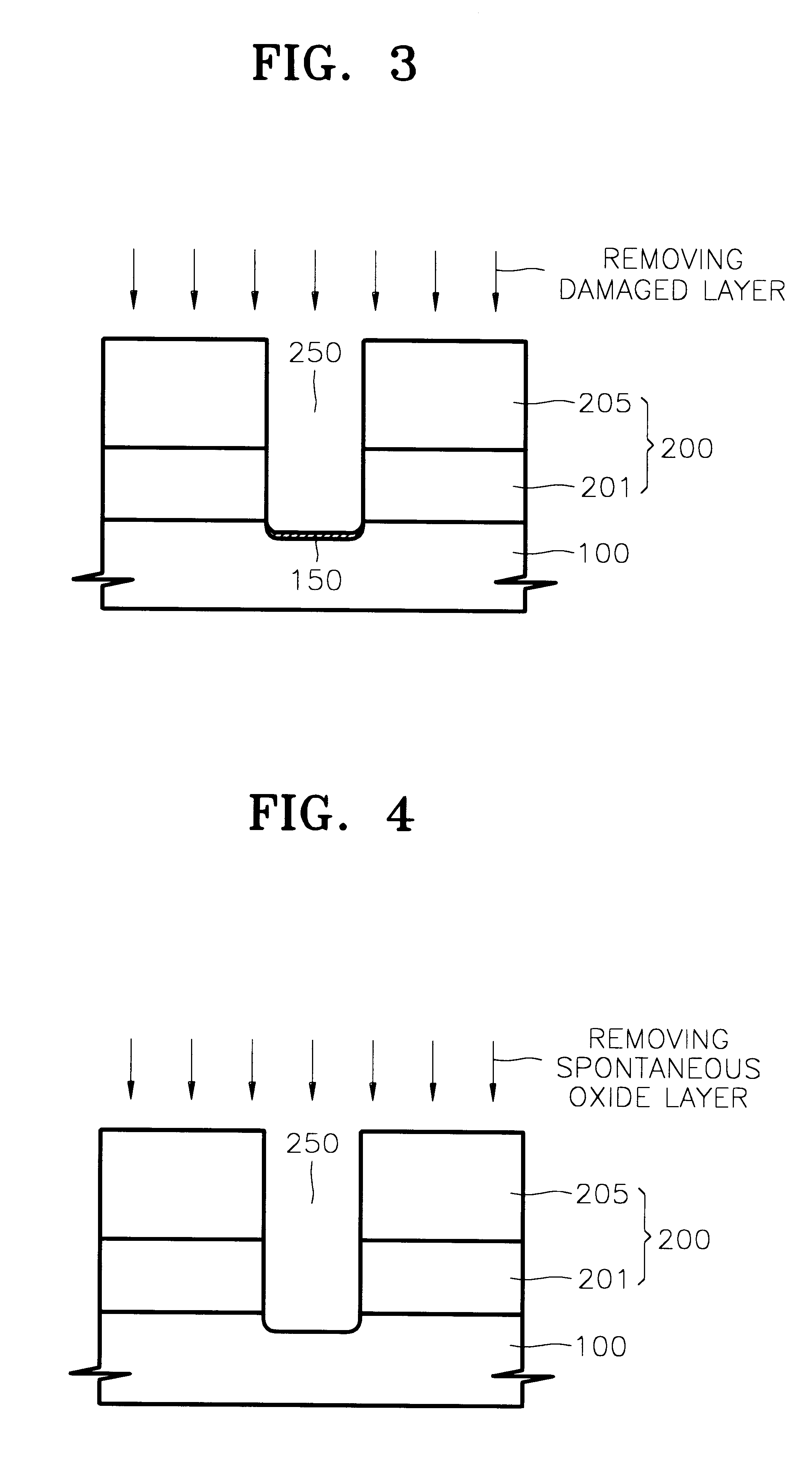

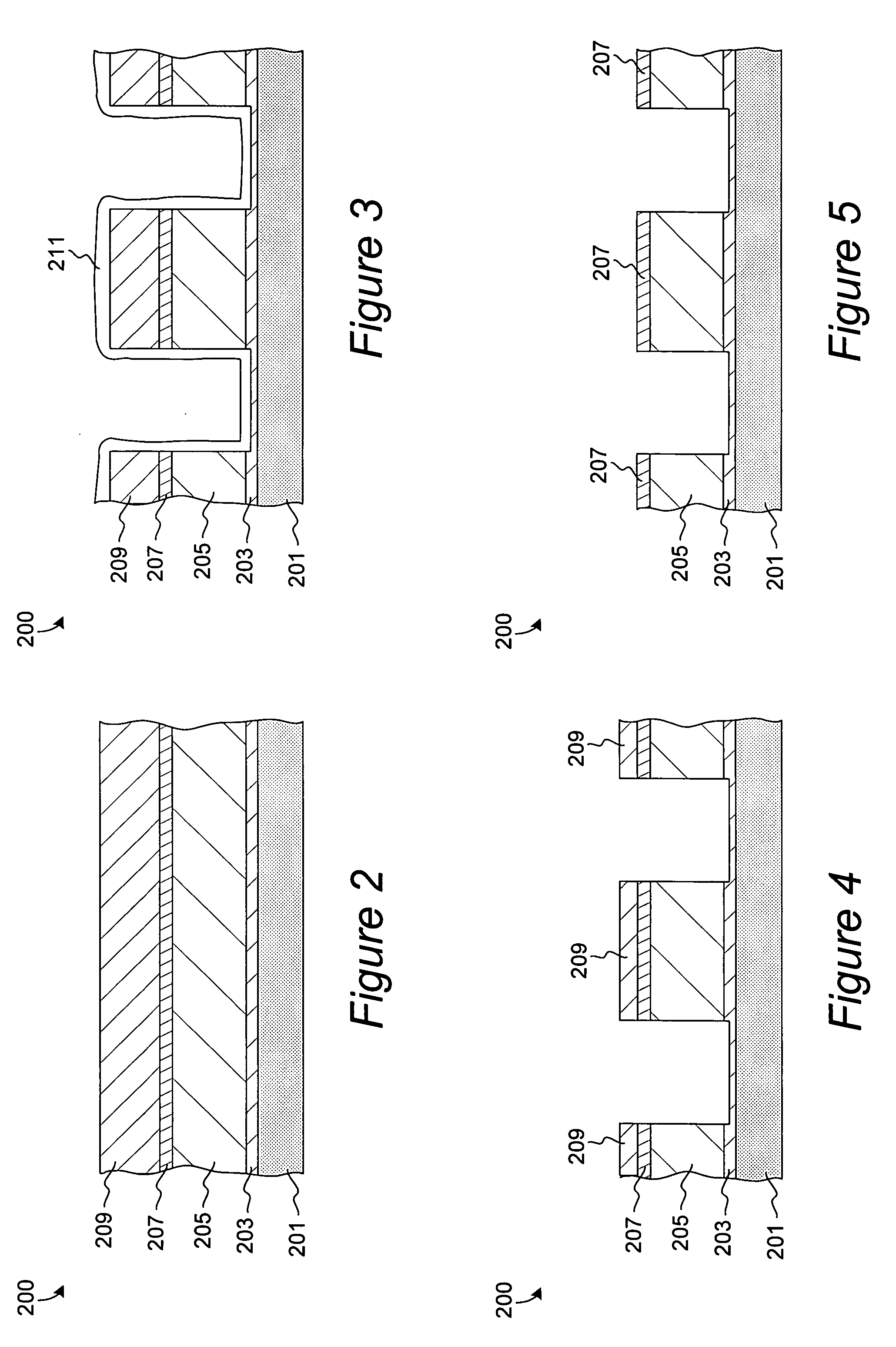

Method of filling contact hole of semiconductor device

InactiveUS6638855B1Reduce contact resistanceRecontamination of the cleaned inside of a contact holeSemiconductor/solid-state device manufacturingSemiconductor devicesDry etchingContamination

A method of filling a contact hole of a semiconductor device preceded by dry cleaning for removing a damaged layer resulting from dry etching is provided. The method includes selectively exposing an underlying material layer by a dry etch and dry cleaning including passing plasma excited from a source gas over the exposed underlying material layer to remove the damaged layer formed from the dry etch. Subsequently, an electrically conductive layer with which to fill the contact hole is formed. The formation of the electrically conductive layer is performed in a separate chamber connected sequentially to a chamber for performing the dry cleaning to prevent the exposed underlying material layer inside the dry cleaned contact hole from being exposed to a source of contamination.

Owner:SAMSUNG ELECTRONICS CO LTD

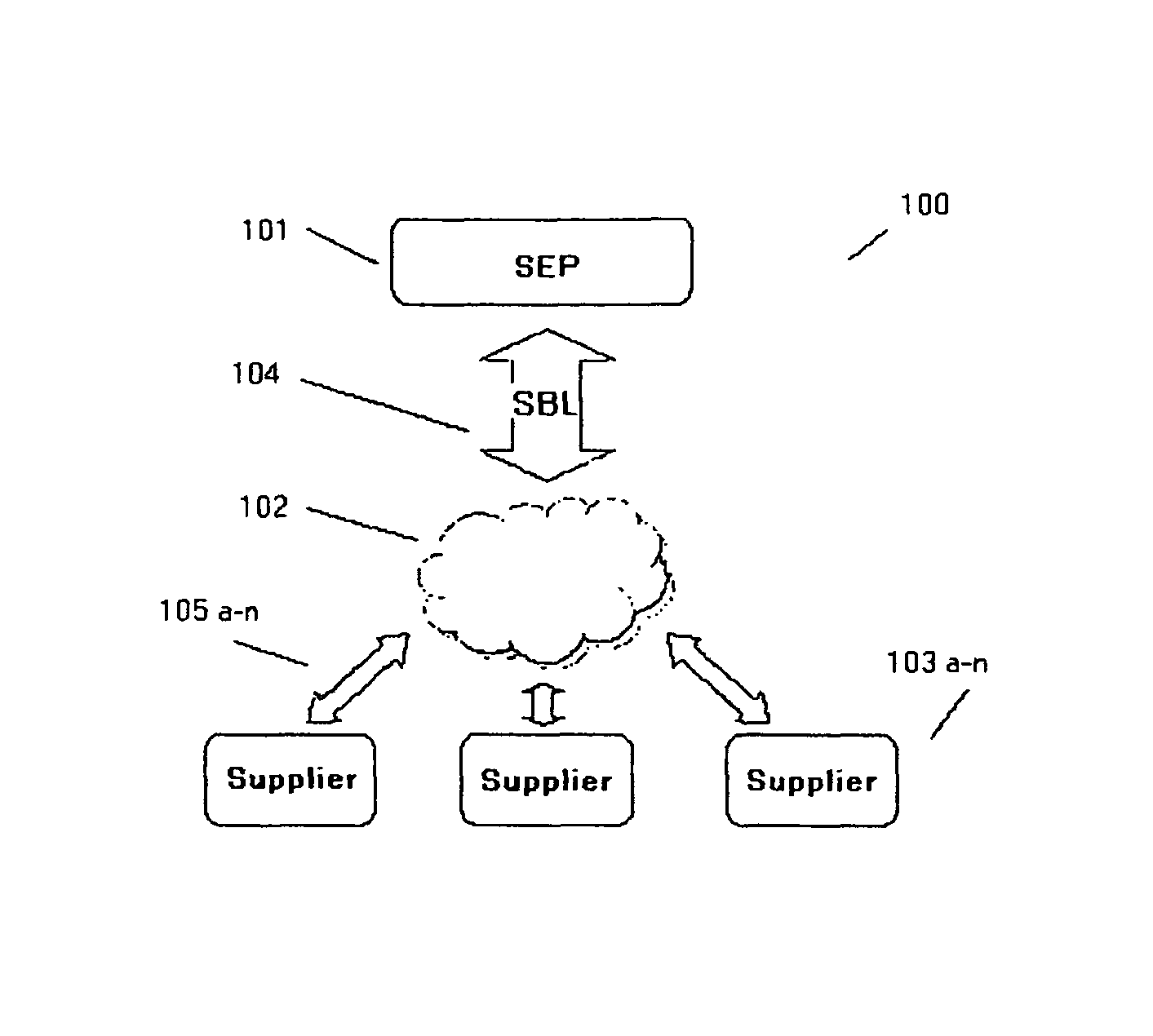

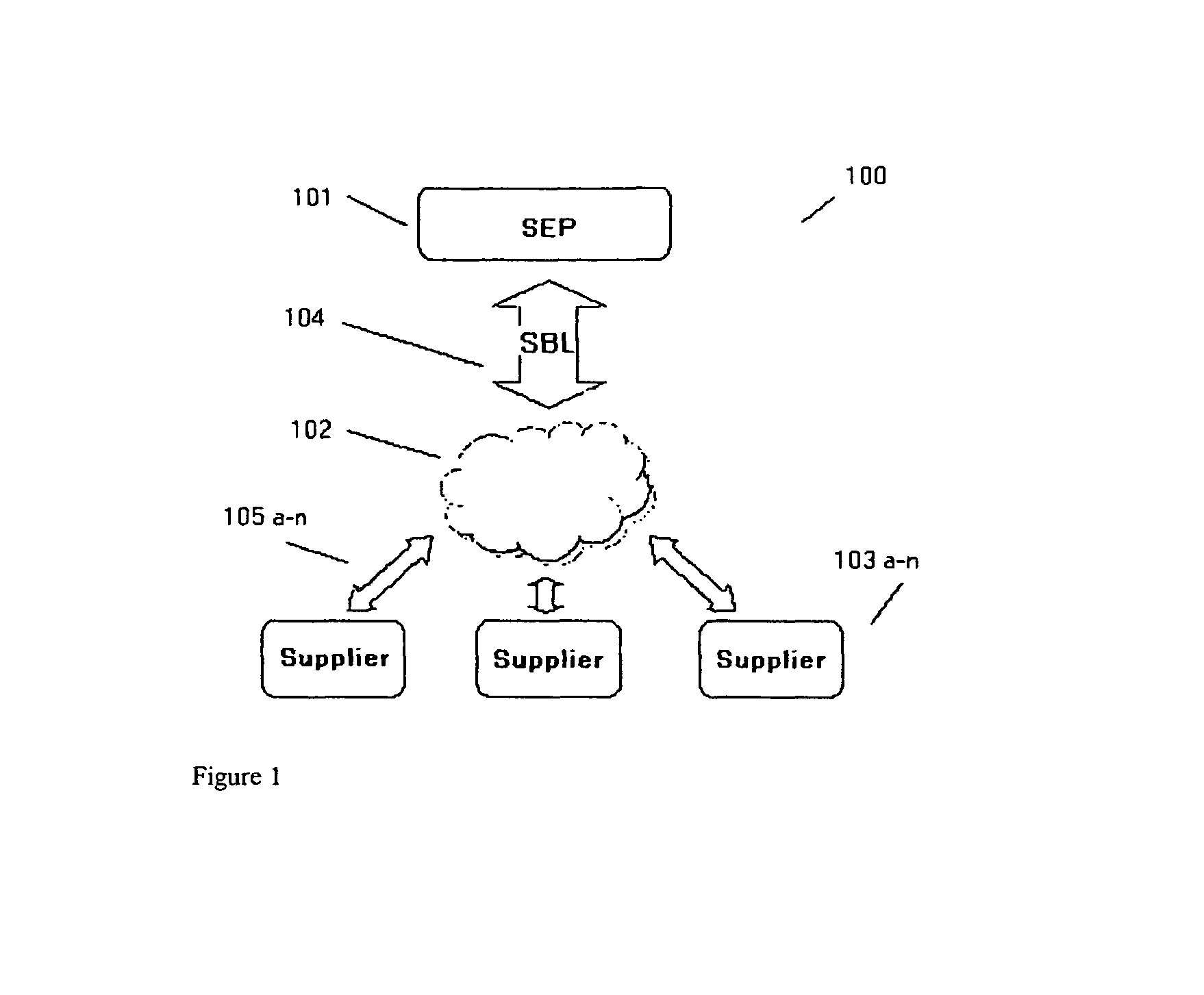

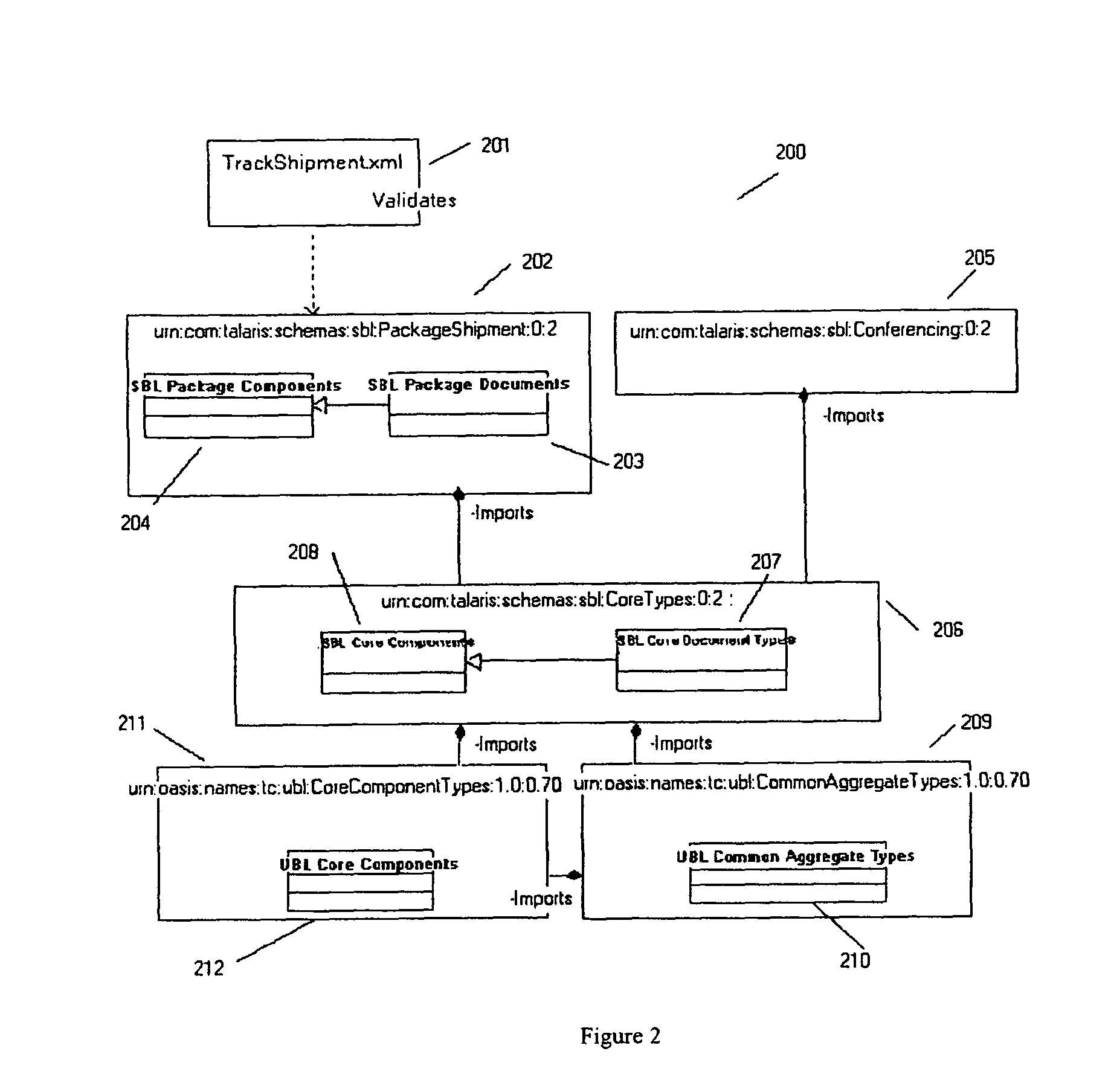

Supplier integration with services business language

The present invention describes a method comprising of a services business language (SBL) providing a common interface for communication with one or more multiple providers in one or more vertical segments. In one embodiment, the vertical segments comprise one or more of package shipping, courier services, flights, hotels, rental cars, and dry cleaners. In another embodiment, the SBL documents of the SBL are defined by Universal Business Language (UBL). In one embodiment, the SBL document includes multiple namespaces that are used in documents as element types and attribute types.

Owner:DEEM

Method and apparatus for processing a wafer

InactiveUS20070093071A1Semiconductor/solid-state device manufacturingPhotomechanical coating apparatusEngineeringAshing

A method of a single wafer wet / dry cleaning apparatus comprising: a transfer chamber having a wafer handler contained therein; a first single wafer wet cleaning chamber directly coupled to the transfer chamber; and a first single wafer ashing chamber directly coupled to the transfer chamber.

