Dry cleaner and drying machine

a technology of drying machine and dryer, which is applied in the field of drying machine, can solve the problems of environmental problems, remarkably difficult installation operation such as piping work, and poor generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

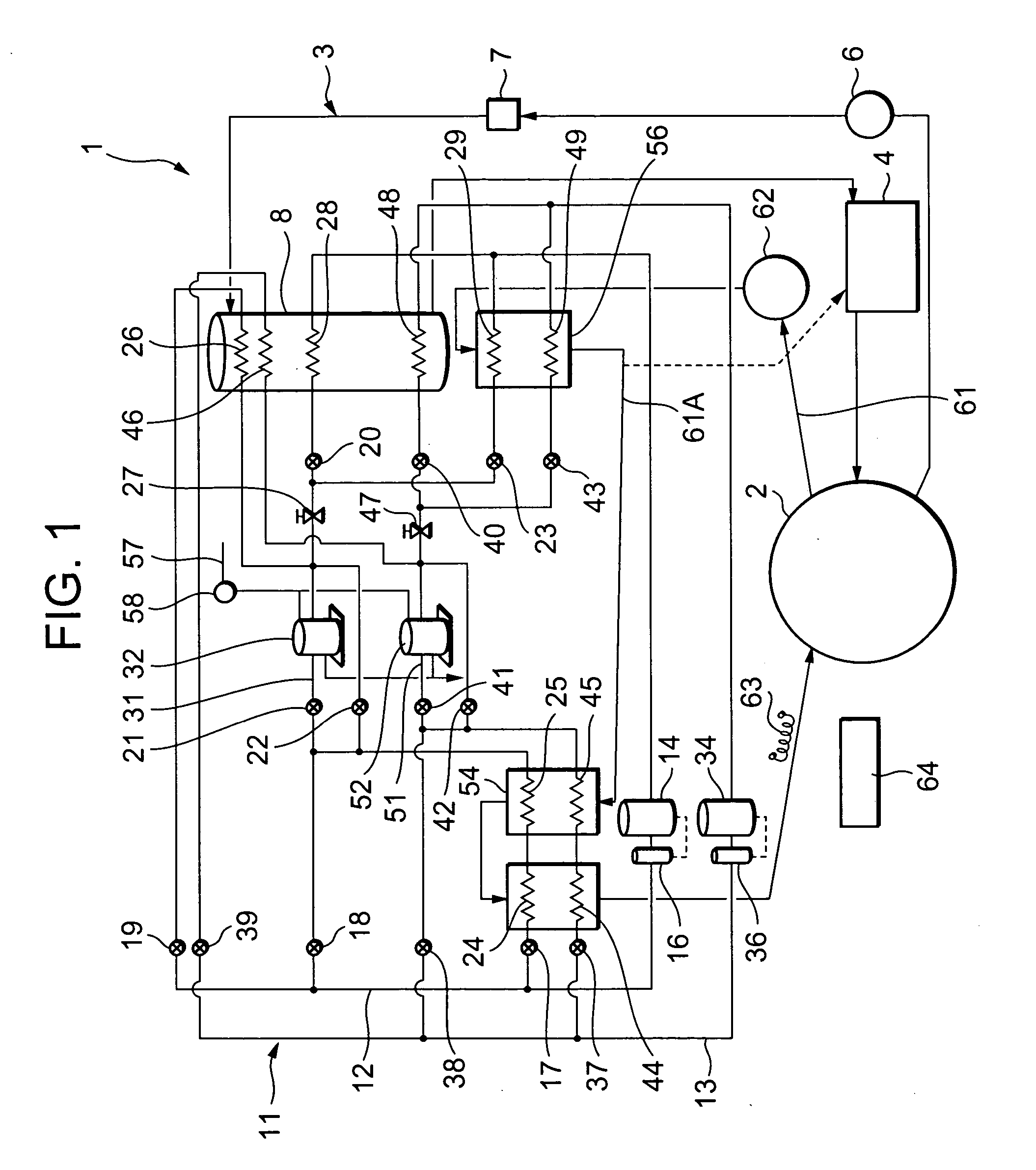

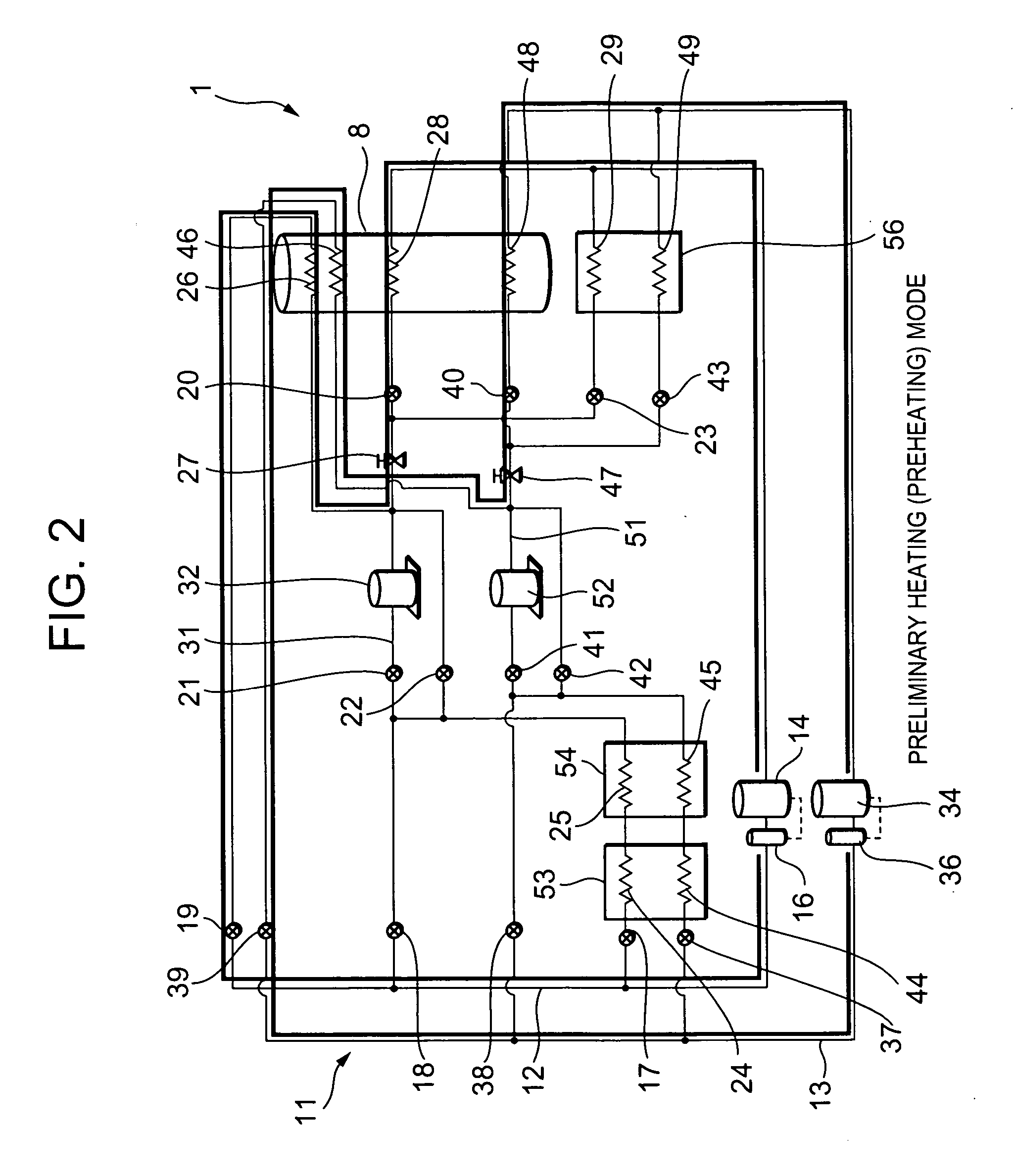

[0062]FIG. 1 shows a constitution diagram of a dry cleaner 1 according to one embodiment of the present invention. FIG. 8 shows a rear perspective view of the dry cleaner 1, and FIG. 9 shows a perspective view of a heat pump device 11 of the dry cleaner 1 in FIG. 8. In the respective figures, reference numeral 2 denotes a cylindrical drum including a large number of through holes formed in a peripheral wall, clothing is washed by a washing liquid in this drum 2, and subsequently drying is also performed. This drum 2 is rotated by a drum motor (not shown), for example, at a speed of 30 to 50 rpm.

[0063] Moreover, reference numeral 3 denotes a washing liquid circulation channel for circulating the washing liquid in the drum 2, and the washing liquid circulation channel 3 is connected to a washing liquid tank 4, a washing liquid pump 6, a filter 7, a washing liquid temperature control tank 8 and the like. When the washing liquid pump 6 is operated, the washing liquid is supplied to the...

embodiment 2

[0106] Next, another embodiment of the present invention will be described in detail with reference to FIGS. 10 to 19.

