Patents

Literature

131results about How to "Slide to achieve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

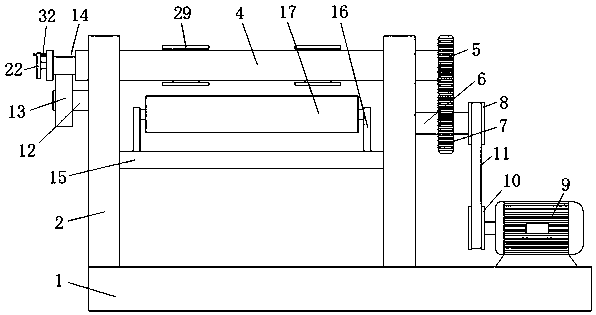

Coiling device applied to textile machinery

The invention discloses a coiling device applied to a textile machinery. The coiling device comprises a pedestal; the upper surface of the pedestal is vertically, symmetrically and fixedly connected with supporting plates; each supporting plate is of a reversed-U-shaped structure; the middle parts of the top ends of the two supporting plates are each provided with an accommodating groove; each accommodating groove is internally provided with a coiling roller; one end of each coiling roller is fixedly connected with a first gear; corresponding to the lower portion of the first gear, one side ofone supporting plate is rotationally connected with a fixing rod; the fixing rod is fixedly connected with a second gear; the second gear is engaged with the first gears; the side, corresponding to the second gear, of the fixing rod is fixedly connected with a first belt disc; the side, corresponding to one side of one supporting plate, of the upper surface of the pedestal is fixedly connected with a motor; and the output end of the motor is fixedly connected with a second belt disc. The coiling device disclosed by the invention prevents the phenomena that fabrics are coiled not closely, areeasily loosened and are not in order, is convenient to use, is also used for conveniently fixing a hard paper coiling cylinder, is simple to mount and dismount and improves the work efficiency.