Owner:VERHAVERBEKE STEVEN +3

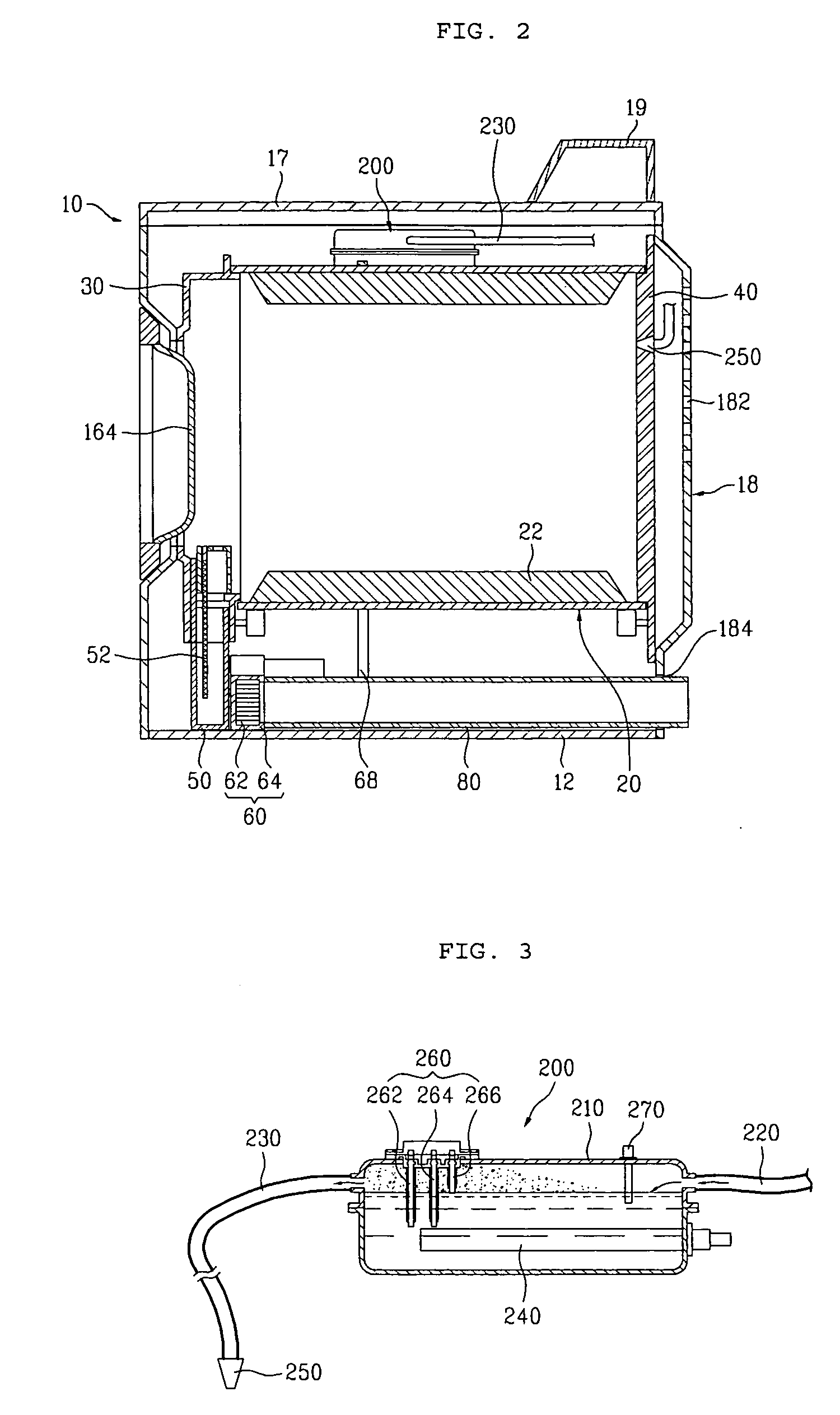

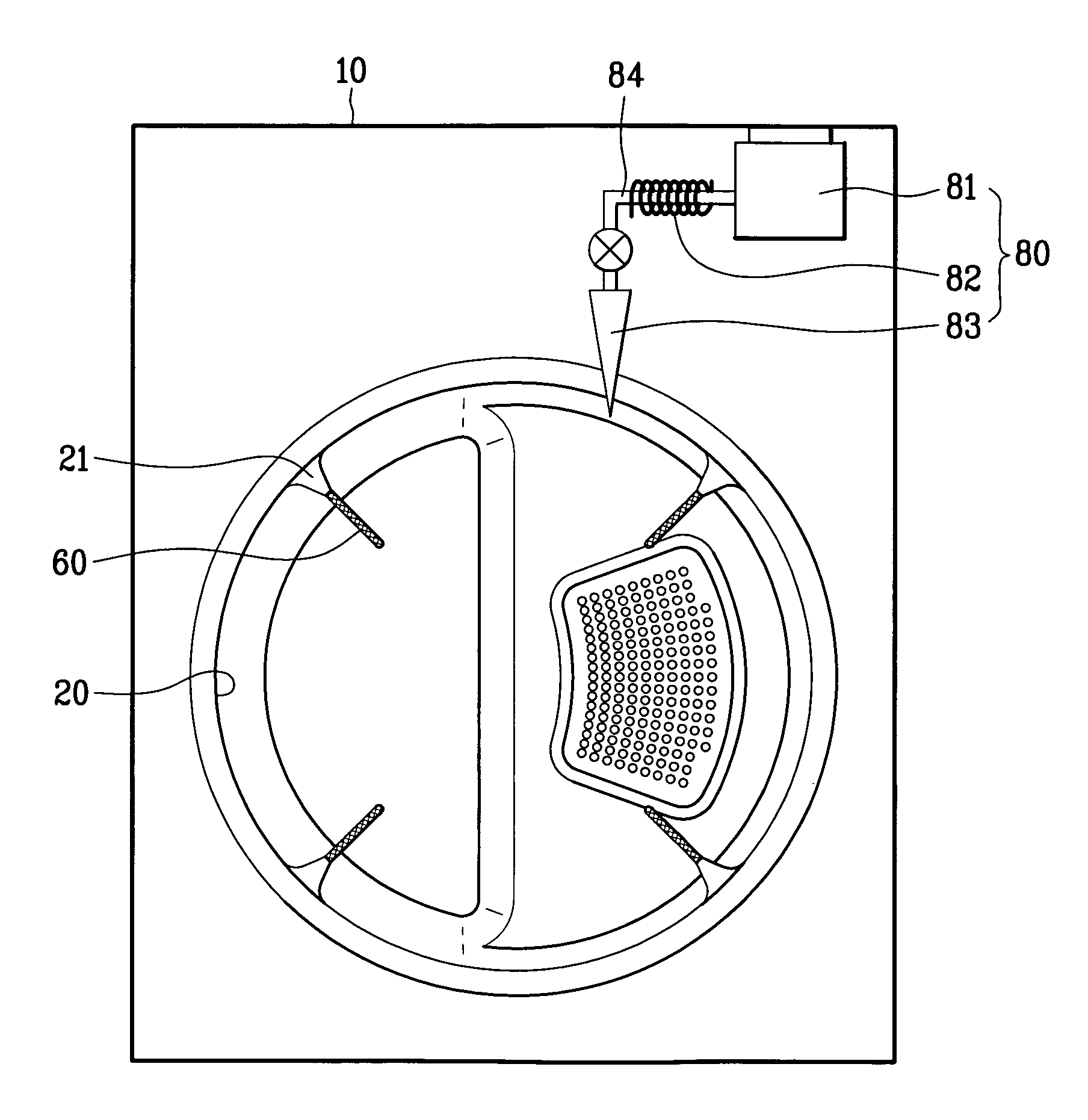

Laundry treating apparatus

ActiveUS20090126423A1Improve ease of useEasy to addDrying solid materials with heatDrying solid materials without heatCold airProcess engineering

A laundry treating apparatus, particularly, a laundry treating apparatus using steam is disclosed. The laundry treating apparatus such as a washing machine, a dryer, a drying and washing machine is an apparatus which washes or dries articles such as clothes. The laundry treating apparatus includes an operation course including a drying process in which hot air is supplied into a drum adapted to accommodate articles to dry the articles and a cooling process in which cool air is supplied into the drum to cool the articles, wherein the operation course further includes a steam process in which steam is supplied into the drum, and the laundry treating apparatus includes a controller which controls a heater adapted to generate the steam such that an operation time point of the heater varies according to an amount of the articles. The laundry treating apparatus includes a drum adapted to accommodate articles, a control panel adapted to provide an interface with a user, and a controller to perform a steam process for supplying steam into the drum, wherein the controller controls a heater adapted to generate the steam to perform the steam process such that an operation time point of the heater varies according to an amount of the articles.

Owner:LG ELECTRONICS INC

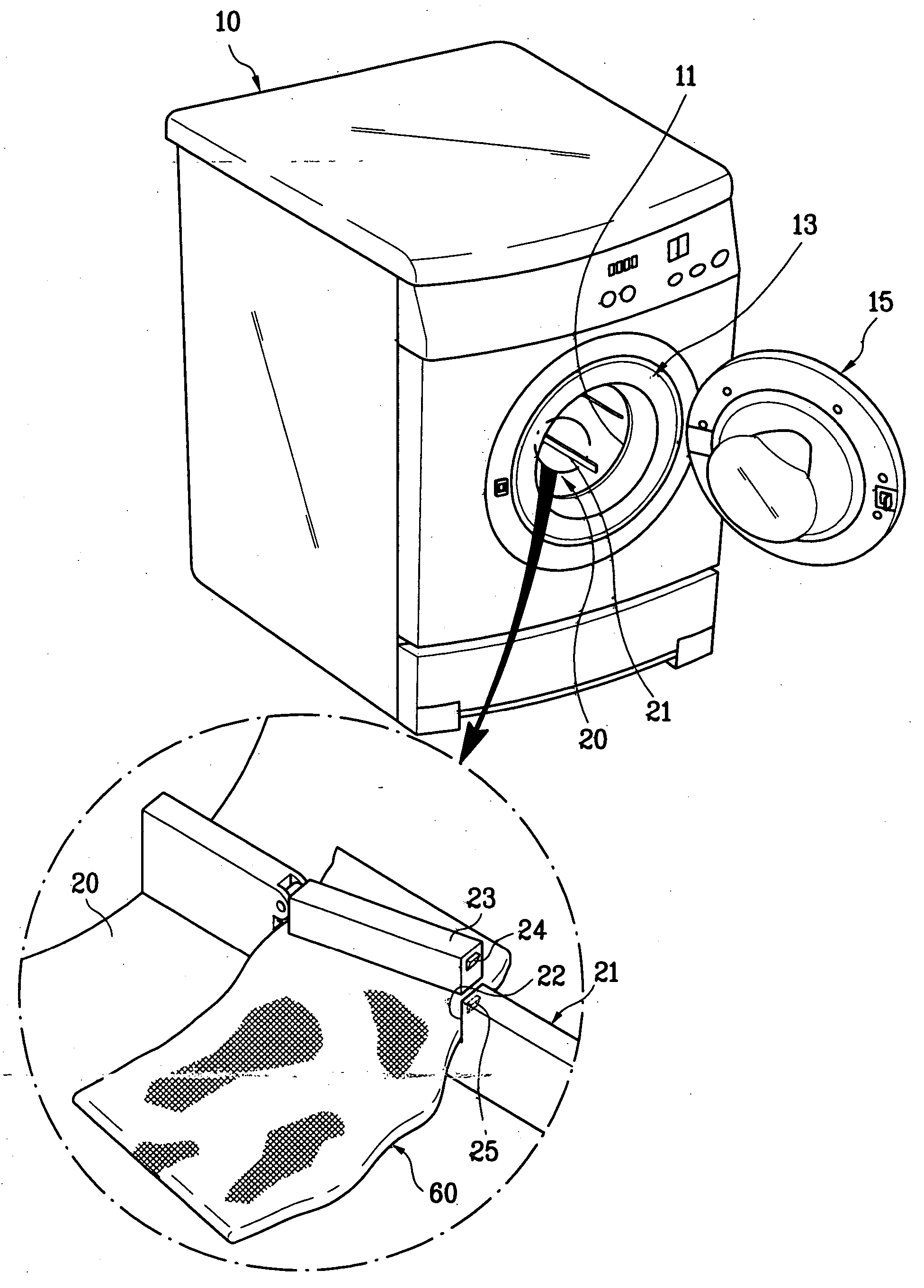

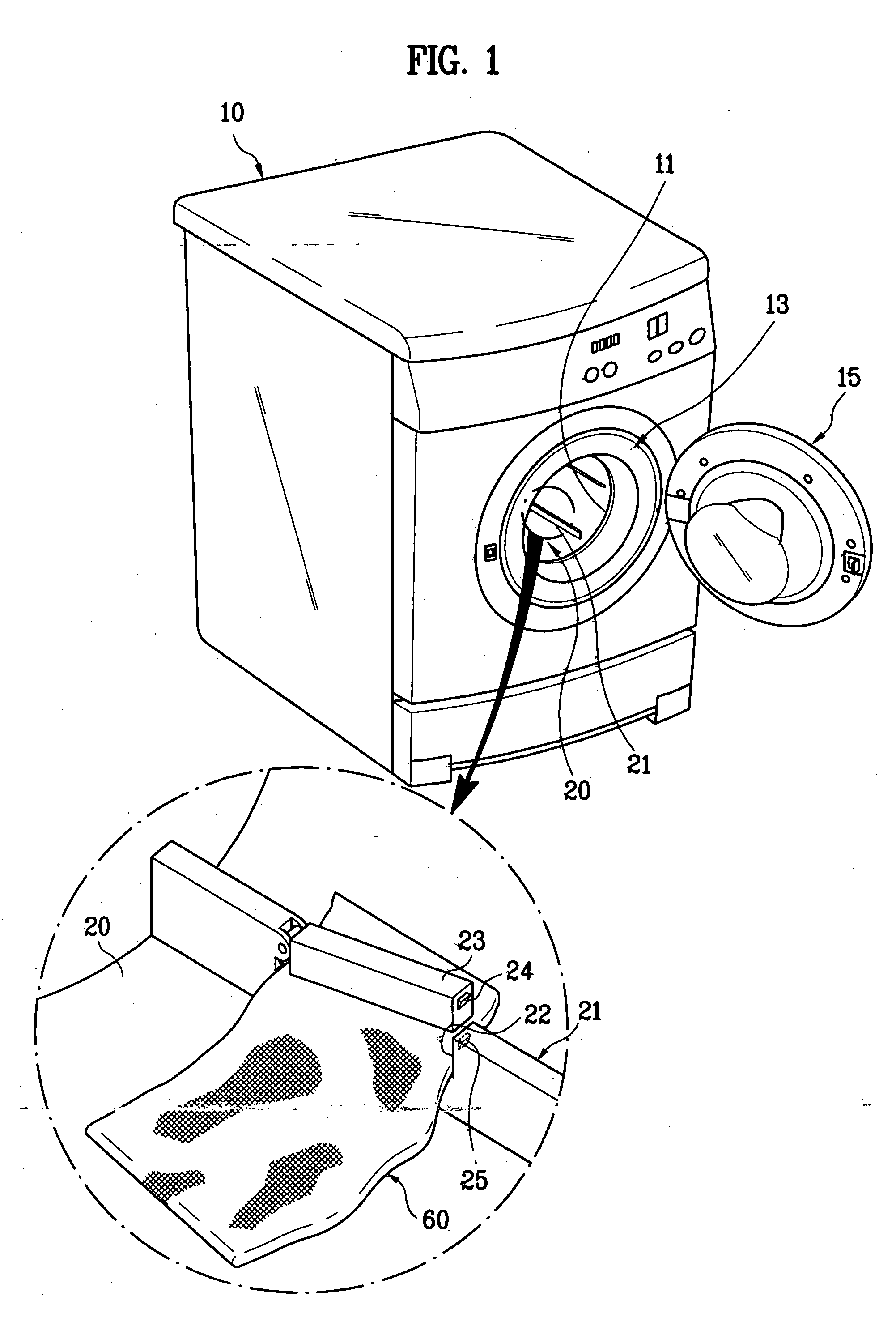

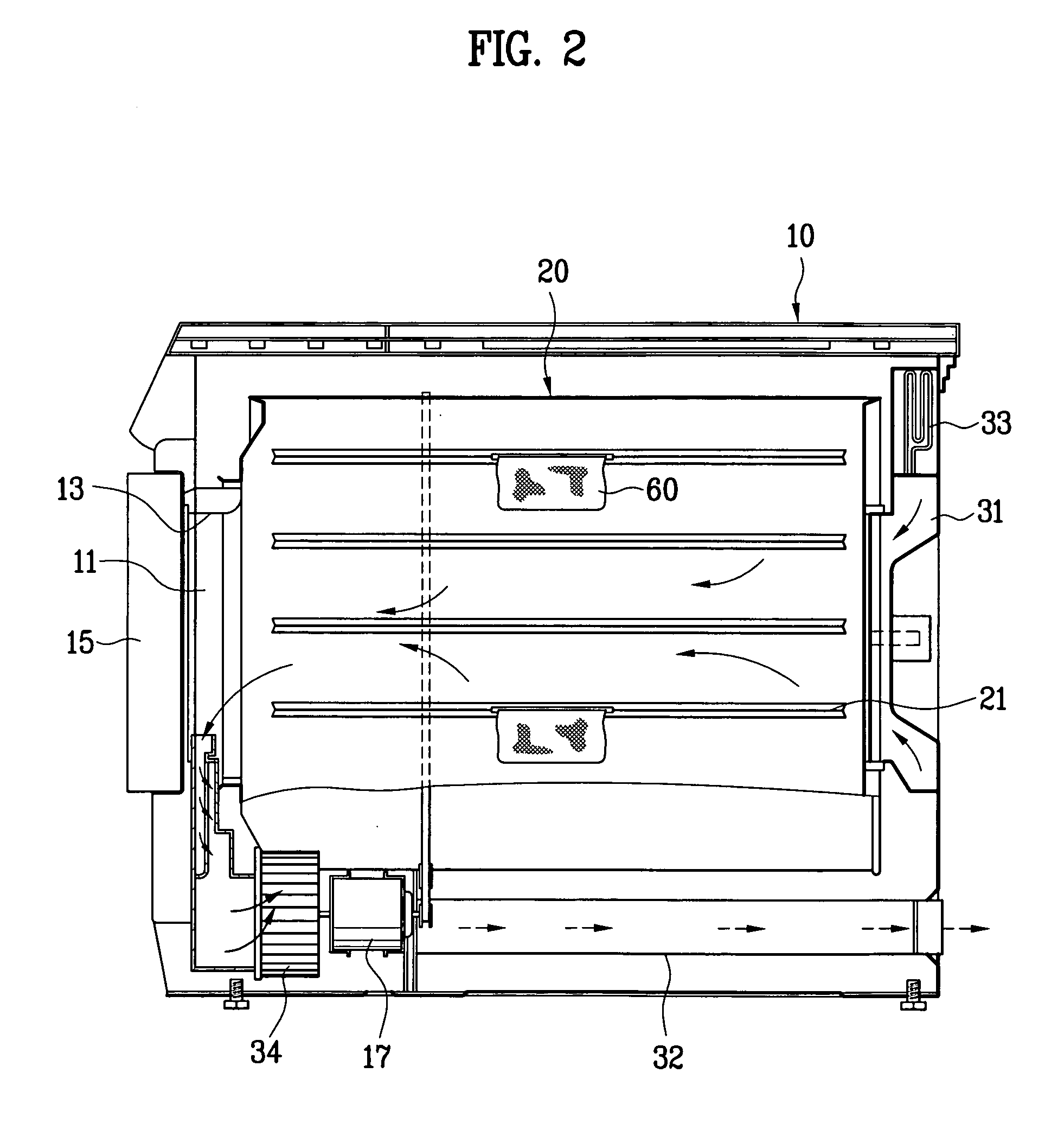

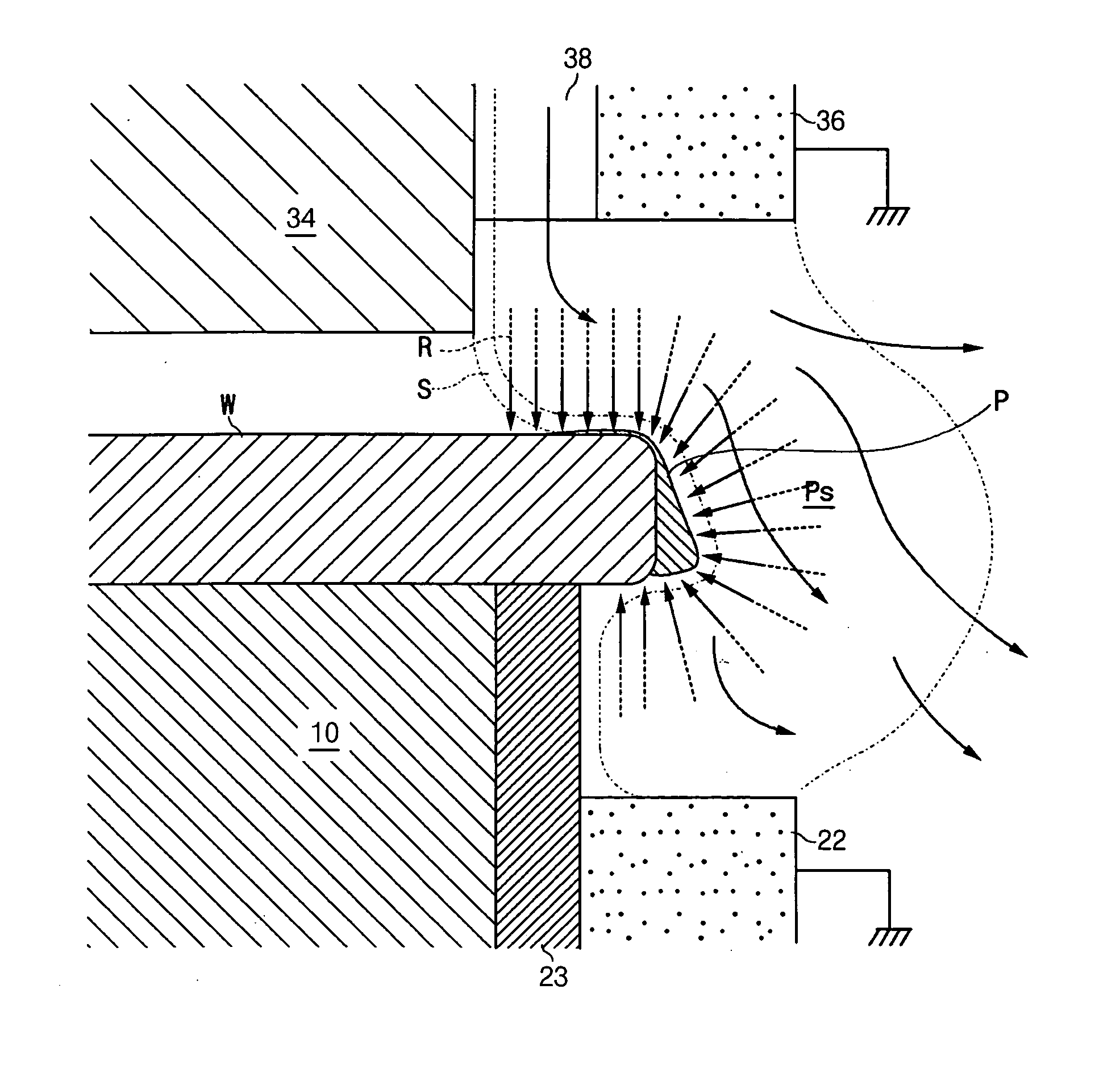

Washing apparatus and control method thereof

ActiveUS7600402B2Prevent wettingOptimize quantityWringing machinesDry-cleaning apparatusEngineeringMechanical engineering

The present invention provides a washing apparatus and control method thereof, by which laundry can be dry-cleaned through the loaded configurations of the wet pad cloth, the filth transfer cloth, the steam providing unit, the fragrance spraying unit, and the detergent supplying unit using either the wet pad cloth or the filth transfer cloth or without using both of the wet pad cloth and the filth transfer cloth.

Owner:LG ELECTRONICS INC

Methods for laundering delicate garments in a washing machine

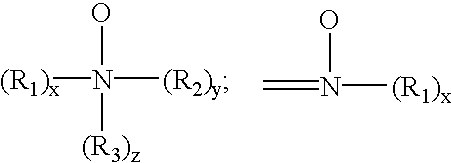

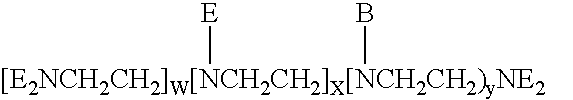

InactiveUS20030008799A1Improve performanceProcess can be usedInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsEngineeringDry cleaner

A product and process for laundering delicate or dry-clean only garments in a washing machine, such as a conventional home washing machine. The process may utilize a garment container, such as a flexible wrap to protect the garments. The process also includes at least one cleaning composition specially formulated for delicate garments. The cleaning composition(s) can be in a number of suitable forms, and can be introduced into the process in a number of different manners. The products used in the process may be provided in the form of a kit. The kit may also include a pretreatment applicator.

