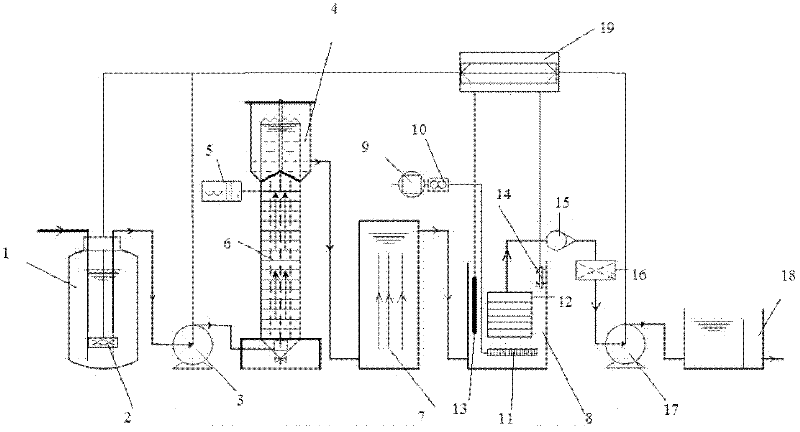

Experimental device for treating emulsified oil wastewater by UASB/MBR technology

An experimental device and wastewater technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Avoid sludge bulking, small footprint, convenient operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

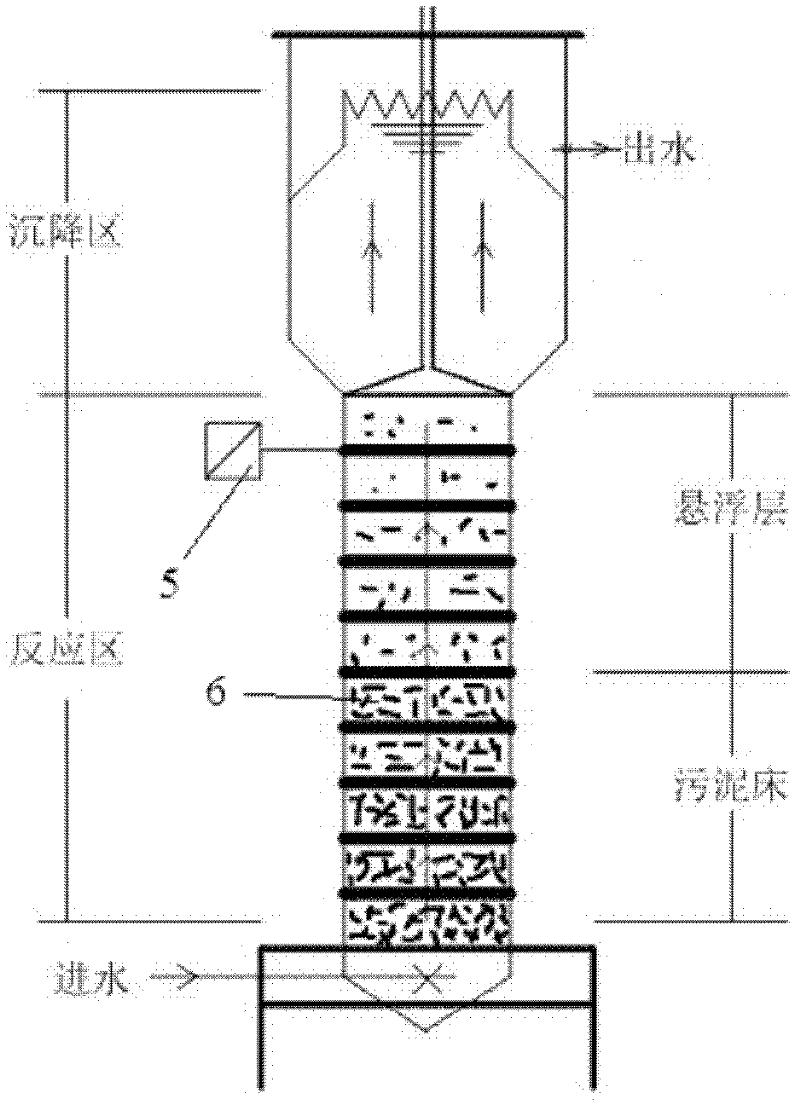

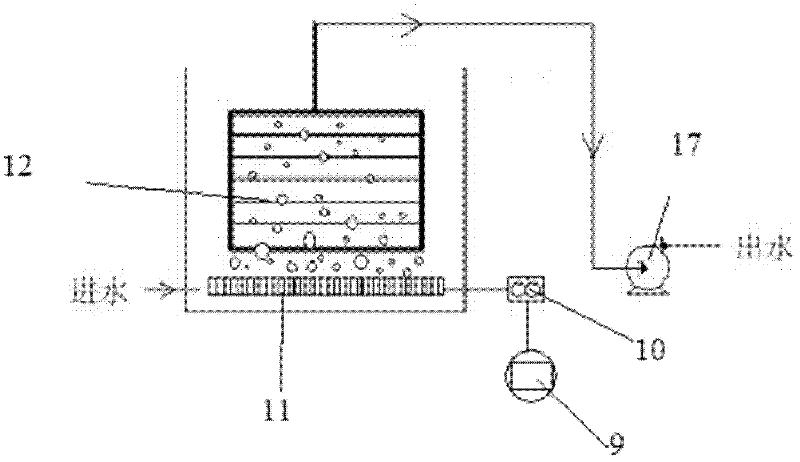

[0021] This embodiment UASB / MBR process treatment emulsified oily wastewater experimental device, such as figure 1 As shown, the submersible mixing pump 2 is placed in the water distribution bucket 1, and the water outlet of the water distribution bucket 1 is connected to the peristaltic pump 3 through the pipeline, and the peristaltic pump 3 is connected to the upflow anaerobic sludge bed 4 through the pipeline, and the upflow anaerobic sludge bed 4 is connected to the upflow anaerobic sludge bed. The sludge bed 4 is provided with an electric heating belt 6 and a temperature controller 5, and the outlet of the upflow anaerobic sludge bed 4 is connected to the sedimentation tank 7 through a pipeline, and the outlet of the sedimentation tank 7 is connected to the membrane bioreactor 8 through a pipeline. The microporous aeration pipe 11 is placed in the membrane bioreactor 8 and connected with the gas flowmeter 10 and the air compressor 9 in sequence, and the membrane module 12 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com