Owner:安徽双盈纺织有限公司

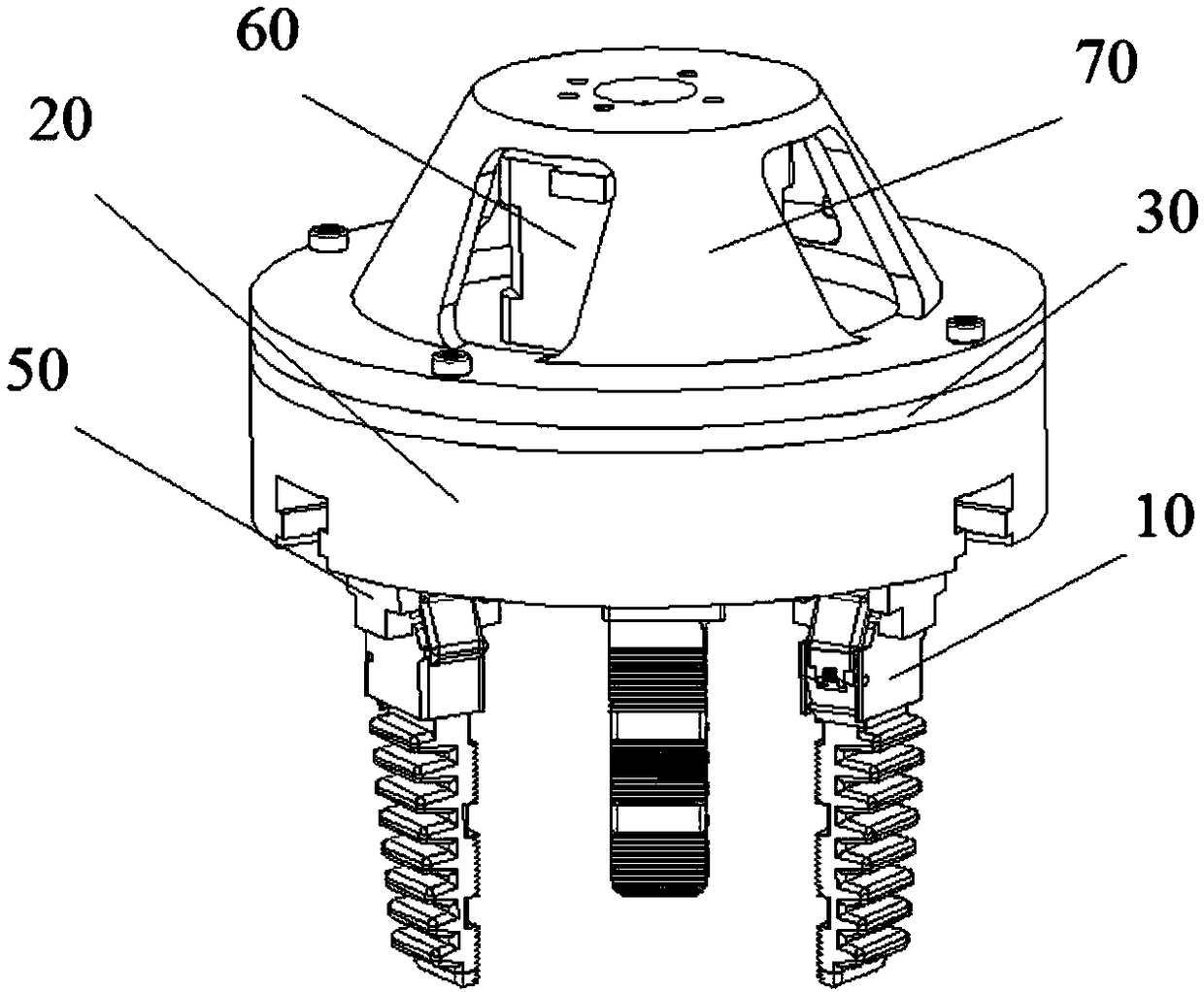

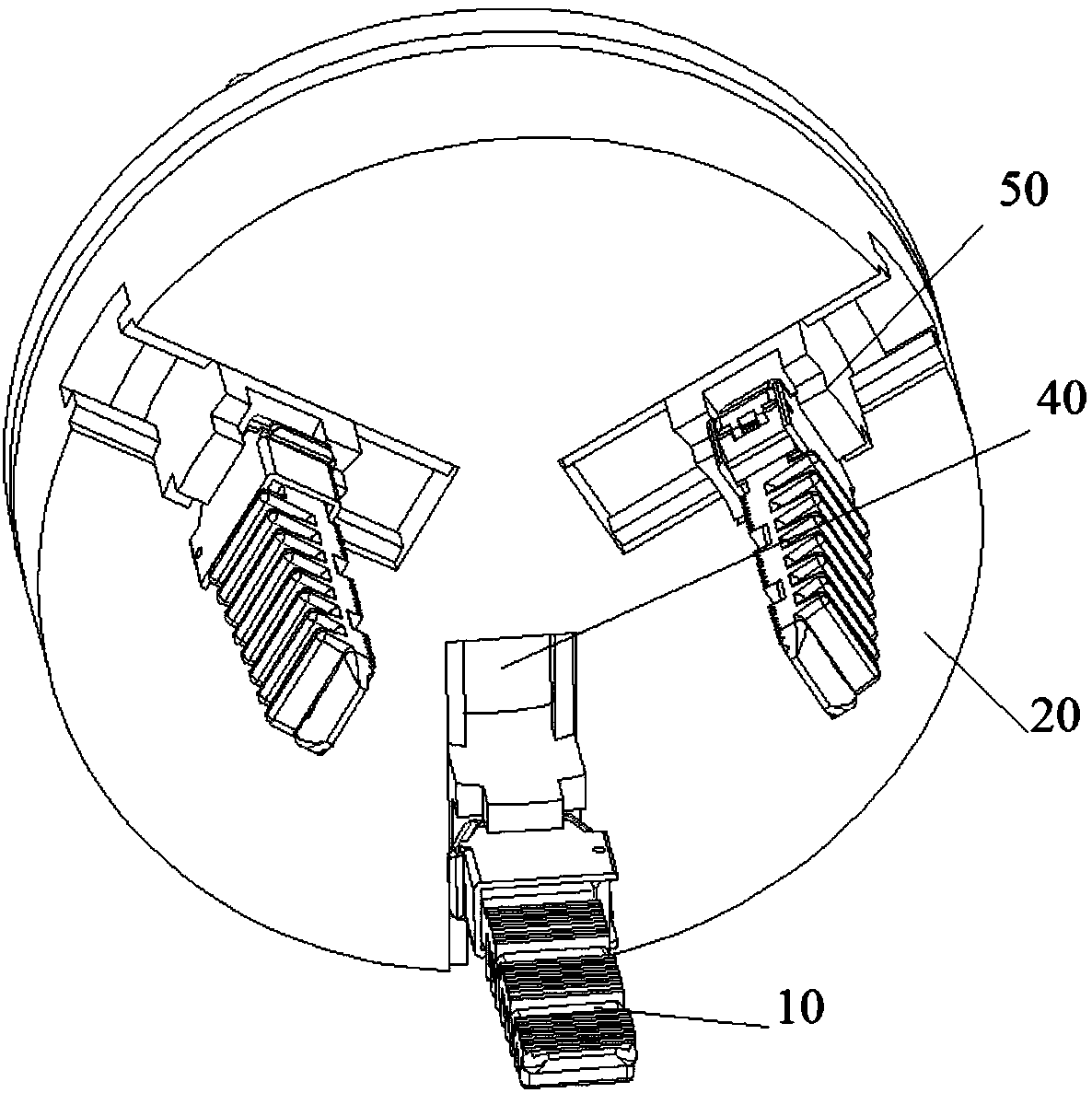

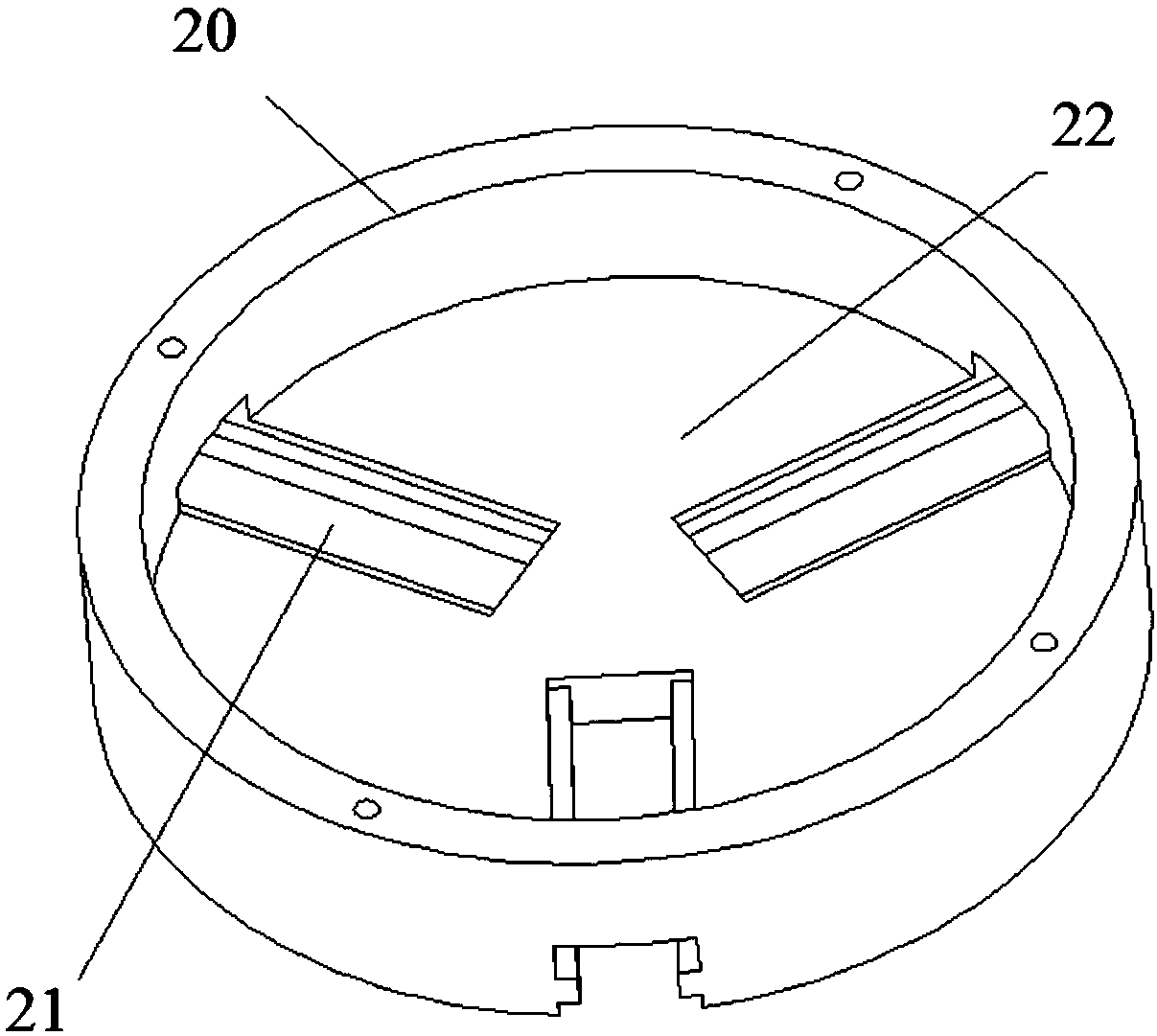

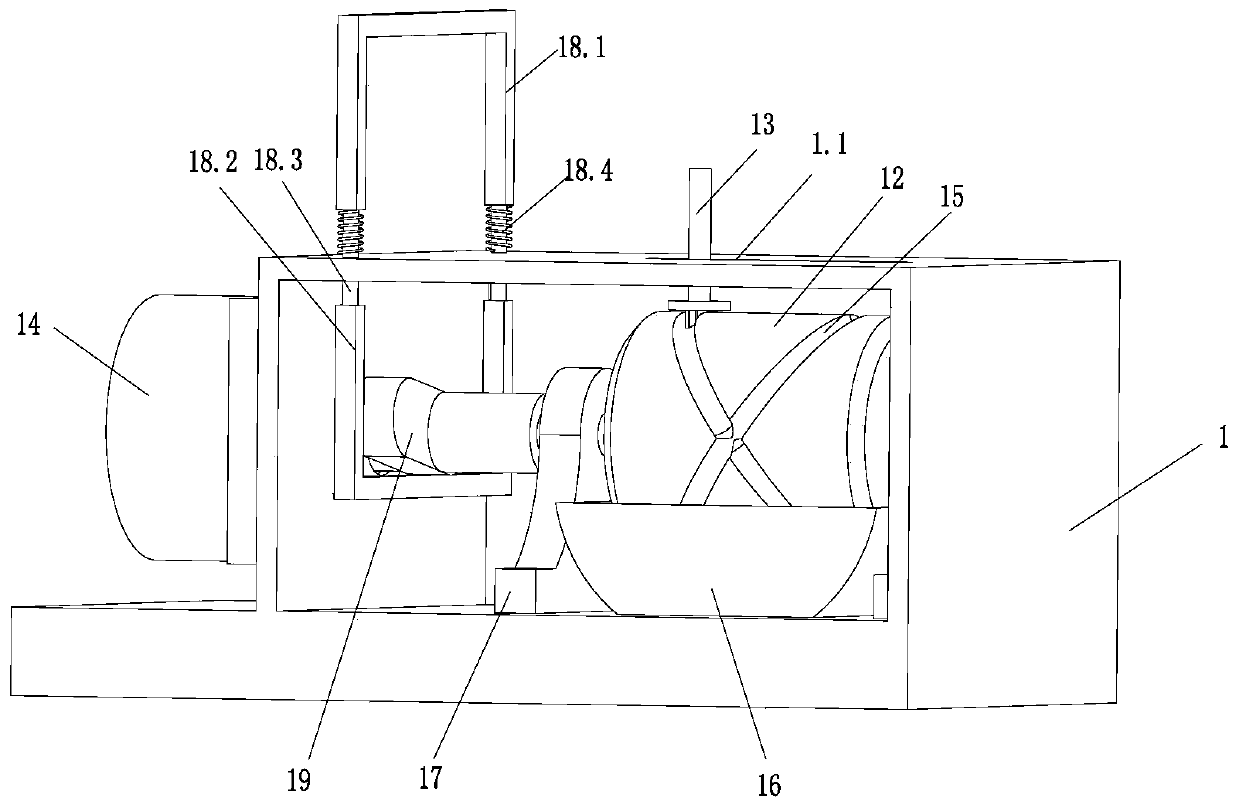

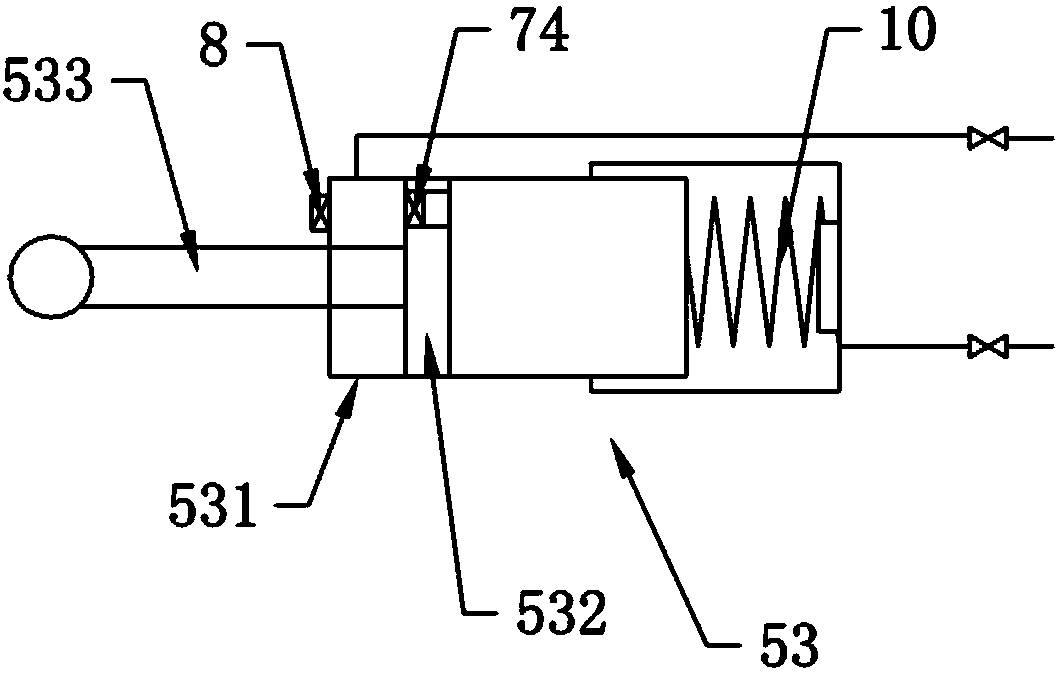

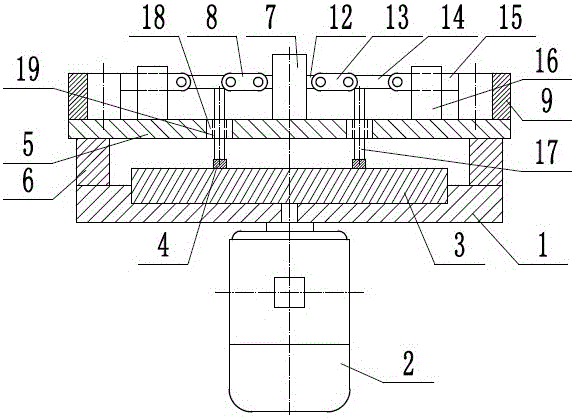

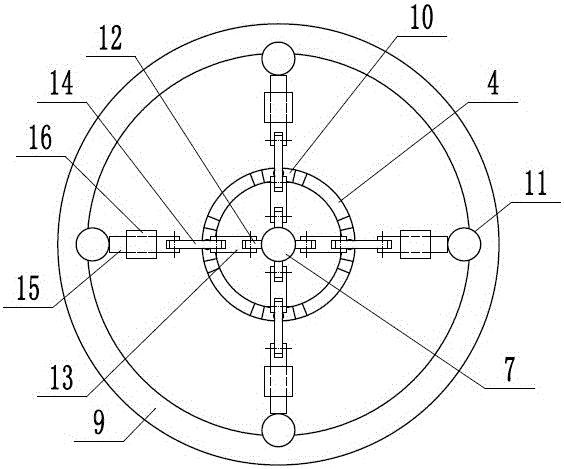

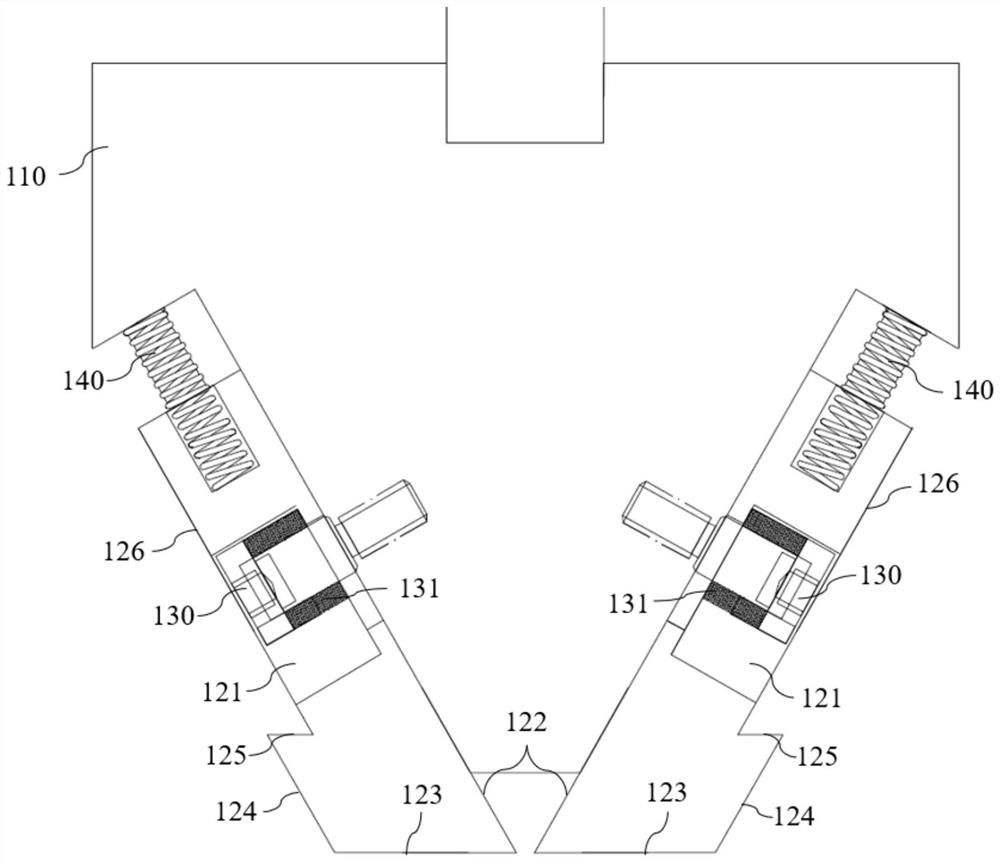

Self-adaptive type flexible gripper

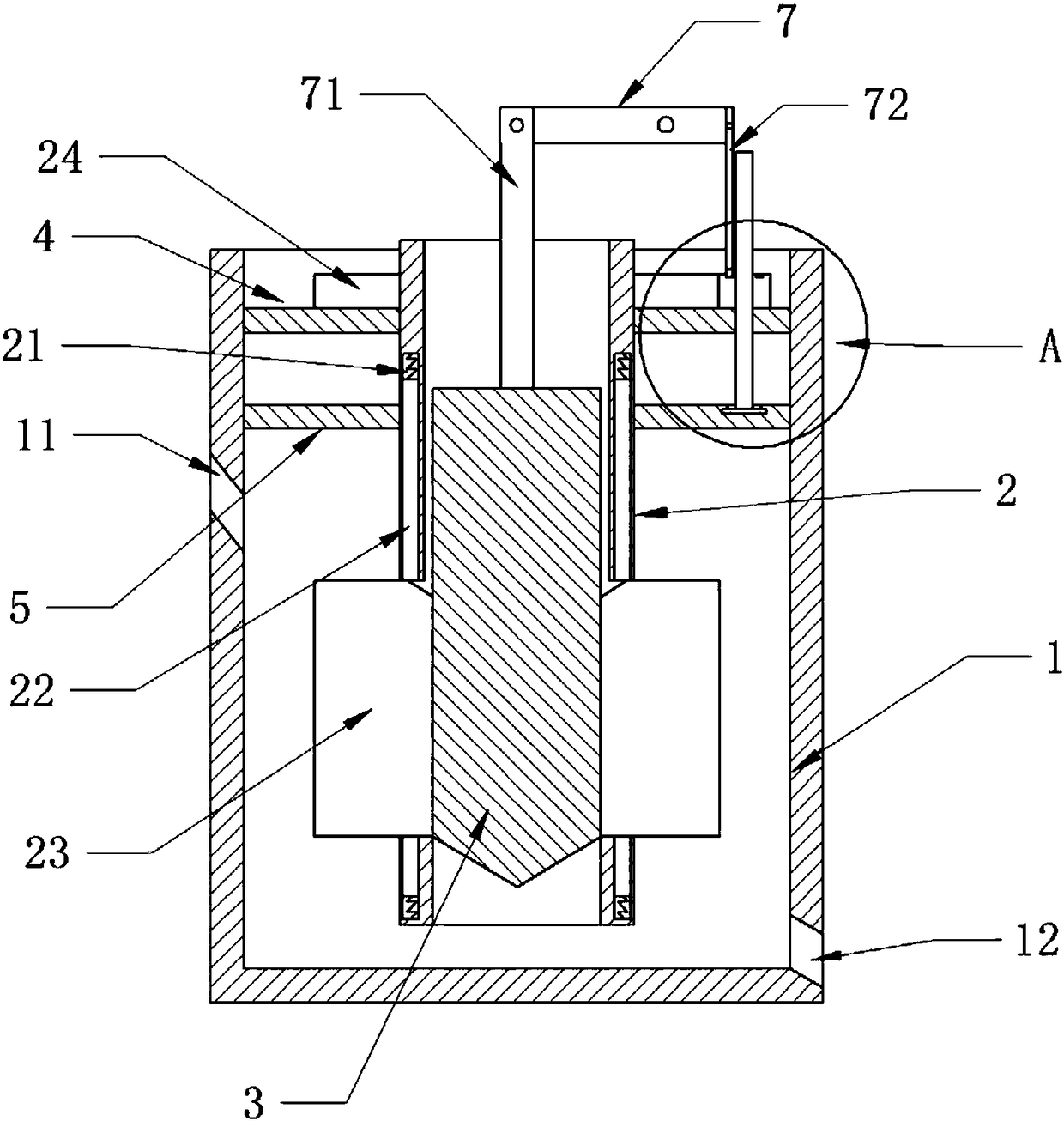

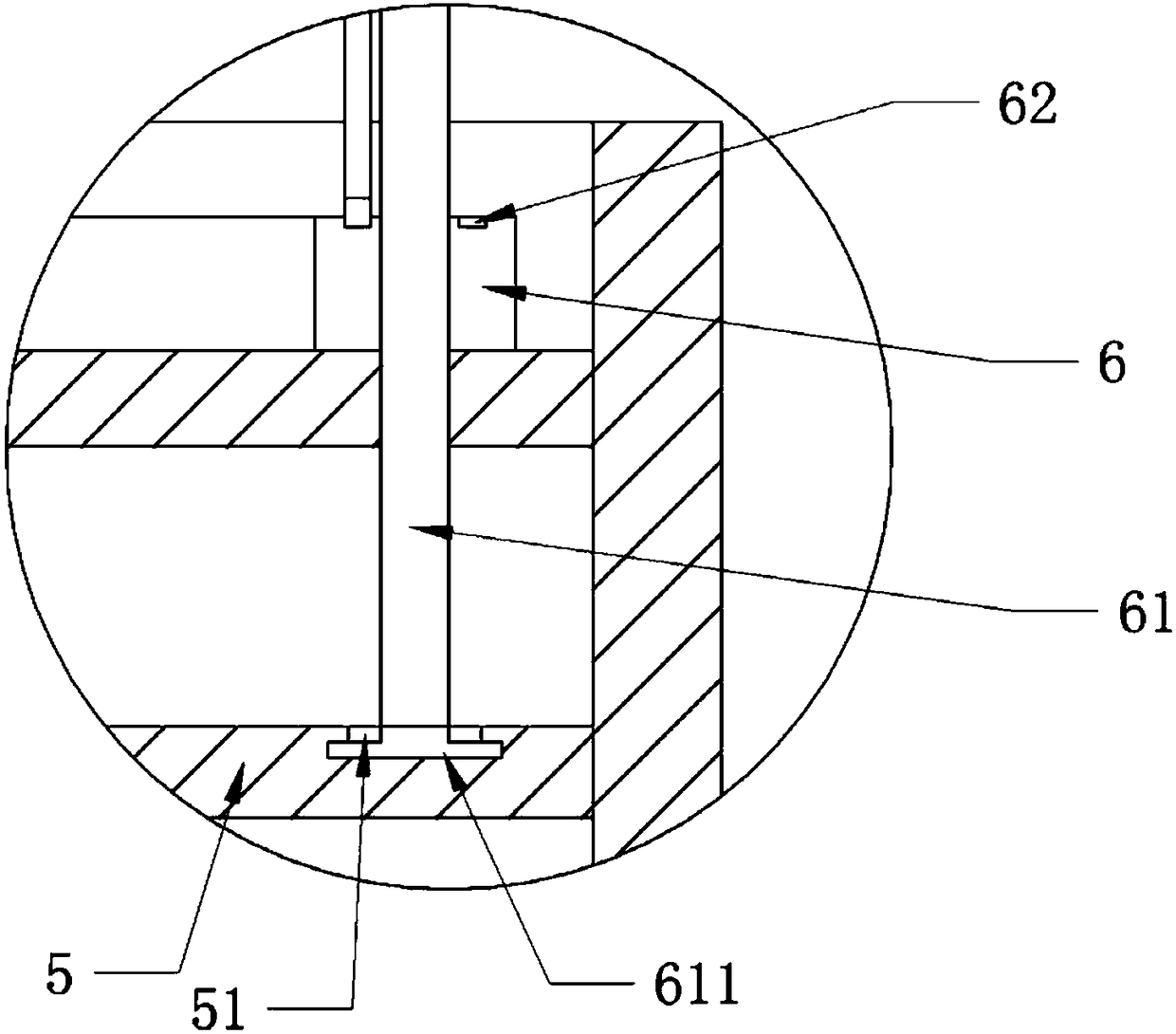

ActiveCN108555958AGuaranteed normal slidingSlide to achieveGripping headsEnergy efficient computingEngineeringSelf adaptive

The invention discloses a self-adaptive type flexible gripper. The self-adaptive type flexible gripper comprises a slide block rail bracket, an end cover, a spiral rail disc, slide blocks, a motor andflexible single fingers, wherein the end cover is fixedly arranged on the slide block rail bracket; the spiral rail disc is arranged in the slide block rail bracket; the slide blocks are arranged onthe slide block rail bracket; the motor is fixedly arranged on the end cover and is used for driving the spiral rail disc to rotate; each flexible single finger is arranged under the corresponding slide block; an eddy-shaped rail is arranged on the spiral rail disc; a plurality of slide rails are distributed at the bottom end of the slide block rail bracket along the radial direction; the top partof each slide block is matched with the eddy-shaped rail; when the spiral rail disc is driven to rotate by the motor, each slide block drives the corresponding flexible single finger to move along the slide rail. The self-adaptive type flexible gripper has the advantage that the gripping position of each flexible single finger can be changed; the structure is simple, and the installation, detachment and maintenance are easy.

Owner:SUZHOU UNIV

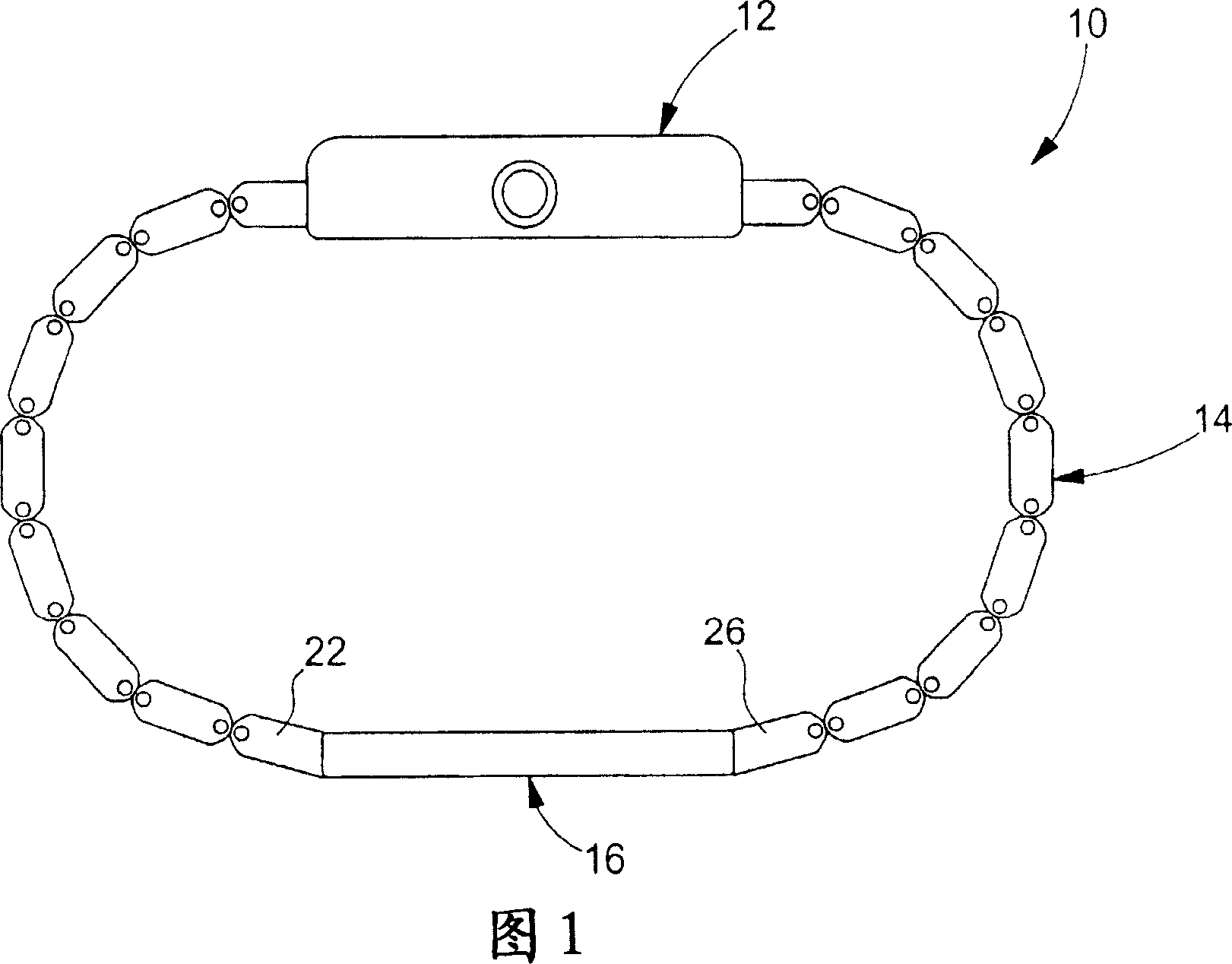

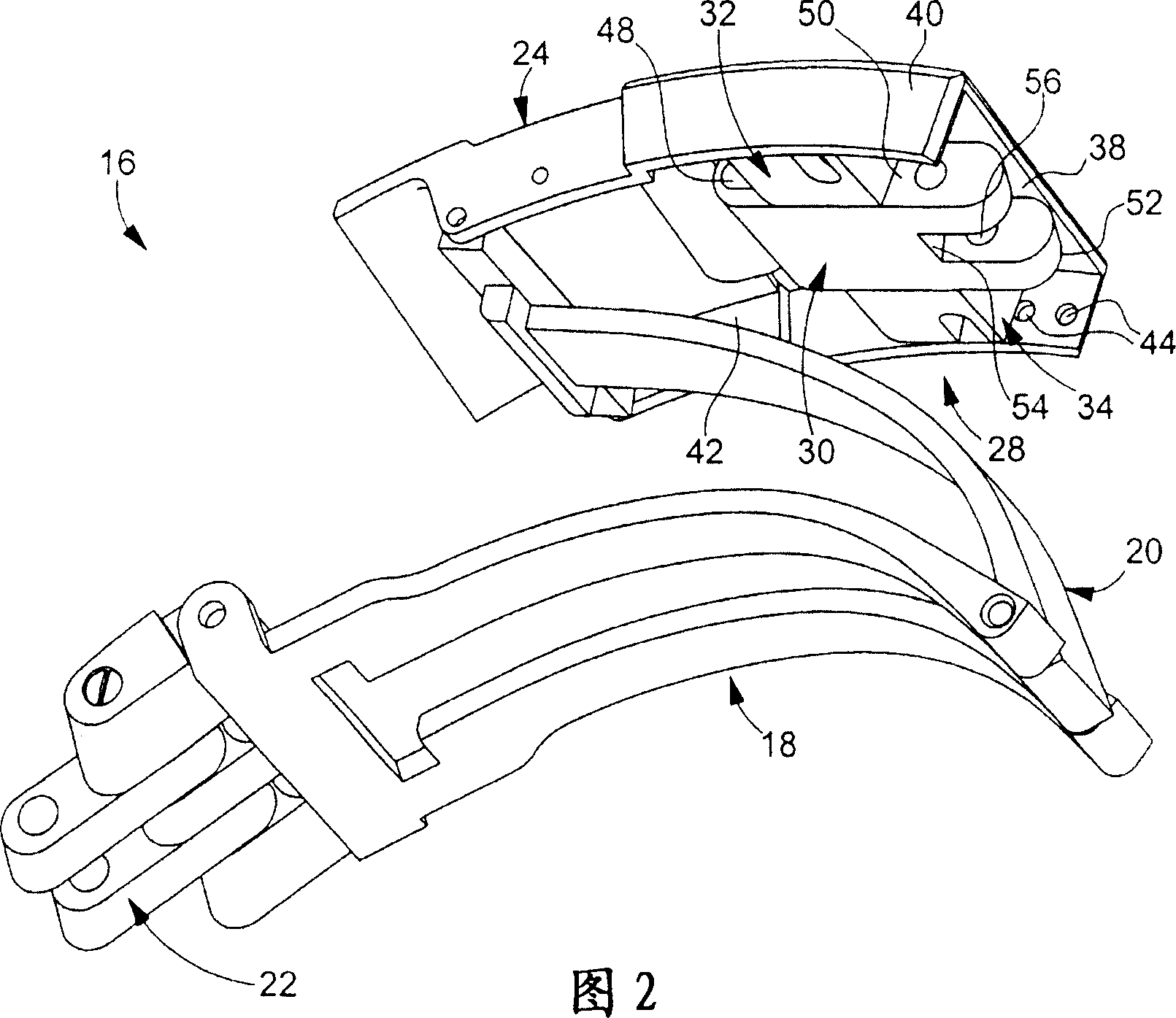

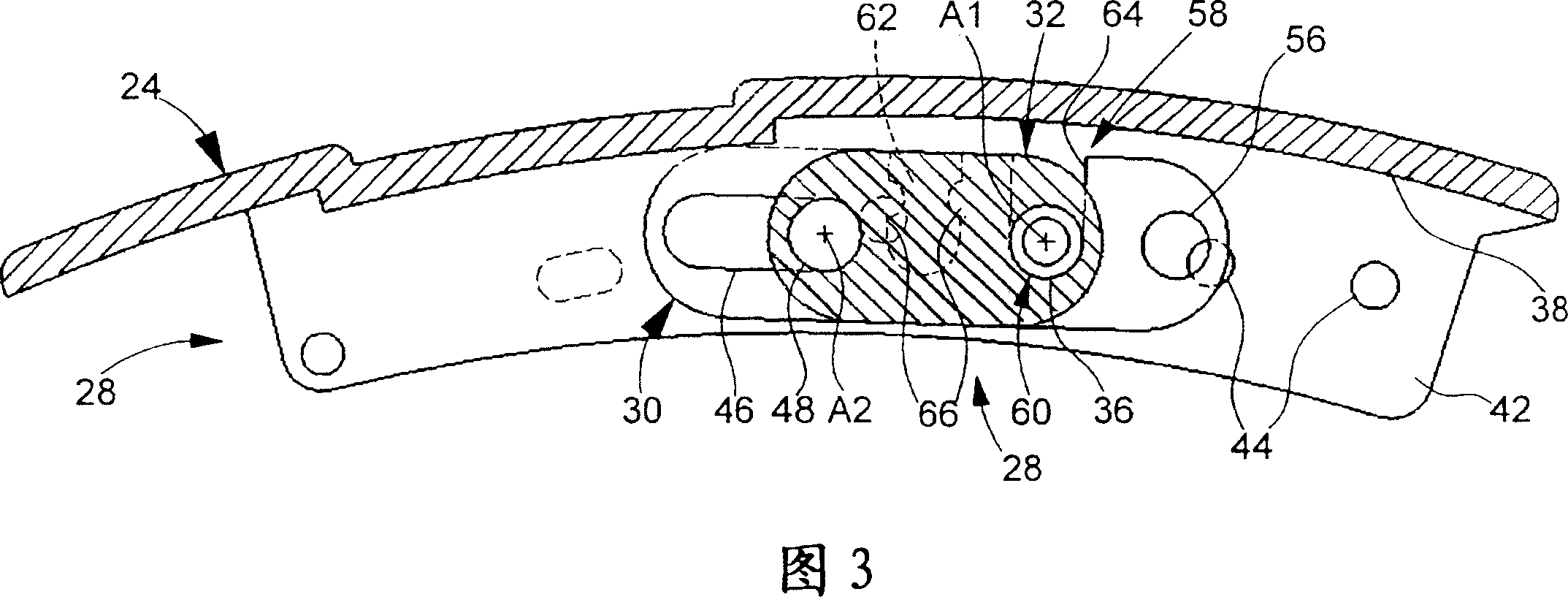

Device for setting the length of a bracelet, bracelet provided with such a device and watch fitted with such a bracelet

