Stepped deep purification method of low-concentration arsenic waste water

A step-depth, low-concentration technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problem that the treatment indicators are easily affected by the external environment, do not meet the national environmental protection standards, and the calcium arsenate slag is stable In order to achieve clean production, improve the efficiency of solid-liquid separation, and reduce the amount of slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

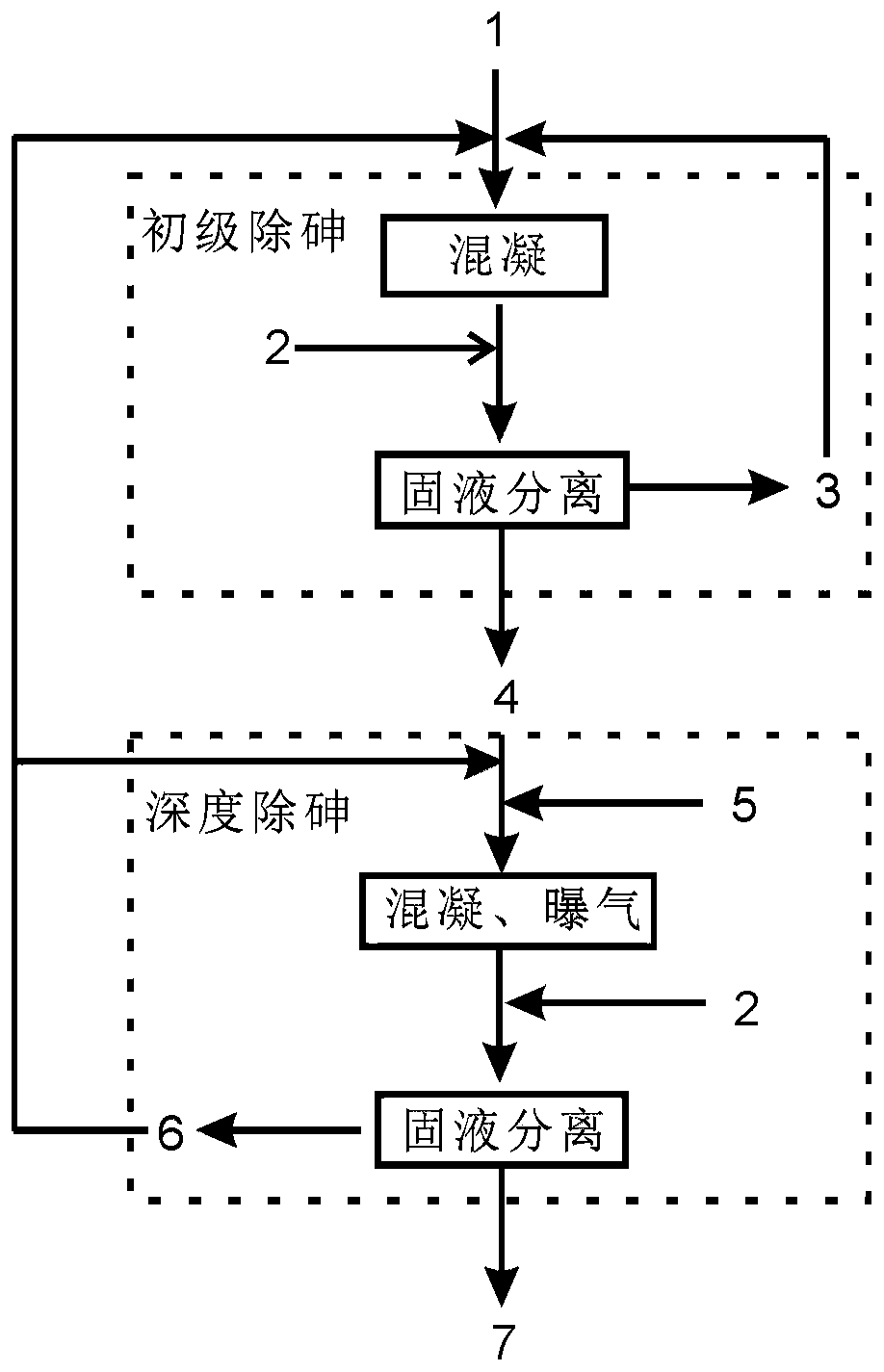

Method used

Image

Examples

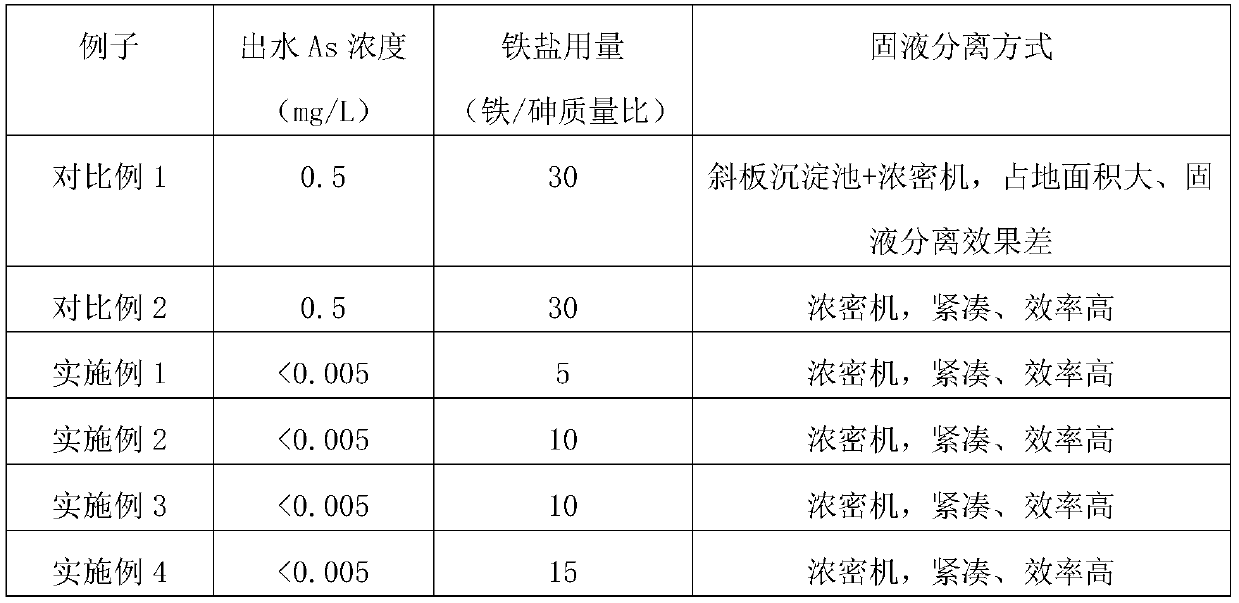

Embodiment 1

[0035] Initially, the low-concentration arsenic-containing wastewater (As 5mg / L) was treated with polyferric sulfate, and the mass ratio of iron to arsenic was 4 for primary arsenic removal, and then the low-concentration arsenic-containing wastewater was combined with primary arsenic removal bottom flow and deep arsenic removal bottom flow (control The iron / arsenic mass ratio is 20), stirred in the reaction tank for 30min, the stirring line speed is 2m / s, the pH detection device of the reaction tank is interlocked with the sulfuric acid or milk of lime metering peristaltic pump, so that the pH of the reaction is controlled at 7 ~9. Pump the preliminary arsenic removal slurry to the thickener, and at the same time add polyacrylamide polymer flocculants with a concentration of 0.1% to the feed barrel of the thickener, and control the amount of polyacrylamide polymer flocculants to 3g / t for preliminary removal Arsenic slag; the dense underflow part of preliminary arsenic removal...

Embodiment 2

