Washer method and apparatus

a technology of washing machine and washing plate, applied in the direction of other washing machines, cleaning using liquids, textiles and paper, etc., can solve the problems of slow filling, low surface area, and inability to always meet normal pressure, so as to increase the surface area, and enhance the washing action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

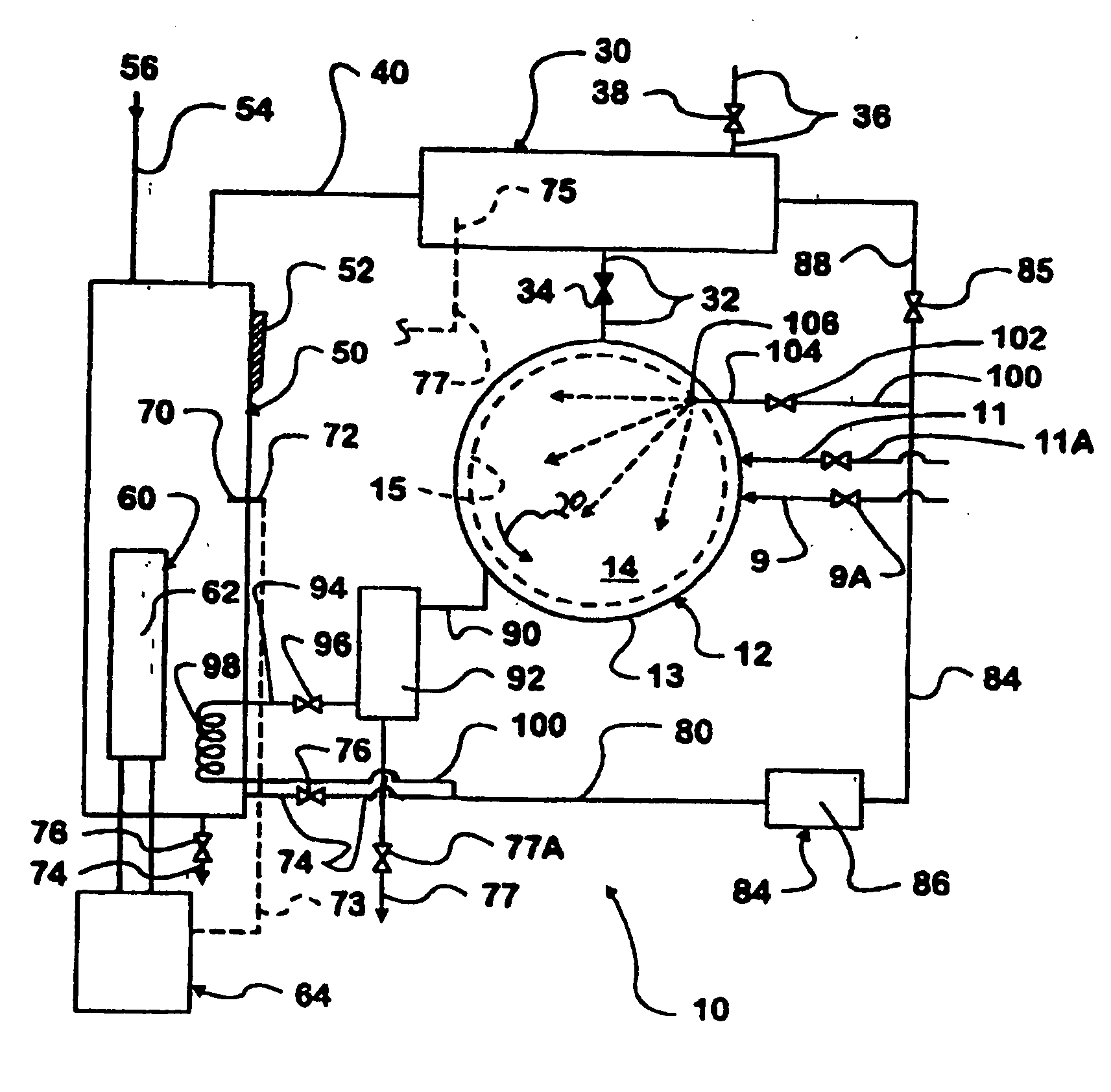

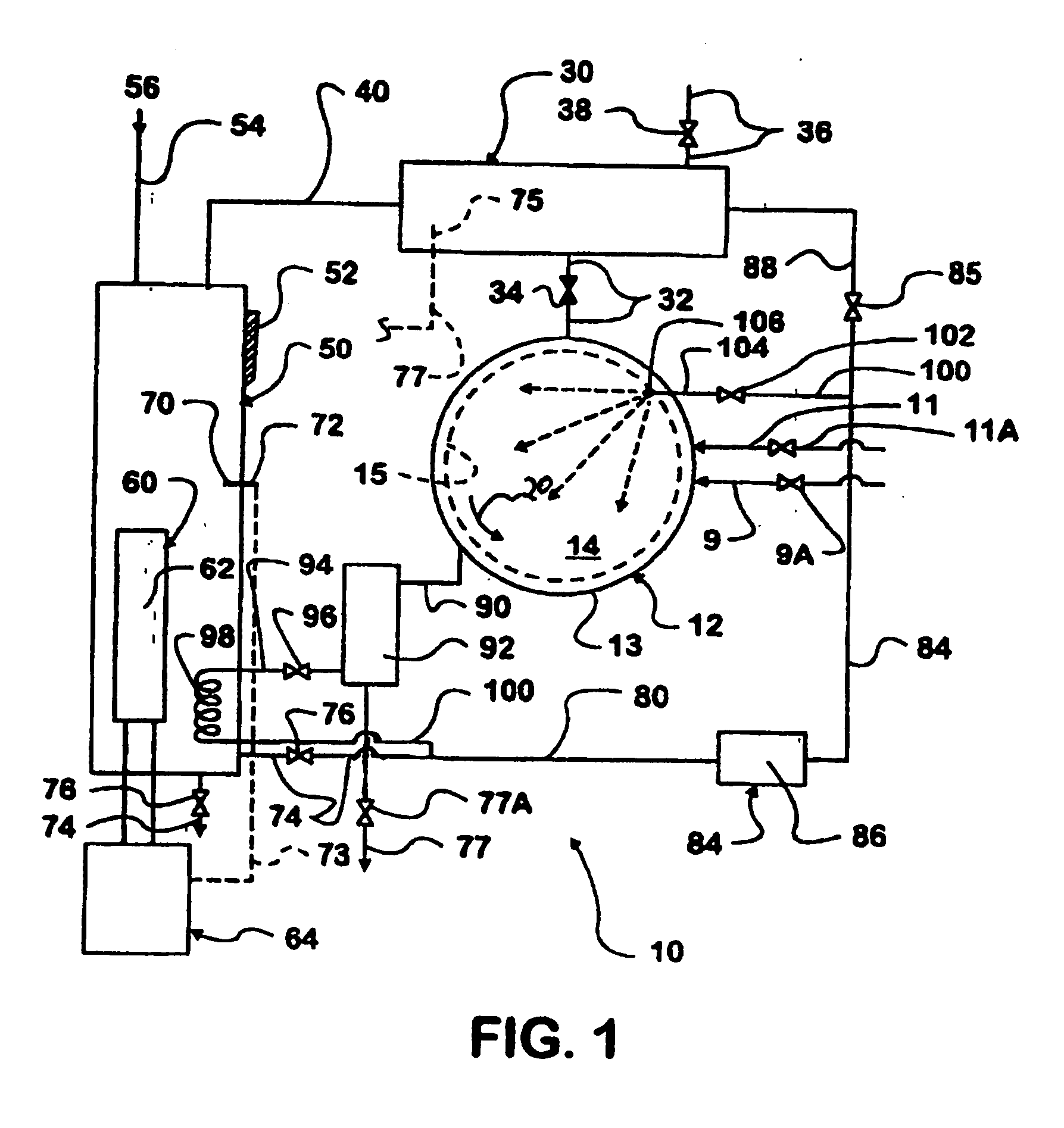

Method used

Image

Examples

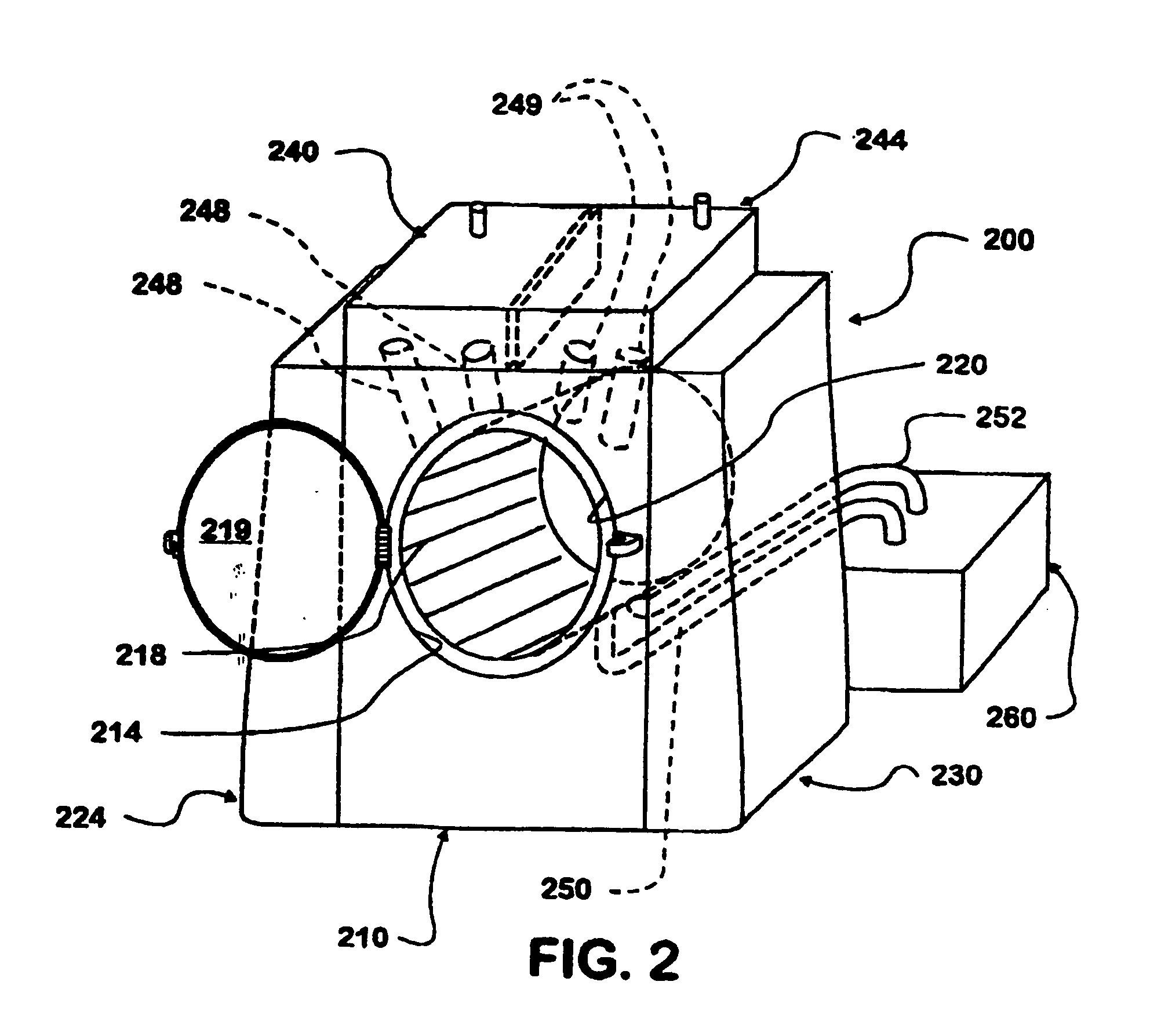

embodiment 710

[0051] The washer 710 has the three water tanks 750A, B and C and is enclosed in a suitable housing (see FIG. 8). The washer mechanism including drum 712 is mounted on a base structure 779 in a frame 781. The washer mechanism in the frame includes the washer motor 782 which carries a drive pulley 783, which via belts 784, drive the driven pulley 784A. The frame 781 mounts the washer mechanism on a plurality of springs 785 with shock absorbers 786 to limit vibrations. In addition, the embodiment 710, has a digital control 777 which controls the operation of the refrigerator unit and its compressor 765 and pump(s) and / or circulating means 787, and all other features and functions of the washer and the various wash cycles. Lines for injecting soap into the drum 712 are shown at 790 and 791. To control and show water levels in the tanks, a triple water level gauge is shown at 792, one for each tank. In addition, multiple bin means 794 are provided to add solid type soaps, conditioners, ...

embodiment 910

[0060] Referring to FIG. 10 is a chart of the same of the operating conditions for the valves 1-9, vent 10 and pump 987 of this embodiment. In this operating chart “C” means “closed” and “O” means “open”. The operation of the embodiment 910 is apparent from the chart in FIG. 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com