Owner:WERTHANOR

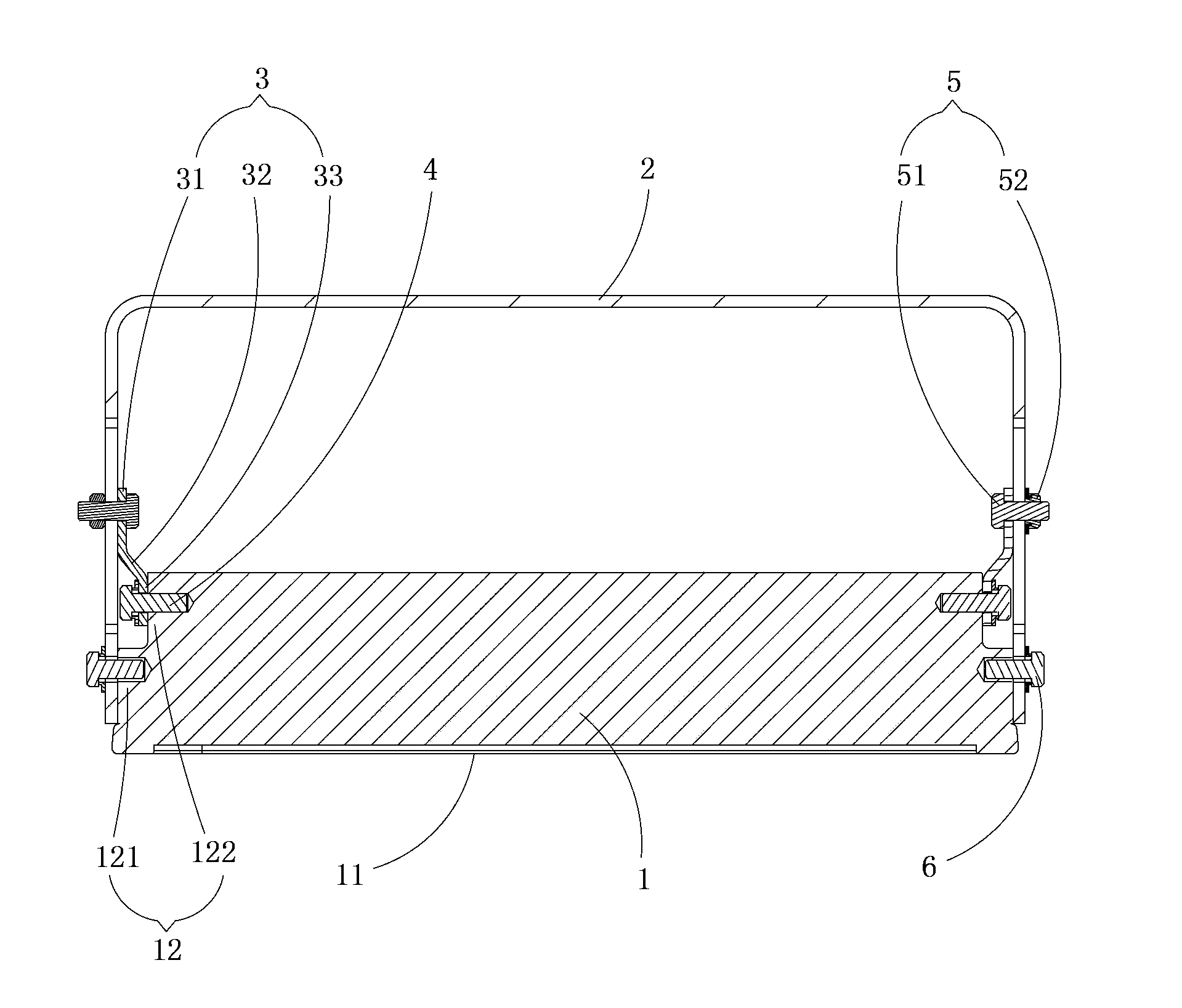

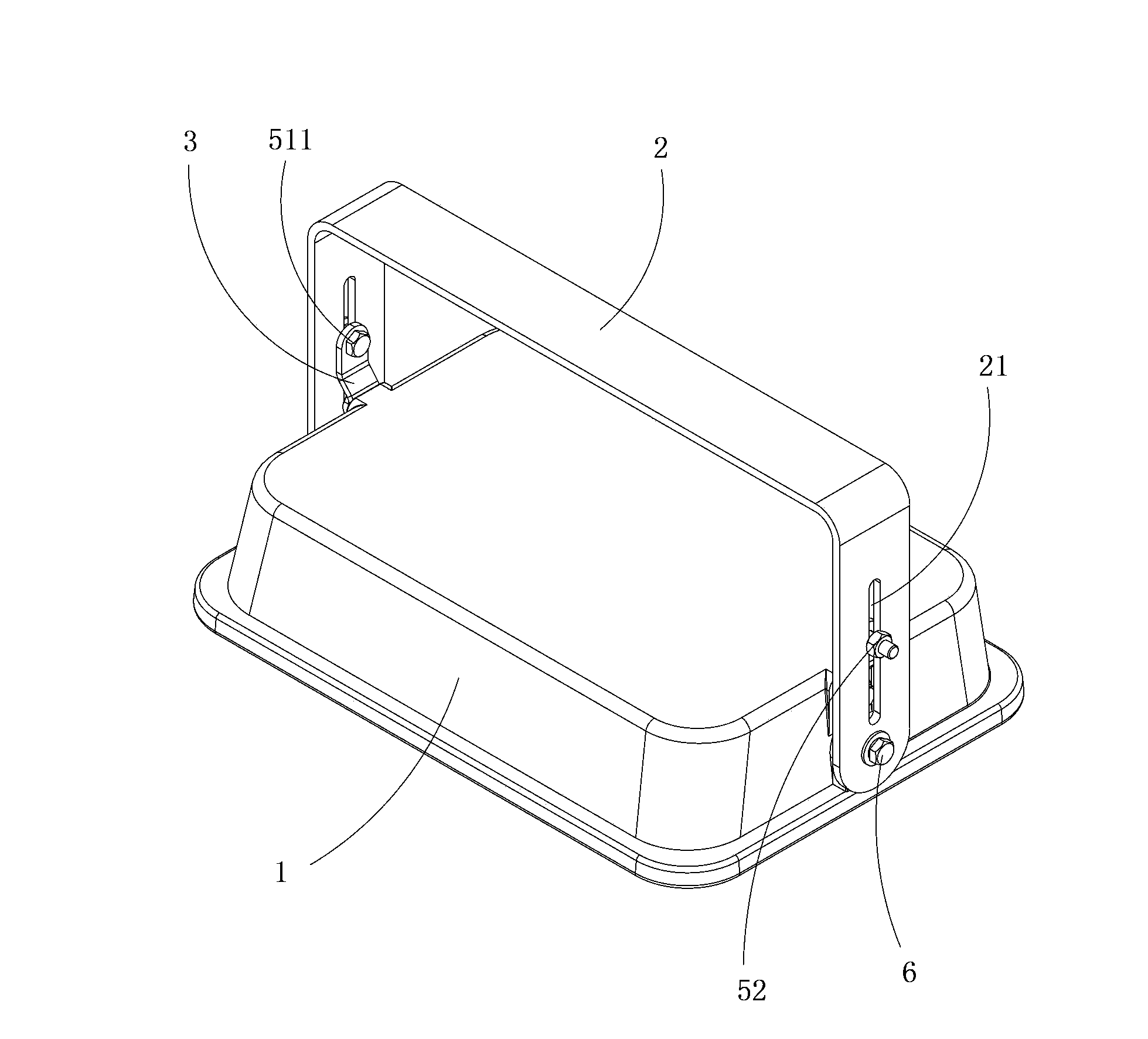

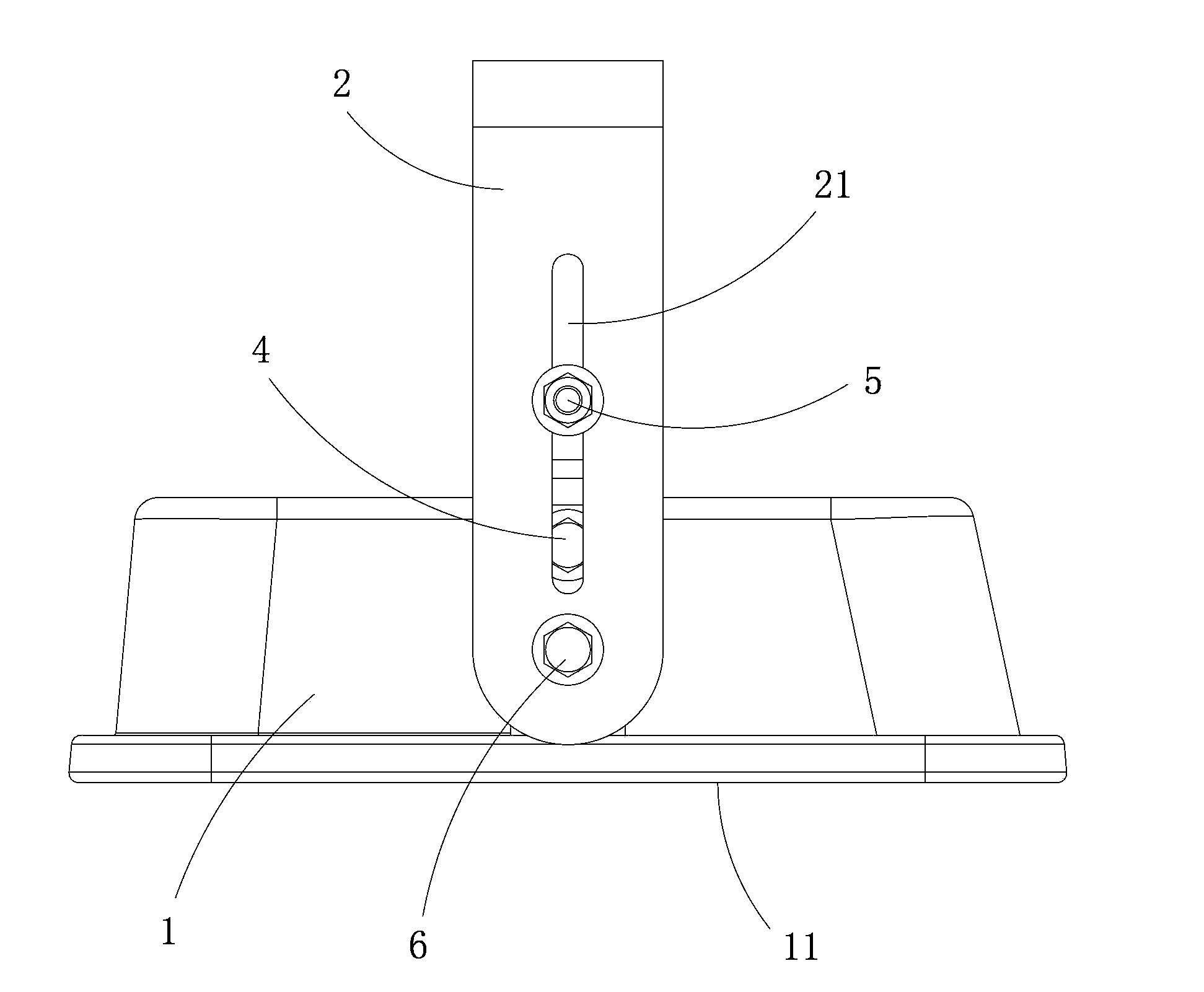

Lamp mounting structure

InactiveCN103791462APrecise positioningIrradiation angle stepless adjustmentLighting support devicesLight fasteningsEngineeringIllumination angle

The invention is applicable to the technical field of lamp installation and discloses a lamp mounting structure. The lamp mounting structure comprises a lamp body and a support, wherein the support is connected with the lamp body in a hanging way, a positioning block capable of preventing the support and the lamp body from rotating relatively is arranged between the support and the lamp body, one end of the positioning block is fixed on the lamp body, while the other end of the positioning block is connected to the support through a locking member, and a sliding groove allowing the locking member to pass therethrough is formed on the support. The lamp mounting structure is characterized in that the positioning block is arranged between the support and the lamp body, one end of the positioning block is fixed on the lamp body, while the other end of the positioning block is connected to the support through the locking member, and the support is further fixedly connected with the lamp body, so that the connection of the lamp body and the support is secured in the three-point positioning way and relative rotation between the lamp body and the support is effectively prevented, and in the meantime, the sliding groove is formed on the support so that the positioning block is slidingly connected to the support and the connection points are continuous, and as a result, the illumination angle of the lamp is accurate and can be adjusted electrodelessly, and the illumination effect of the lamp is improved.

