Process, device and system for biological treatment for internal reflux sewage by magnetic-loading magnetic sludge

A technology for biological sewage treatment and internal reflux, applied in water/sludge/sewage treatment, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problem of improving microbial activity, increasing engineering costs, and low solid-liquid separation efficiency question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

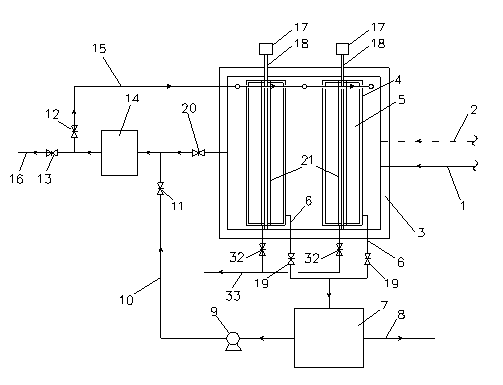

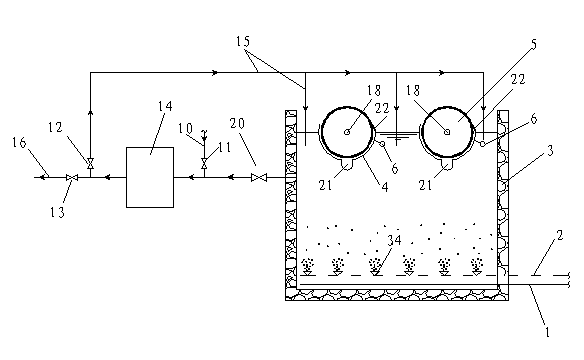

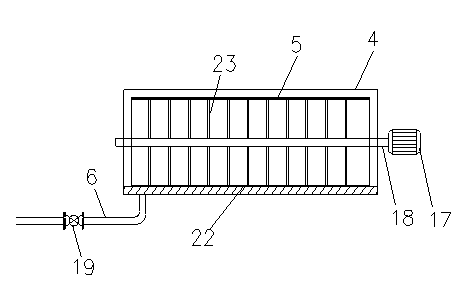

[0020] in Figure 1 to Figure 5 It can be seen that the device system of the sewage biological treatment process of the magnetically loaded magnetic sludge mainly includes a magnetic activated sludge biological reaction tank, a weak magnetic solid-liquid separator and a strong magnetic sludge magnetic separator. The magnetic activated sludge biological reaction tank (3) is mainly composed of the biological reaction tank body, water inlet and water distribution system (1), air intake pipe (2), air diffusion device (34) and residual magnetic activated sludge discharge control valve ( 20) Composition. A weak magnetic solid-liquid separator is installed in the upper part of the magnetic activated sludge biological reaction tank (3), which consists of a semi-cylindrical water tank (4) and a weak magnetic rotating magnetic bucket (5); a semi-cylindrical water tank ( 4) The lower part is provided with a mud collecting tank (21). The side of the mud collecting tank (21) is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com