Electric wastewater treating apparatus

A kind of sewage treatment machine, electric technology, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, fixed filter element filter, etc., can solve the problem that the fine solid waste cannot be settled and the removal efficiency of solid phase dirt is low , increase processing costs and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

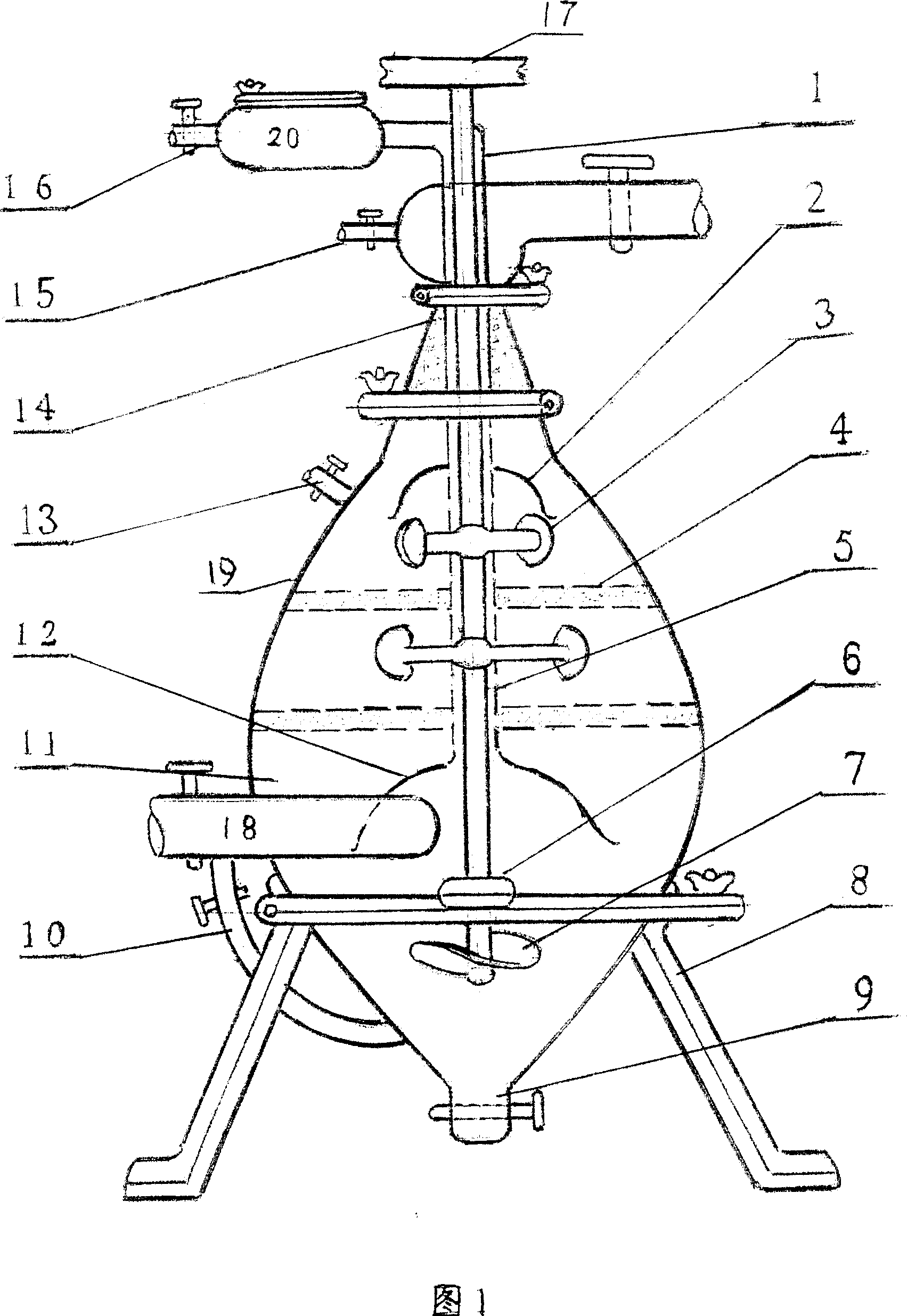

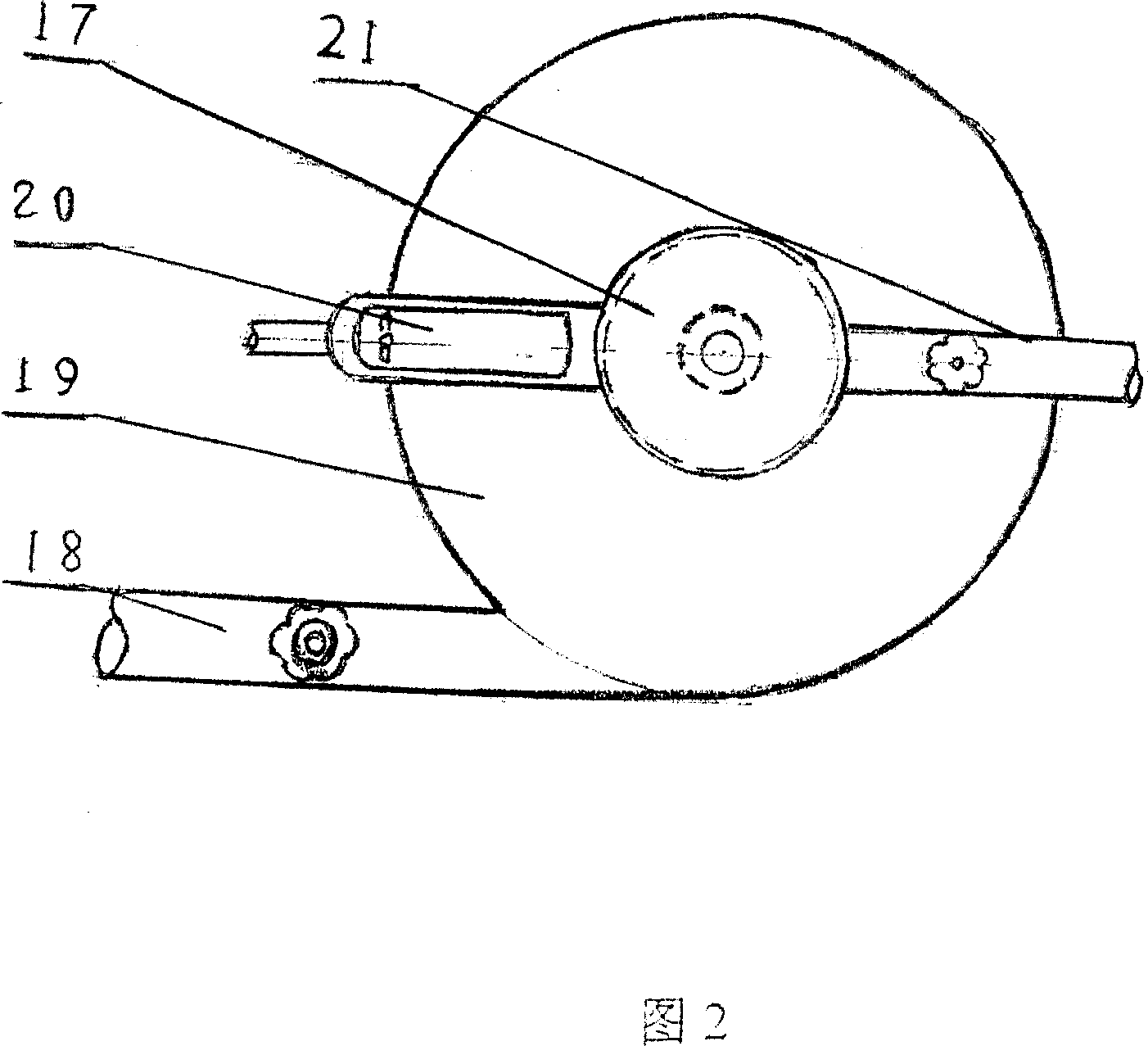

[0012] Referring to Fig. 1 and Fig. 2, the electric sewage treatment machine includes a container shell 19, a water inlet pipe 18, and a water outlet pipe 21. The container is placed on the frame 8, the inner cavity of the container shell is provided with a filter layer 4, and the water outlet pipe 21 is installed on the filter layer 4 On the upper container shell 19, the water inlet pipe 18 is installed on the container shell 19 below the filter layer 4, and the drive shaft 17 is set in the inner cavity of the container shell 19, and the drive shaft 17 is equipped with a spinner 3, an agitator 7, and a spinner 3 Installed above the filter layer 4, the agitator 7 is installed below the filter layer 4, the agitator 7 is connected with the drive shaft 17 through the clutch 6, the drive shaft 17 is driven by a motor, the filter layer 4 can be provided with multiple layers, the spinner 3, agitation Device 7 can be established a plurality of.

[0013] Air receiving pipe 1 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com