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

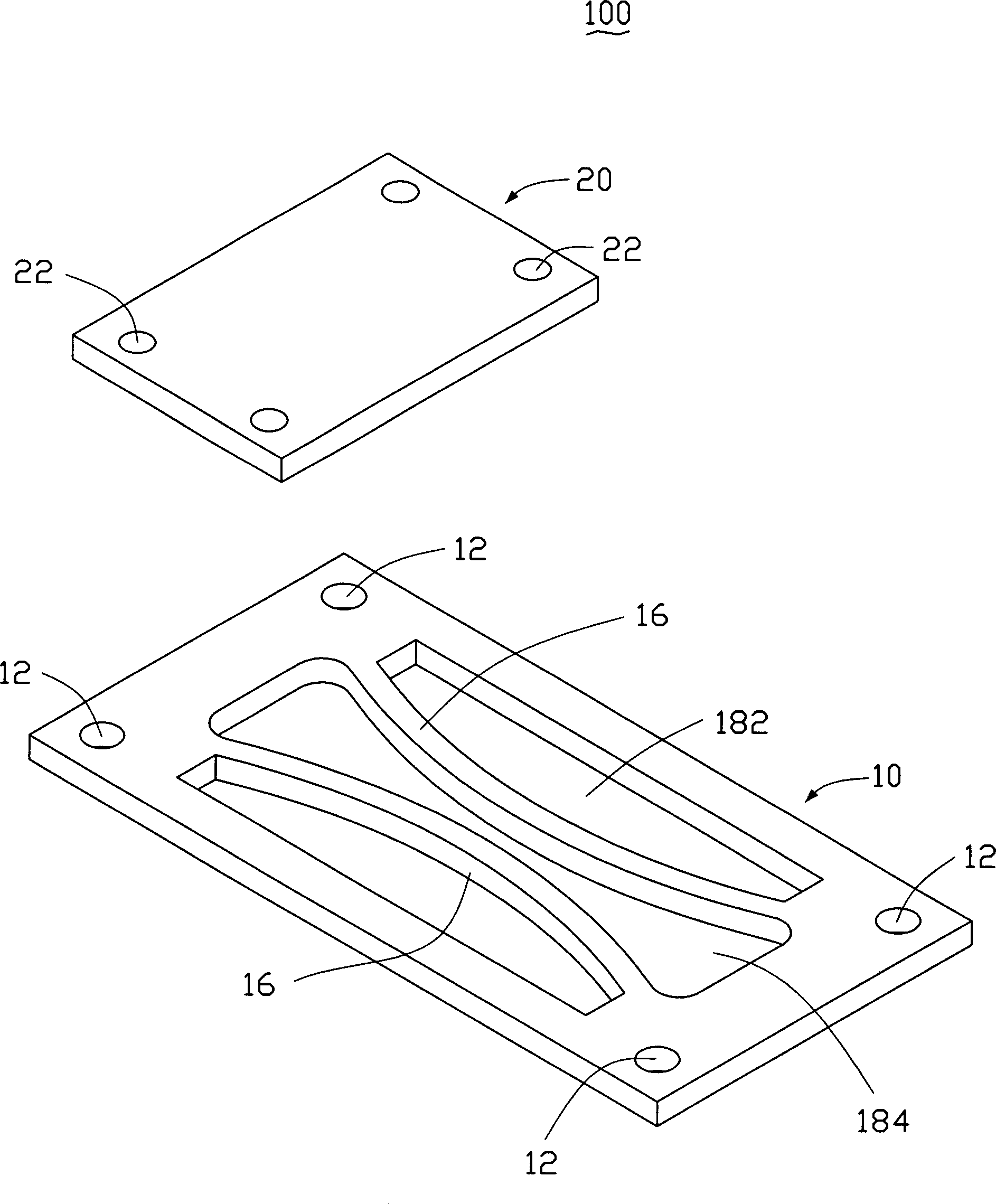

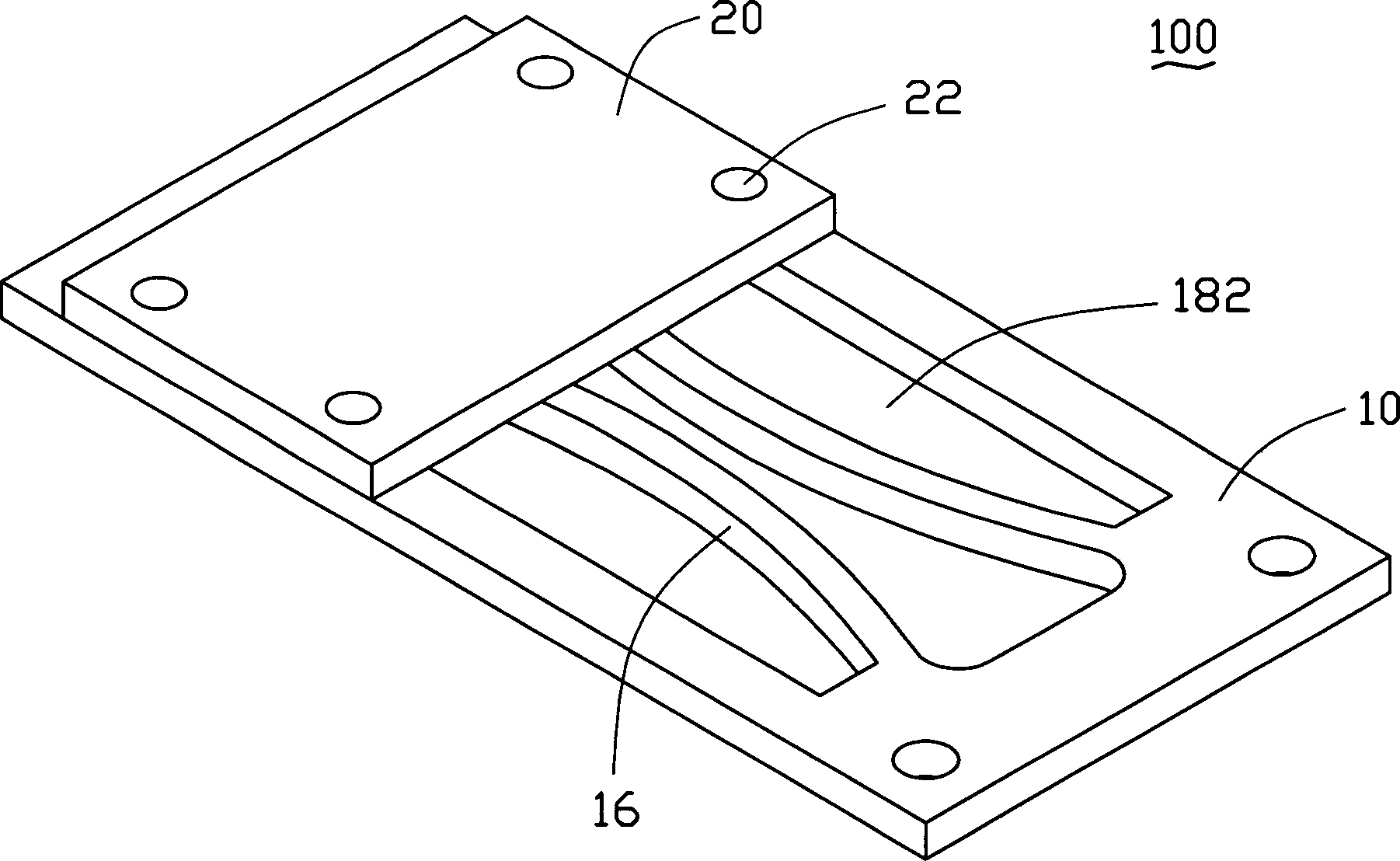

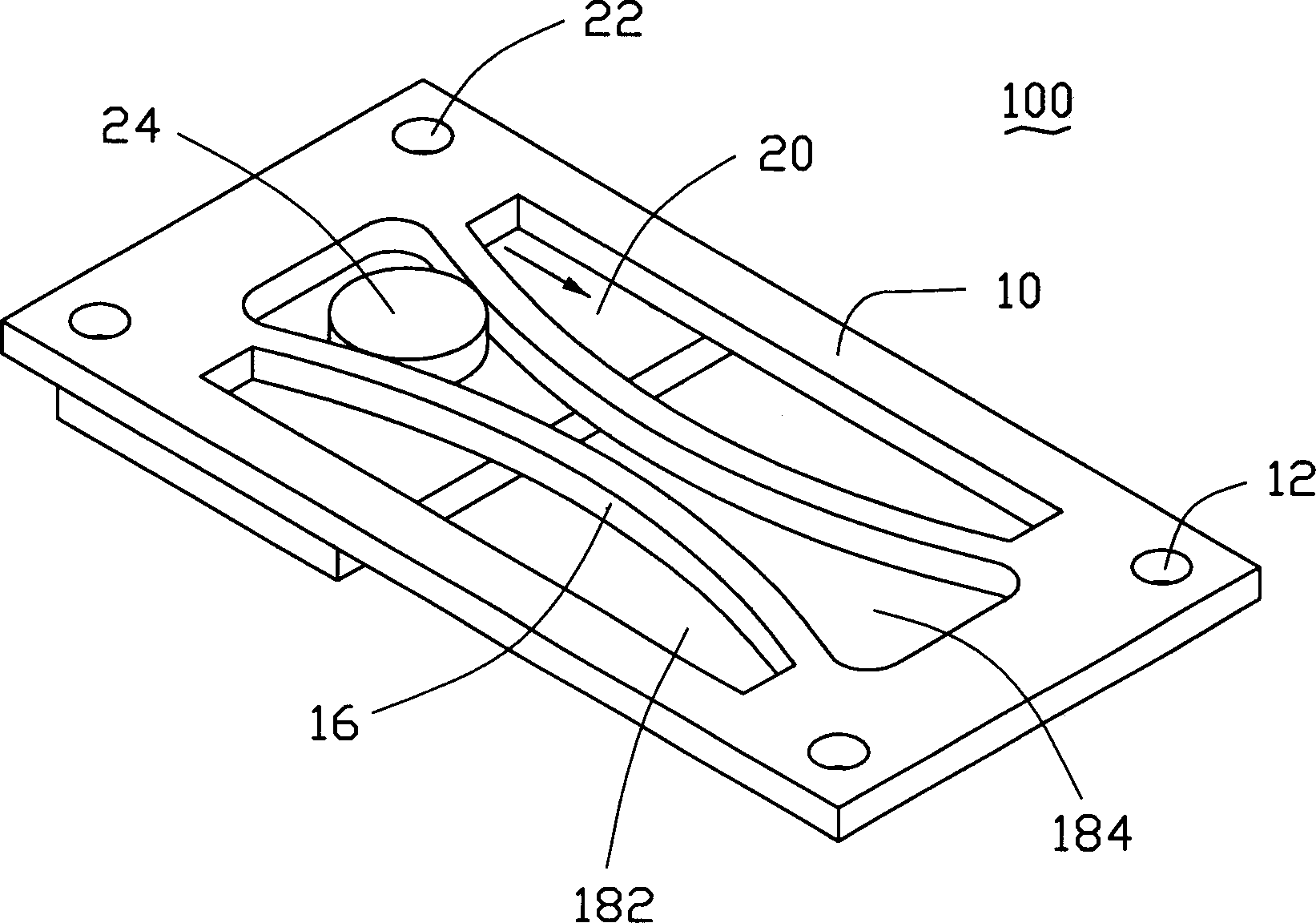

Structure of sliding closure, and portable electronic equipment of using the structure of sliding closure

InactiveCN1874667AImprove operational convenienceSlide to achieveSubstation equipmentRack/frame constructionElastomerEngineering

The invention comprises: a motherboard, an elastic piece and a sliding panel. The elastic piece is located at the motherboard, and incorporates with the motherboard to form a guide hole; the sliding panel can make opposite slide to the motherboard, and it comprises a protruding post located on the one of its sides facing the surface of the motherboard; the protruding post fits guide hole; when the protruding post slides in the guide hole and reaches a preset position, the elastic piece provide a force for the protruding post to push the protruding post move in the guide hole.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

