Method for treating degradation-resistant organic wastewater by membrane potential biological coupling process

A kind of organic wastewater, refractory technology, applied in the direction of electrochemical bio-combination treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problem of sludge microbial enrichment, high content of suspended solids in effluent, and impact of sludge microbial To achieve the effect of improving the sewage treatment effect, stabilizing the effluent water quality and improving the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

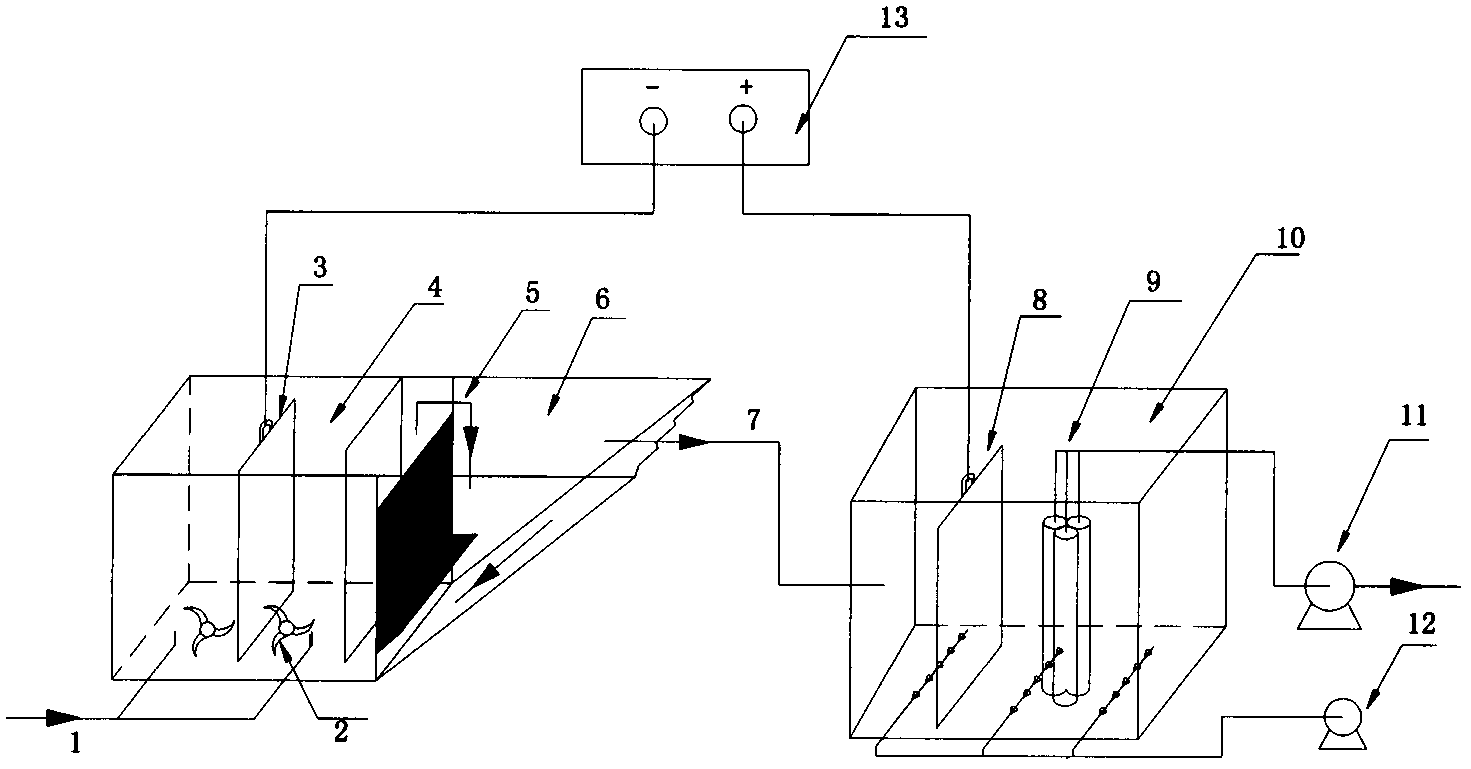

[0011] Coking chemical organic wastewater is treated by membrane electrobiological coupling process, with a treatment volume of 15m 3 / h. The organic wastewater contains phenol, cyanide, chlorophenol, coal tar and other organic matter, COD Cr The content is between 1500~3000mg / L. The residence time of coking chemical organic wastewater in the reactor is 20h, the hydraulic retention time in the anaerobic zone and the aerobic zone are both 10h, the microbial concentration in the anaerobic zone is between 3000-5000mg / L, and the microbial concentration in the aerobic zone is 2000 ~4000mg / L. The stirring power in the anaerobic zone is 150W, the gas-water ratio of aeration in the aerobic zone is 8:1, the cathode plate is made of titanium-based palladium-plated mesh flat plate, the anode is made of graphite plate, and the voltage applied by the DC power supply is 1.2V.

[0012] After commissioning and stable operation, the water quality of membrane effluent is as follows: phenol ...

Embodiment 2

[0014] The sewage from the printing and dyeing wastewater treatment station contains disperse blue ionic dyes with a chroma of 300 to 500 times and COD Cr 300~500mg / L, SS 130mg / L, treated water volume 200m 3 / d, BOD / COD is 0.25, poor biochemical properties. The original treatment process adopts the process of coagulation sedimentation-microbial anaerobic degradation-microbial aerobic degradation, and the effluent COD Cr The concentration is 100-150mg / L, and the effluent color is high, which does not meet the requirements of environmental protection discharge. In order to improve the removal effect, the electric biofilm filtration coupling process of the invention is used for transformation. A drum-shaped mesh titanium-based palladium-plated cathode plate is installed in the anaerobic reactor, and a mesh steel plate is installed as an anode in the aerobic tank. The regulated DC voltage provides a voltage of 1.5V. After the installation of the pole plate was completed, after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com