Owner:THE PROCTER & GAMBLE COMPANY

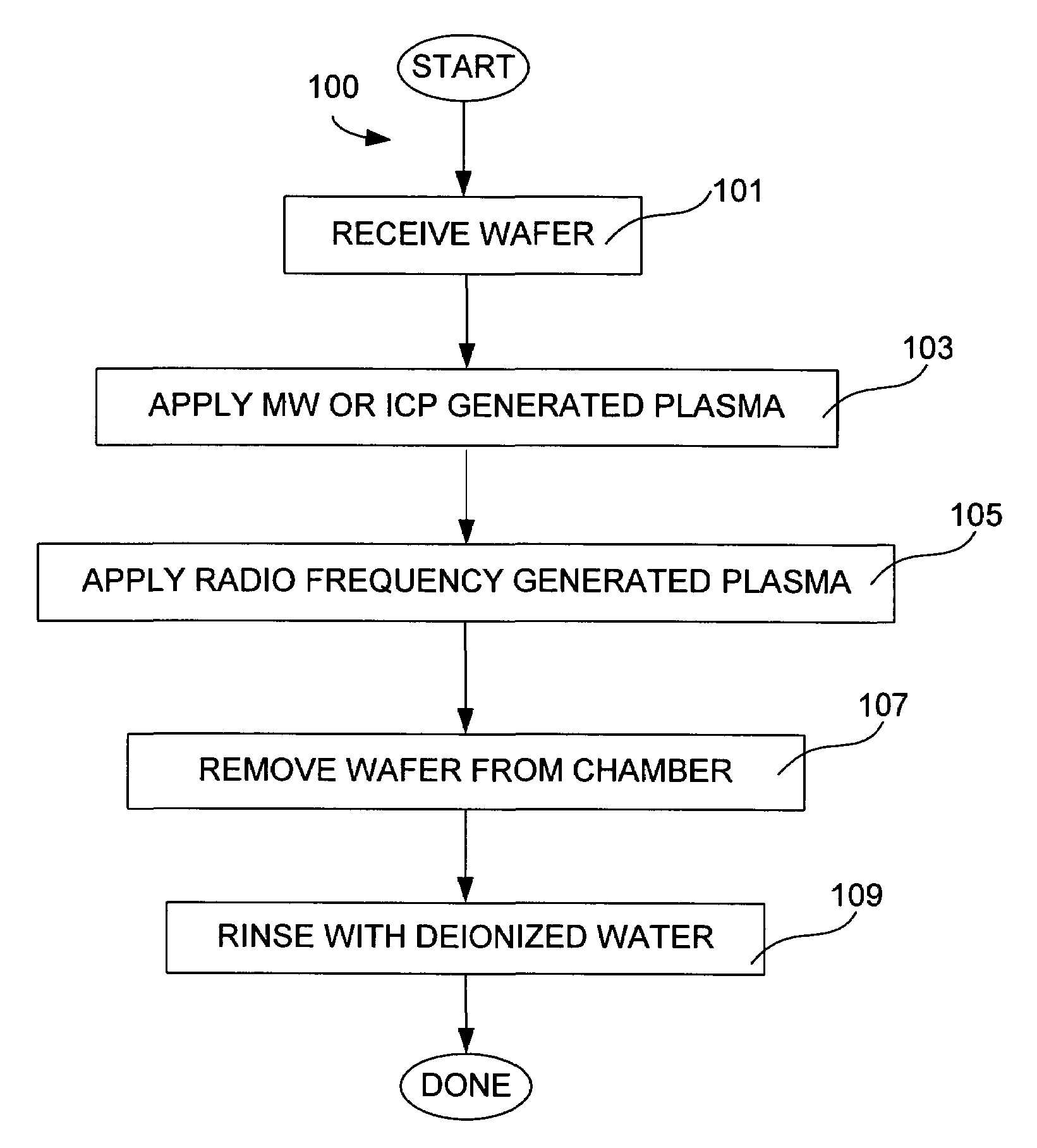

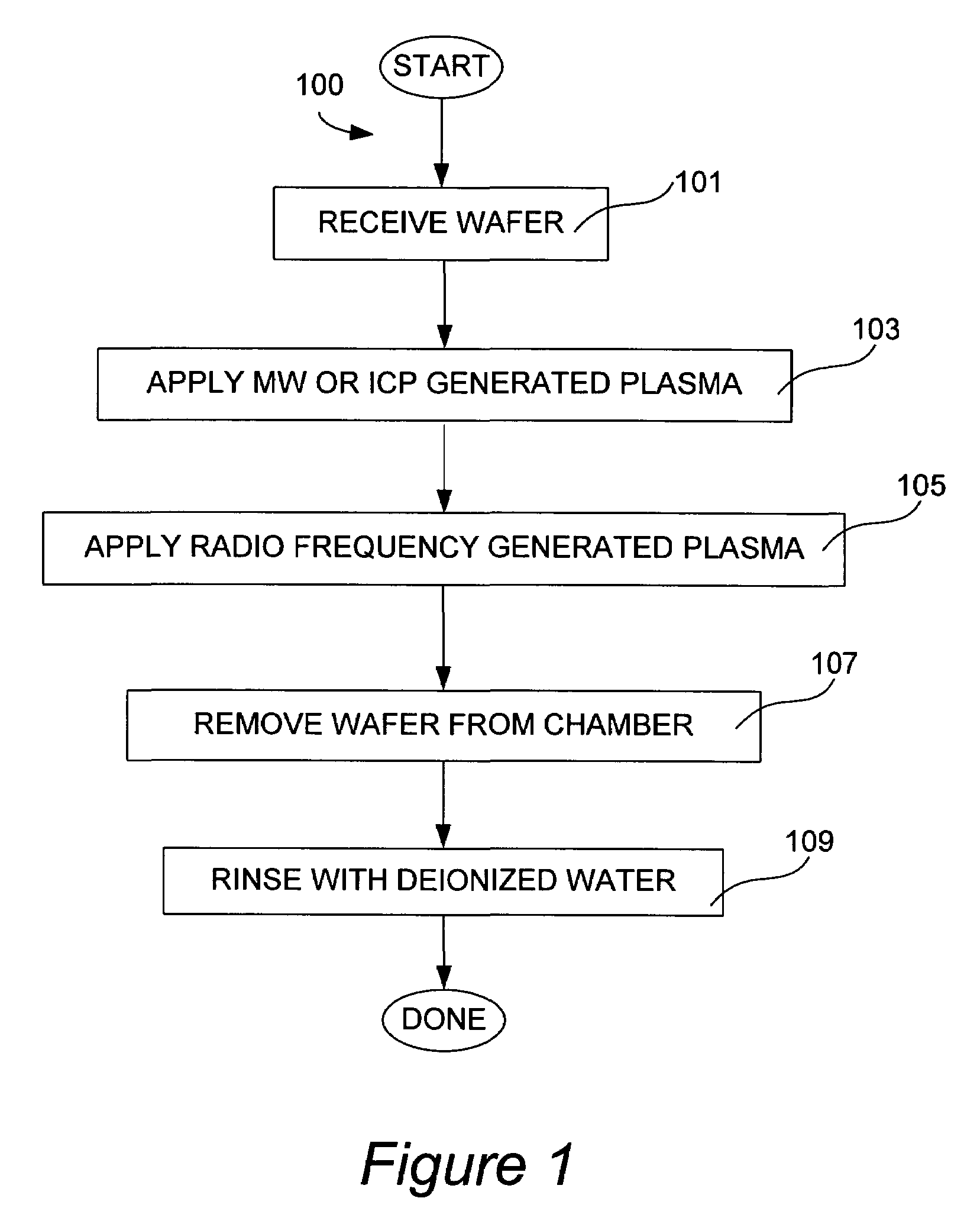

Methods for post polysilicon etch photoresist and polymer removal with minimal gate oxide loss

InactiveUS6955177B1Etch rate can be limitedHigh selectivityElectric discharge tubesElectrostatic cleaningCleaning methodsInductively coupled plasma

The present invention pertains to methods for cleaning semiconductor wafers, more specifically, for removing polymeric and other residues from a wafer using dry plasmas generated with microwave (MW), electromagnetic field (inductively-coupled plasma (ICP)), and radio frequency (RF) energy. First, a wafer is treated by applying a microwave-generated plasma or an inductively-coupled plasma. Second, a radio frequency generated plasma is applied. Each of the microwave-generated plasma and the inductively-coupled plasma is produced from a gas mixture, which includes an oxygen source gas, a fluorine source gas, and a hydrogen source gas. Using such plasmas provides more controllable etch rates than conventional plasmas via control of fluorine concentration in the plasma. Application of a radio frequency generated (preferably oxygen-based) plasma is used for additional photoresist and polymer removal. The use of this two-step approach provides superior wafer cleaning compared to conventional wet and dry clean methods.

Owner:NOVELLUS SYSTEMS

Methods for laundering delicate garments in a washing machine

InactiveUS6966696B1Inexpensive convenient processEasy to cleanBrush bodiesDry-cleaning apparatusPre treatmentWet cleaning

A product and process for laundering delicate or dry-clean only garments in a conventional home washing machine. The process represents a home version of the commercial wet-cleaning processes for cleaning of delicate garments. The product may comprise a liquid cleaning composition, a wash pretreatment composition, a wash pretreatment applicator, an apparatus for dispensing a rinse cycle conditioner and a flexible wrap container within which the garments are contained during washing.

Owner:THE PROCTER & GAMBLE COMPANY

Method and system of dry cleaning a processing chamber

InactiveUS20050241669A1Reduce particulate pollutionKeep clean and dryElectric discharge tubesHollow article cleaningParticulatesEngineering

A method of dry cleaning a plasma processing system is described, wherein the formation of particulate during dry cleaning is substantially minimized. In one embodiment, the dry cleaning process is adjusted in order to substantially reduce spatial variations of the dry cleaning rate within the plasma processing system. In another embodiment, endpoint detection is utilized to determine the completion of the dry cleaning process in order to avoid excessive ion sputtering of the underlying process chamber components.

Owner:TOKYO ELECTRON LTD

Methods for in-situ chamber clean utilized in an etching processing chamber

Embodiments of the invention include methods for in-situ chamber dry cleaning a plasma processing chamber utilized for gate structure fabrication process in semiconductor devices. In one embodiment, a method for in-situ chamber dry clean includes supplying a first cleaning gas including at least a boron containing gas into a processing chamber in absence of a substrate disposed therein, supplying a second cleaning gas including at least a halogen containing gas into the processing chamber in absence of the substrate, and supplying a third cleaning gas including at least an oxygen containing gas into the processing chamber in absence of the substrate.