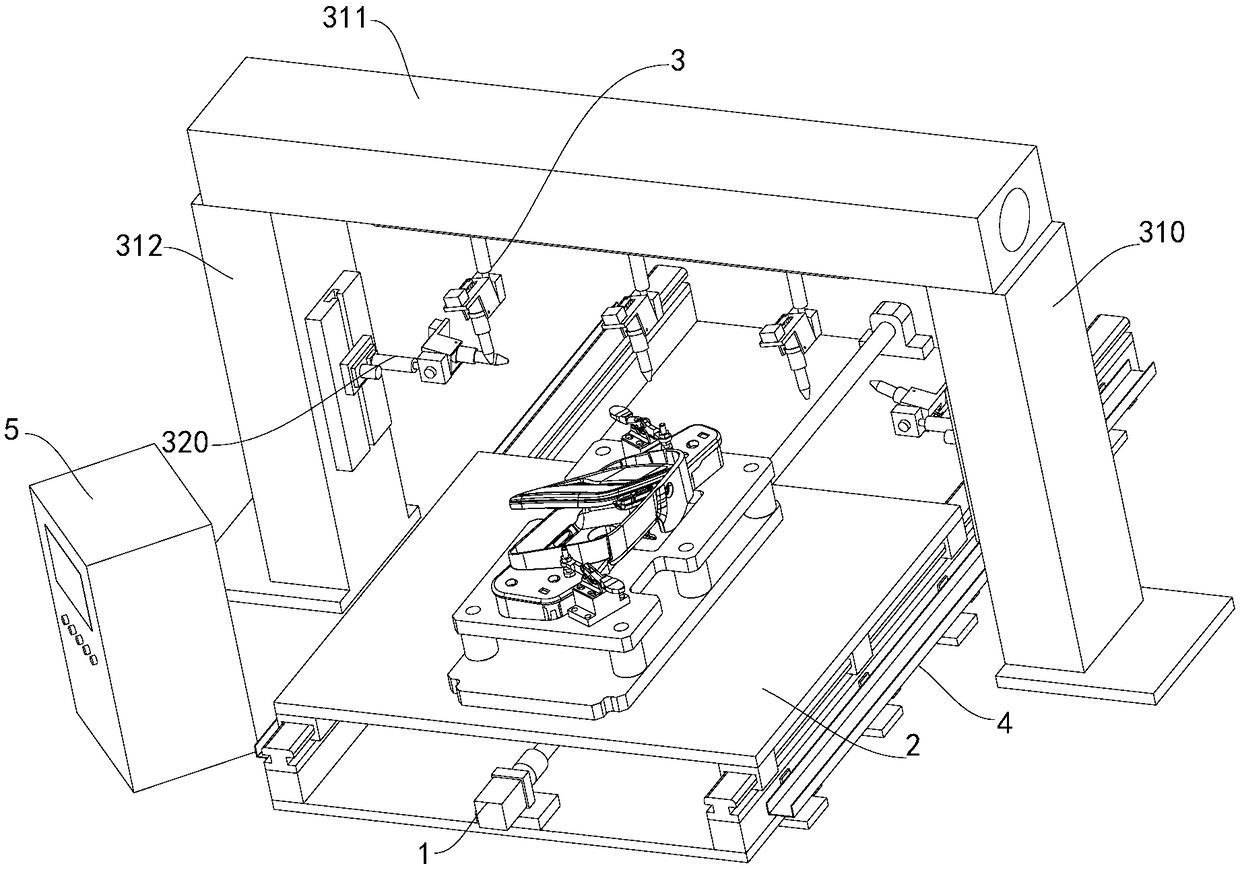

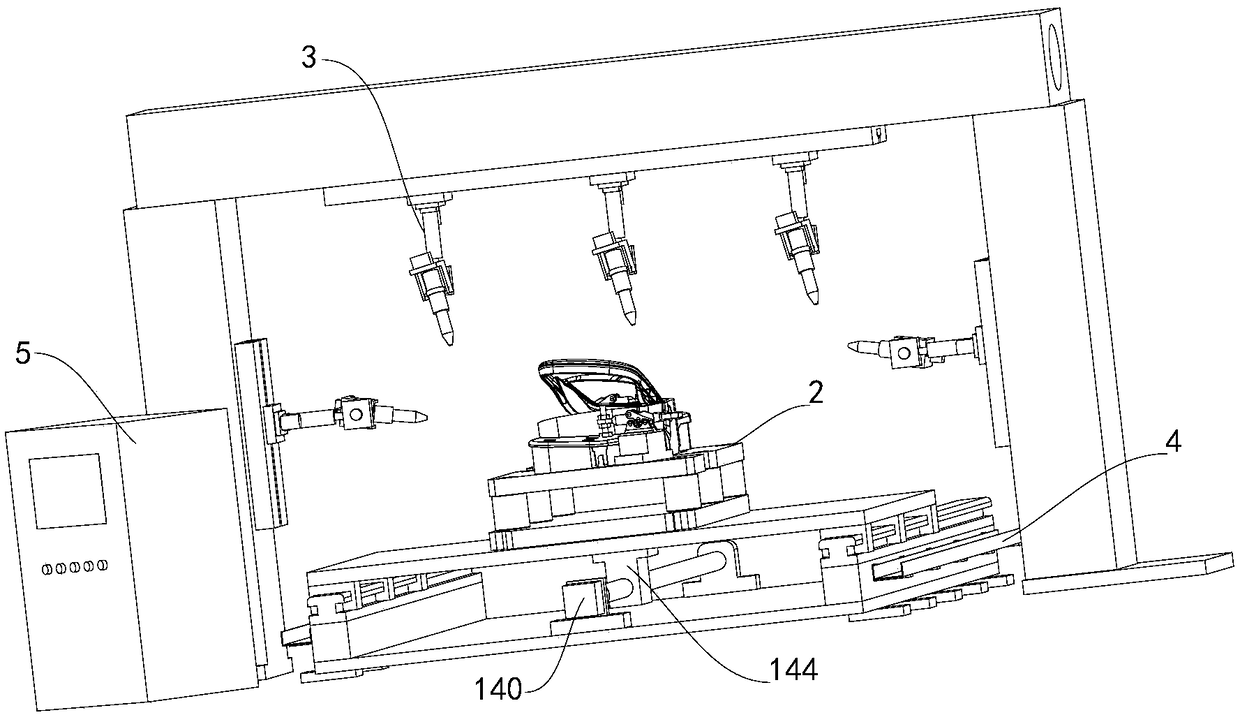

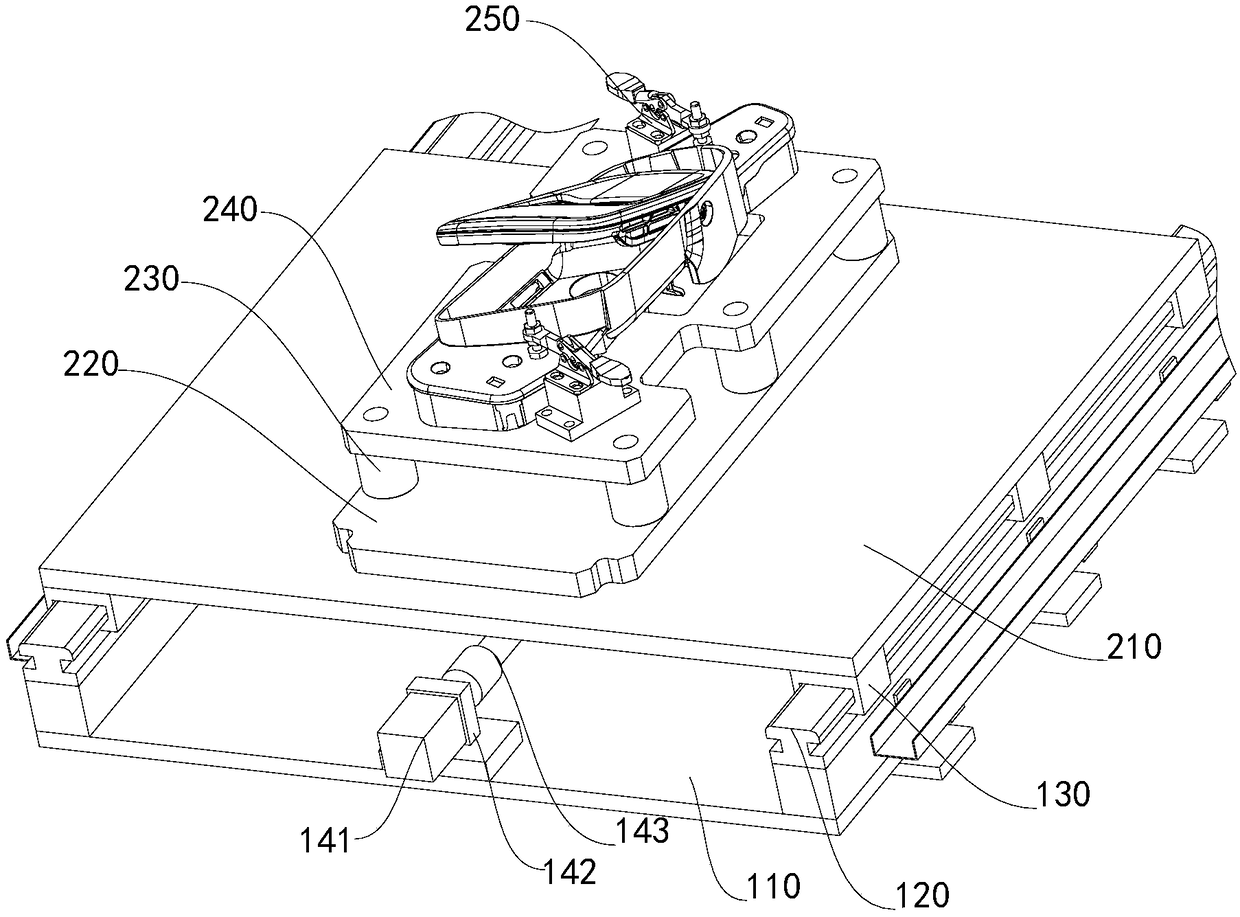

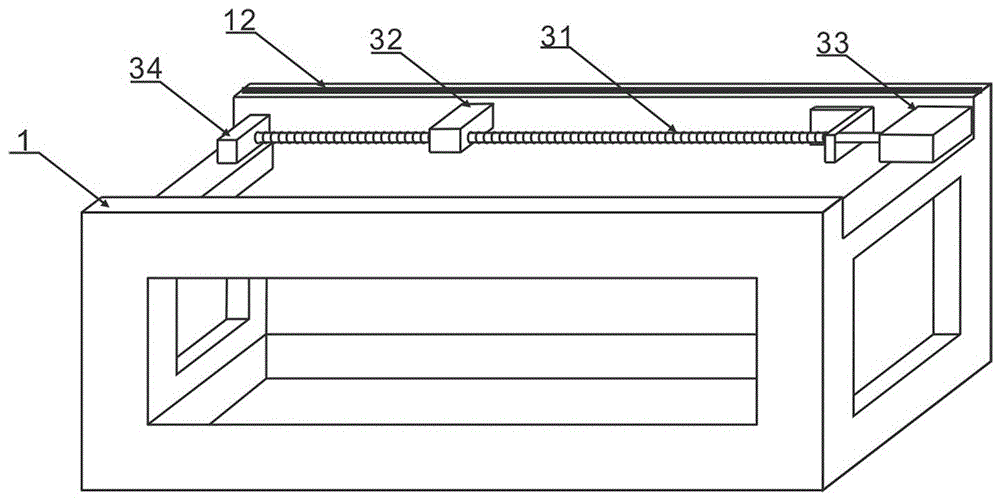

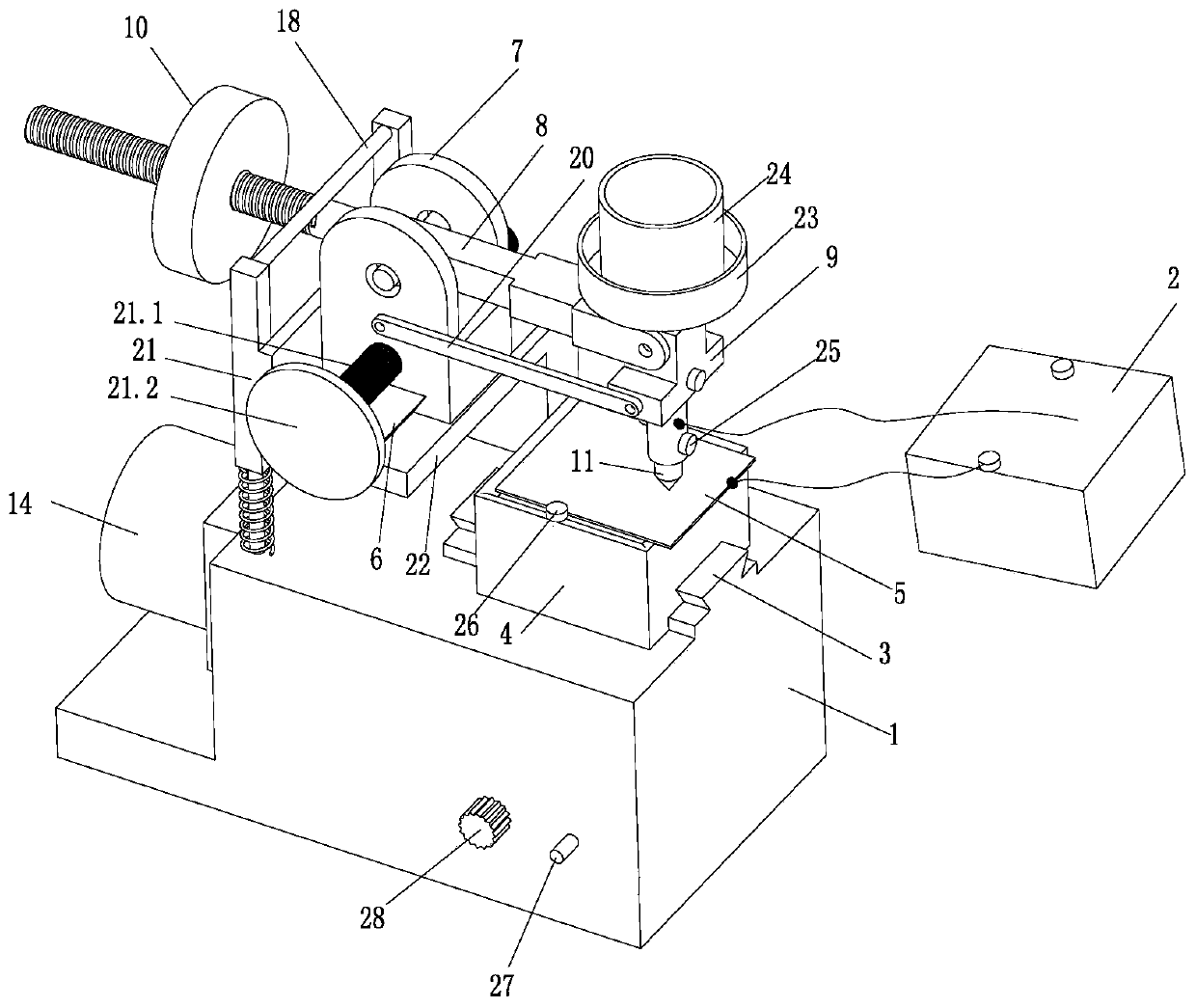

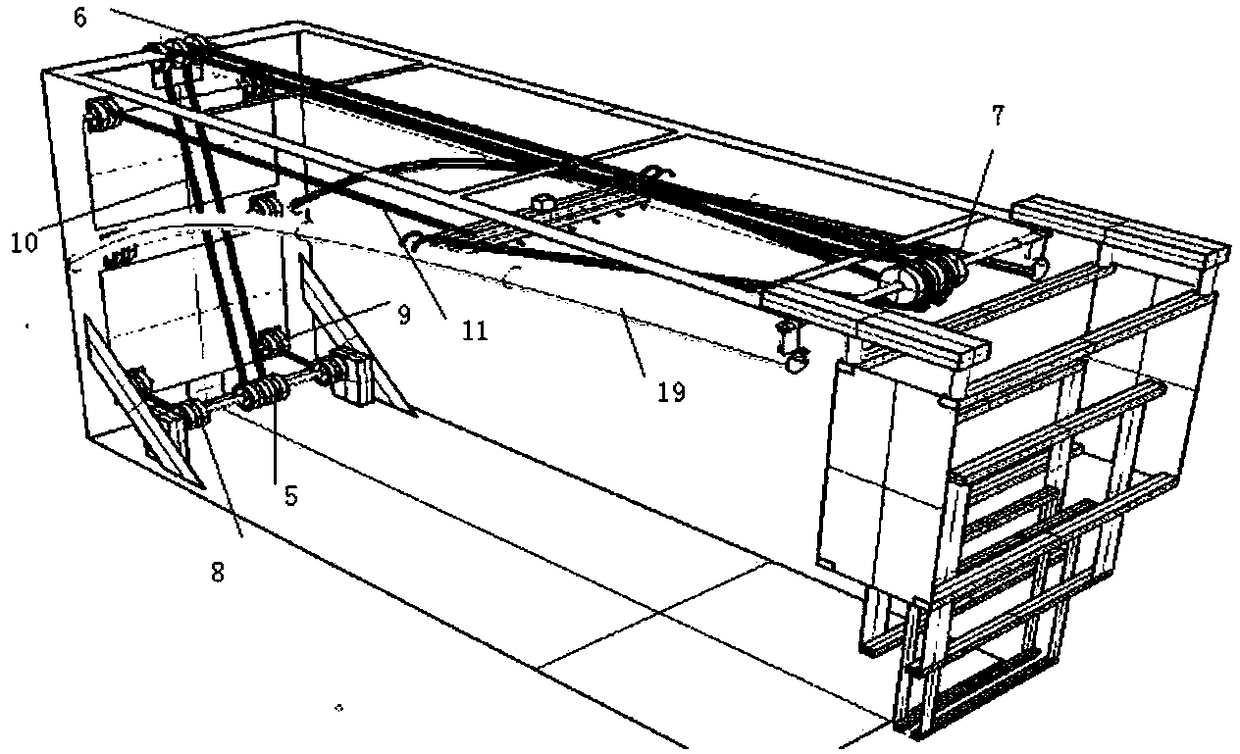

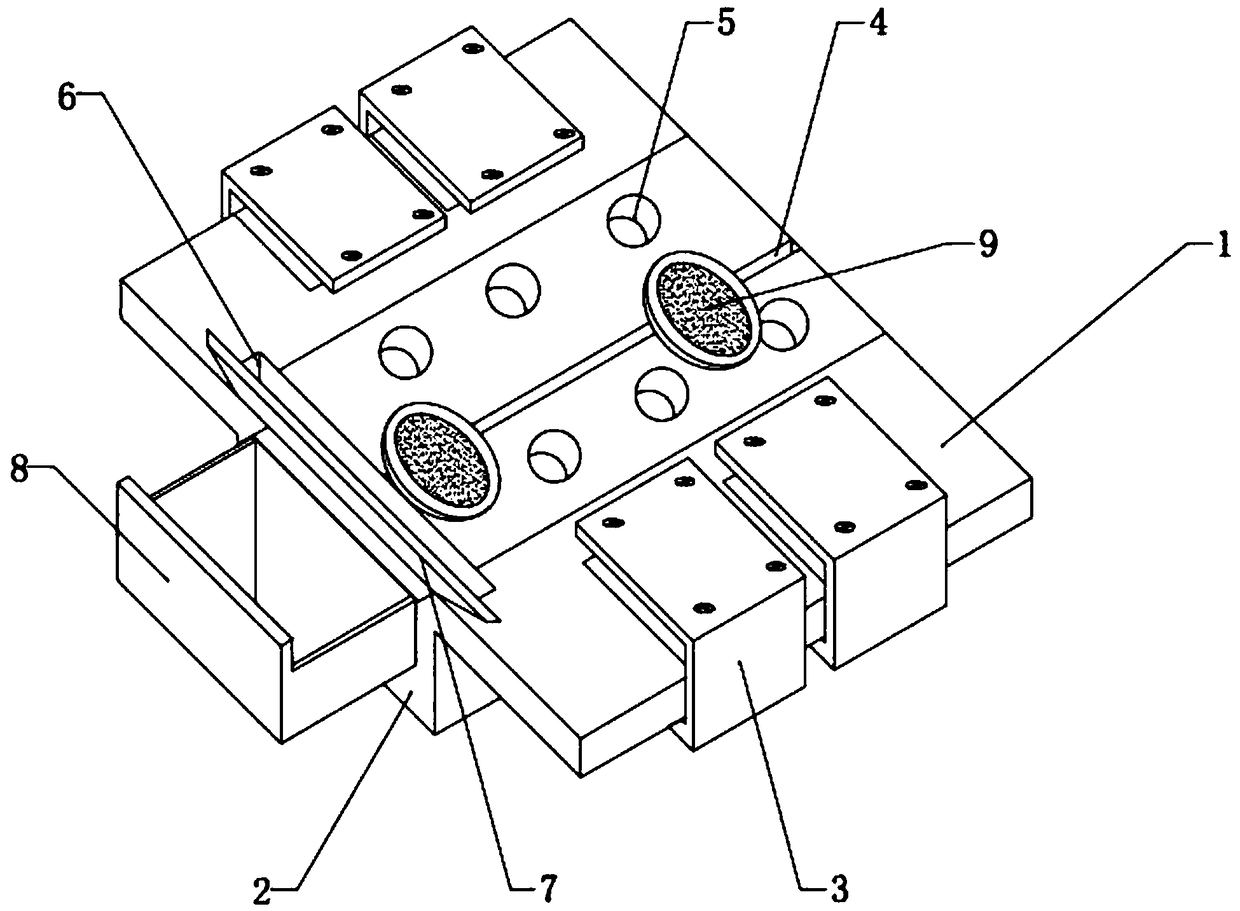

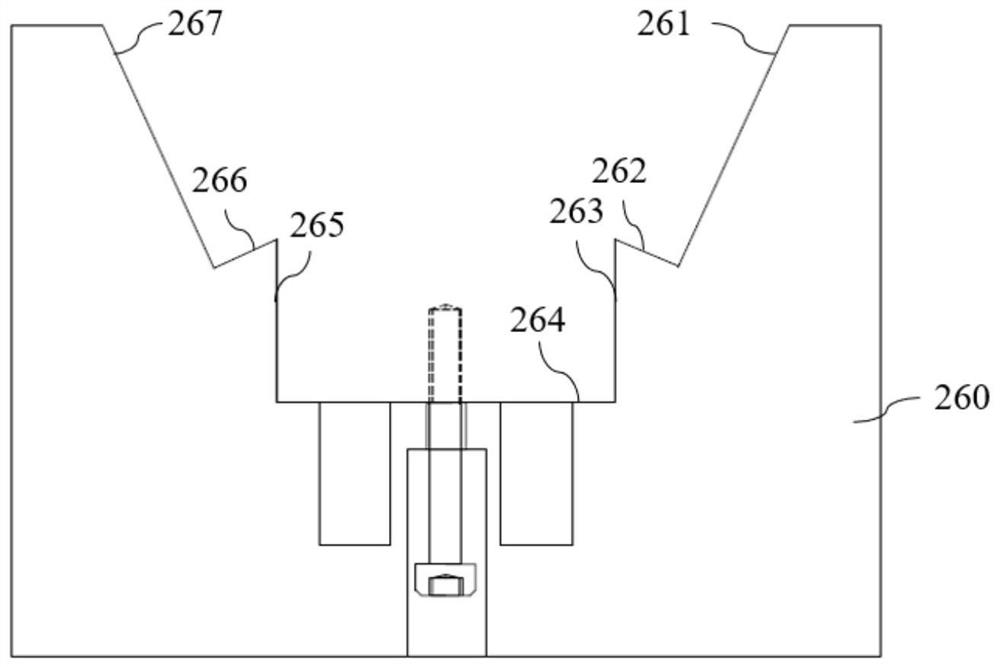

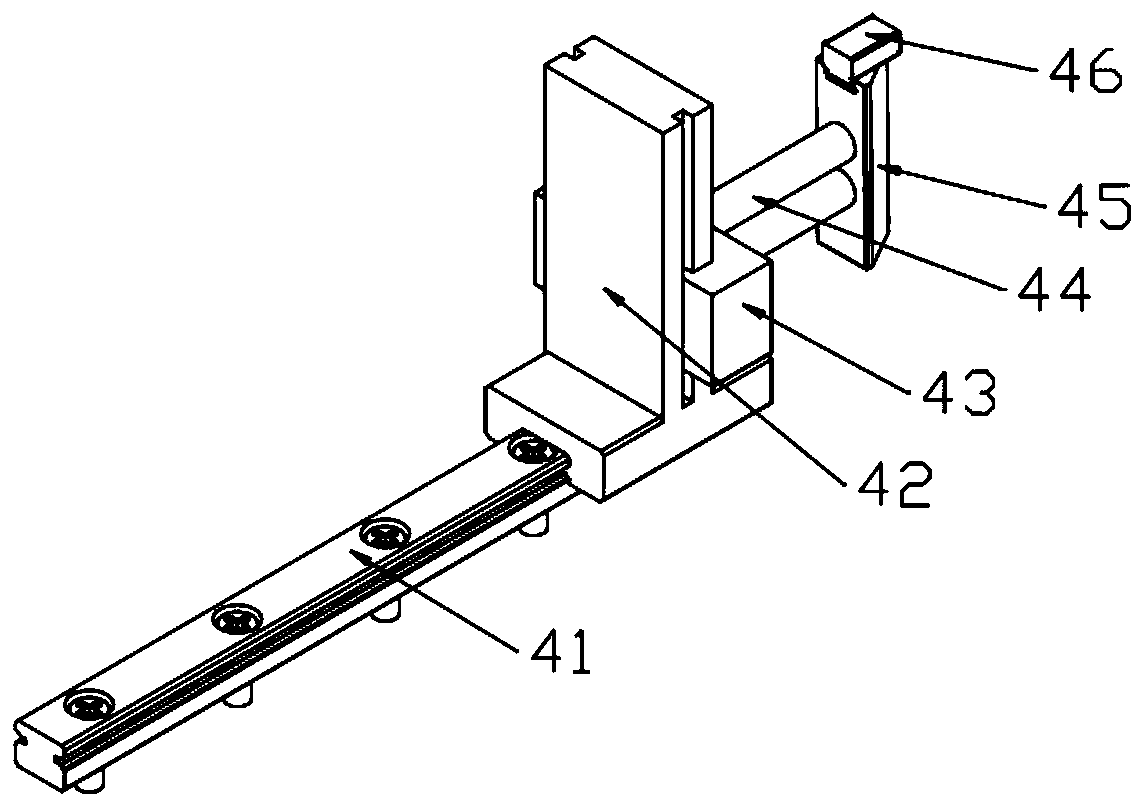

Simple automatic welding system

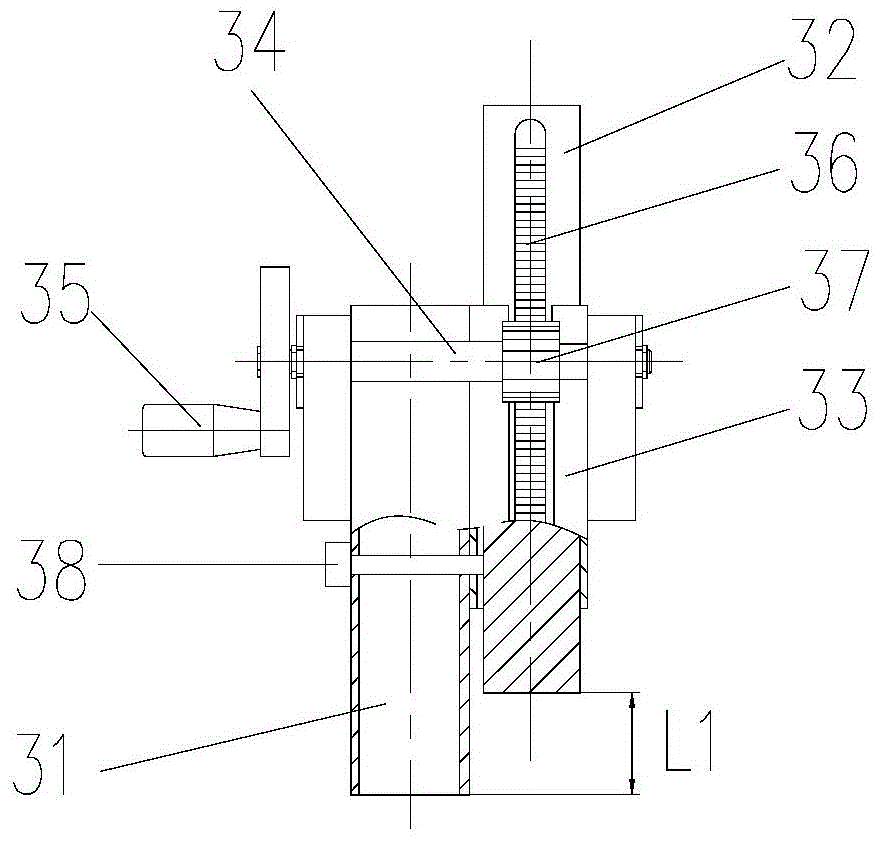

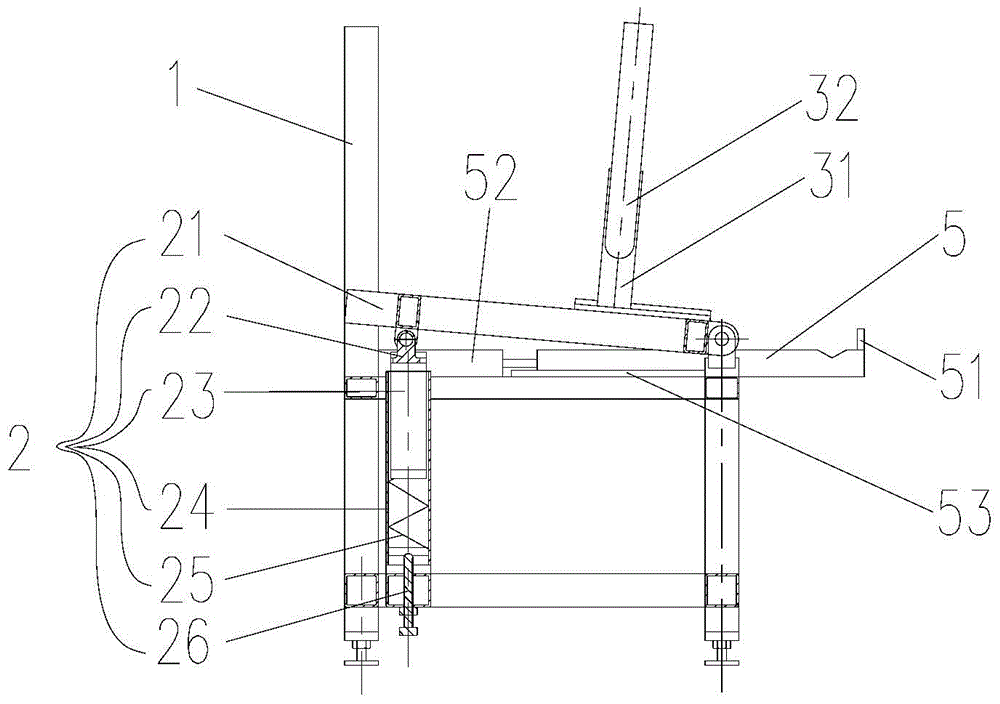

PendingCN109352226AAutomatically adjust the positionEasy to weldWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention relates to a simple automatic welding system. The simple automatic welding system comprises a driving mechanism, a clamp assembly and a welding assembly, wherein the clamp assembly is arranged on the driving mechanism and moves through the driving mechanism; and the welding assembly is used for welding a workpiece clamped on the clamp assembly. The simple automatic welding system hasthe beneficial effects that compared with a suspension type spot welding machine, the simple automatic welding system can automatically adjust the position of the workpiece, is convenient for the welding of different welding points of the workpiece and facilitates the efficiency improvement; and compared with a spot welding robot, the simple automatic welding system has high flexibility, simple structure and low cost.

