Preparation method and application of amino-functionalized manganese dioxide-loaded nano-magnetic bentonite

An amino-functionalized, nano-magnetic technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of cadmium removal efficiency that needs to be further improved, low cadmium selectivity, etc. Achieve the effect of solving material recycling, high saturation magnetization, and solving separation difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of a magnetic adsorbent, specifically comprising the following steps:

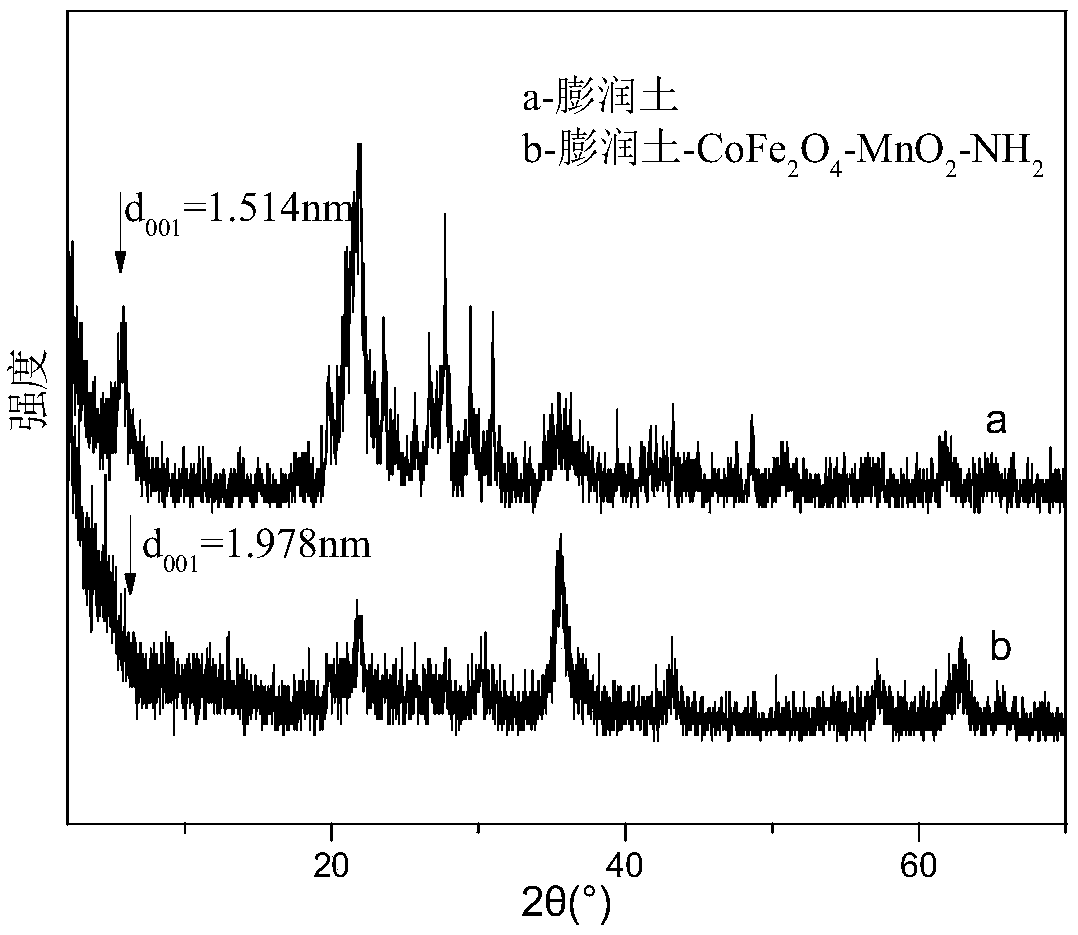

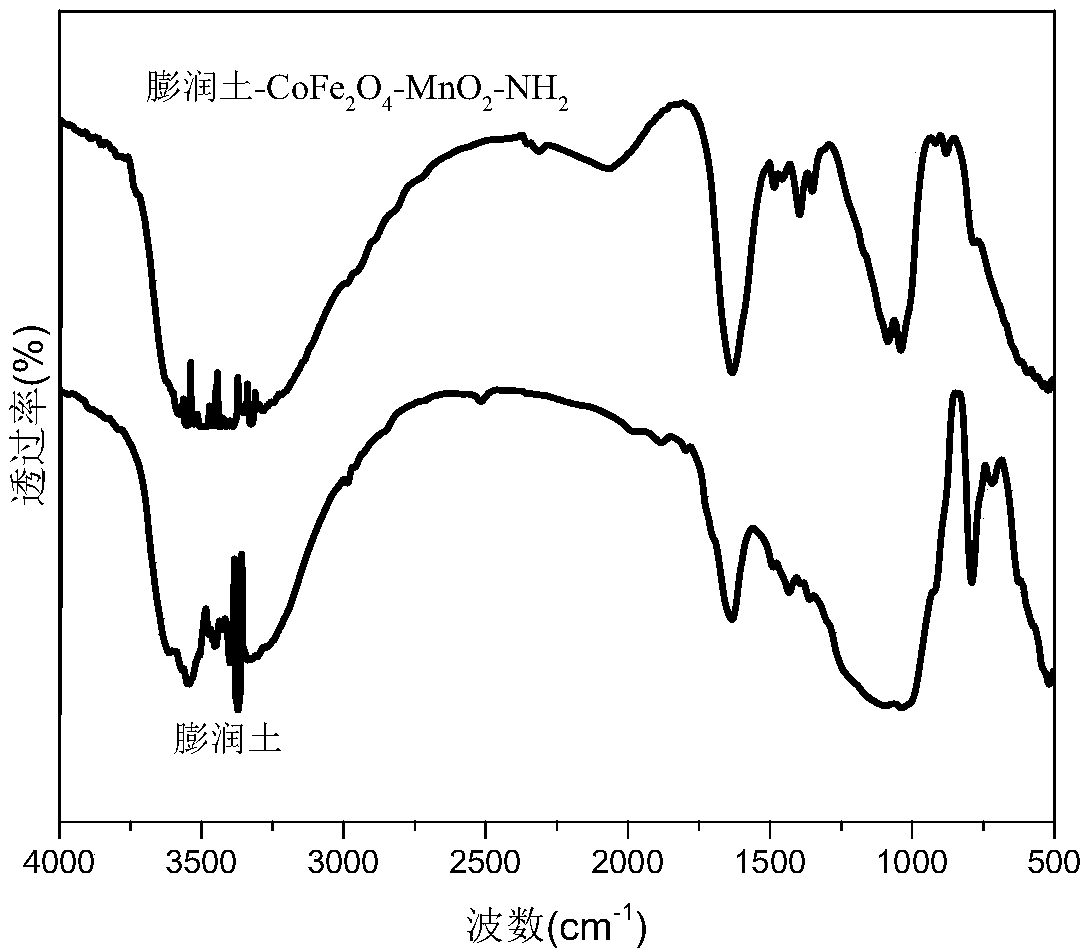

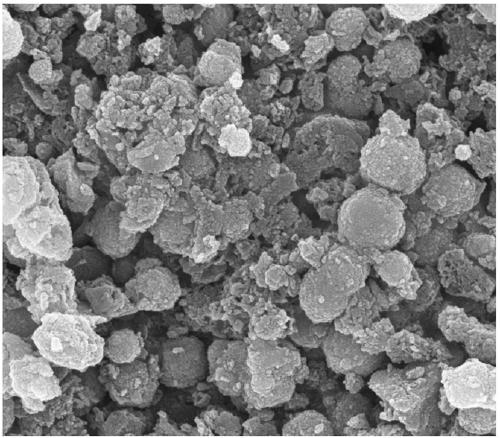

[0038] Dissolve 6.0g of ferric chloride, 3.0g of cobalt chloride, and 18.0g of sodium acetate in 150mL of ethylene glycol to obtain a mixed solution Ⅰ, mix 4.0g of sodium bentonite with 150mL of mixed solution Ⅰ, and age for 5 hours. The mixed solution II was obtained, and then the mixed solution II obtained above was packaged in a polytetrafluoroethylene reactor for hydrothermal reaction, heated at 200° C. for 12 hours, and cooled to room temperature after the reaction was completed. Wash the obtained solid with absolute ethanol and distilled water for 3 to 5 times, vacuum-dry, grind, and pass through a 200-mesh sieve to obtain nano-magnetic bentonite A. Take 6.0g of nano-magnetic bentonite A in a beaker, add 600mL of ultrapure water, and ultrasonically disperse for 15min. Add 2.0g of manganese chloride during the stirring process to obtain a suspension, then place the suspens...

Embodiment 2

[0045] A preparation method of novel nano-magnetic bentonite, specifically comprising the following steps:

[0046] Dissolve 9.0g of ferric chloride, 3.0g of cobalt chloride, and 12.0g of sodium acetate in 100mL of ethylene glycol to obtain a mixed solution Ⅰ, mix 5.0g of sodium bentonite with 100mL of mixed solution Ⅰ, and age for 3 hours. The mixed solution II was obtained, and then the above mixed solution II was packaged in a polytetrafluoroethylene reactor for hydrothermal reaction, heated at 200°C for 12 hours, and cooled to room temperature after the reaction was completed. Wash the obtained solid with absolute ethanol and distilled water for 3 to 5 times, vacuum-dry, grind, and pass through a 200-mesh sieve to obtain nano-magnetic bentonite A. Take 6.0g of nano-magnetic bentonite A in a beaker, add 600mL of ultrapure water, and ultrasonically disperse for 15min. Add 2.0g of manganese chloride during stirring to obtain a suspension, then place the suspension in a water...

Embodiment 3

[0050] A preparation method of novel nano-magnetic bentonite, specifically comprising the following steps:

[0051] Dissolve 4.0g of ferric chloride, 4.0g of cobalt chloride, and 16.0g of sodium acetate in 150mL of ethylene glycol to obtain a mixed solution Ⅰ, mix 3.0g of sodium bentonite with 150mL of mixed solution Ⅰ, and age to obtain Mixed solution II, and then the mixed solution II obtained above was packaged in a polytetrafluoroethylene reactor for hydrothermal reaction, heated at 200°C for 12 hours, and cooled to room temperature after the reaction was completed. Wash the obtained solid with absolute ethanol and distilled water for 3 to 5 times, vacuum dry, grind, and pass through a 200-mesh sieve to obtain nano-magnetic bentonite A. Take 6.0g of nano-magnetic bentonite A in a beaker, add 600mL of ultrapure water, and ultrasonically disperse for 15min. Add 2.0g of manganese chloride during the stirring process to obtain a suspension, then place the suspension in a wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com