Owner:APPLIED MATERIALS INC

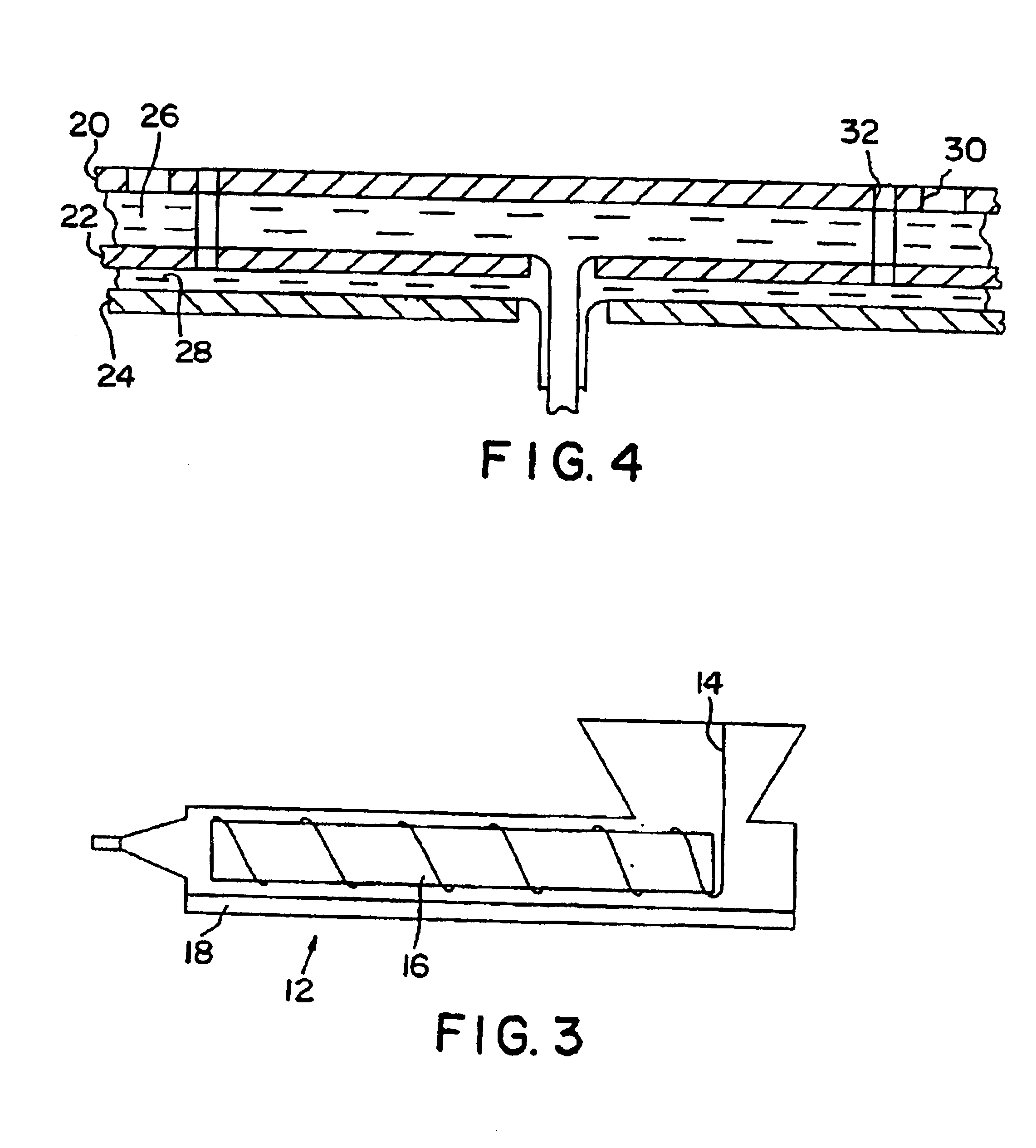

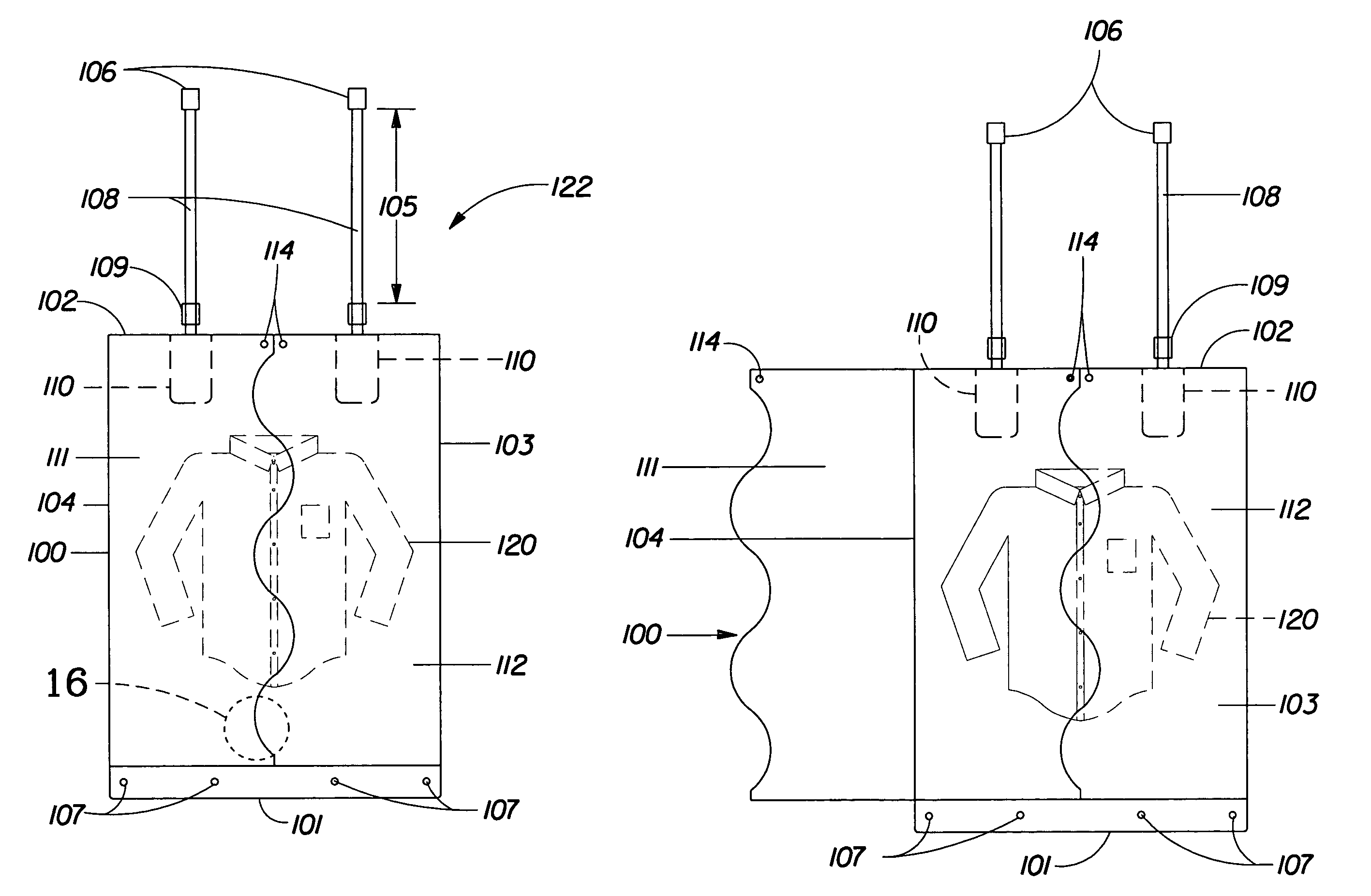

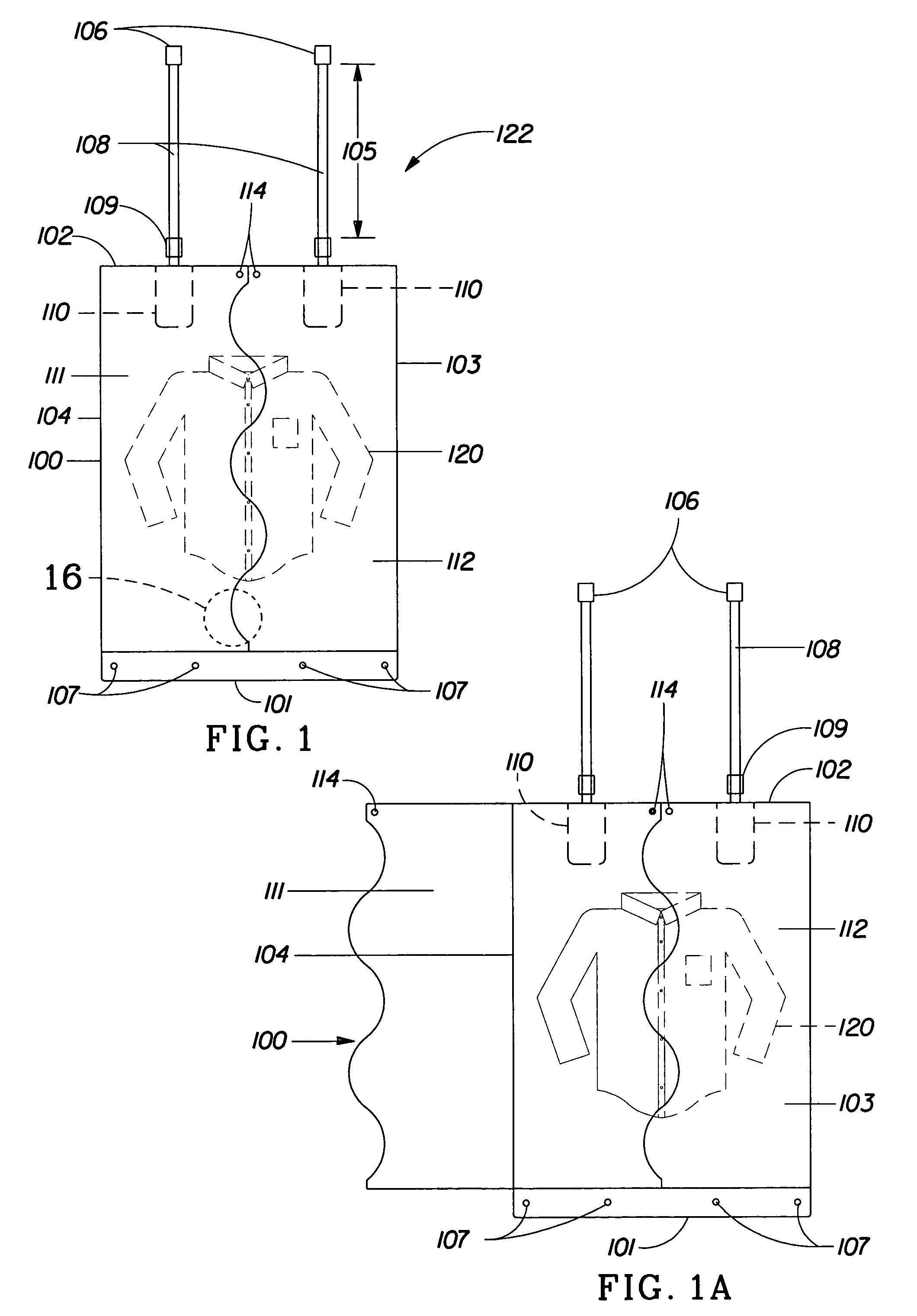

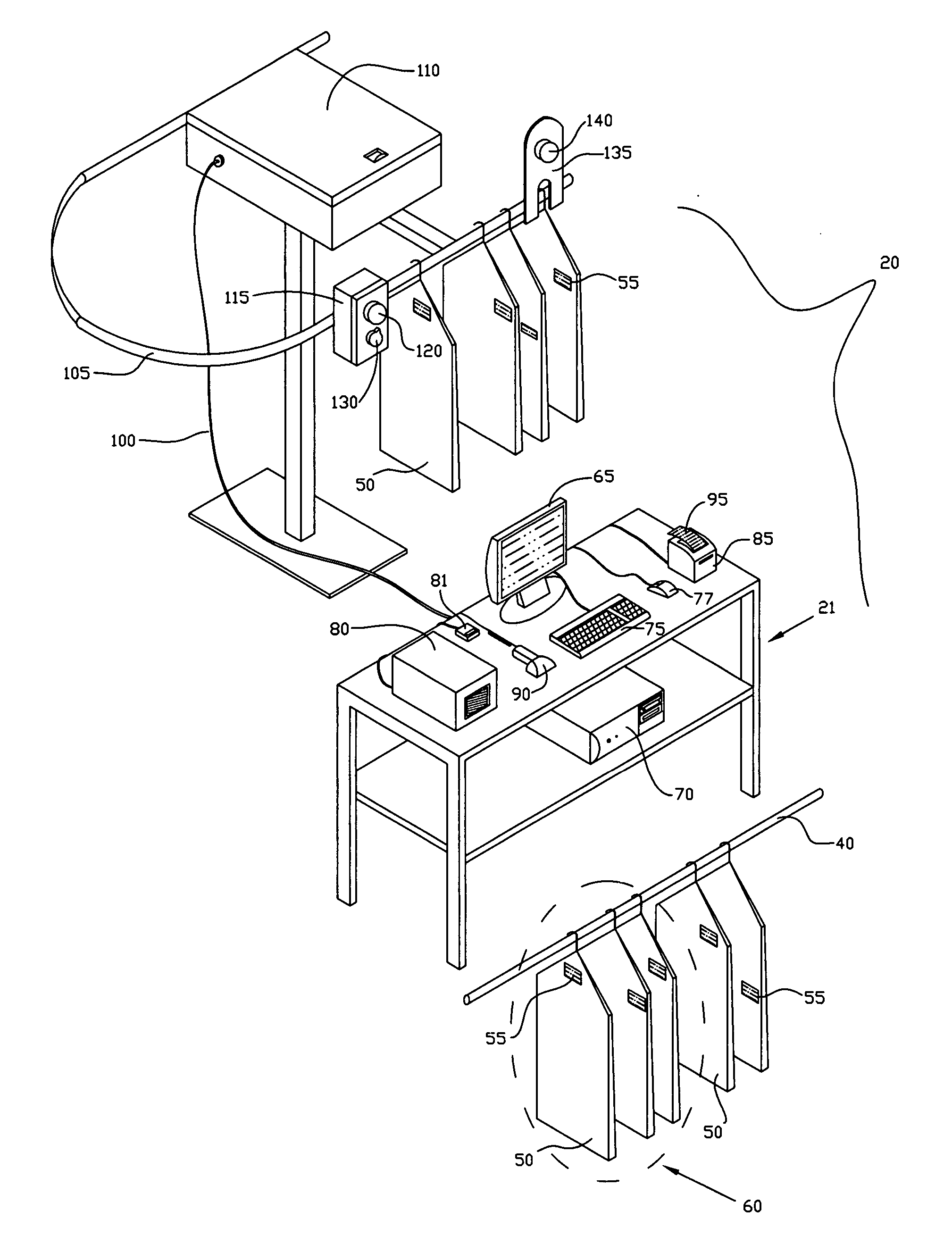

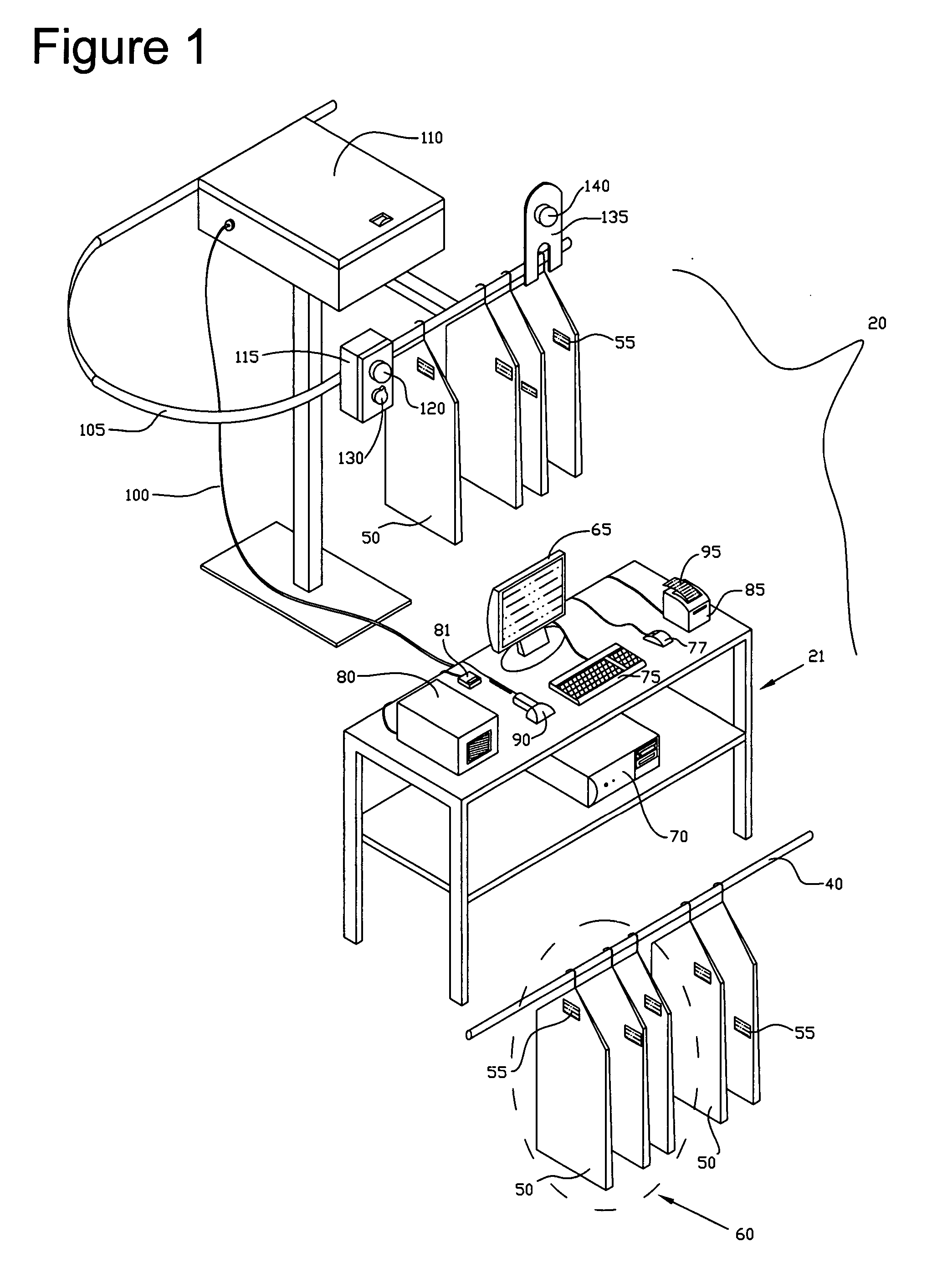

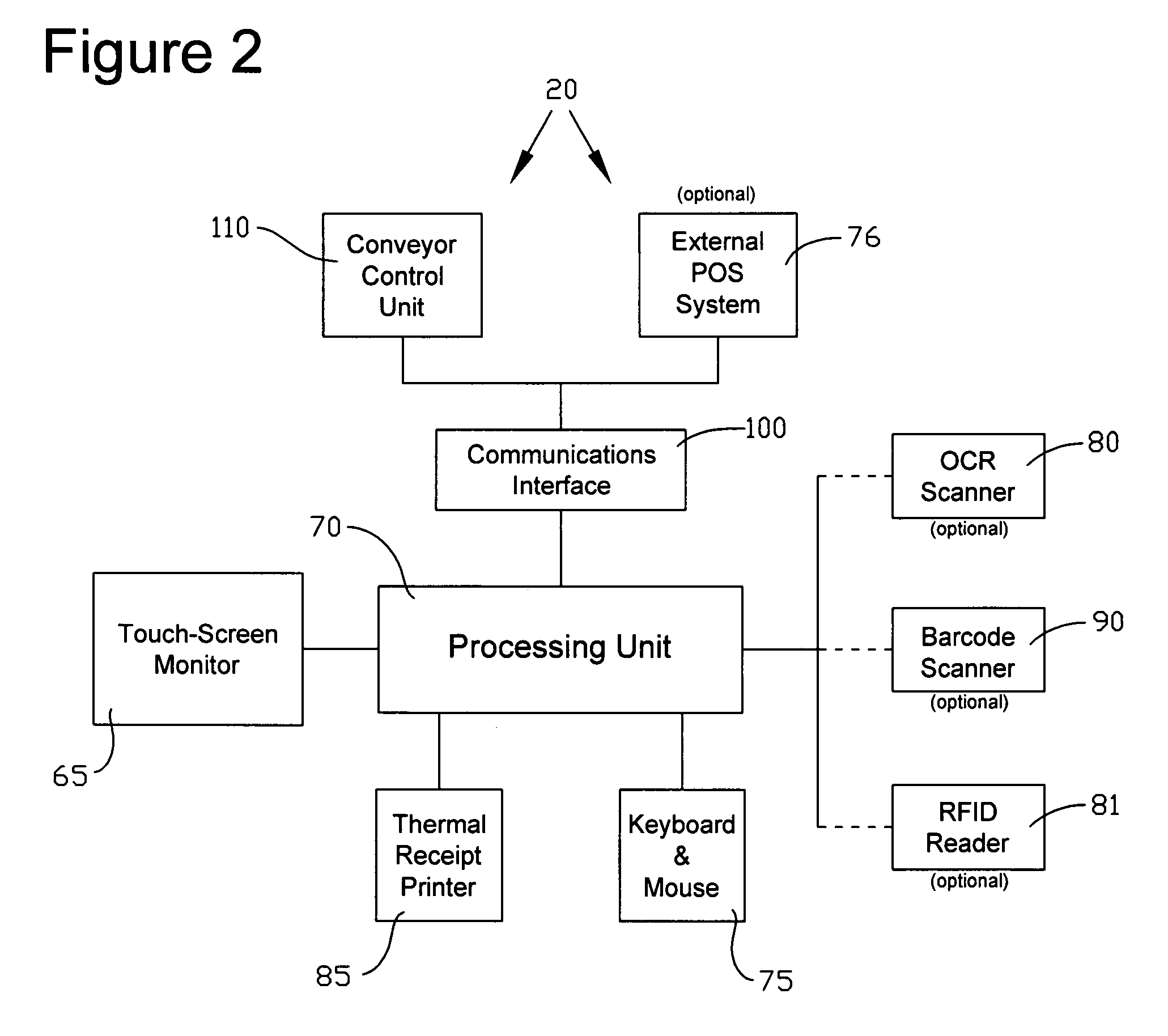

Automated dry cleaning assembly conveyor system

InactiveUS20070261997A1Easy to assembleDigital data processing detailsCharacter and pattern recognitionBarcodeEngineering

An automated assembly conveyor method and apparatus for dry-cleaners recognizes, associates, and consolidates garments in customer transactions by reading garment identification tags. A scanning apparatus whose construction may vary depending upon they type of garment tagging system utilized by a given retail drycleaner reads tags through Optical Character Recognition (OCR) scanning, Bar Code scanning, or Radio Frequency (RF) means, and manual error correcting input is also facilitated. A large inventory of garments assembled into unique orders by customer., each “group” having at least one garment. The software collects information relating to “promised day,”“piece count”, “tag color”“striped or non-striped”, and “tag style” for operator display.

Owner:HMC SOLUTIONS

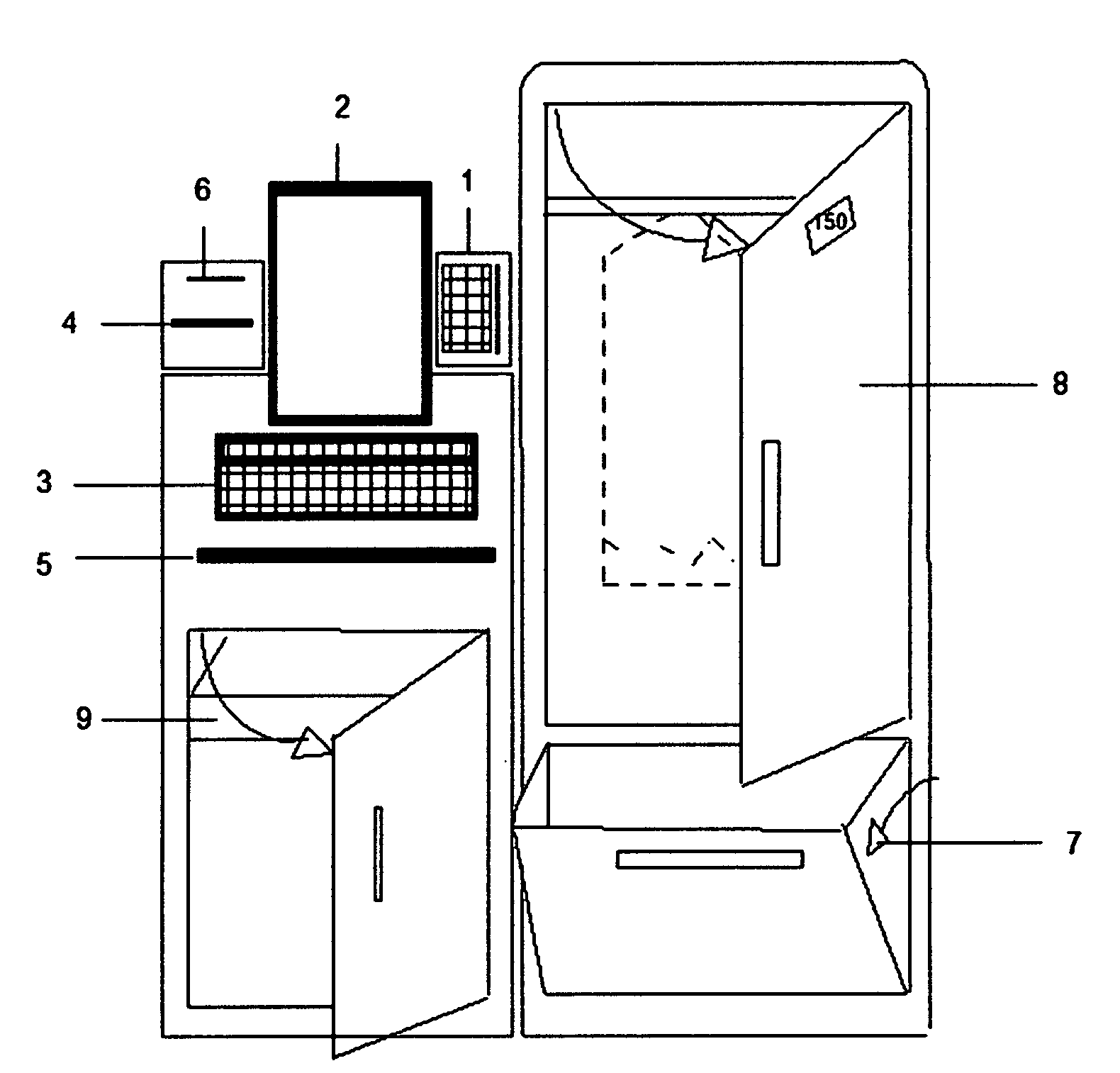

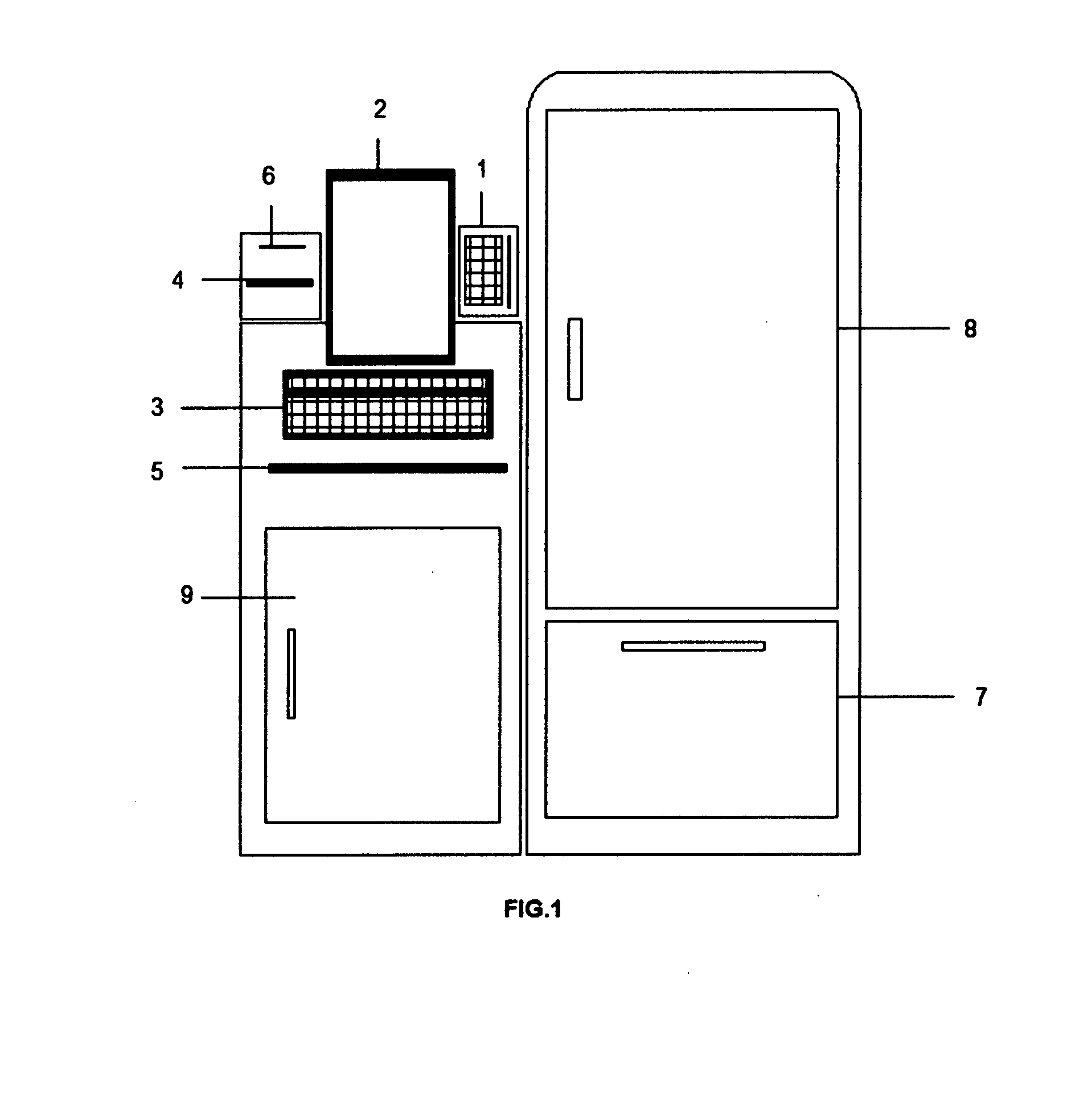

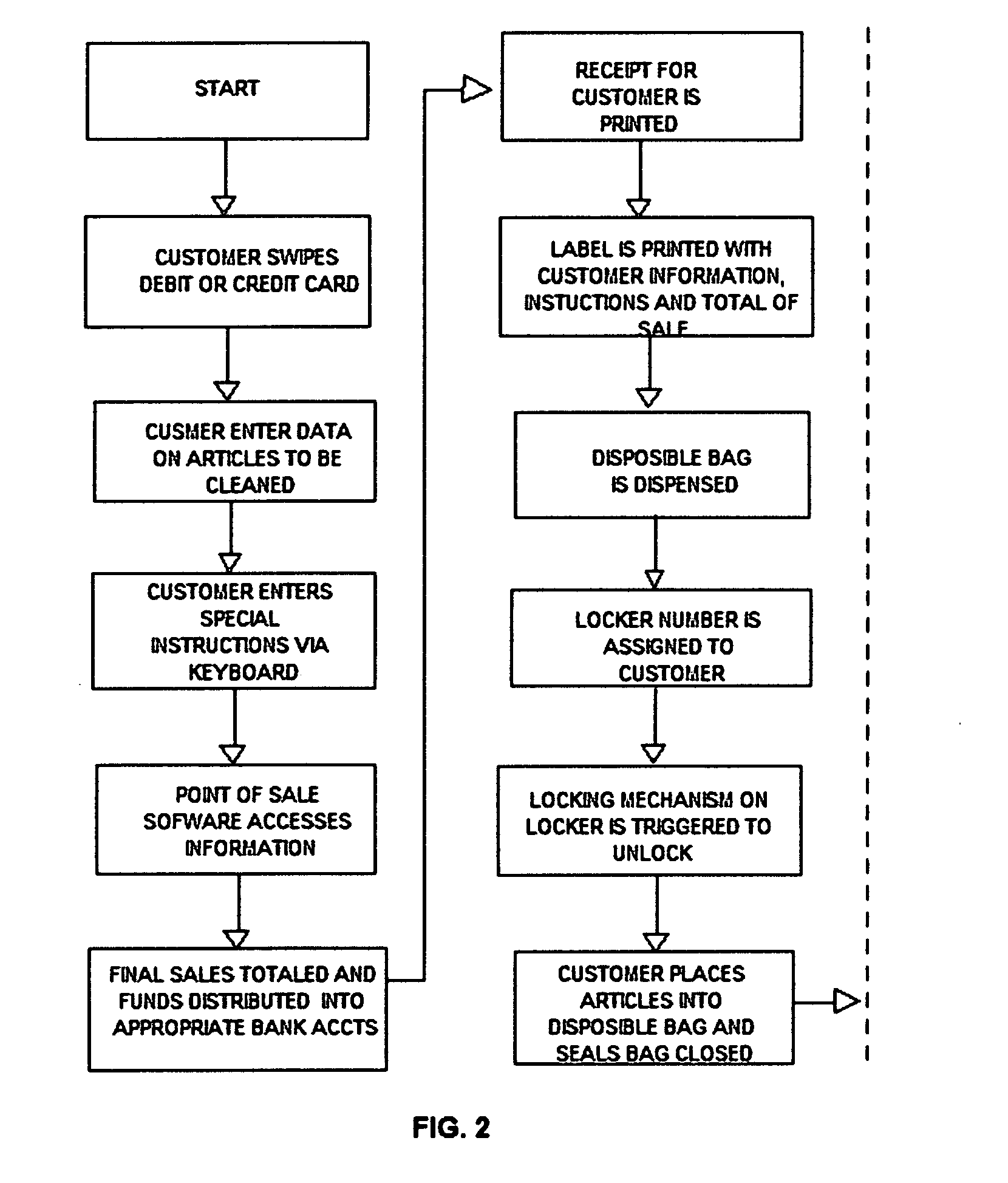

Self service prepay dry cleaning locker system

InactiveUS20070251990A1Apparatus for meter-controlled dispensingSpecial data processing applicationsWork periodSelf-service

The self service prepay dry cleaning locker system is composed of a unit which houses the software, keyboard, printer, disposable bags and a determinate number of lockers for the available space. The system allows for customers to access a drop off and delivery location for their articles to be dry cleaned. This would be accessible 24 hours a day, 7 days a week. This would also allow for a dry cleaning establishment to keep their overhead low, while being able to expand their customer base by being accessible outside of normal operating hours.