Owner:WUHAN JIEZHONG AUTO PARTS CO LTD

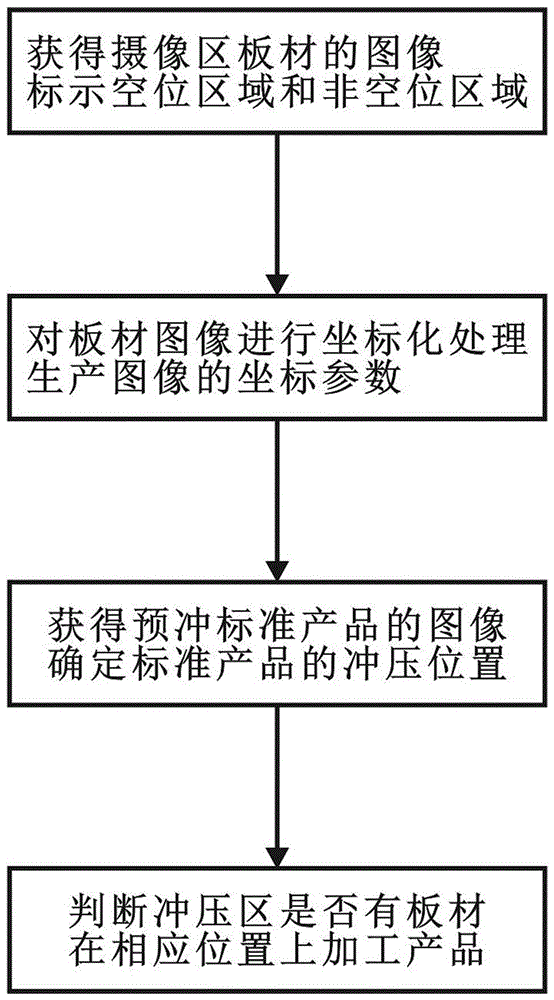

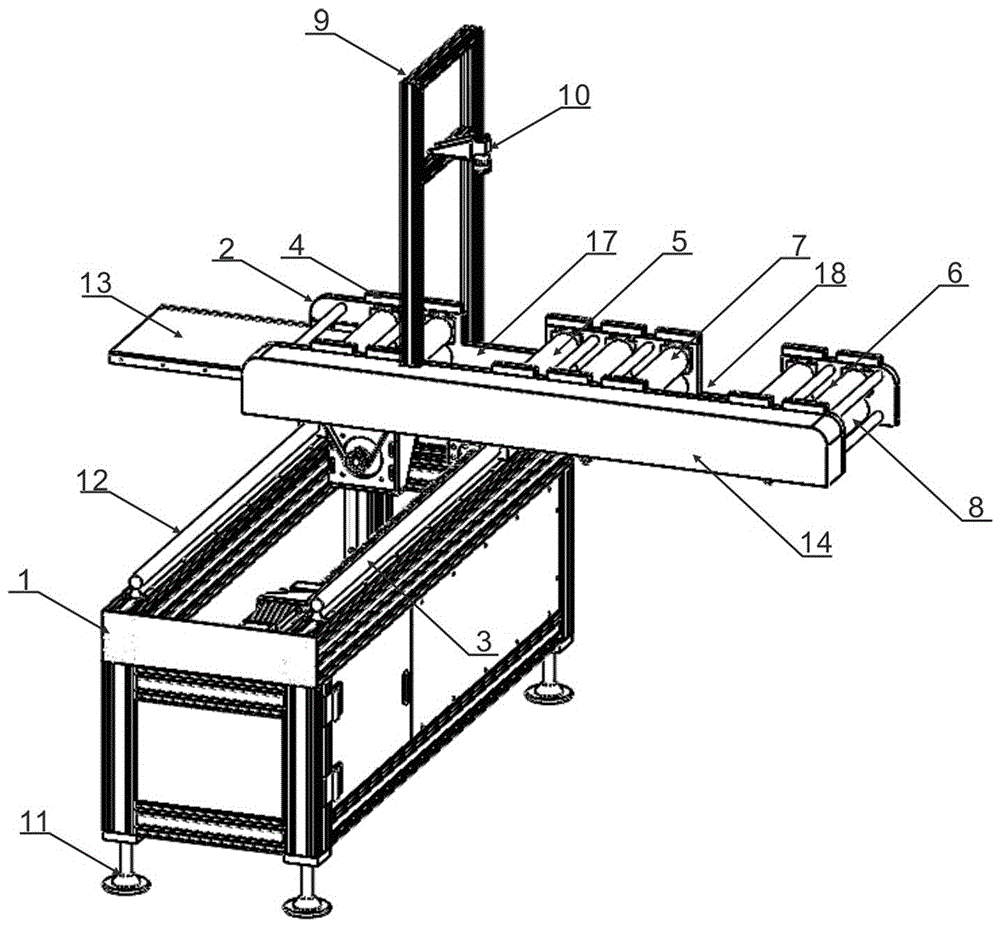

Production method based on intelligent vision feeder

InactiveCN106216545ALow shape requirementIncrease profitMetal-working feeding devicesMetal working apparatusPunchingForm processing

The invention discloses a production method based on an intelligent vision feeder. The production method based on the intelligent vision feeder comprises the steps of obtaining the image of a plate to be machined in the camera shooting area of the vision feeder, and processing the image to obtain the shape information, in the image, of the plate; carrying out coordinate forming processing on the image to generate the coordinate parameters of the vacancy areas and the non-vacancy areas of the plate; acquiring the transmission speed of the rolling shaft group of the vision feeder to obtain the conveying speed of the plate to be machined; inputting the dimension information of a machining die; and judging whether a plate to be machined exists in the punching area of the feeder, and after the plate to be machined enters the punching area, and starting a punching die to carry out punching on the corresponding machining coordinates after the plate to be machined enters the punching area so as to obtain punching products. With the production method based on the intelligent vision feeder, it can be achieved that the feeder and a punching machine are used in cooperation to realize linkage, the requirements on the shapes of plates are low, even irregular or waste plates can also be punched in the non-vacancy areas, and consequently, the use ratio of plates is increased, the cost is greatly reduced, and the production efficiency is improved.

Owner:成都柯博特自动化科技有限公司

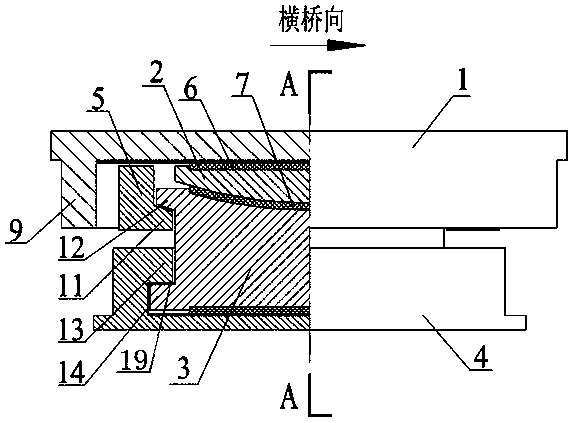

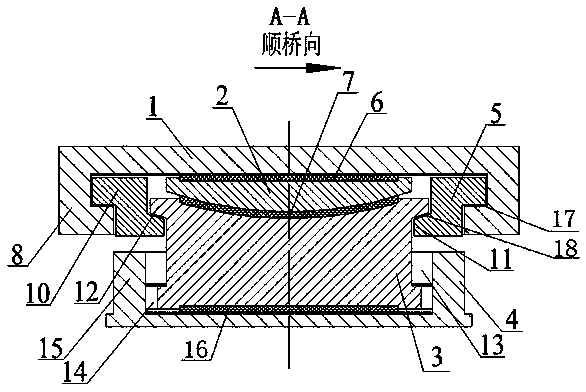

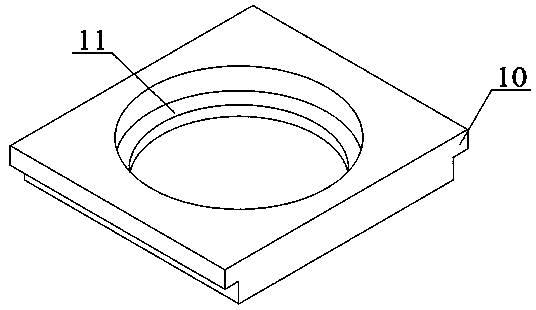

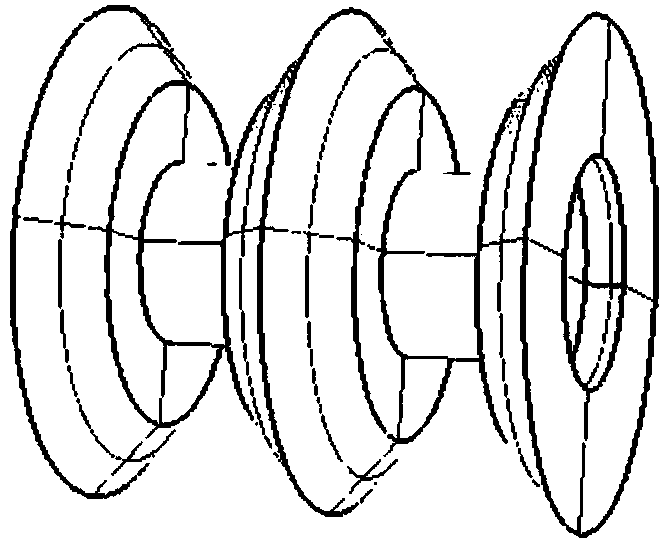

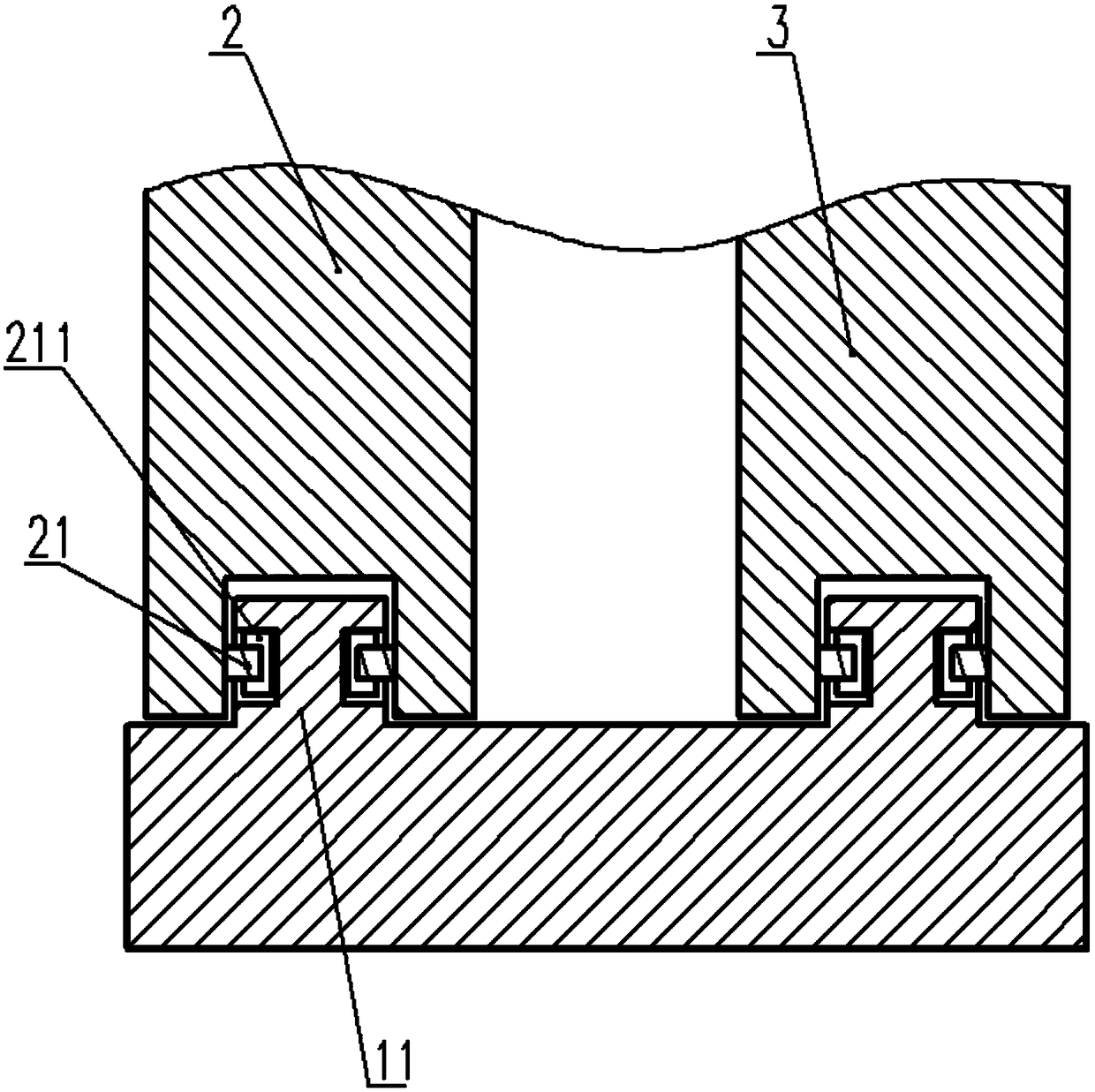

Bi-directional sliding anti-pulling ball type bridge bearing

PendingCN109112957AExtended service lifeEconomical and practicalBridge structural detailsEngineering

The invention discloses a bi-directional sliding anti-pulling ball type bridge bearing, which comprises a support top plate, a ball crown liner, a middle bracket and a lower support plate which are slidably connected from top to bottom. A pull-out member is added between the top plate of the support and the middle bracket, and the upper end of the pull-up member is slidably connected to the planeof the top plate of the support, and a gap is retained between the pull-out member and the rectangular block I of the support top plate, and the pull-out member is retained. The lower end is rotatablyconnected with the upper end of the middle bracket, and the lower end of the middle bracket is slidably connected with the lower support plate plane, and the middle bracket and the lower bracket plate rectangular stopper II retain a certain gap. The design can realize the sliding of the bearing in the transverse direction and along the bridge direction, and the rotation of the bearing around themain and auxiliary directions, and the bearing has good anti-pulling ability, which is suitable for various bridges in special circumstances, and has the advantages of long service life, higher safety, strong economic practicability and high popularization.