[0037] Initially, the low-concentration arsenic-containing wastewater (As 3mg / L) was treated with polyaluminium chloride, and the primary arsenic removal was carried out at an aluminum / arsenic mass ratio of 7, and then the low-concentration arsenic-containing wastewater (As 3mg / L) was mixed with the primary arsenic removal underflow and deep arsenic removal underflow (control iron / arsenic mass ratio is 20), stir in the reaction tank for 20min, the stirring line speed is 2m / s, the pH detection device of the reaction tank is interlocked with the metering peristaltic pump of sulfuric acid or milk of lime for interlocking control, The pH of the reaction was controlled at 7-9. Pump the preliminary arsenic removal slag to the thickener, and at the same time add a polyacrylamide macromolecule flocculant with a concentration of 0.2% to the feed barrel of the thickener, and control the amount of polyacrylamide polymer flocculant to 5g / t for the preliminary arsenic removal slag; The den...

Embodiment 3

[0039] Initially, the low-concentration arsenic-containing wastewater (As 2mg / L) was used as a coagulant combined with ferric sulfate and polyaluminium chloride, and the mass ratio of iron (aluminum) / arsenic was 10 for primary arsenic removal, and then the low-concentration arsenic-containing wastewater ( As 2mg / L) and primary arsenic removal underflow and deep arsenic underflow (control iron / arsenic mass ratio is 30), stirred in the reaction tank for 10min, the stirring line speed was 1.0m / s, the pH detection device of the reaction tank and Sulfuric acid or milk of lime metering peristaltic pumps are interlocked to control the pH of the reaction at 7-9. Pump the preliminary arsenic removal slag to the thickener, and at the same time add polyacrylamide with a concentration of 0.1% to the feed barrel of the thickener, and control the amount of polyacrylamide to 8g / t dry preliminary arsenic removal slag; preliminary arsenic removal dense The underflow part is pumped to step (1),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com