Owner:LENORMAN ANITA

Water-free dry washing agent for automobile

ActiveCN101024801ANo emissionsNo pollution in the processNon-surface-active detergent compositionsVehicle cleaningEmulsionSunscreen agents

The invention relates to a vehicle dry cleaner that is made up from 65-85% brazilian trypanosomiasis , 3-7% penetrant, 2-4% dispersable emulsifier OP-10, 5-20% regulator, 1-5% sunscreen agent, 1-3% quality maintain agent, and 0.01-0.03% essence. The manufacture method includes following steps: weighing raw material according to weight percent, heating Brazilian trypanosomiasis to fusion, putting into mixer to gain the first raw product; putting the raw material into emulsion machine to take second emulsification to gain the product. The invention has advantages of saving water resource and no environment pollution problem, low cost and lower customer vehicle cleaning cost.

Owner:朱正龙

Method and device for generating aerosol in large grain size in use for testing efficiency of air filter

InactiveCN101093218AEasy to getLow insulation requirementStructural/machines measurementParticle suspension analysisThermodynamicsAir filter

A device used for generating big particle diameter of airosol used in efficiency test of air filter is prepared for forming air-processing unit by air filter and flow meter as well as heater, forming an atomizing unit by solution bottle and nozzle, setting nozzle at top of drying tower, feeding dried clean air into drying tower at bottom of said tower, making atomized small solution drop be dried in falling down process to from solid aerosol by controlling pressure and flow rate of compressed air as well as concentration of different potassium chloride solutions.

Owner:CHINA ACAD OF BUILDING RES

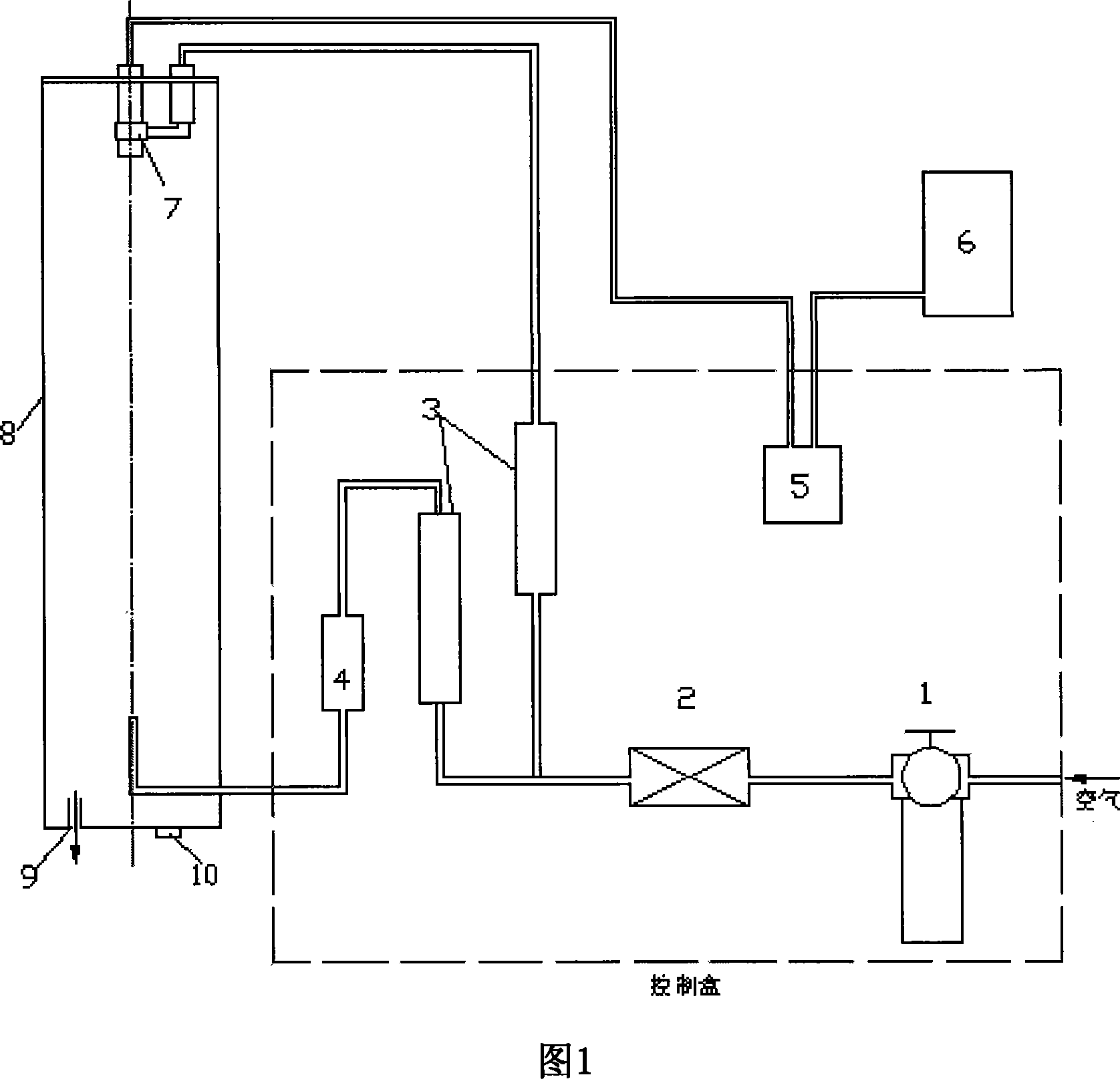

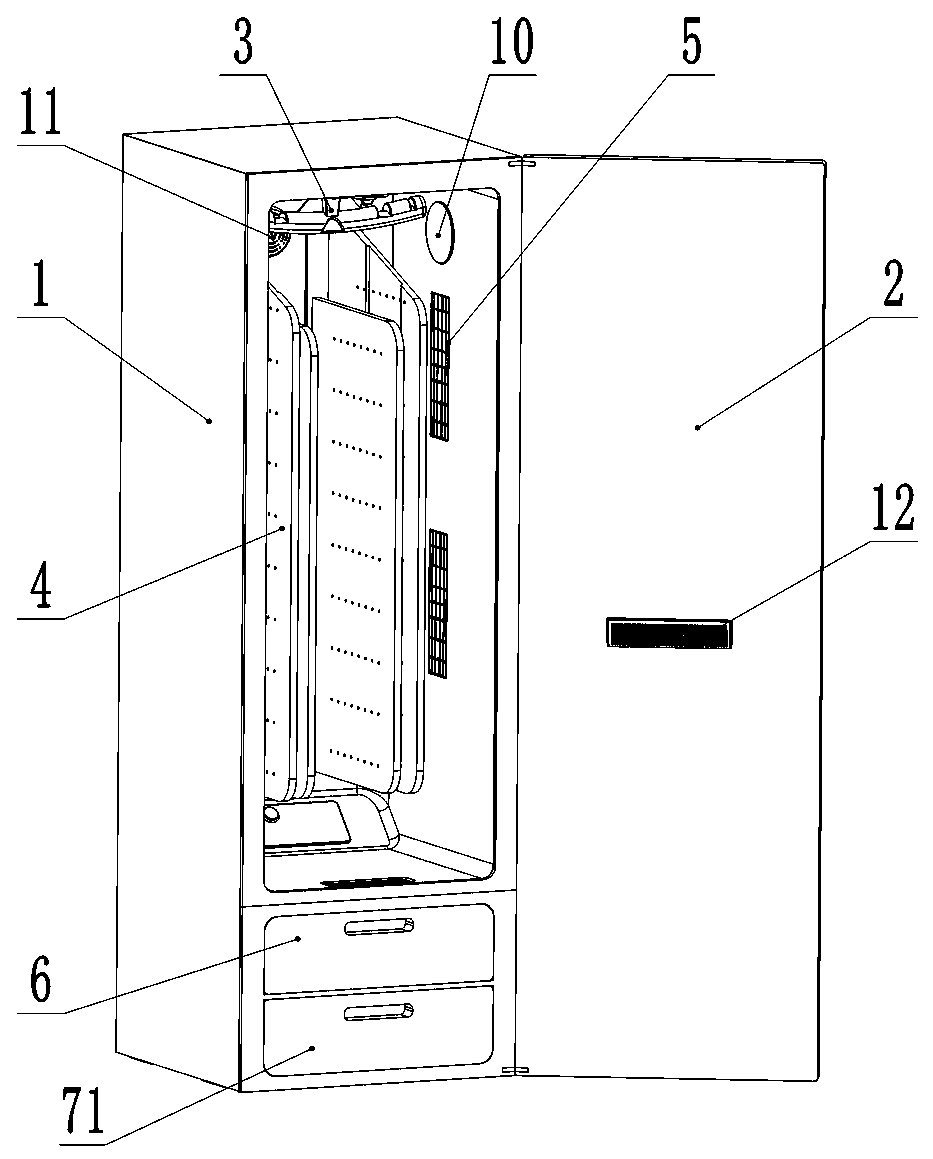

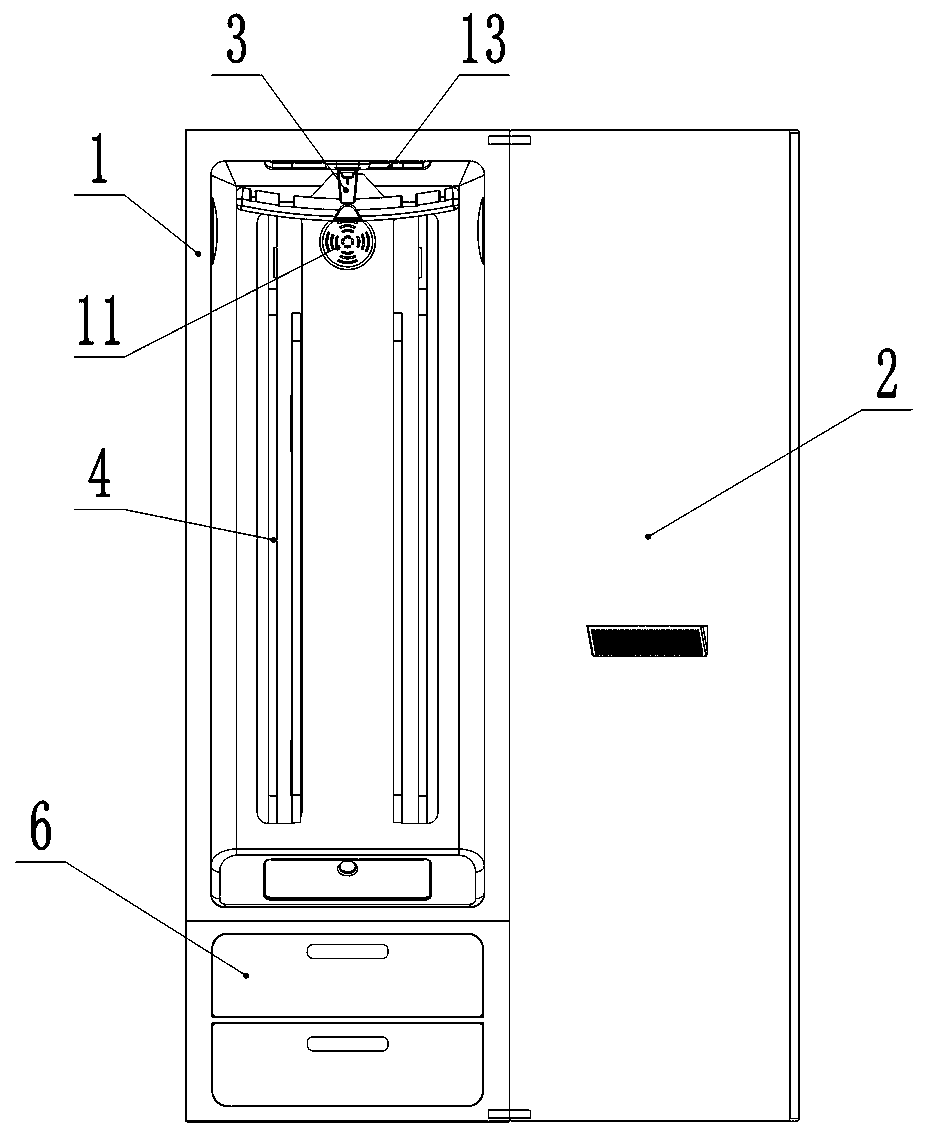

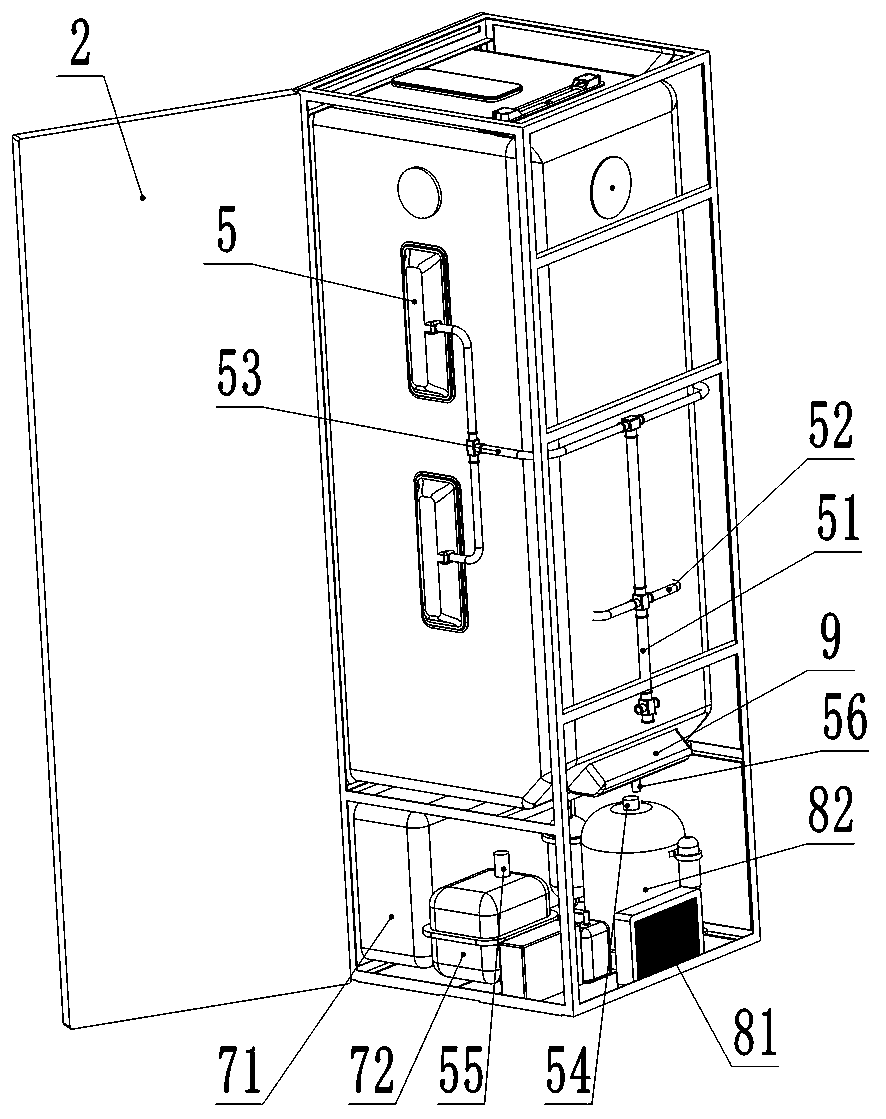

Clothing care machine

PendingCN109695146AImprove nursing effectConserve waterIroning apparatusTextiles and paperAir filterAgricultural engineering

The invention discloses a clothing care machine which comprises a shell, a sealing door, a drying device, an ironing device, a fan, a dry cleaning device, an air duct and a wind hood, wherein an ironing and drying chamber is formed in the shell; the drying device comprises an air filter and a heat exchange chamber; the heat exchange chamber is communicated with the air duct; a drainage bunker is arranged at the bottom of the ironing and drying chamber; the wind hood is fixed on the side wall of the wind hood; the ironing device comprises a water inlet tank and a steam generator; the steam generator is communicated with the air duct; the dry cleaning device comprises a dry cleaning agent storage box and an atomizer; the atomizer is communicated with the air duct; dry cleaning agents in thedry cleaning agent storage box enter the air duct via the atomizer and then are sprayed onto clothing in the ironing and drying chamber by virtue of the wind hood. According to the clothing care machine disclosed by the invention, the clothing can be subjected to dry cleaning and anti-wrinkle ironing, the comprehensive care ability of the product clothing is improved, and water usage and airing time can be saved.