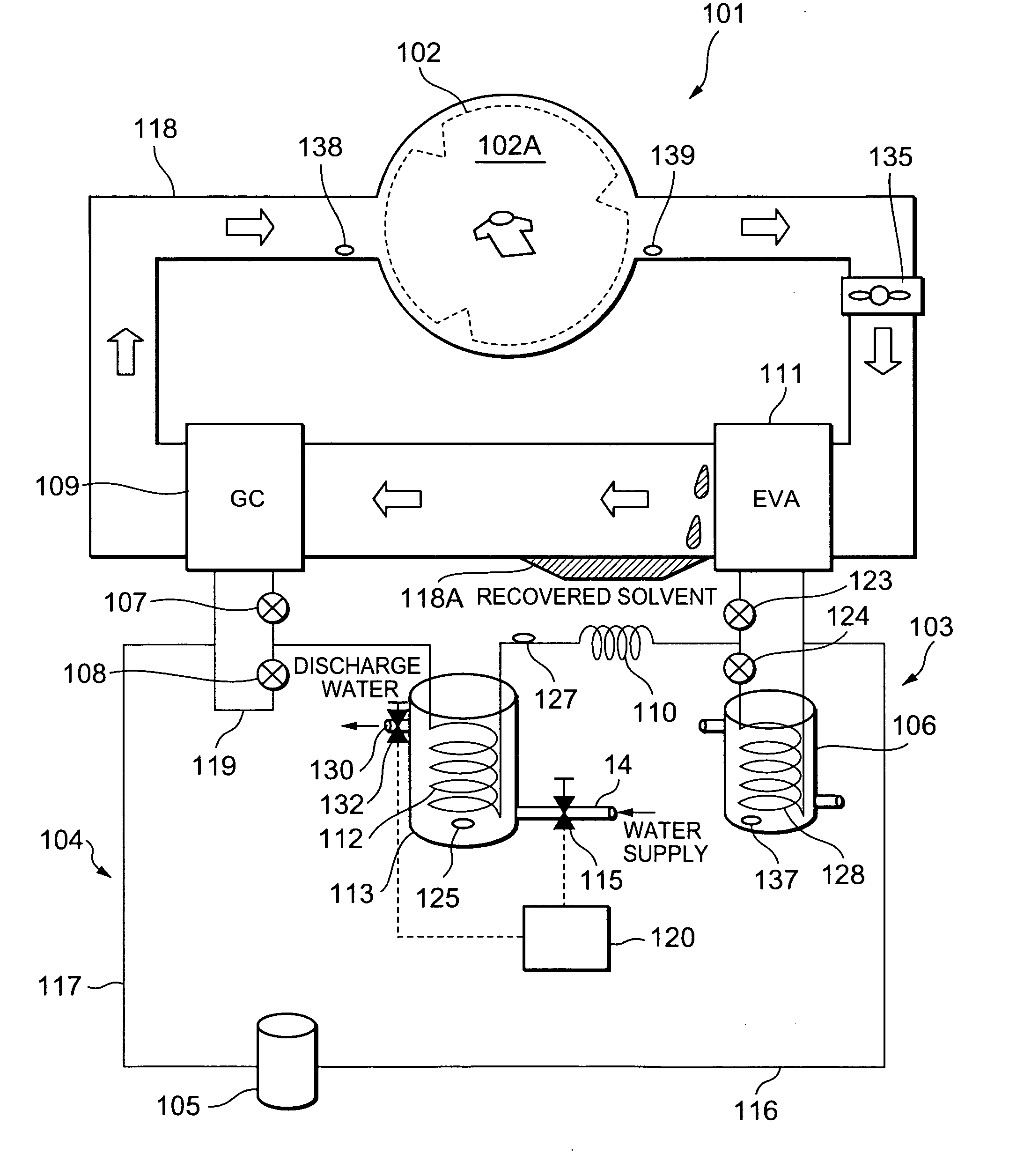

[0107] In this case, there is provided a drying machine capable of reducing a drying time of a matter to be dried.

[0108]FIG. 10 shows a schematic constitution diagram of a dry cleaner 101 using, for example, a petroleum-based solvent as a washing liquid in one embodiment of a drying machine to which a heat pump device 103 of the present invention is applied in this case. In this figure, reference numeral 102 denotes a cylindrical drum including a large number of through holes formed in a peripheral wall. Clothing or the like is stored as a matter to be washed (matter to be dried in a recovering•drying step) in a storage chamber 102A in the drum 102. In the storage chamber 102A, steps of washing, dewatering, and drying the clothing by a washing liquid are executed. That is, the dry cleaner 101 performs the washing and the subsequent drying in the storage chamber 102...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com