Feeding well device for thickener

A thickener and feeding technology, which is applied to the feeding/discharging device of the settling tank, etc., can solve the problems of uneven mixing of flocculant and pulp, weak flow stabilization effect of feeding well, and large disturbance of flocculation pulp. To facilitate popularization, improve solid-liquid separation efficiency and good flocculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

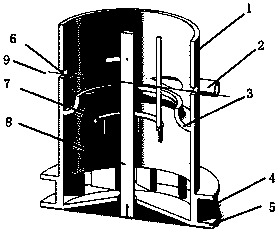

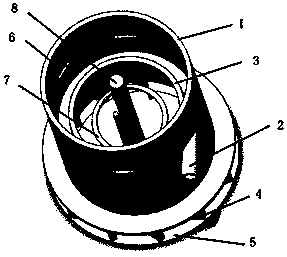

[0020] The feeding well device of the central drive concentrator of the present invention will be further described below in conjunction with the accompanying drawings.

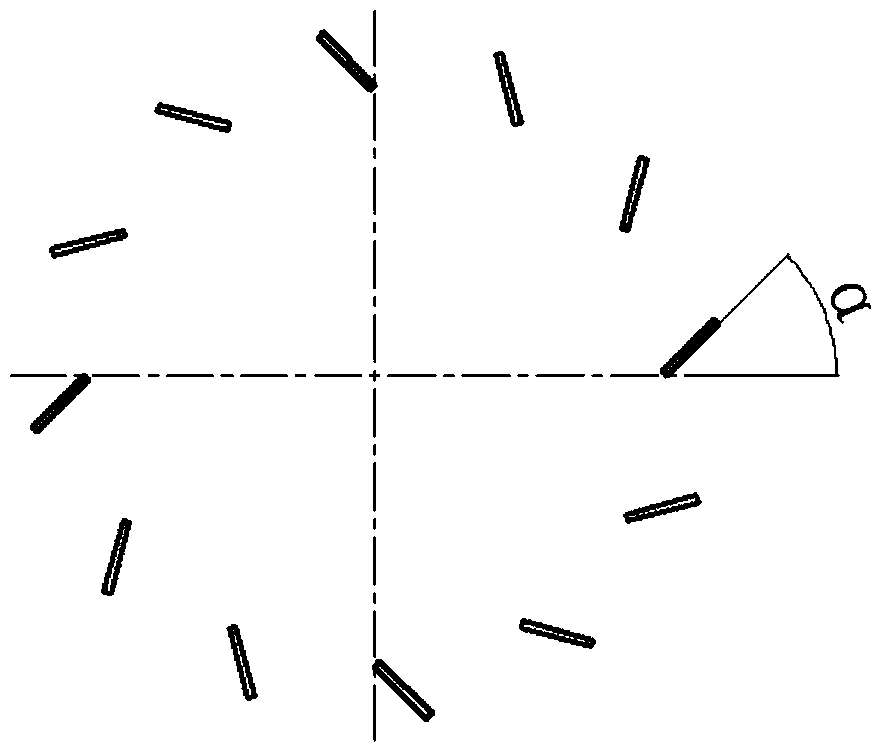

[0021] Such as figure 1 , figure 2 As shown, the feed well is composed of a feed well wall 1, a feed pipe 2, an overflow tank 3, a guide vane 4, a conical guide plate 5, a dilution port 6, a flocculant addition pipe 7, and a drive shaft 8. The feed well wall 1 is cylindrical, with an annular horizontal outer edge on the lower edge, the feed pipe 2 feeds material in a horizontal tangential direction, and is connected to the outside of the feed well wall 1, and the overflow groove 3 is connected to the inside of the feed well wall 1. It is located below the feed pipe, distributed horizontally, and the edge of the overflow tank is of equal height. There is a certain cone angle in the center of the conical guide plate 5, and its edge is connected with the outer edge of the lower edge of the feed well wall 1 thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com