Owner:郑州市恋日智能家居有限公司

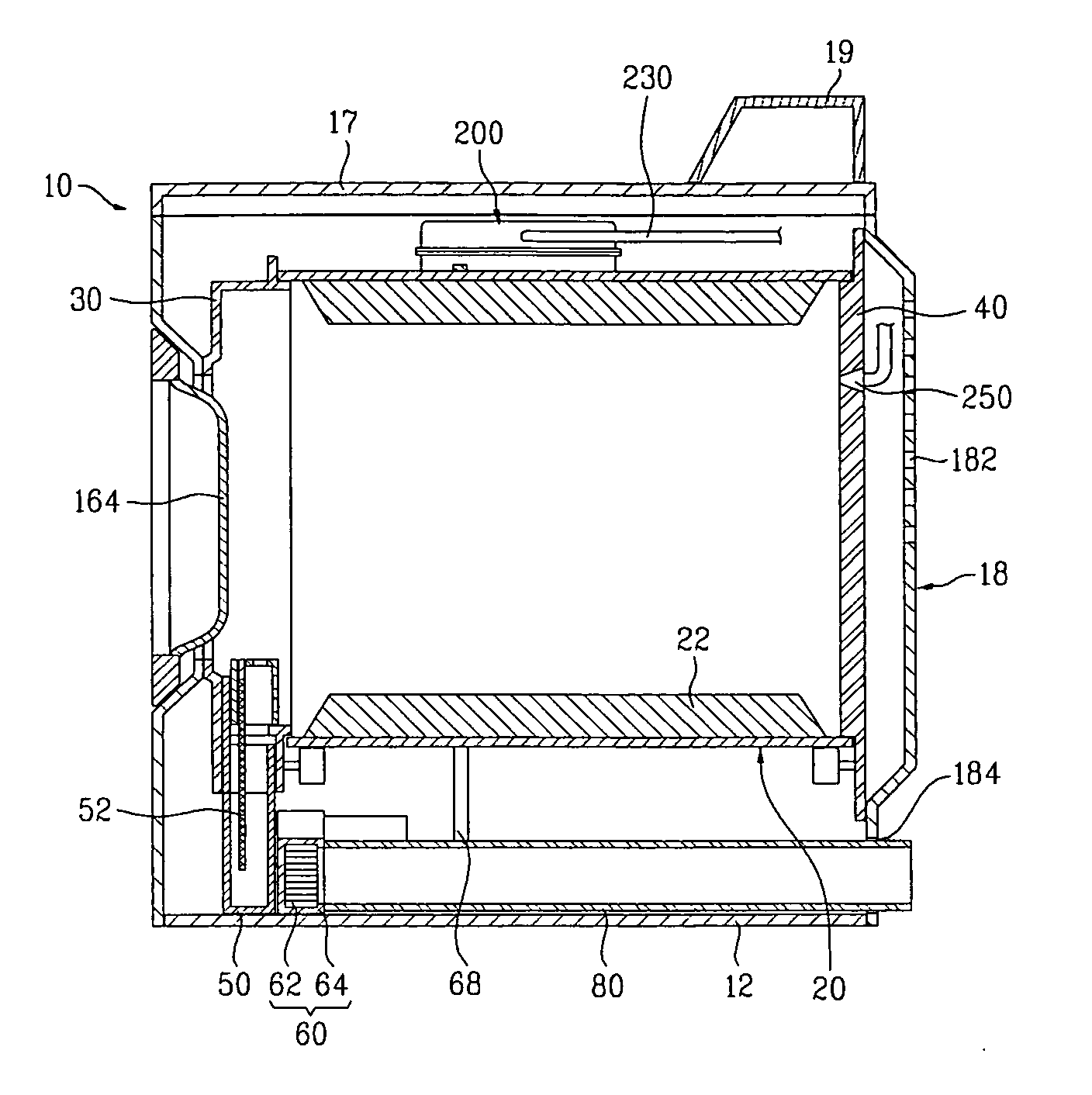

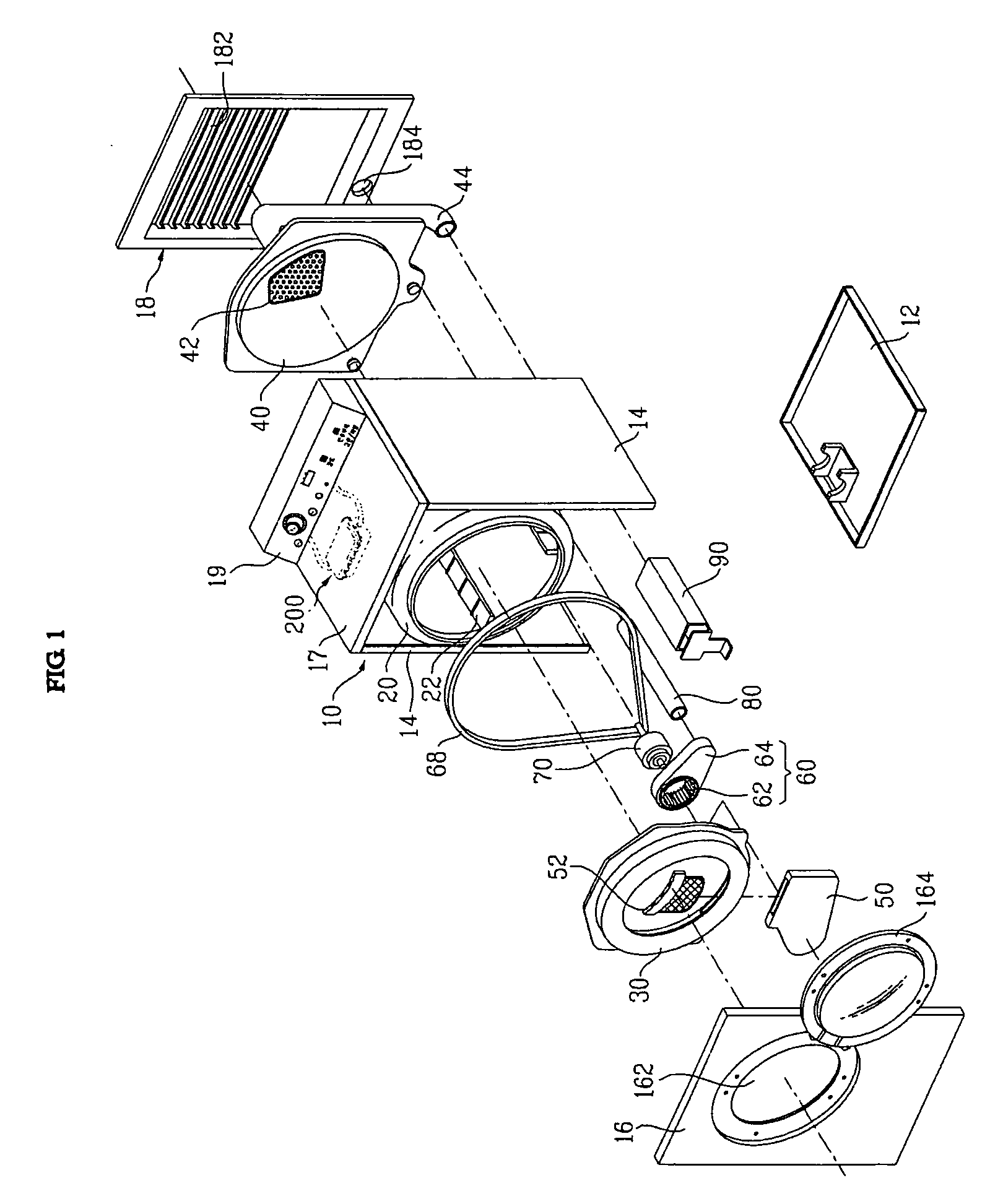

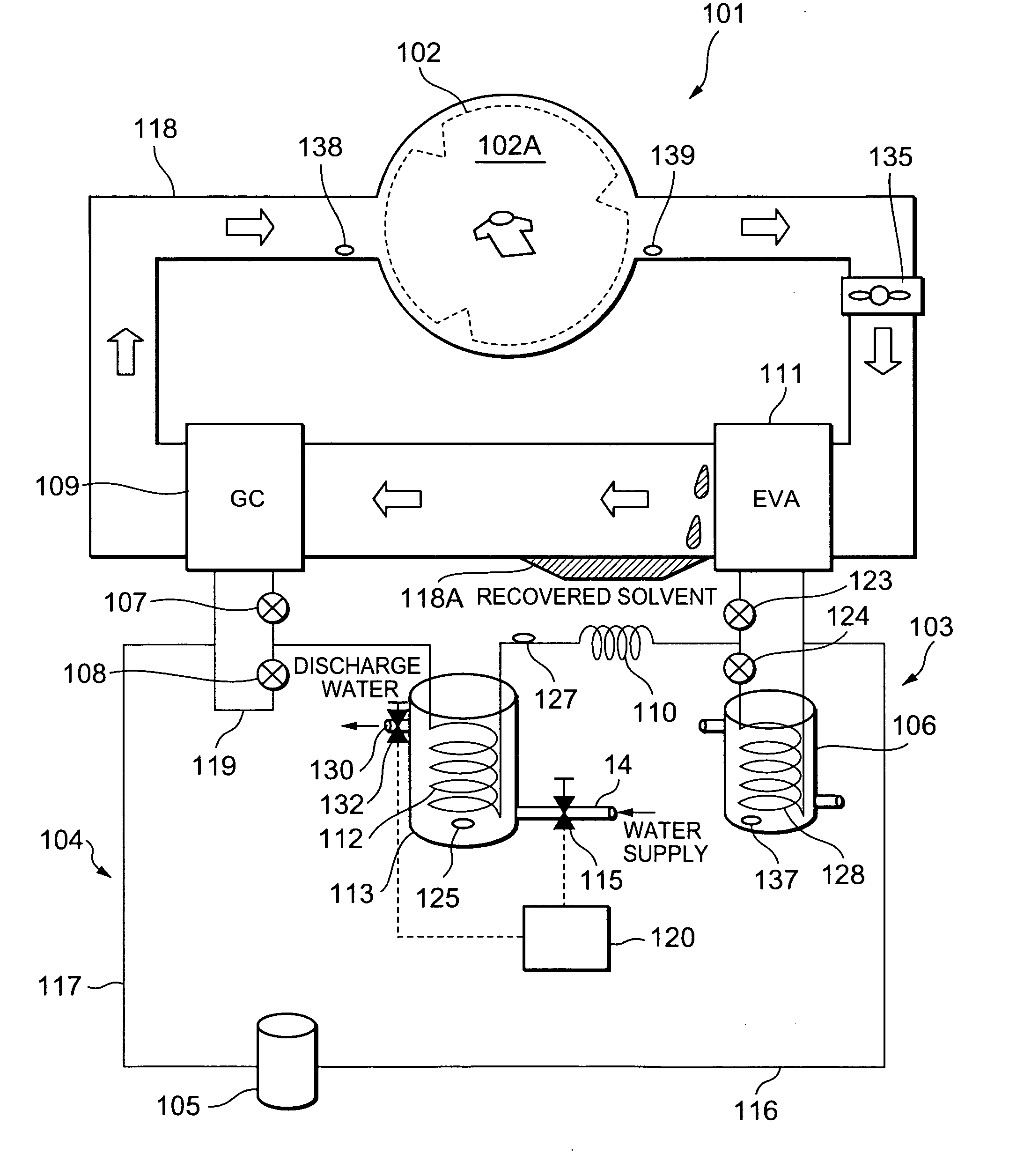

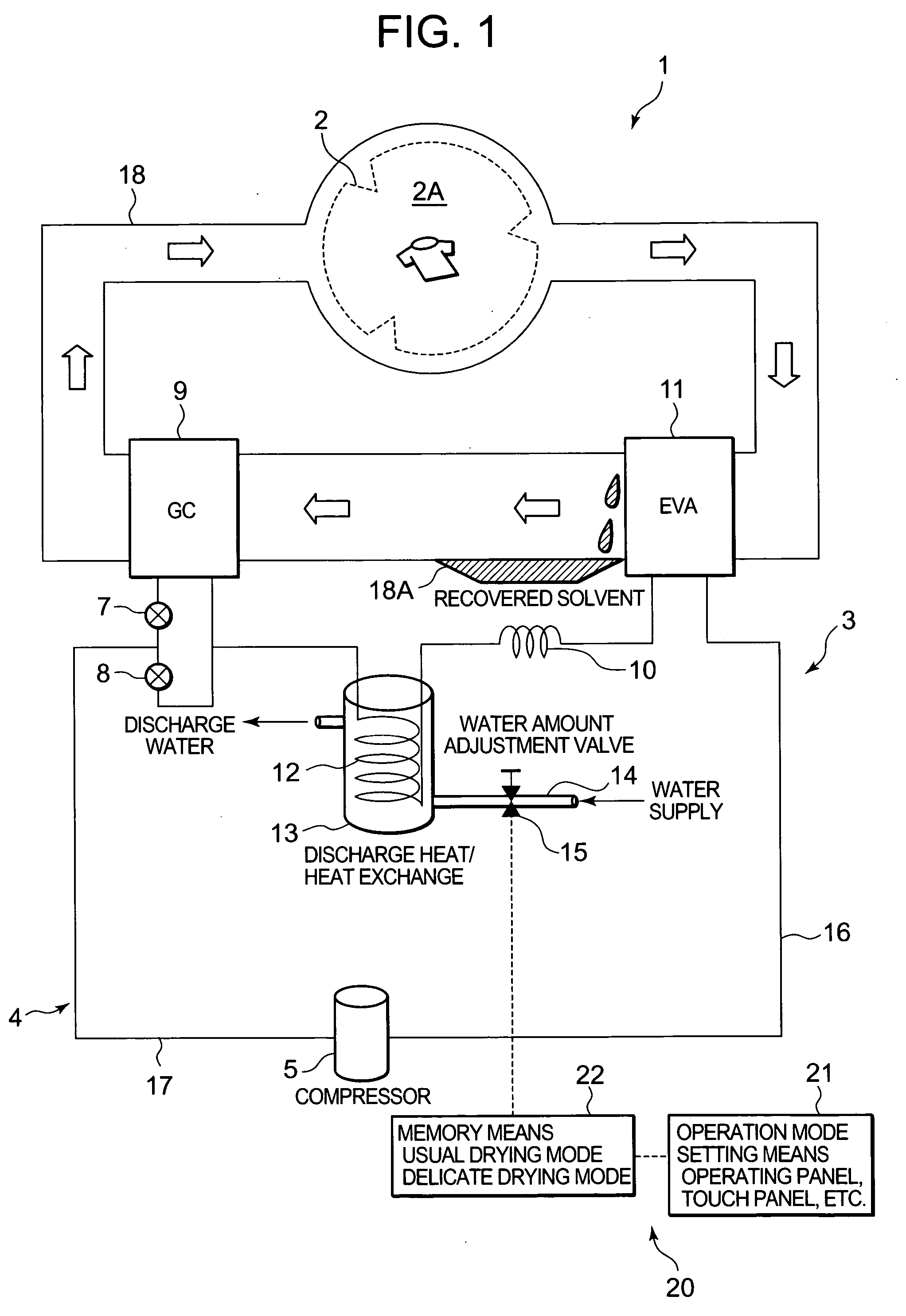

Dry cleaner and drying machine

InactiveUS20050199016A1Increase temperatureImprove energy efficiencyDry-cleaning apparatusDrying gas arrangementsProcess engineeringRefrigerant

An object is to provide a dry cleaner in which an installing operation is facilitated and in which environments are taken into consideration, and the dry cleaner rotates a drum containing clothing and successively executes a washing step using a washing liquid, a dewatering step, and a drying step. Heating and cooling units for executing the respective steps comprise a heat pump device, the washing liquid is heated by the heat pump device using carbon dioxide as a refrigerant of a refrigerant circuit constituting the heat pump device, the washing liquid is cooled by the heat pump device, air supplied to the drum in the drying step is heated by the heat pump device, and the air discharged from the drum in the drying step is cooled by the heat pump device.

Owner:SANYO ELECTRIC CO LTD

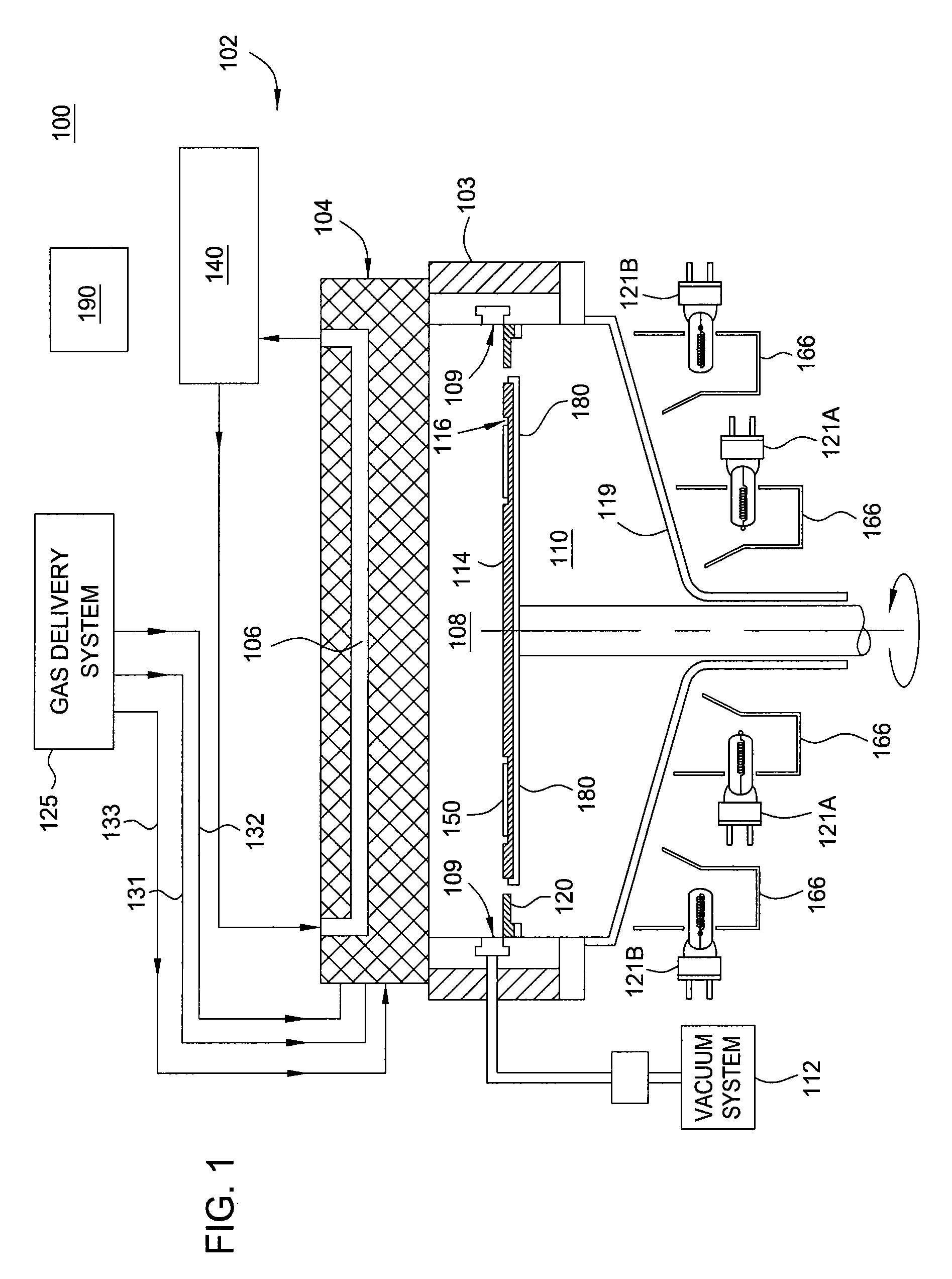

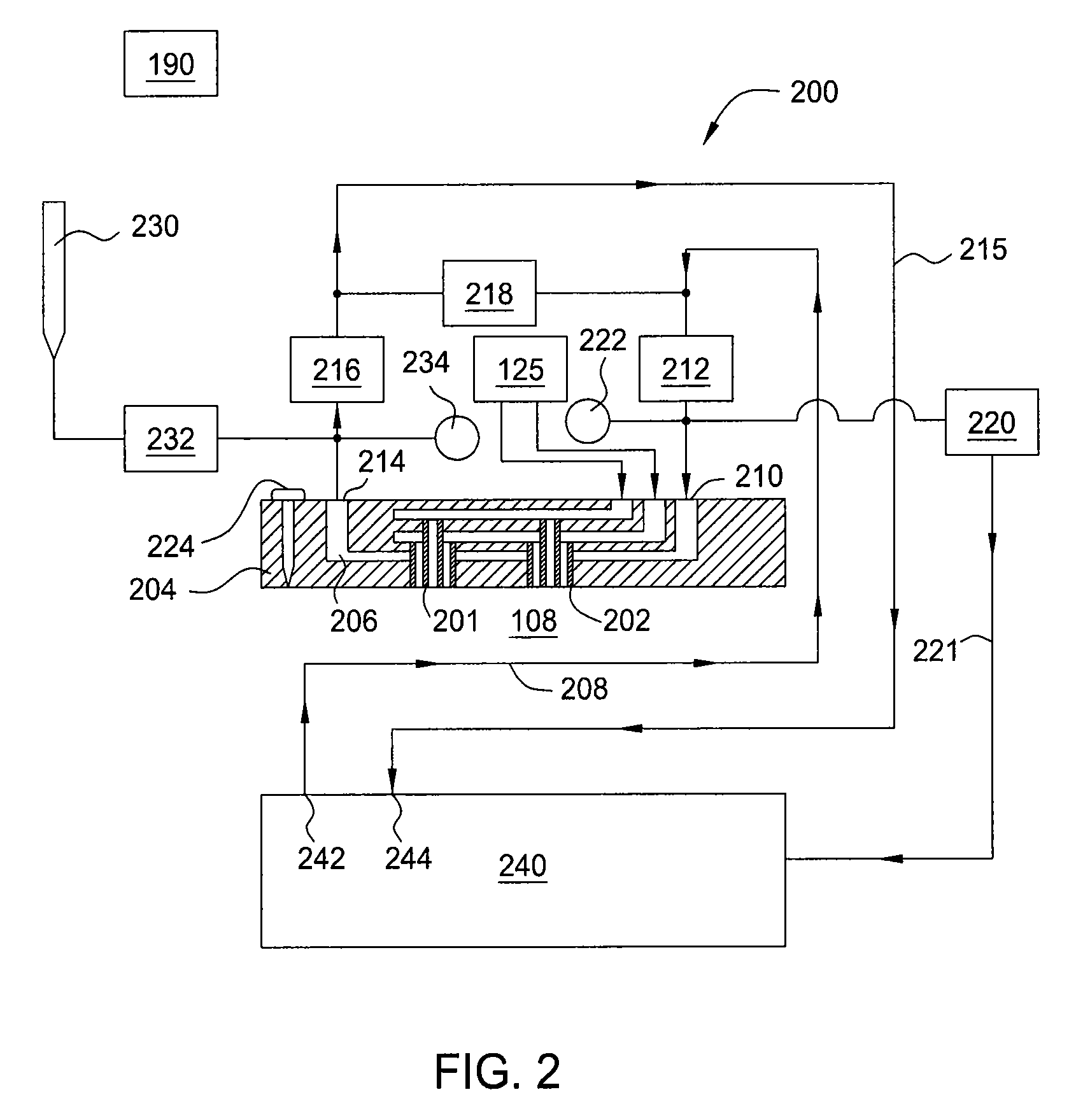

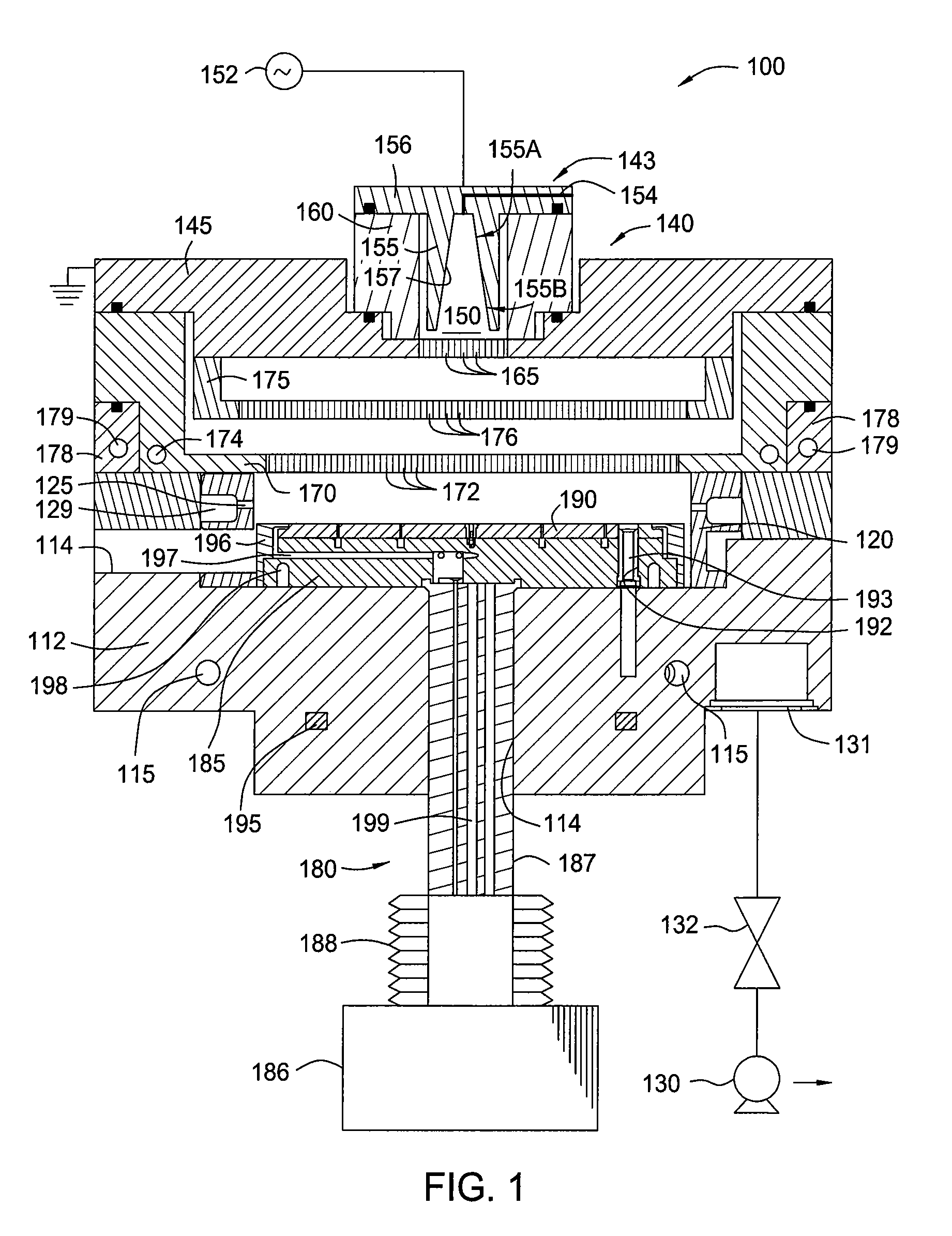

Method and apparatus for dry cleaning a cooled showerhead

InactiveUS20110030615A1Reduce the temperatureLiquid surface applicatorsLighting and heating apparatusNuclear engineeringChemical vapor deposition

The present invention generally provides a method and apparatus for cleaning a showerhead of a deposition chamber, such as a metal organic chemical vapor deposition (MOCVD) chamber. In one embodiment, the showerhead is cleaned without exposing the chamber to the atmosphere outside of the chamber (i.e., in situ cleaning). In one embodiment, flow of liquid coolant through a cooling system that is in fluid communication with the showerhead is redirected to bypass the showerhead, and the liquid coolant is drained from the showerhead. In one embodiment, any remaining coolant is flushed from the showerhead via a pressurized gas source. In one embodiment, the showerhead is then heated to an appropriate cleaning temperature. In one embodiment, the flow of liquid coolant from the cooling system is then redirected to the showerhead and the system is adjusted for continued processing. Thus, the entire showerhead cleaning process is performed with minimal change to the flow of coolant through the cooling system.