Owner:GUIZHOU TRANSPORTATION PLANNING SURVEY & DESIGN ACADEME

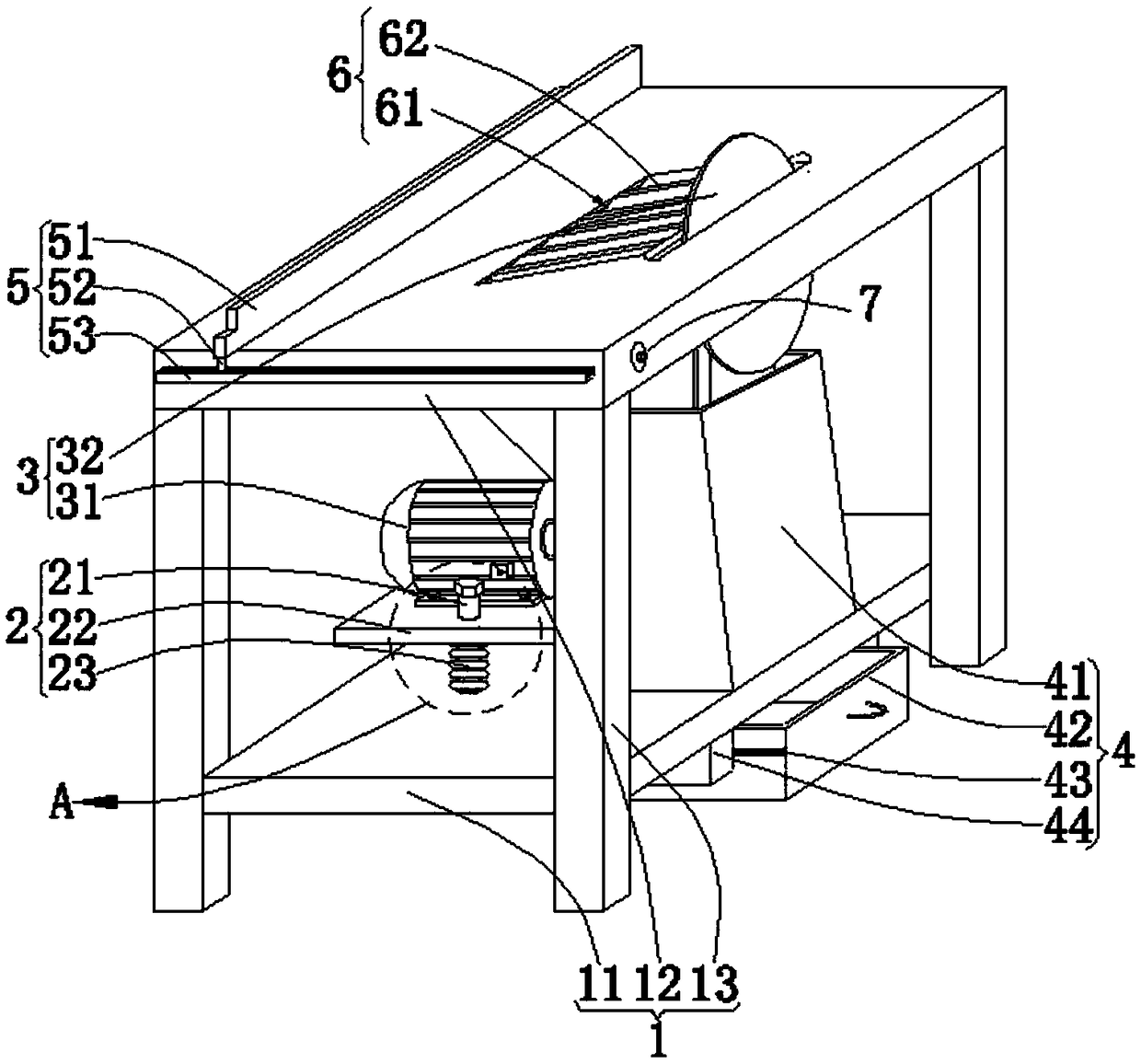

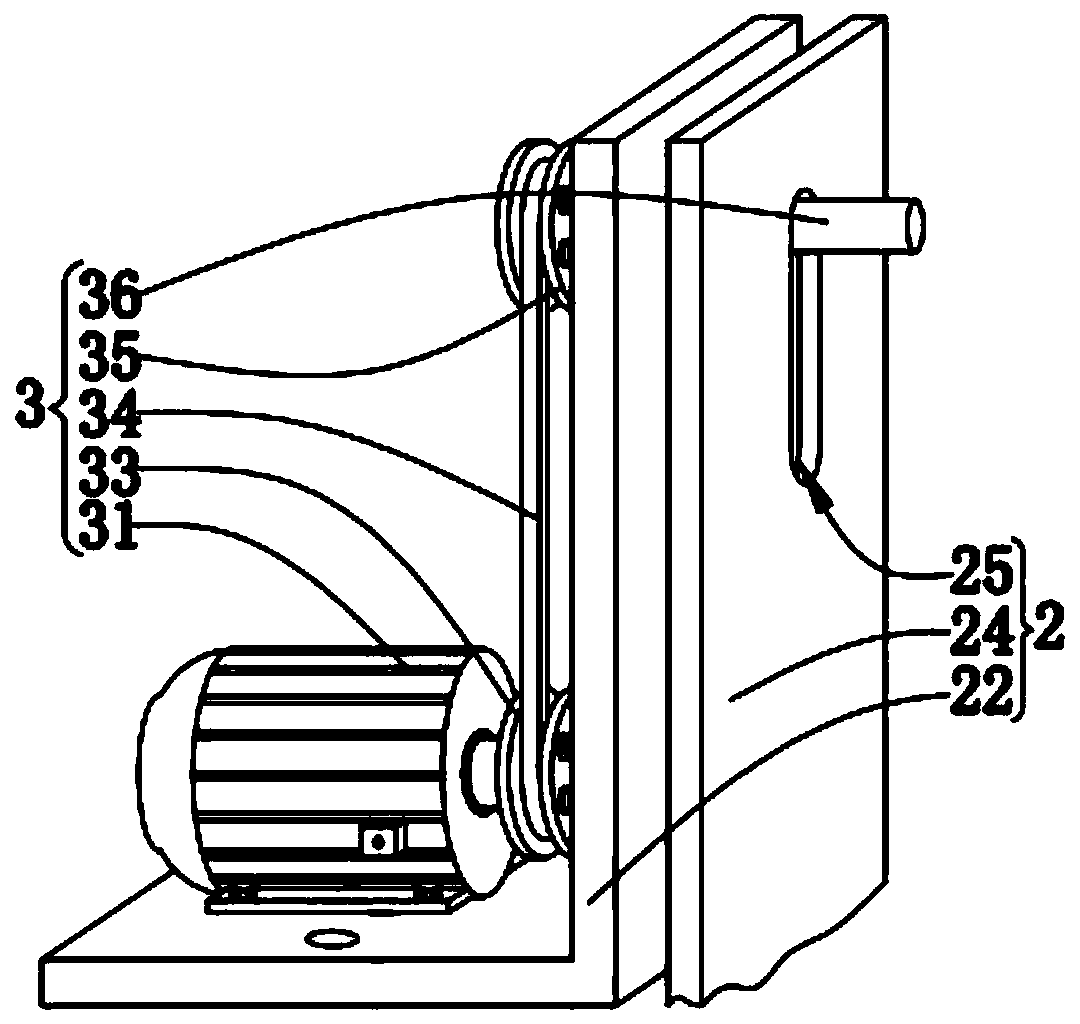

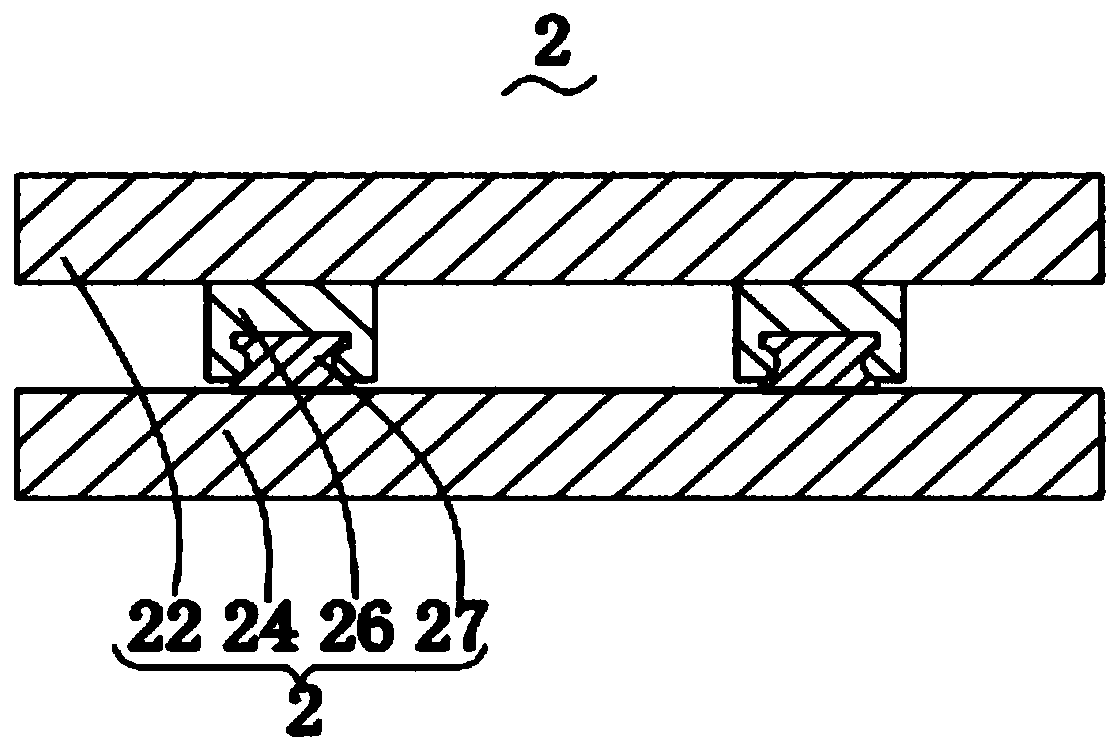

Wood disc saw

ActiveCN108943152AEvenly distributed oilGood cooling effectCircular sawsBark-zones/chip/dust/waste removalWood machiningCircular disc

The invention belongs to the technical field of wood processing, and particularly relates to a wood disc saw. The wood disc saw comprises a supporting structure, an adjusting structure, a working structure and an oil outlet mechanism, wherein the supporting structure comprises a bottom plate, the adjusting structure comprises screw rods, a movable plate, springs, a fixed plate, a fixing groove, first sliding blocks, first sliding rails and bearings, the rectangular fixed plate is arranged at one end of the bottom plate, the kidney-shaped fixing groove is formed in the fixed plate, the number of the first sliding rails is two, the two first sliding rails are fixedly arranged on one side of the fixed plate in parallel, the two first sliding blocks are arranged at one ends, deviating from thefixed plate, of the two first sliding rails correspondingly, the movable plate is fixed at one ends, deviating from the first sliding rails, of the first sliding blocks, the screw rods penetrate through the movable plate and extend to the bottom plate, the bearings are arranged on the bottom plate, and the springs are clamped between the movable plate and the bottom plate. According to the wood disc saw, the disc saw can be cooled, and chippings can be conveniently collected.

Owner:阜南县猛发工艺品有限公司

Device and method for testing adhesive force between metal coating and organic coating

InactiveCN110631990AGuaranteed dimensional accuracyHigh precisionUsing mechanical meansMaterial analysisTest sampleMechanical engineering

The invention discloses a device and a method for testing adhesive force between a metal coating and an organic coating, wherein the device comprises a base and a power-on indicating device, wherein an X-direction sliding rail is arranged on the base, and an X-direction sliding base capable of sliding along the X-direction sliding rail is arranged on the X-direction sliding rail; a Y-direction sliding rail is further arranged on the base, a Y-direction sliding base capable of sliding along the Y-direction sliding rail is arranged on the Y-direction sliding rail, a supporting main beam hinged with the middle part of the Y-direction sliding base is arranged on the Y-direction sliding base, a scribing tool rest is arranged at one end of the supporting main beam, and a balance weight fine adjustment wheel is arranged at the other end of the supporting main beam; the top of the scribing knife rest is provided with a balance weight disc, the bottom of the scribing knife rest is provided witha scribing knife used for scribing a to-be-tested sample block, and two electrodes of the power-on indicating device are respectively connected with the to-be-tested sample block and the scribing knife rest. According to the device of the invention, through an indication principle of the power-on indicating device, the purpose that the balance weight of the scribing knife only cuts a surface coating layer without damaging the metal coating is realized, so that the adhesive force between the metal coating and the organic coating is accurately measured.

Owner:DONGFENG COMML VEHICLE CO LTD

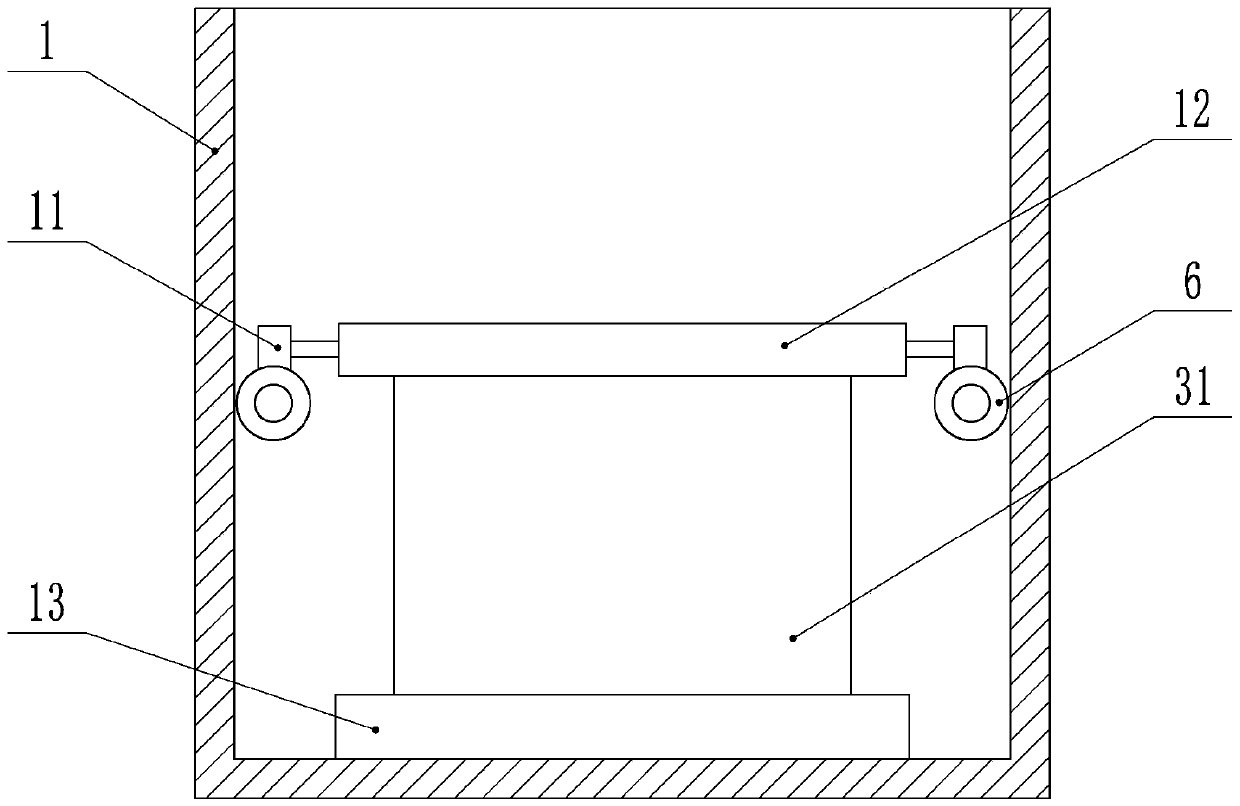

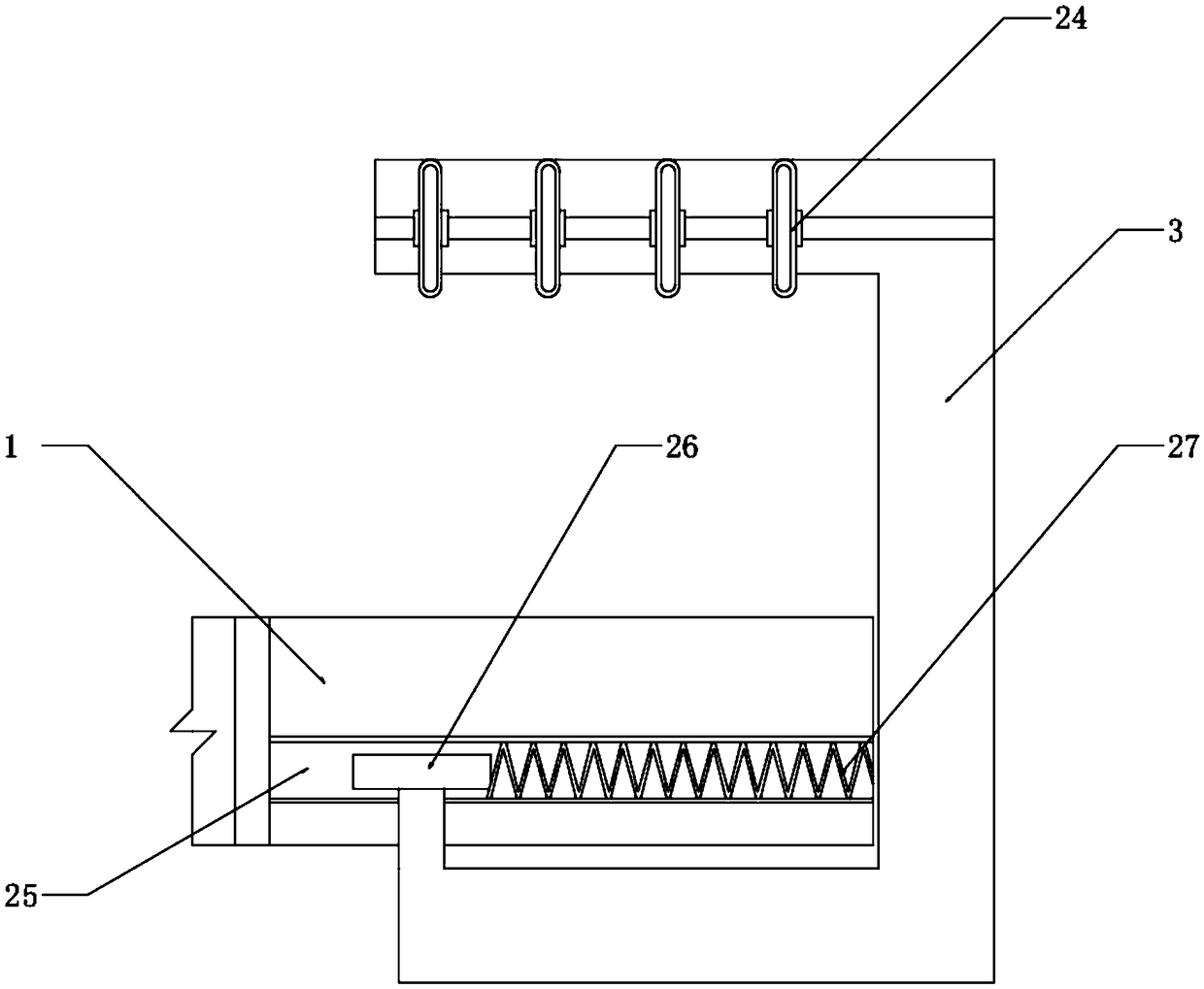

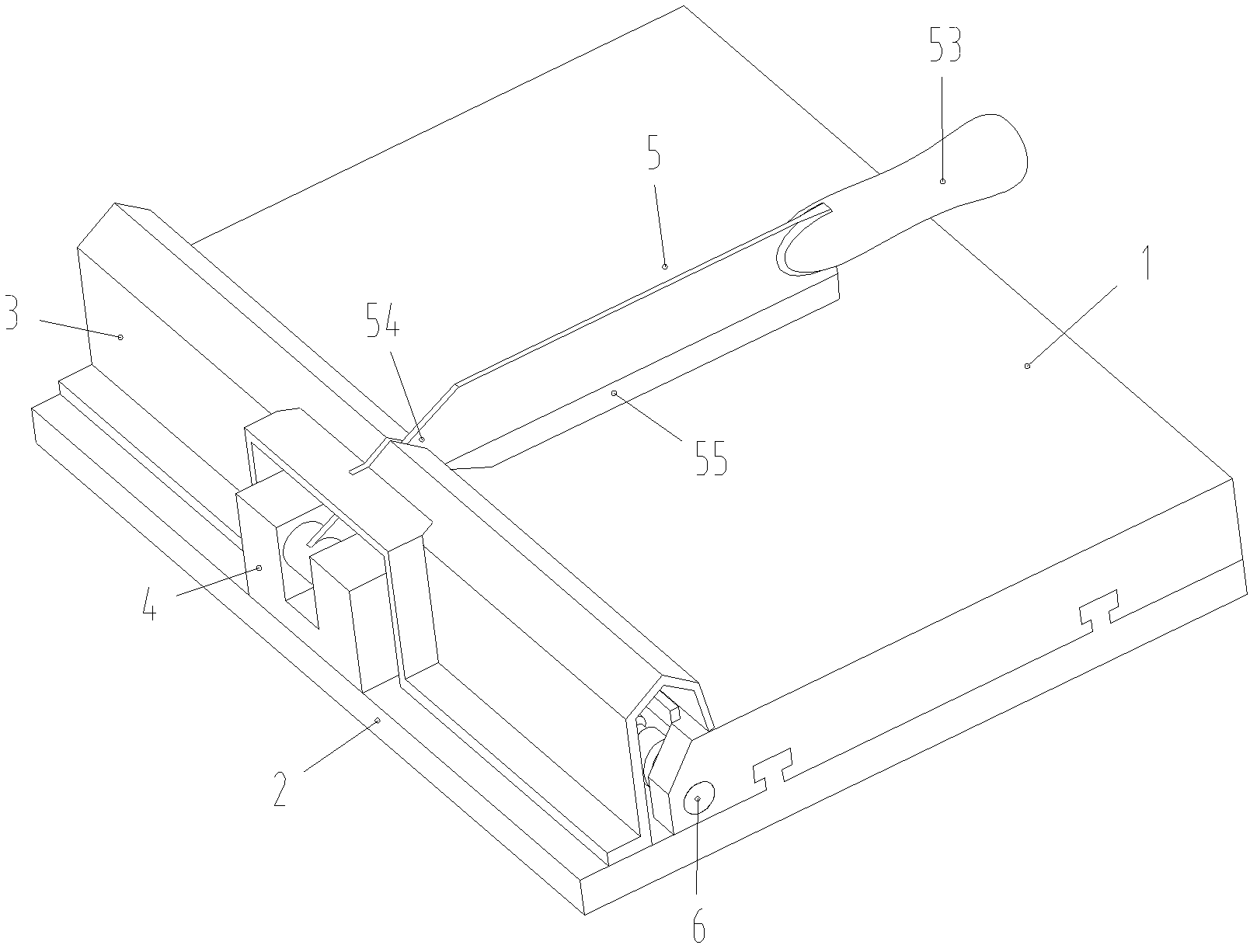

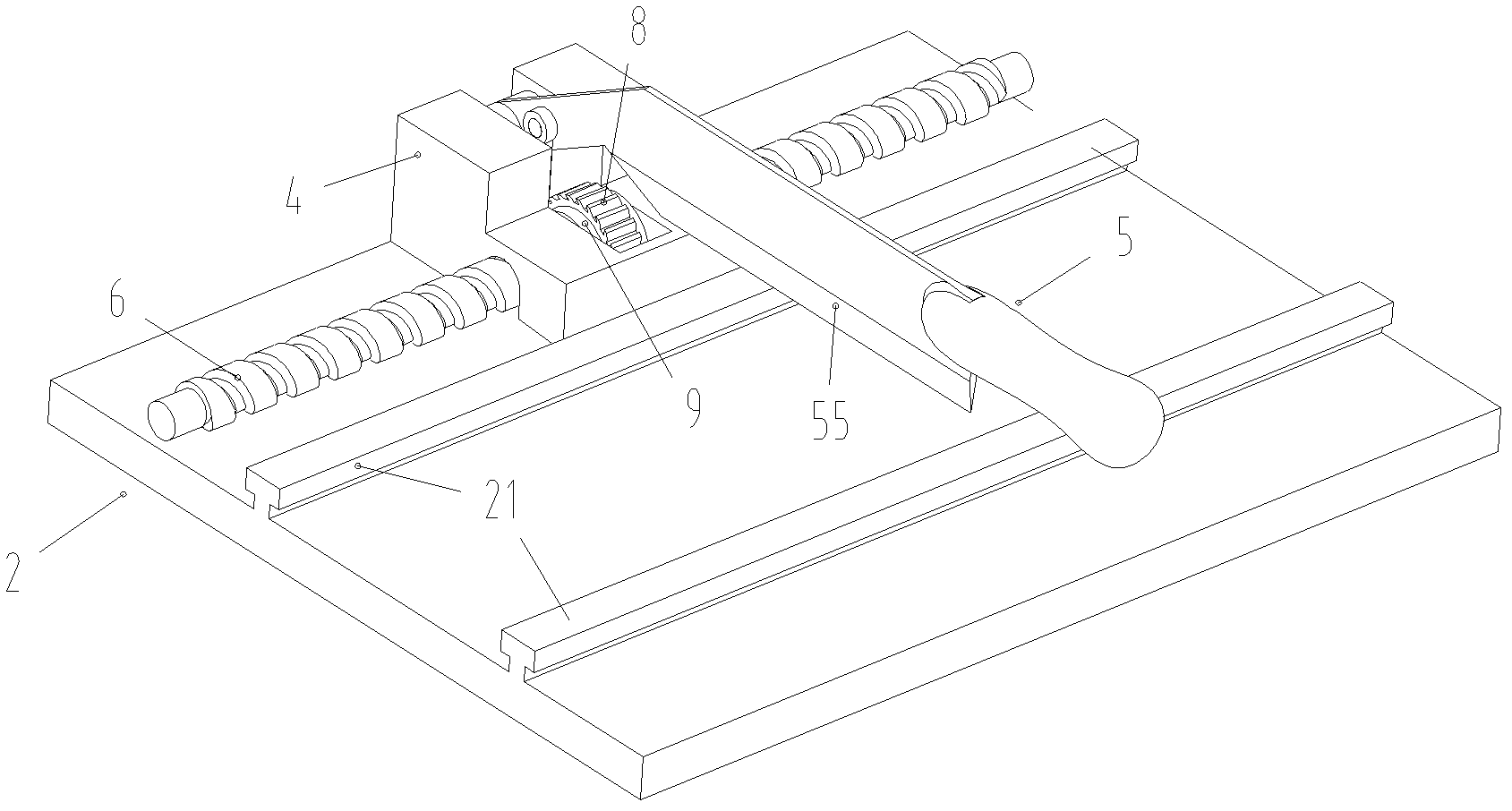

Slidable laundry rack

InactiveCN108396526ASlide to achieveOther drying apparatusTextiles and paperAgricultural engineeringLaundry

The invention relates to a slidable laundry rack and belongs to the field of intelligent home. In order to achieve the aim of slidable airing of the laundry rack, the laundry rack is mainly composed of a baseplate, a vertical plate, an upper frame, a first pulley set, a second pulley set, a third pulley set, a fourth pulley set, a fifth pulley set, a first traction rope set, a second traction ropeset, a slidable clothes drying rod and parallel guide rails. The slidable laundry rack has the advantages that the slidable clothes drying rod is combined with a traditional structure, and clothes slide on the slidable laundry rack.

