Delicate dry clean

a technology of delicate dry cleaning and ppt, applied in the direction of decorative surface effects, electrical equipment, decorative arts, etc., can solve the problem of delicate alternatives to treatmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

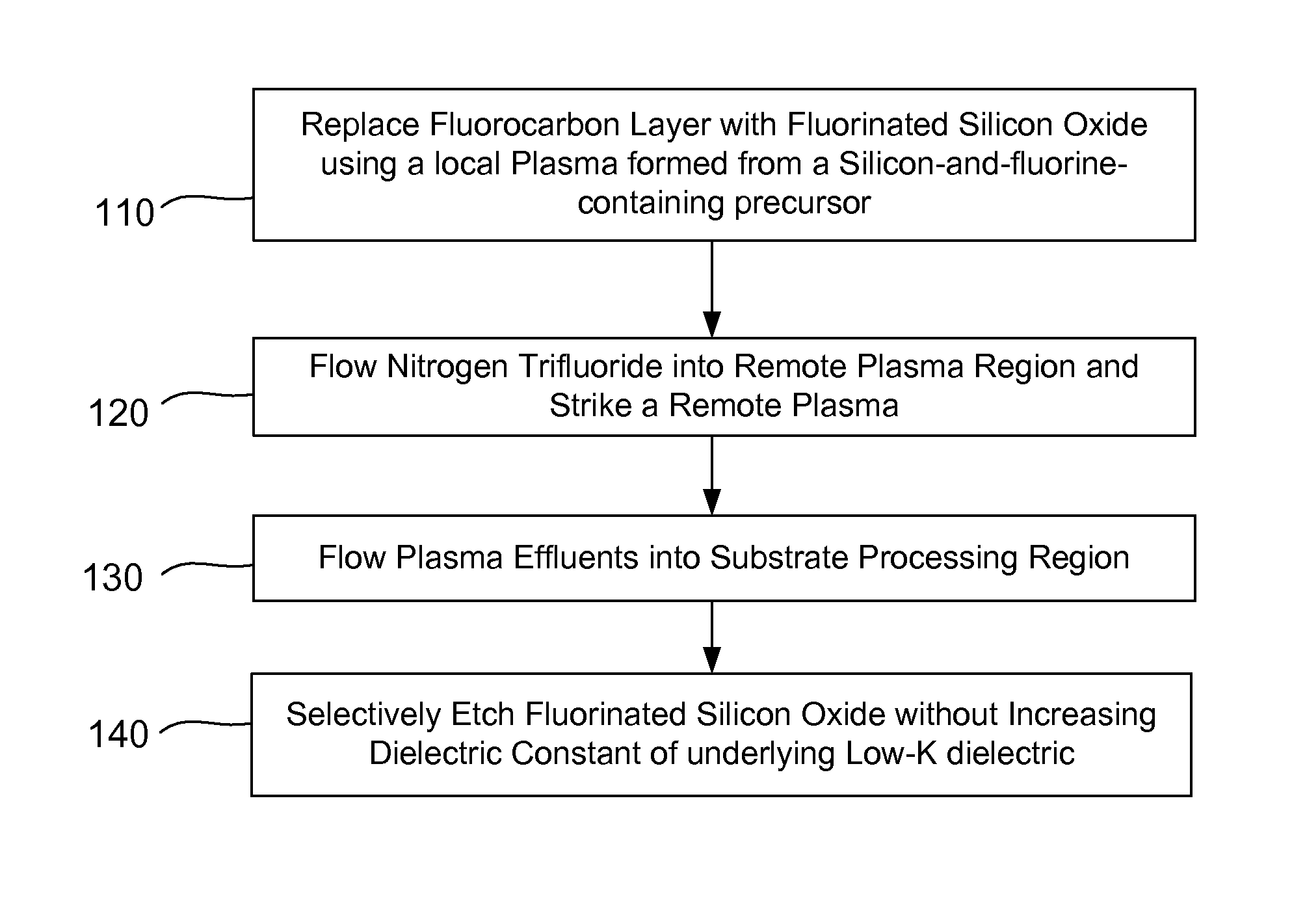

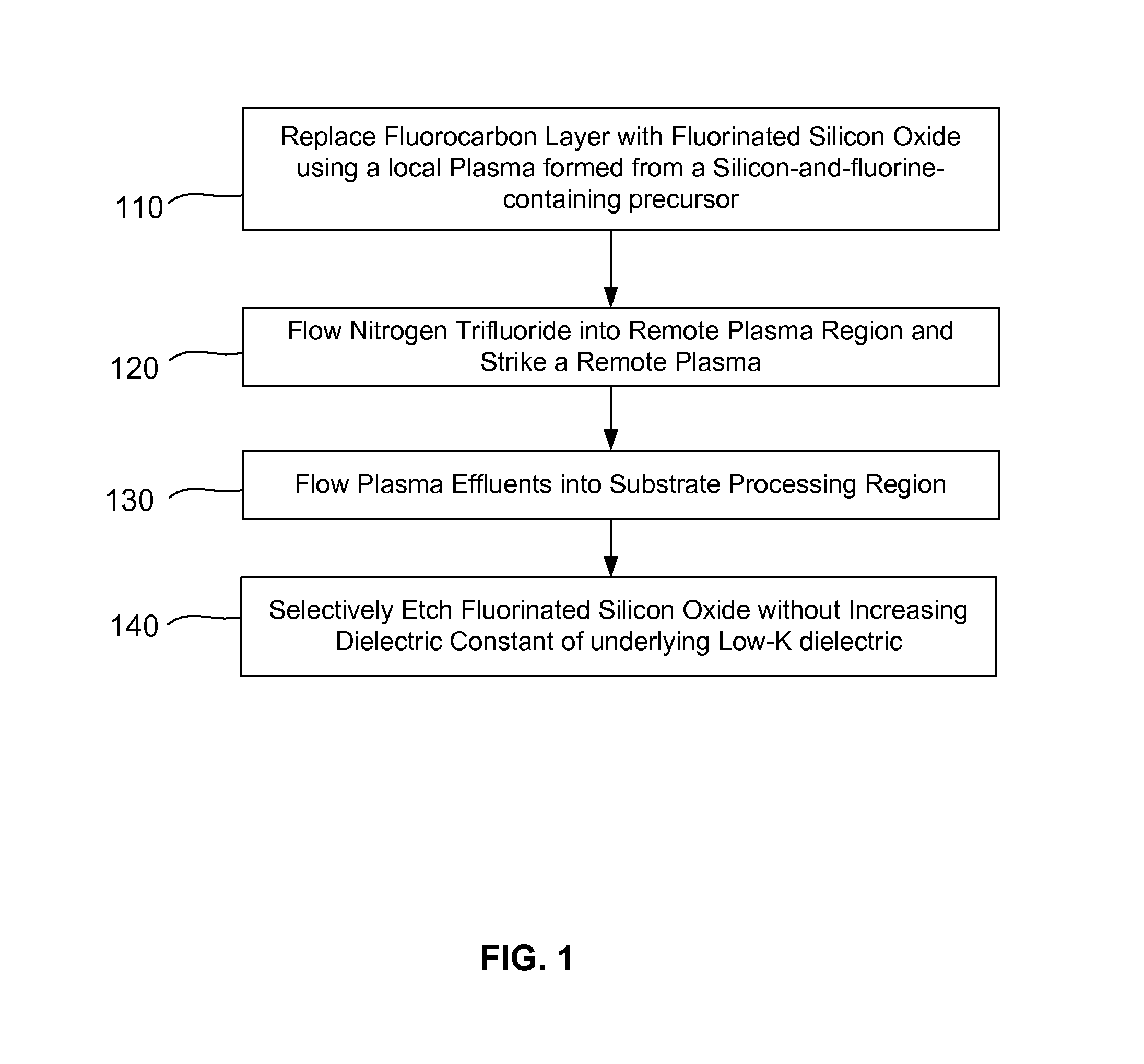

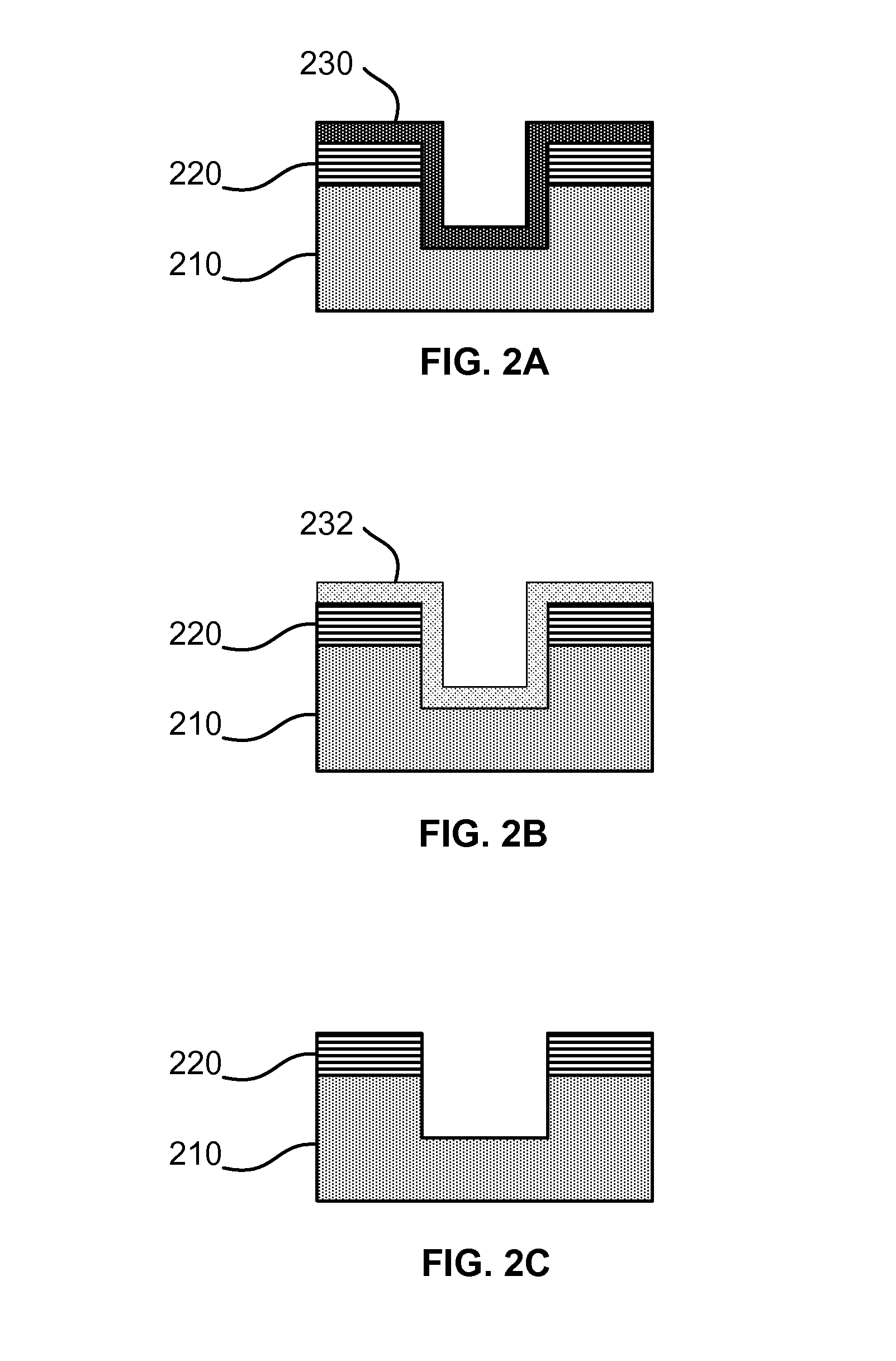

[0019]A method of selectively removing fluorocarbon layers from overlying low-k dielectric material is described. These protective plasma treatments (PPT) are delicate alternatives to traditional post-etch treatments (PET). The method includes sequential exposure to (1) a local plasma formed from a silicon-fluorine precursor followed by (2) an exposure to plasma effluents formed in a remote plasma from a fluorine-containing precursor. The remote plasma etch (2) has been found to be highly selective of the residual material following the local plasma silicon-fluorine exposure. The sequential process (1)-(2) avoids exposing the low-k dielectric material to oxygen which would undesirably increase its dielectric constant.

[0020]The inventors have found new ways to selectively remove dielectric etch remnants without harming underlying low-k and ultra low-k (ULK) dielectric material. A two-step sequence includes (i) a local plasma treatment step which transforms / replaces etch-remnant fluor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| plasma power | aaaaa | aaaaa |

| plasma power | aaaaa | aaaaa |

| RF power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com