Owner:APPLIED MATERIALS INC

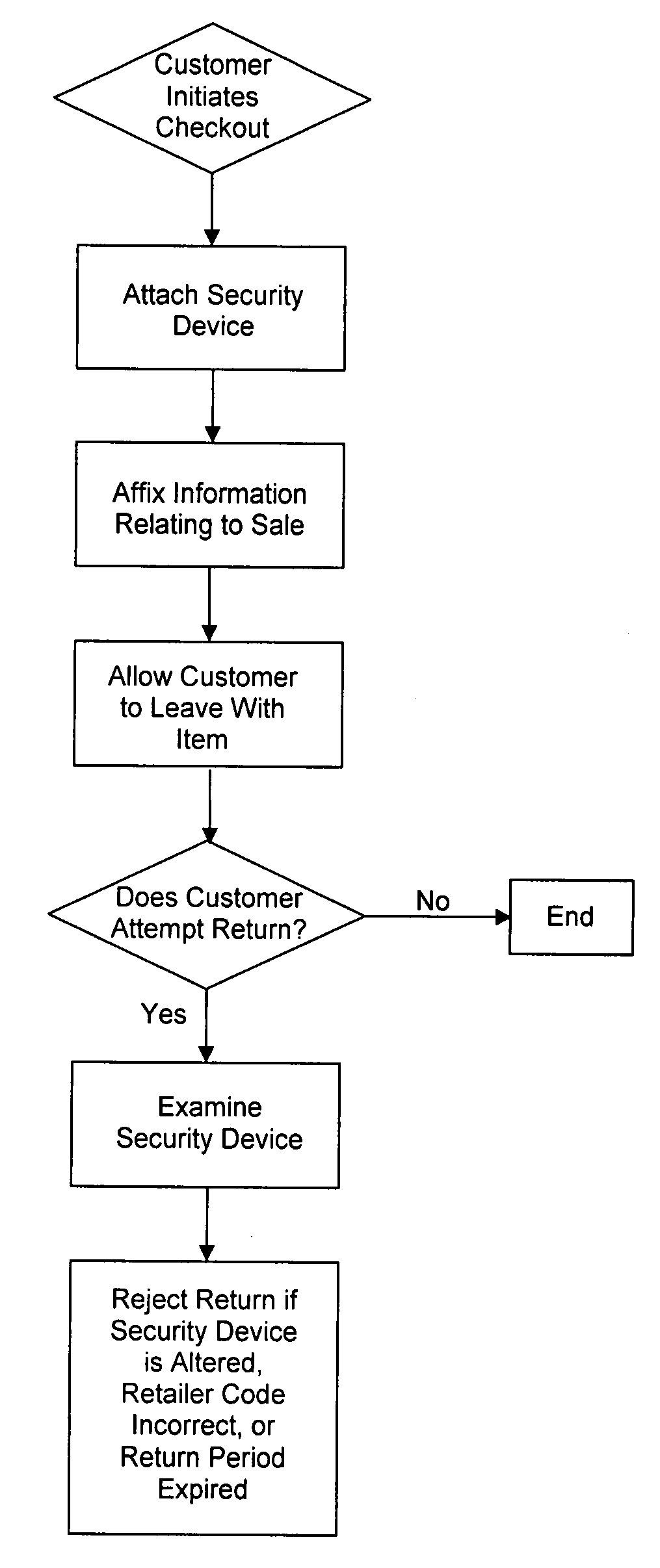

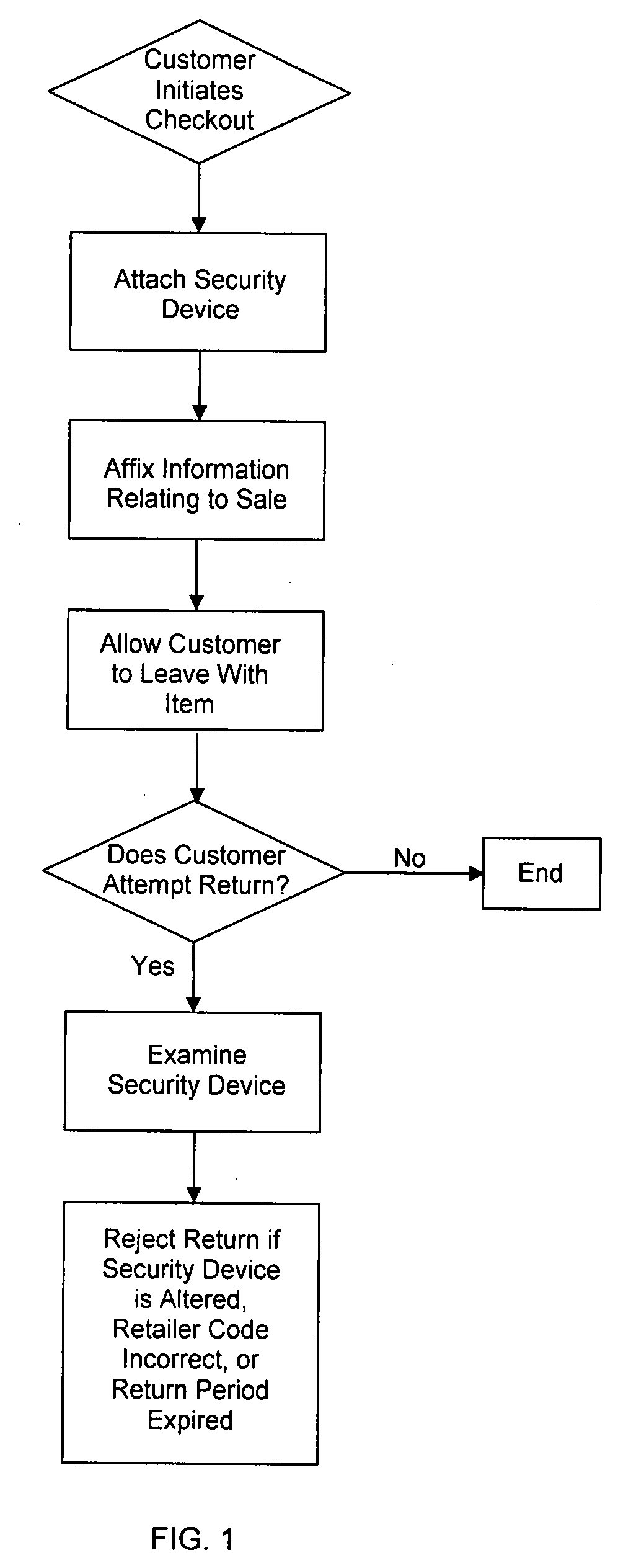

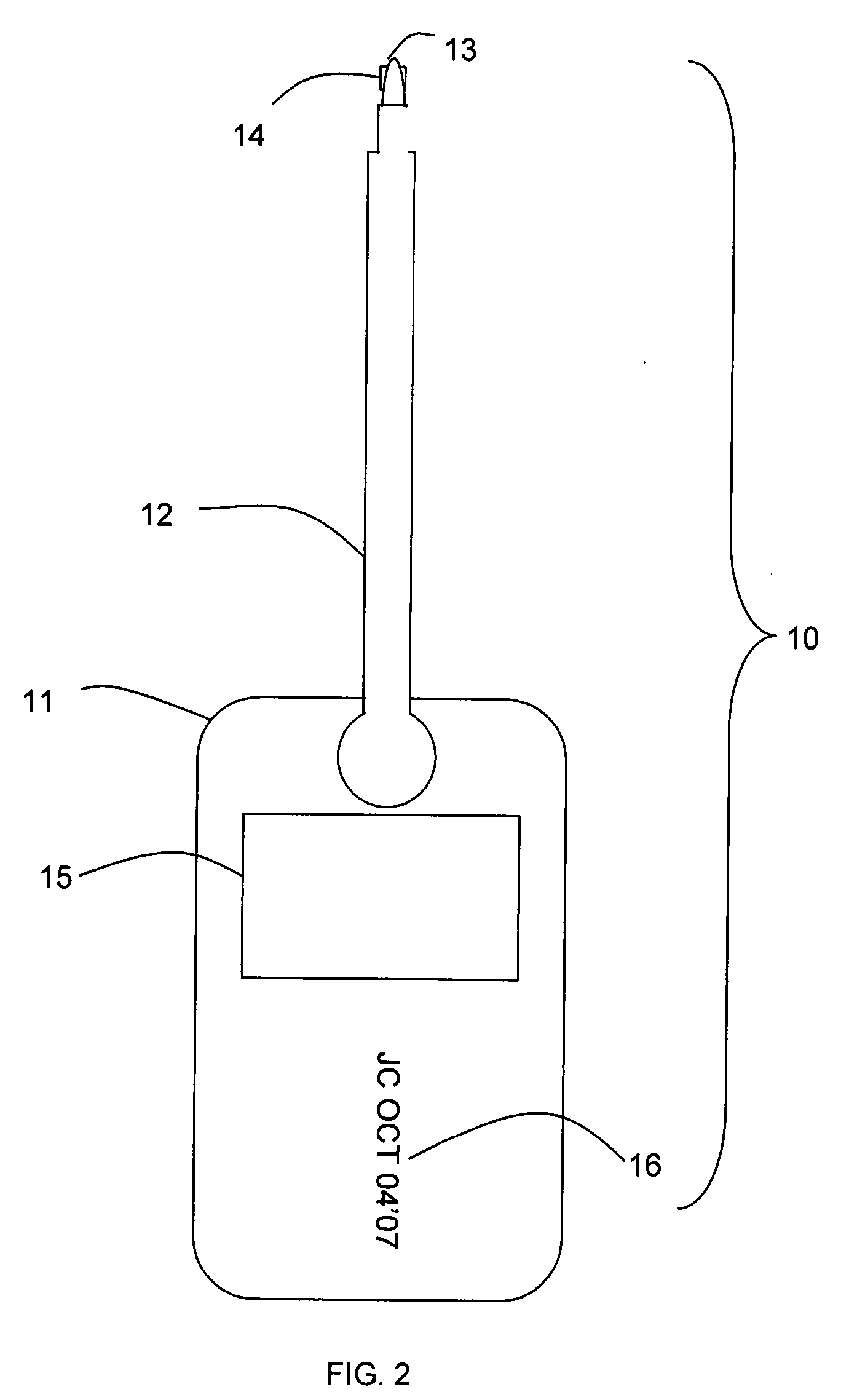

Merchandise tagging to prevent theft and fraud

InactiveUS20080048030A1Preventing retail return fraudInhibit wearVisual presentationBuying/selling/leasing transactionsTamper resistanceEngineering

A method for preventing retail return fraud is implemented by attaching a security tag to a customer's purchased garment at checkout or before the customer leaves the store. The security tag displays text stating that the merchandise cannot be returned to the retail store if the security tag is removed or if the security tag or garment is washed or dry-cleaned. The security tag is attached by a tamper-proof attachment mechanism, such as a loop tie. The security tag is large and ostentatious, and attached in a location on the garment that will discourage the customer from wearing it without removing the security tag. Immediately before attachment, the security tag is stamped by a stamping machine with a code designating the retail store and time and date of purchase, and may optionally be stamped with additional identifying information such as the sale price. If the customer attempts to return the item to the seller and the security device has been altered, the seller refuses to accept return.

Owner:GARNER RALPH

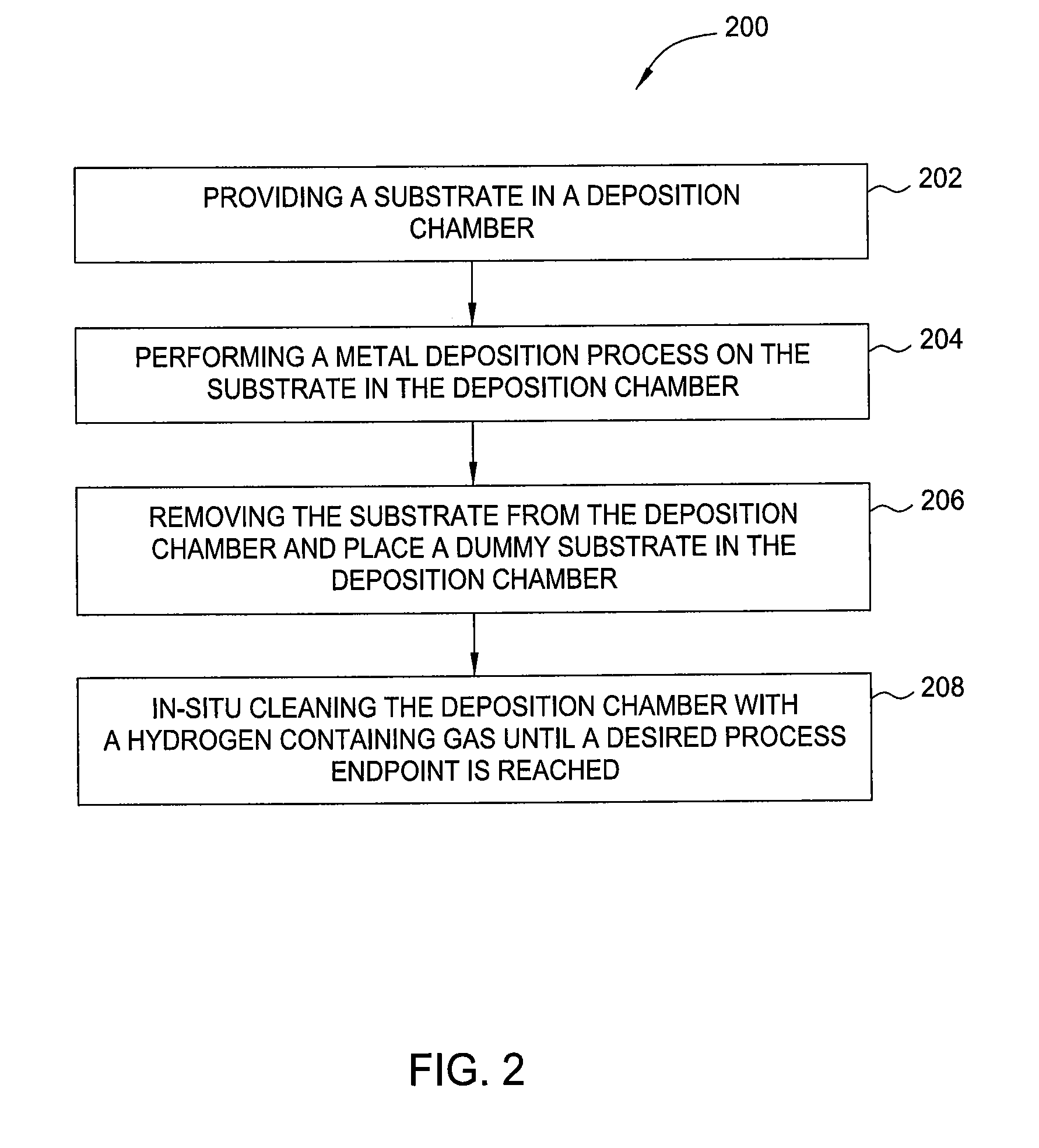

In-situ clean process for metal deposition chambers

Embodiments of the invention include methods for in-situ chamber dry clean for metal deposition chambers. In one embodiment, a method for in-situ chamber dry clean after a metal deposition process includes placing a substrate in a processing chamber, performing a metal deposition process on the substrate in the processing chamber, removing the substrate from the support pedestal, and performing an in-situ cleaning process by supplying a cleaning gas containing H2 to the processing chamber while a dummy substrate is disposed in the processing chamber

Owner:APPLIED MATERIALS INC

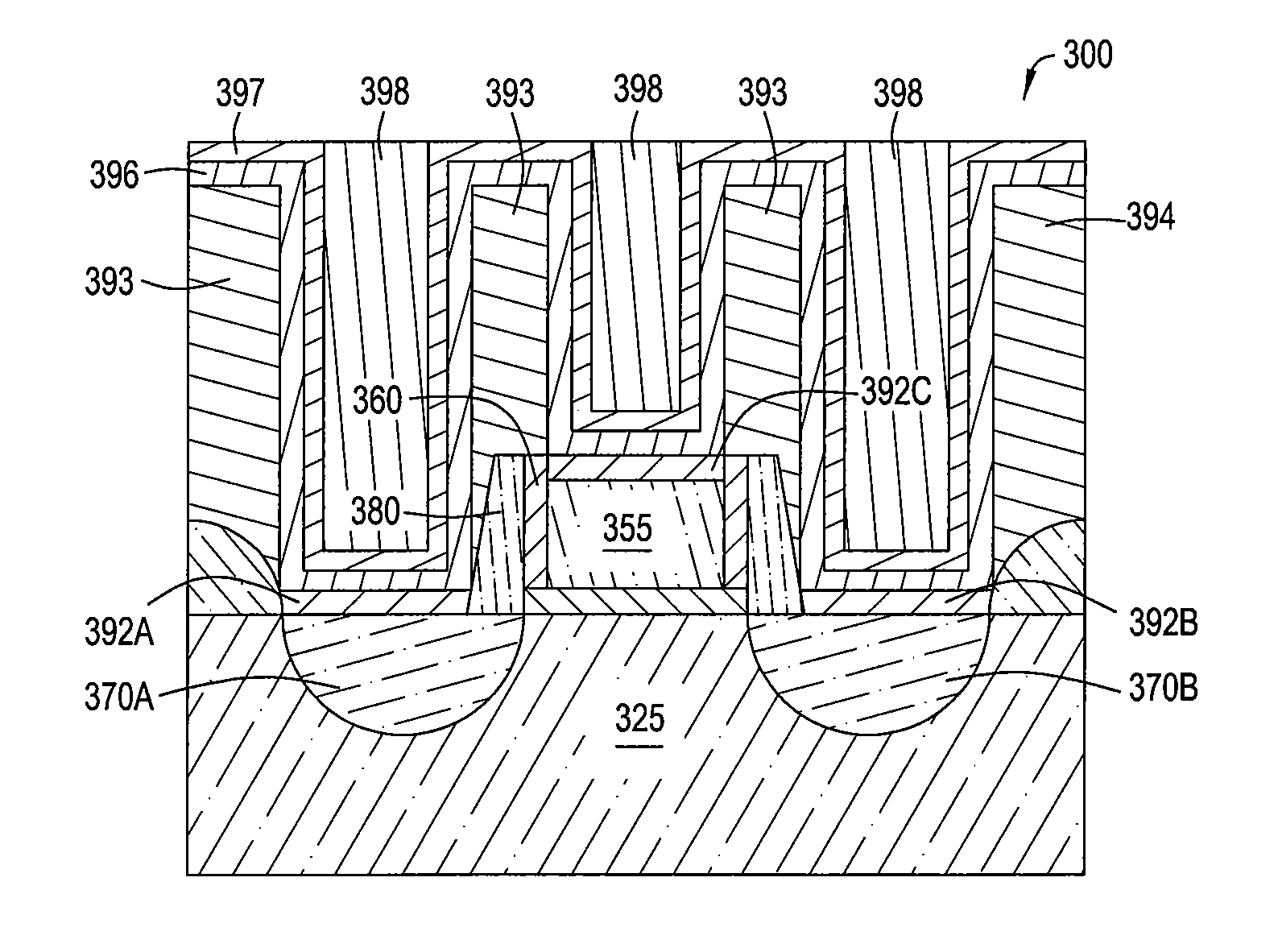

Process with saturation at low etch amount for high contact bottom cleaning efficiency for chemical dry clean process

InactiveUS20090191703A1Stay in shapeSemiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingCompound (substance)Distortion

A method for removing oxides from the bottom surface of a contact hole is provided. The method provides efficient cleaning of the bottom surface without distortion of the contact hole upper and sidewall surfaces.

