Kitchen waste recycling equipment

A technology of kitchen waste and equipment, which is applied in the field of kitchen waste treatment equipment, can solve the problems of reducing the solid utilization value of kitchen waste, damage to solid-liquid separation devices, and easy breeding of harmful bacteria, so as to improve the oil-water separation rate , Improve the utilization rate and prevent the growth of harmful bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

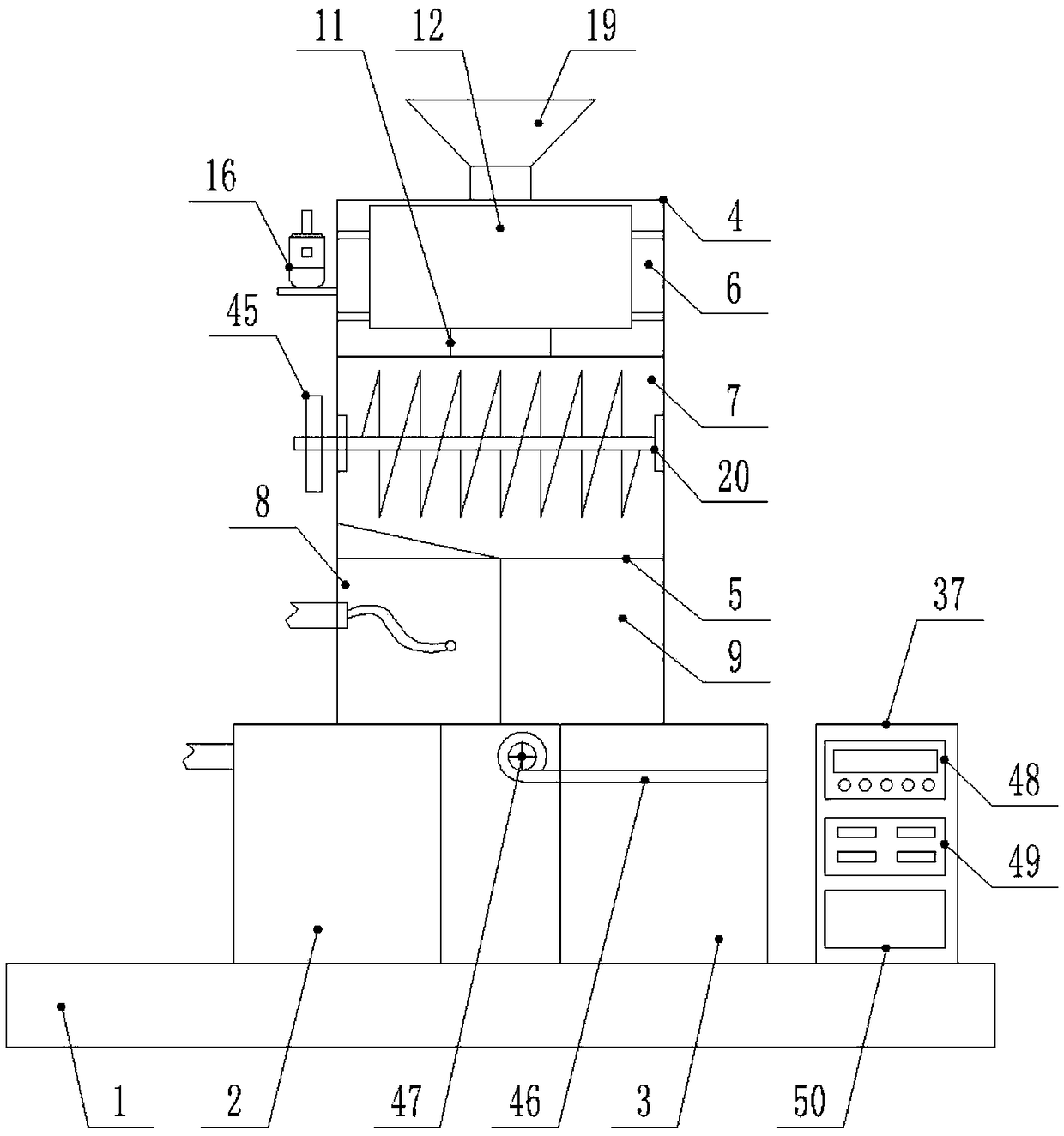

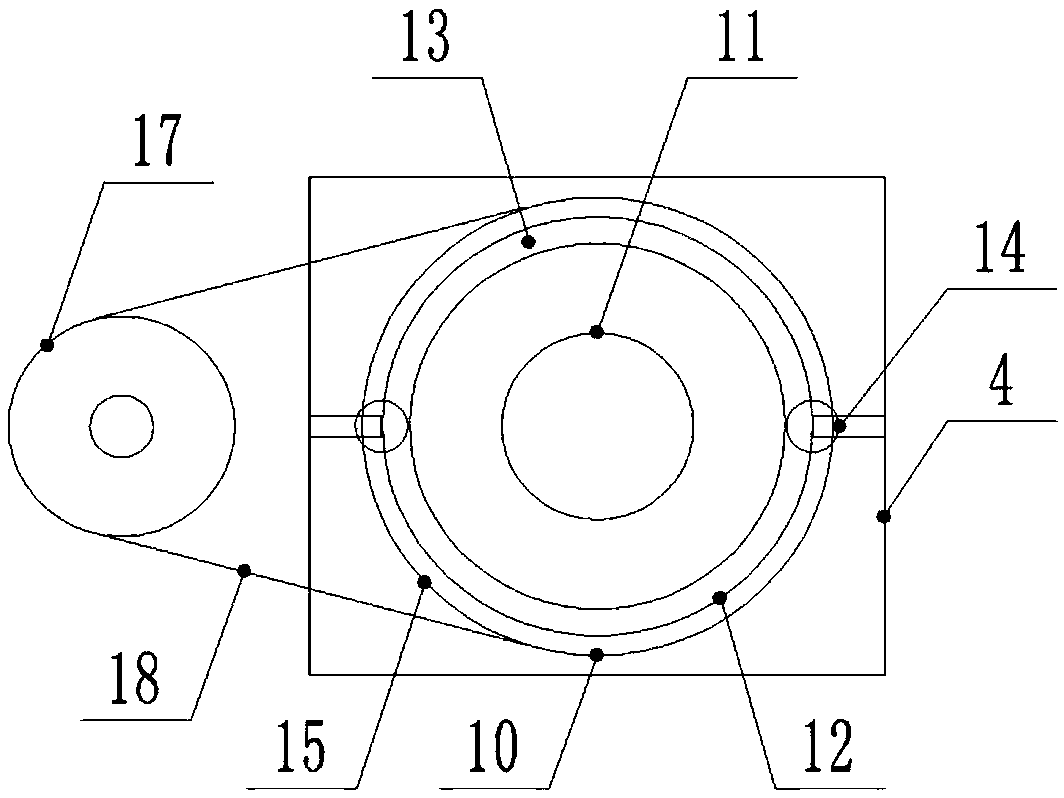

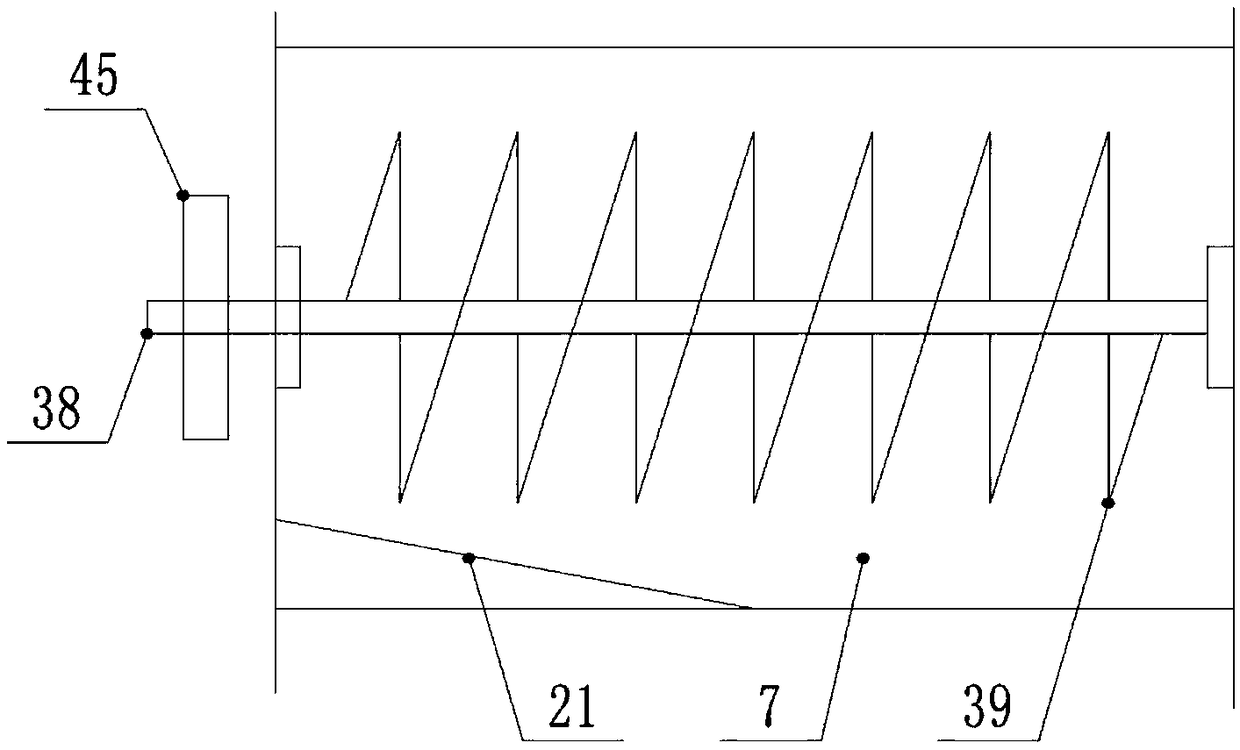

[0022] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-6As shown, a kitchen waste recycling equipment includes a basic installation base 1, the upper end of the basic installation base 1 is provided with an oil collection box 2 and a collection box 3, and the oil collection box 2 and the collection box 3 is provided with a feeding box 4 above, and the inner cavity of the feeding box 4 is divided into a solid-liquid separation chamber 6, a chopping chamber 7, and a left oil-water Separation chamber 8 and right collection chamber 9, described solid-liquid separation chamber 6 is provided with solid-liquid separation device 10, and described solid-liquid separation device 10 is provided with in the bottom middle part of inner cavity of described solid-liquid separation chamber 6 Cylindrical support base 11, rotating cylinder 12 provided on the upper end of cylindrical supporting base 11, annular wheel grooves 13 respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com