Method and apparatus for processing a wafer

a technology of semiconductors and wafers, applied in the direction of photomechanical equipment, instruments, cleaning using liquids, etc., can solve the problems of affecting the yield of electronic circuits, and affecting the availability of other process chambers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] I) Dry / Wet Processing Tool

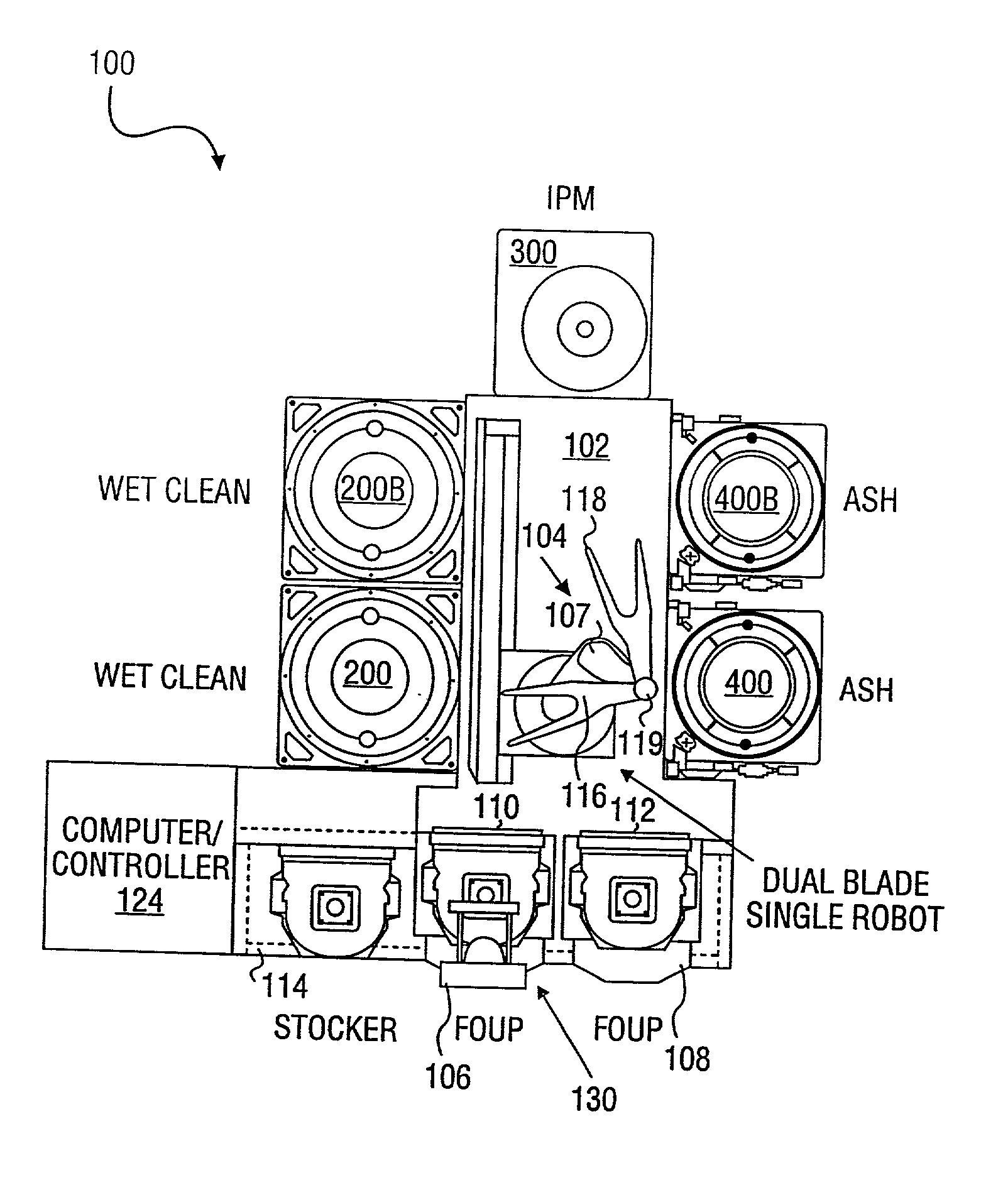

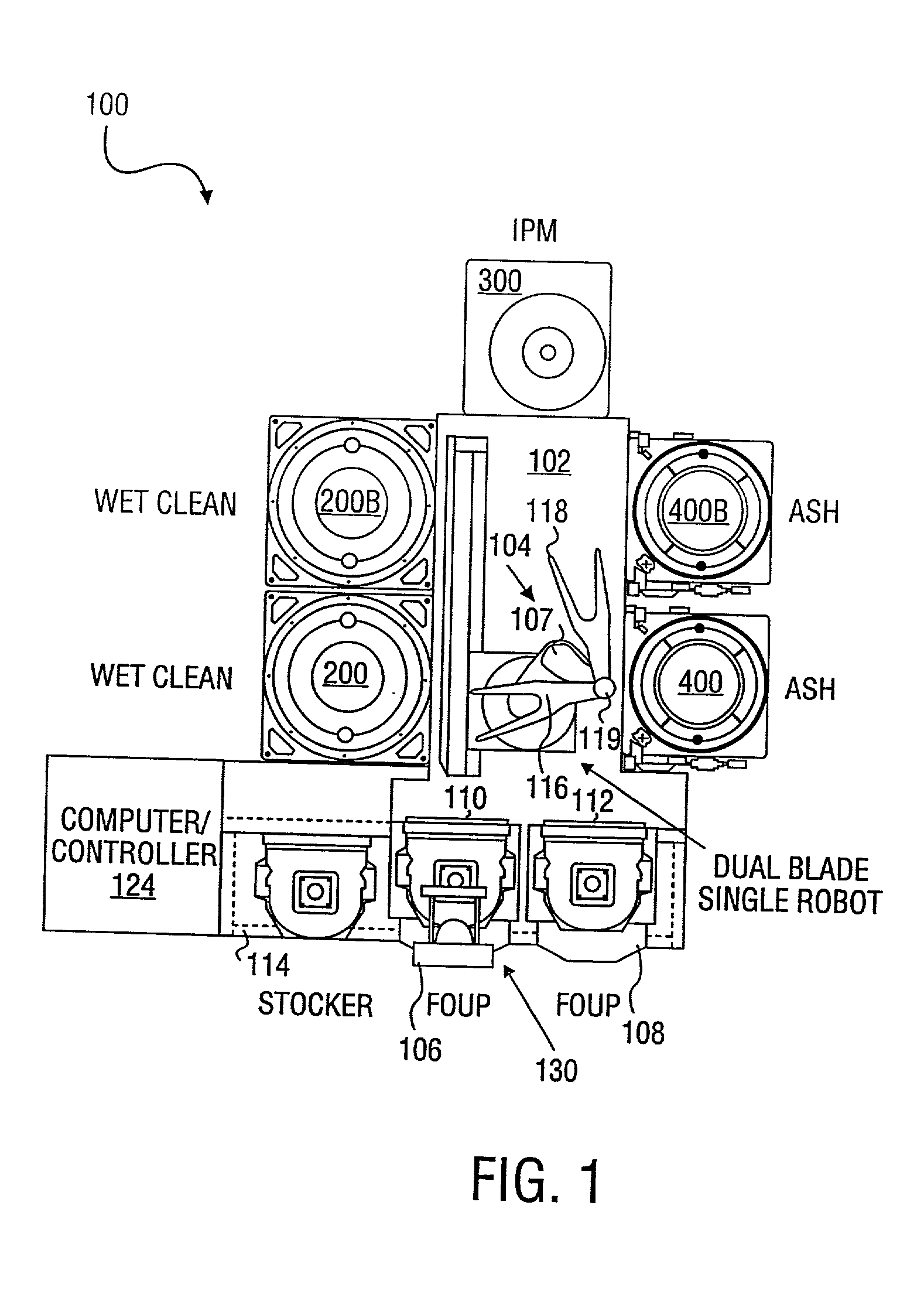

[0042] FIG. 1 illustrates an apparatus or system 100 for the stripping (ashing), wet cleaning and particle monitoring of a wafer during the manufacture of a semiconductor integrated circuit. The cleaning apparatus 100 includes a central transfer chamber 102 having a wafer handling device 104 contained therein. Directly attached to transfer chamber 102 is a single wafer wet cleaning module 200, a strip module 400, and an integrated process monitoring tool 300, such as an integrated particle monitor. Wet cleaning module 200, strip module 400, and integrated particle monitor 300 are each connected to transfer chamber 102 through a separately closable opening. In an embodiment of the present invention, a second wet cleaning module 200B and / or a second strip module 400B are also coupled to transfer chamber 102. In an embodiment of the present invention, transfer chamber 102 is maintained at substantially atmospheric pressure (i.e., atmospheric transfer ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Dielectric polarization enthalpy | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com