Owner:APPLIED MATERIALS INC

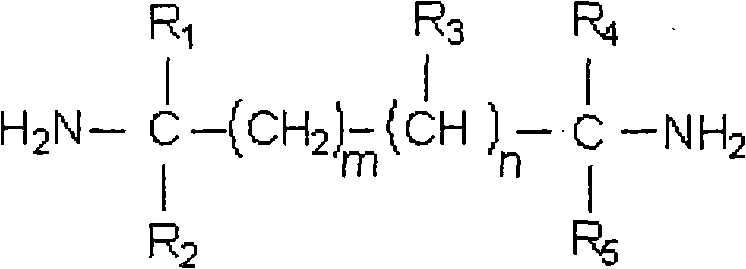

High temperature resistant water washing polyamide hot-melt adhesive for clothes and preparation method thereof

The invention provides a high temperature resistant water washing daiamid hot melt adhesive used for clothes and a method for preparing the same. The preparing method comprises the following steps that: aliphatic dicarboxylic acid with 5 to 12 carbon atoms, aliphatic monocarboxylic acid with 5 to 12 carbon atoms, aliphatic diamine with 6 to 15 carbon atoms, lactam with 6 to 12 carbon atoms, water and a stabilizing agent react and are dehydrated to discharge so that the daiamid hot melt adhesive is obtained. The daiamid hot melt adhesive used for the clothes has the characteristics of small range of molecular weight, rapid solidification and excellent high temperature resistant water washing performance, etc. Chain diamine with more than one carbon atom is selected as the formula of the hot melt adhesive, thereby greatly improving the water resisting property and solvent resisting property; the loss rate of the peeling strength of the product which is washed by water containing soda at a temperature more than 80 DEG C is less than 20 percent and the loss rate of the peeling strength of the product which is dry-cleaned by tetracarp is less than 10 percent.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD

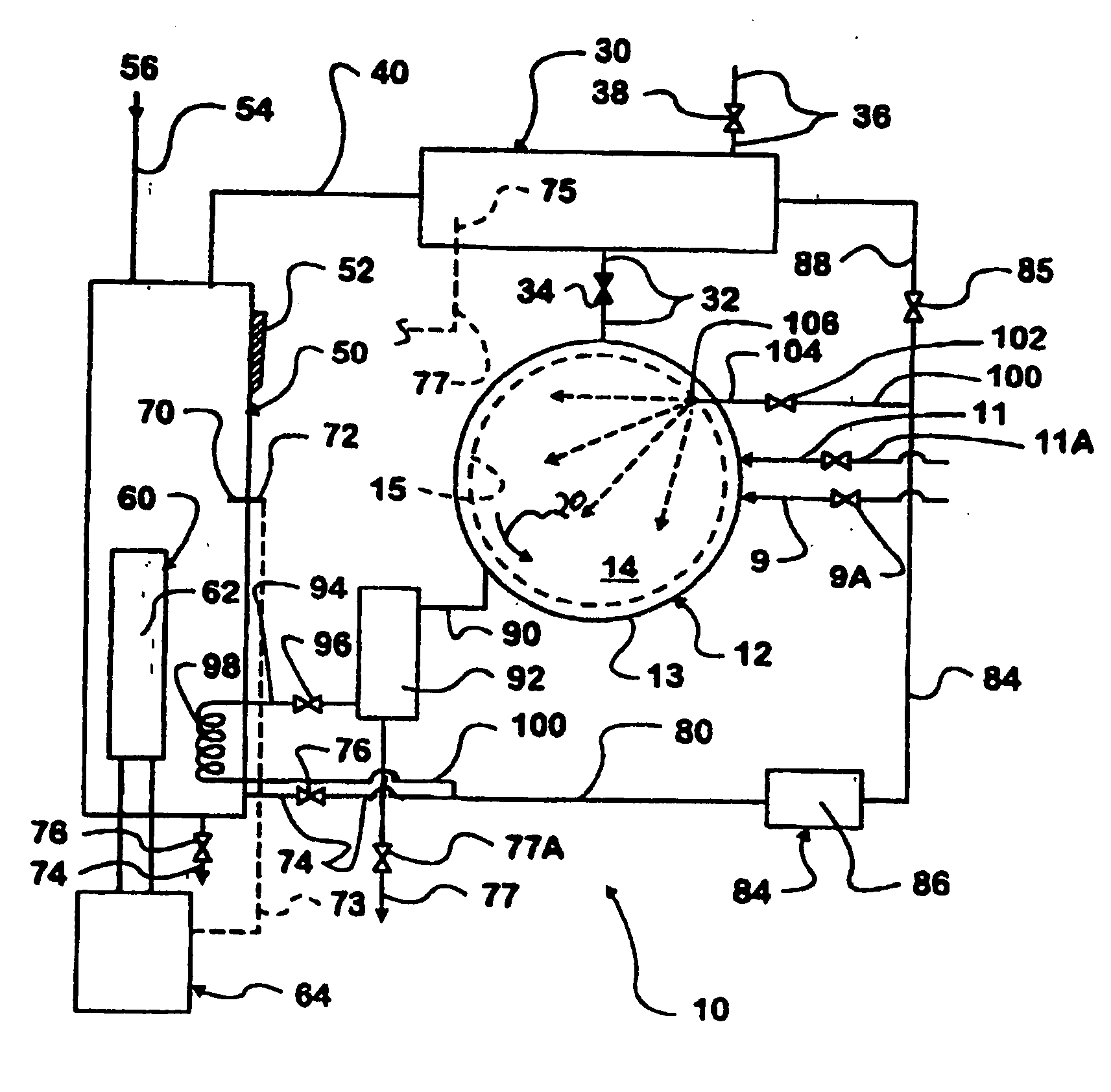

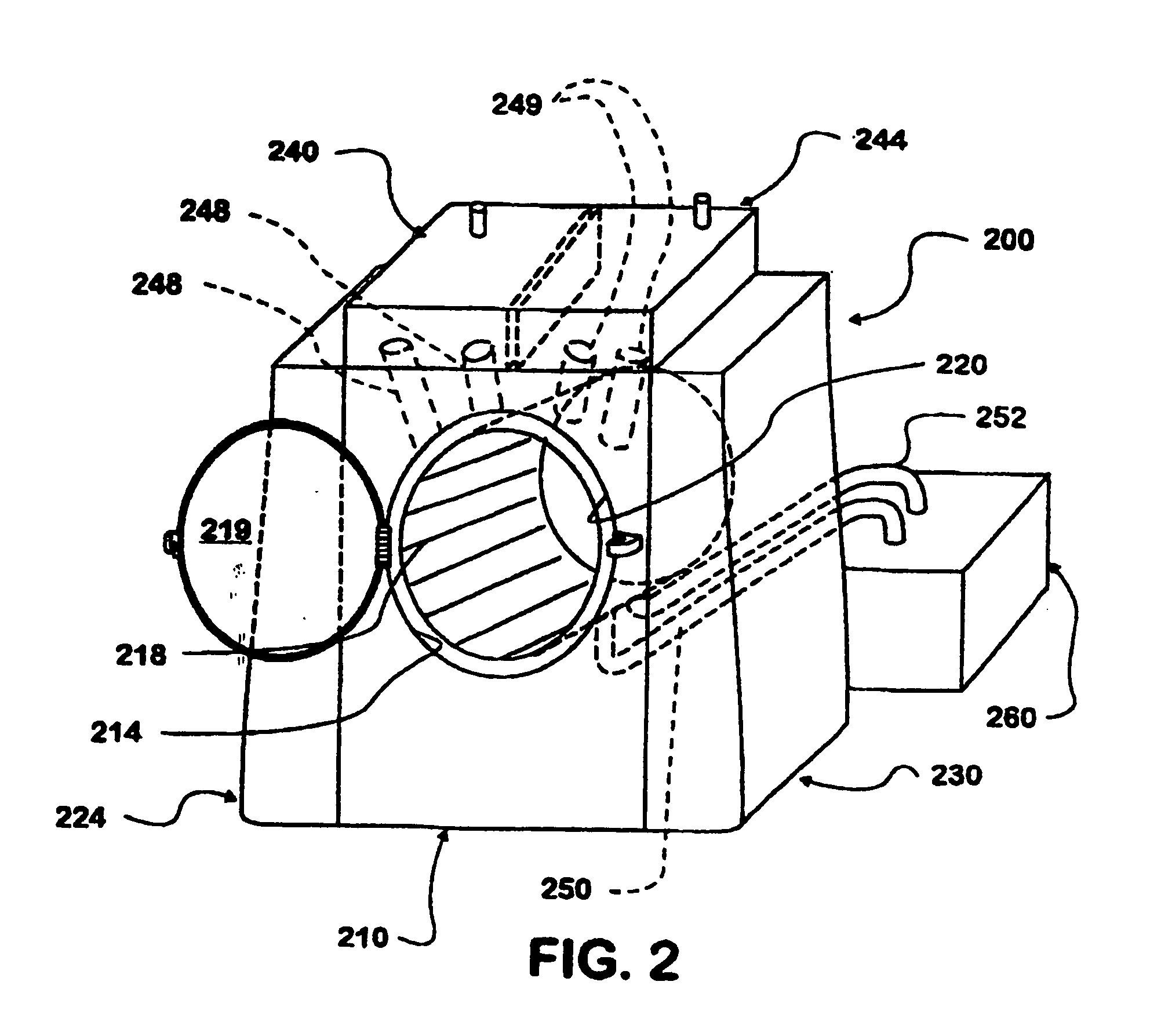

Washer method and apparatus

InactiveUS20070130698A1Improve washing effectIncrease water flow areaOther washing machinesTextiles and paperEngineeringRefrigeration

An improved washer (10, 210, 710) having a quick fill (32, 34) and a quick drain (36, 38) with reduced overall wash time is provided. Means are provided for doing a very cold wash to permit machine washing of fine clothing that heretofore was hand washed or dry cleaned. The washer (10, 210, 710) can be provided with one (30), two (224, 230) or three tanks (750A, B & C, 950A, B & C) for water at three temperatures, very cold (refrigerated), tap or city water supply temperature, or hot water. The very cold can be made by a refrigeration or chilling means (62, 64, 98), located in or adjacent the very cold water tank. The hot water can be provided from or have a heater (230, 320, 750C, 950C) therein one of the tanks. The washer also includes an improved embossed basket (600) with increased surface area. The features can be built into a new washer or retrofitted into an existing washer. Very cold water wash and rinse can be provided so that cloths, and particularly clothes such as made of wool, rayon, acetate or other clothes, such as leathers or furs, usually dry cleaned or hand washed, can be machine washed with the present invention without use of hazardous chemicals or shrinkage.

Owner:KIM SU HEON

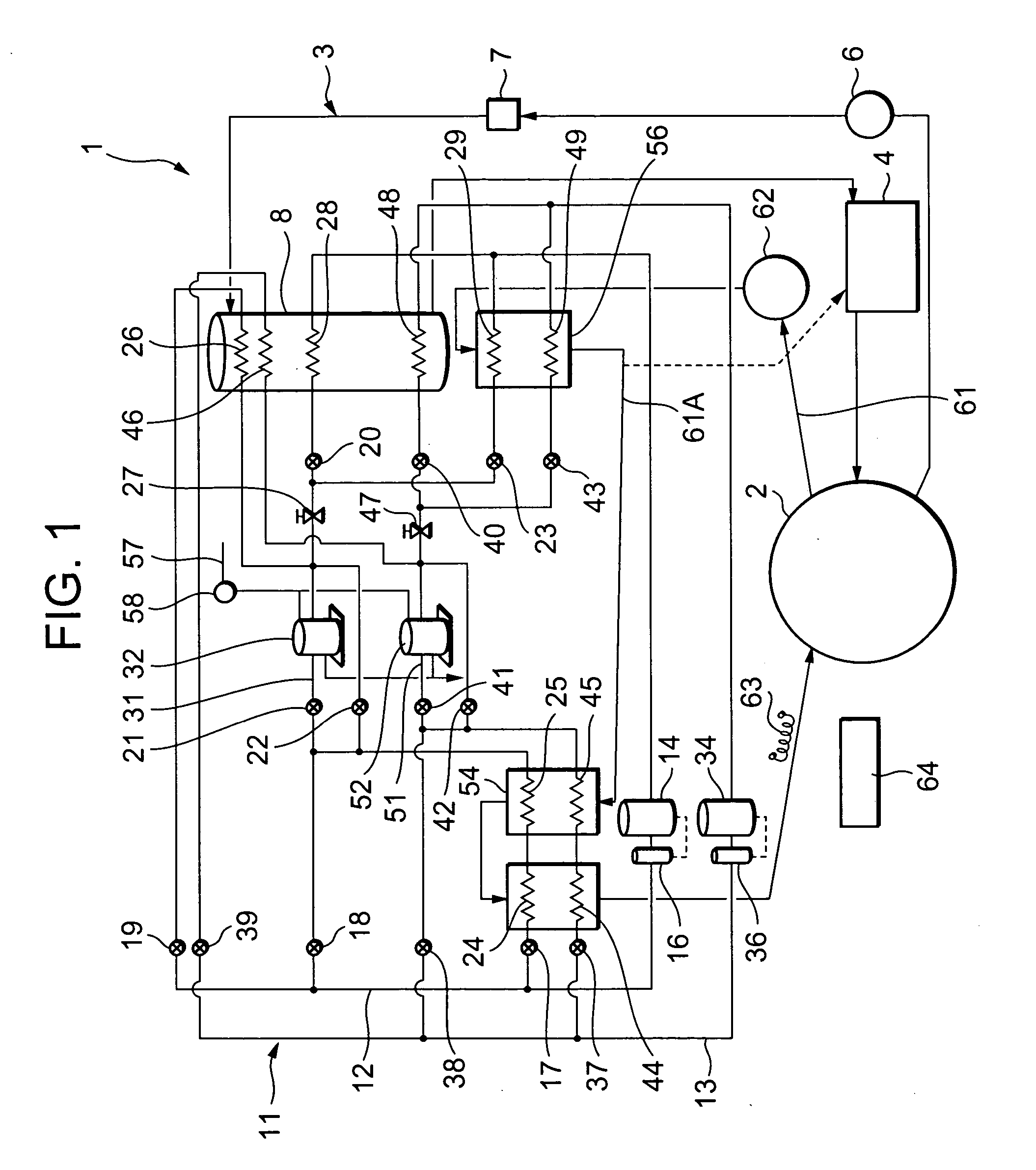

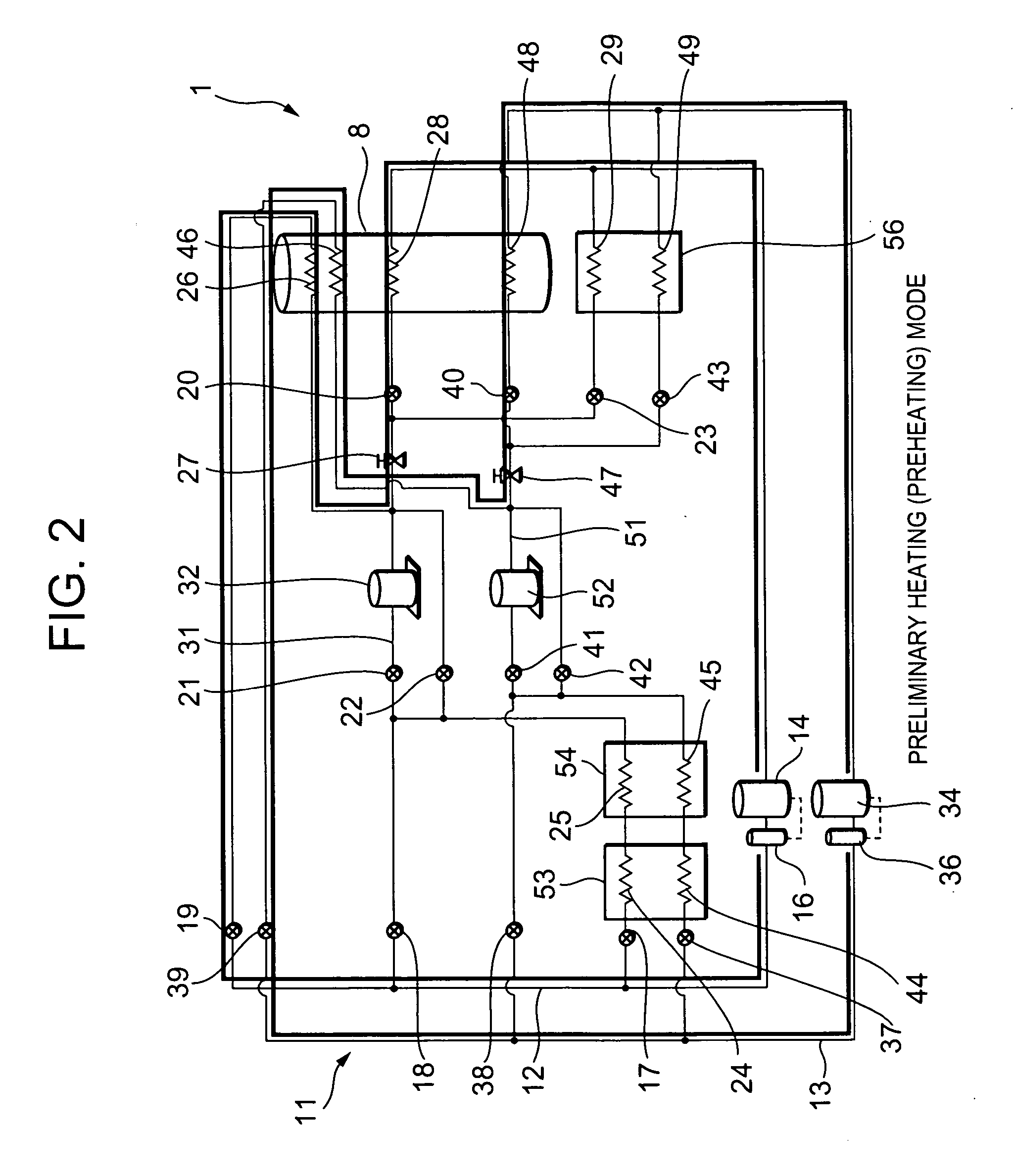

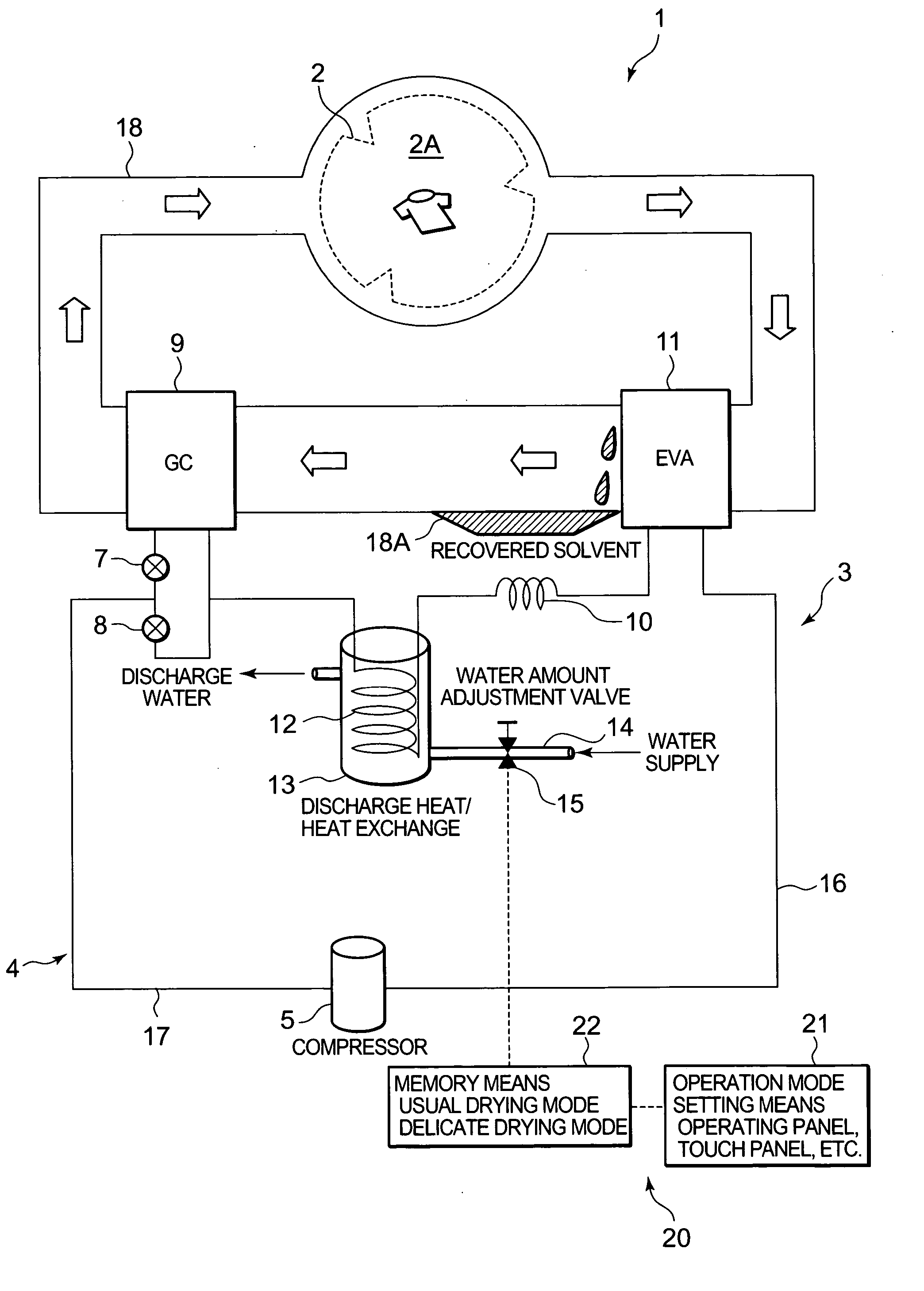

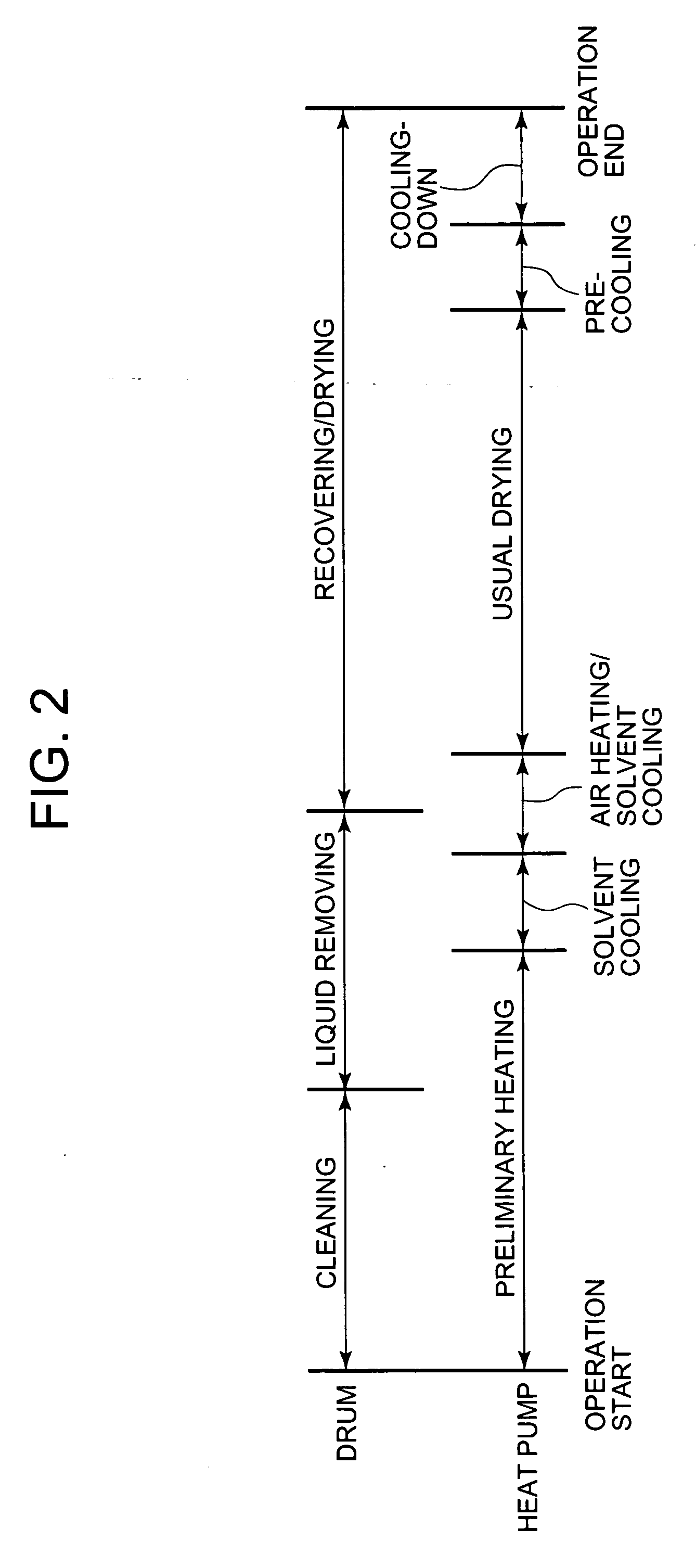

Drying machine

InactiveUS20060053651A1Reduce cooling effectReduce the temperatureDrying solid materials with heatDry-cleaning apparatusPlate heat exchangerProcess engineering

An object is to provide a drying machine which can accomplish delicate drying and reduce burdens on a matter to be dried during drying while securing a predetermined evaporation temperature in an evaporator. In summary, a dry cleaner equipped with a heat pump device comprises a water-cooling heat exchanger which removes heat from a refrigerant entering a capillary tube; and a control device which variably controls a discharged heat amount in the water-cooling heat exchanger and capacity of the compressor, wherein the control device has at least two kinds of drying modes including a usual drying mode and a delicate drying mode, and in the delicate drying mode, a temperature of air discharged into a storage chamber is set lower than in the usual drying mode to control the capacity of the compressor and to increase the discharged heat amount in the water-cooling heat exchanger.

Owner:SANYO ELECTRIC CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com