Environmental-friendly and energy-saving solid-liquid separation device

A solid-liquid separation, environmental protection and energy-saving technology, applied in the feeding/discharging device, separation method, sedimentation separation and other directions of the sedimentation tank, which can solve the problems of irregular replacement of the scraper, troublesome cleaning and maintenance, wear or chain lock, etc. Achieve the effect of low cost, high solid-liquid separation efficiency, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

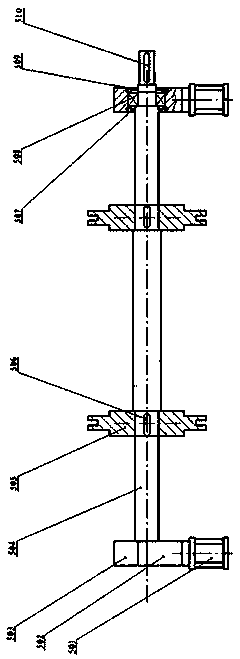

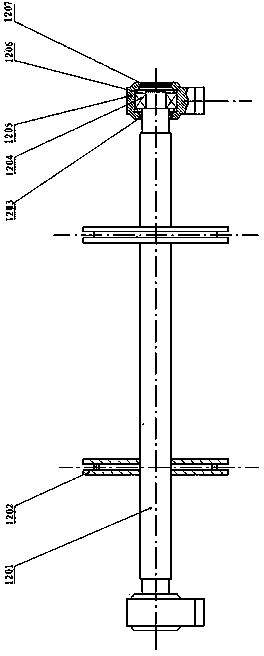

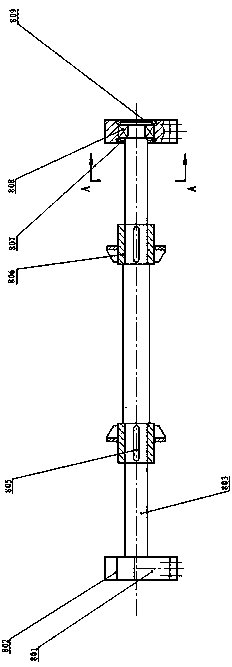

[0041] like Figure 1 to Figure 12 The shown environmental protection and energy-saving solid-liquid separation device includes a tank body, a driving device 1, a driving wheel device 5, a supporting wheel device 12, a scraper device 9, a steering wheel device 8, a pole 11 and a large flat frame 2, The trough includes a chute 3, a guide chute 7, a front trough 10 and a rear trough 13 connected in sequence, the driving device 1 is connected with the driving wheel device 5 through a shaft coupling 1002, and the driving wheel device 5 passes through The driving wheel support 4 is supported at the end of the guide groove 7, and the scraper device 9 is divided into an underwater part and an above-water part, and the above-water part is supported on the water surface by the supporting wheel device 12, and the chain ring hook 909 of the scraper device 9 is connected with the support Wheel device 12 links to each other with reversing wheel device 8, and carries out transmission by rev...

Embodiment 2

[0066] The treatment solid content is 20-80kg / m 3 During the time stone powder solution, the parameter of the present invention is:

[0067] Speed regulating motor: YCT200-4B 7.5 kw

[0068] Speed range: 1250-125 rpm

[0069] Reducer: BW3922-11×11

[0070] Scraper speed: 2-8 m / min

[0071] Single pond water treatment capacity: 300-600 m 3 / h

[0072] Concentration of mixed solution: 20-80kg / m 3

[0073] Silt particle size: <5 mm

[0074] Solid handling capacity: 5-15t / h

[0075] Sedimentation tank horizontal length: 14.5 m

[0076] Scraper width: 1.9 m

[0077] Tank height: 1.35m

[0078] Lifting height of scraper: 2300 mm

[0079] Guide groove installation slope: 18°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com