Owner:DALIAN NATIONALITIES UNIVERSITY

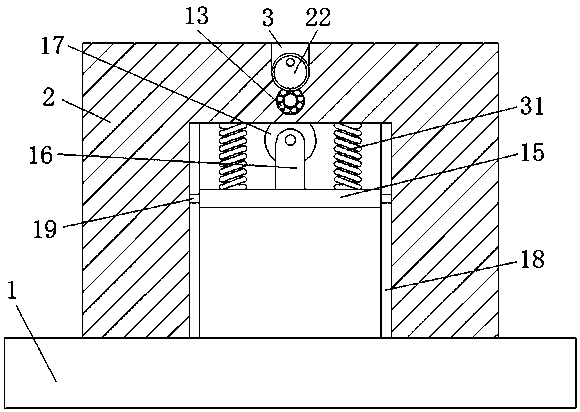

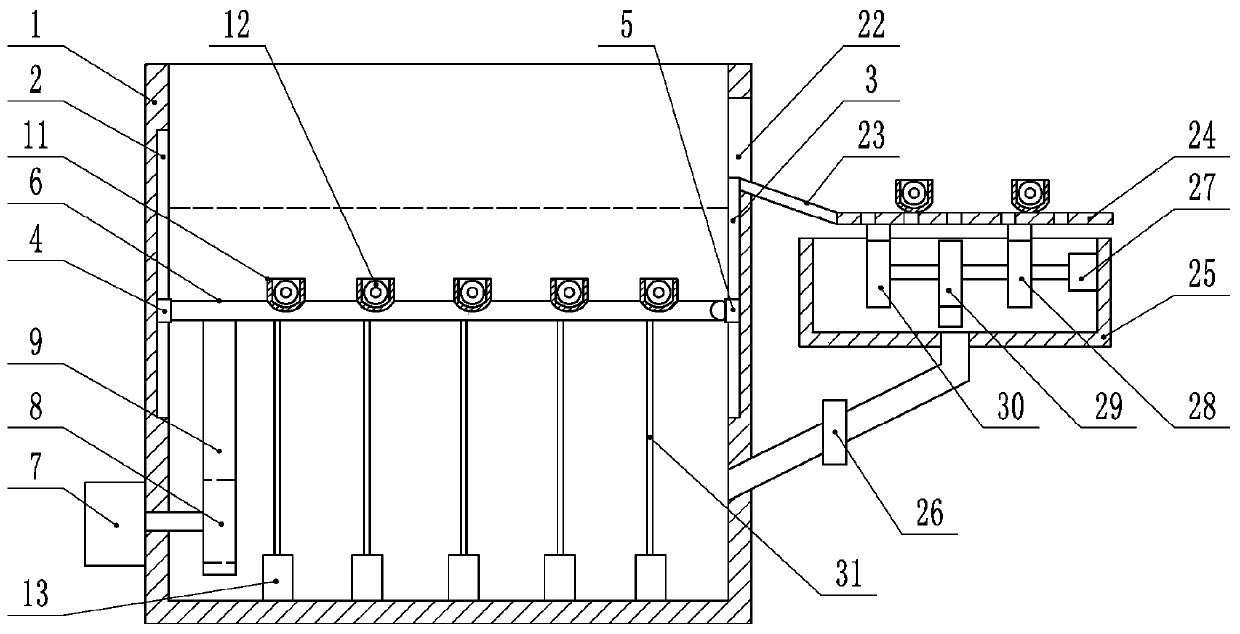

Textile Dyeing Unit

ActiveCN108221230BPrevent extrusionSlide to achieveLiquid/gas/vapor removalTextile treatment machine arrangementsStructural engineeringTextile dyeing

The invention relates to the technical field of textile processing and discloses a textile dyeing device. The textile dyeing device comprises a dyeing box, wherein a first sliding chute and a second sliding chute are formed in the dyeing box, the first sliding chute is slidably connected with a first sliding block, the second sliding chute is slidably connected with a second sliding block, two material guiding rollers are slidably connected in the dyeing box, a limit slot is formed in each material guiding roller, an object carrying frame is arranged in each limit slot, a material rolling roller is rotatably connected in each object carrying frame, a fixing mechanism is arranged in the dyeing box, the fixing mechanism comprises two clamping plates, each clamping plate is fixedly connectedwith a wedge rod, each wedge rod is fixedly connected with a connecting rod, two connecting rods are hinged on the inner wall of the dyeing box, two sliding rods are slidably connected in the dyeing box, a first electromagnet is arranged on each sliding rod, and a second electromagnet is arranged on the inner wall of the dyeing box; a discharging hole is formed in the dyeing box, a touch switch isarranged at the discharging hole, the discharging hole is connected with a material guiding plate, the material guiding plate is connected with a hollow elastic filter screen, and a recycling tank isconnected below the elastic filter screen. The textile dyeing device disclosed by the invention can rapidly and uniformly carry out dyeing.

Owner:NINGBO WENZE TEXTILE CO LTD

Automatic sorting and feeding device

The invention provides an automatic sorting and feeding device. The automatic sorting and feeding device comprises a frame body, a feeding rack, an arrangement mechanism, a shifting mechanism and a feeding rod. The automatic sorting and feeding device is used for sorting and conveying pipe materials, the pipe materials can be conveyed one by one instead of being conveyed bundle by bundle, and the pipe materials are prevented from deviating and are stably conveyed to the next process; the automation degree is high, labor cost is reduced, and safety and reliability are guaranteed.

Owner:武汉昊康激光科技有限公司

Pet snack processing device

InactiveCN108543458AEasy to cleanEasy dischargeFeeding-stuffRotary stirring mixersSlide plateCompanion animal

The invention belongs to the technical field of processing equipment specially applicable to a feed fed for animals, and discloses a pet snack processing device. The pet snack processing device comprises a frame and a mixing drum, and also comprises a hollow stirring shaft and a motor, wherein the mixing drum is provided with a feed inlet and a discharging outlet; the side wall of the stirring shaft is provided with two chutes; the interior of each chute is provided with a stirring blade; the top end of each chute is provided with a limit groove; the interior of each limit groove is provided with a baffle plate; each baffle plate is provided with a magnet; the bottom part of each chute is provided with an electromagnet; each stirring blade is provided with a notch; a driving rod located inthe interior of the stirring shaft is slidably connected with and arranged on the frame; the bottom end of the driving rod is of an inverted cone shape; the interior of the mixing drum is provided with a mounting plate and a sliding plate; the exterior of the stirring shaft is provided with a driving gear; a rotating shaft is in threaded connection with the mounting plate; the bottom end of the rotating shaft is rotatably connected with the sliding plate; and a driven gear meshed with the driving gear is in splined connection with the rotating shaft. The pet snack processing device provided by the invention solves the problem that raw materials adhere to the stirring shaft and the stirring blades and are not prone to be cleaned in the prior art.

Owner:CHONGQING SIWEITE PET SUPPLIES CO LTD

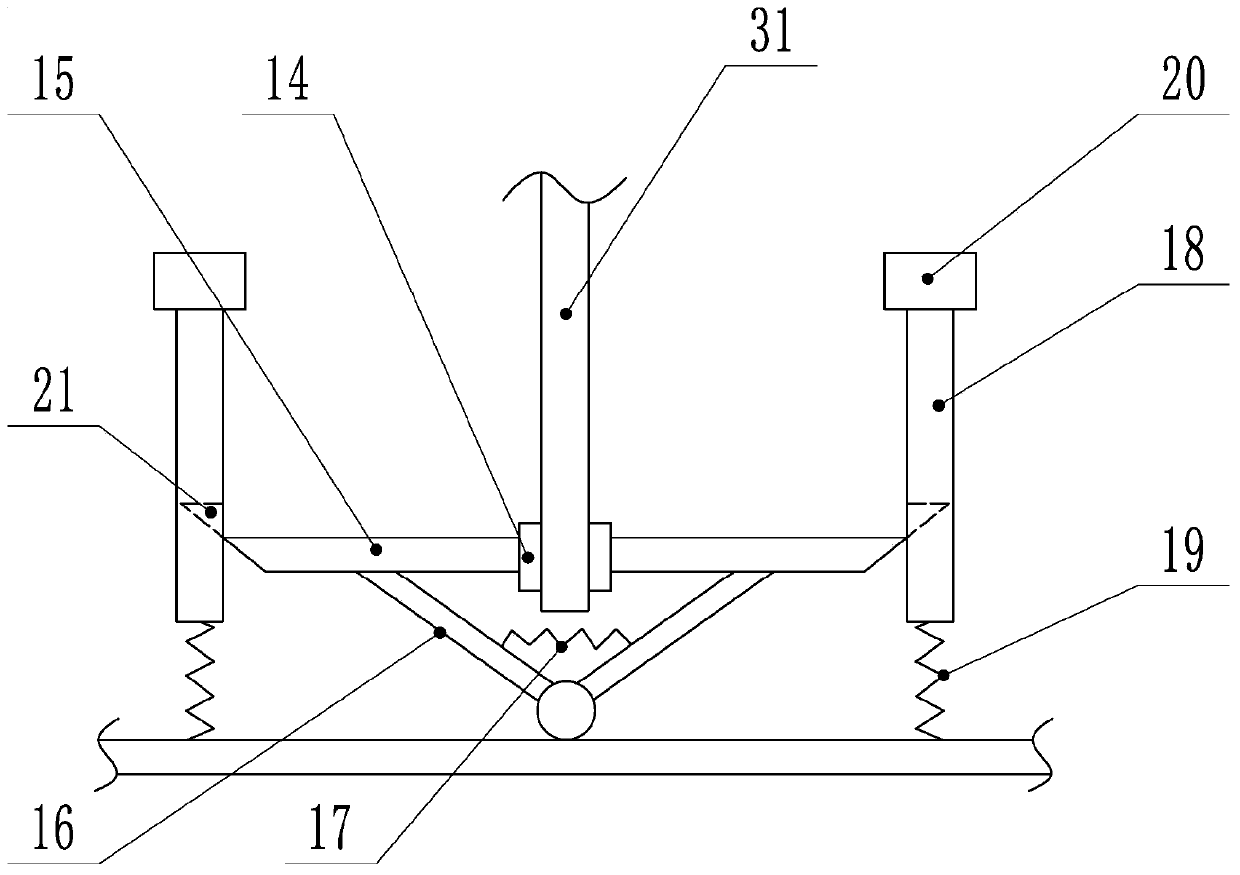

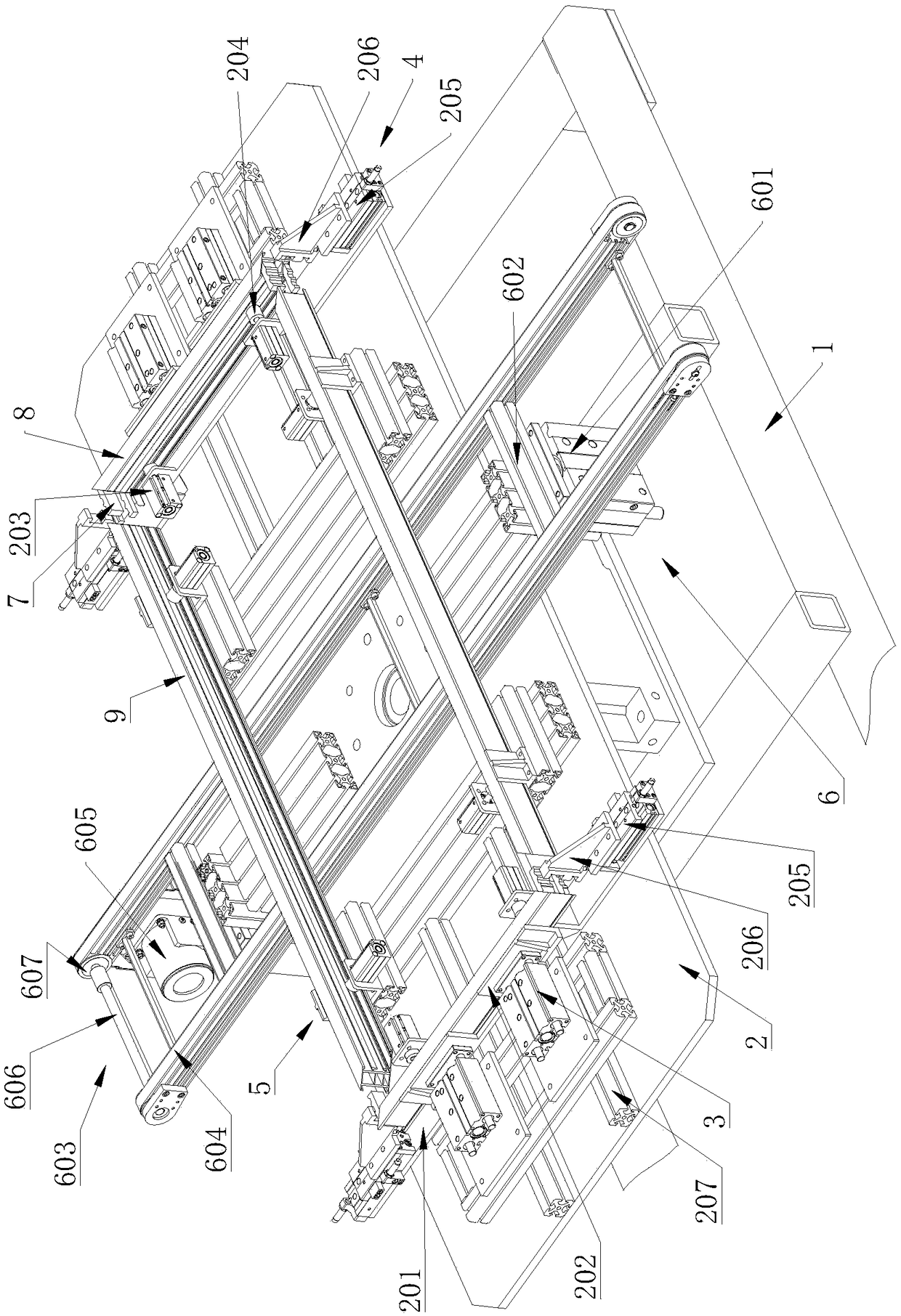

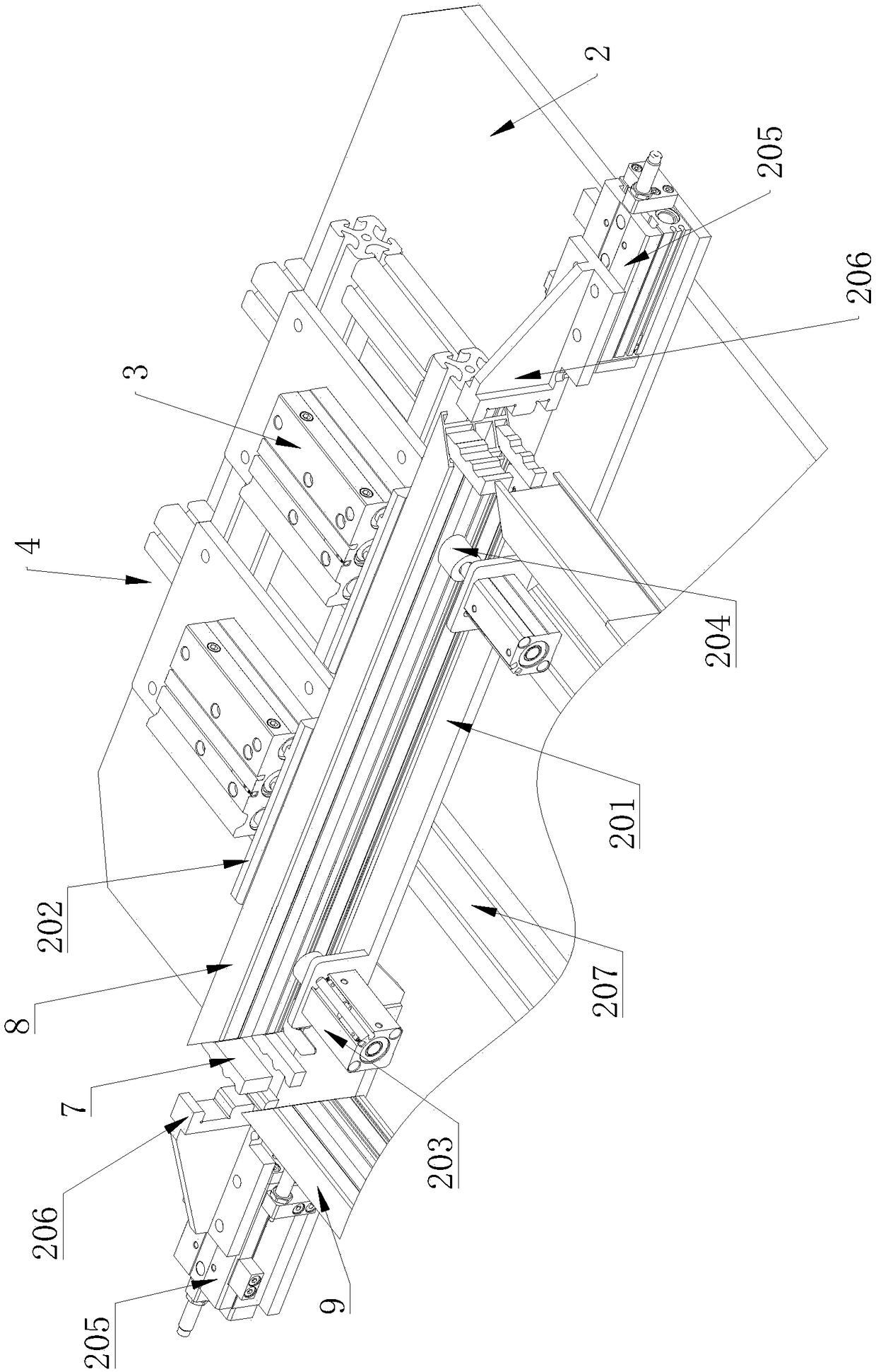

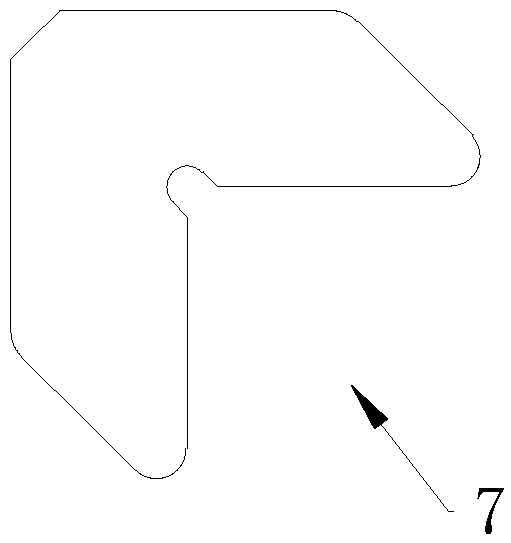

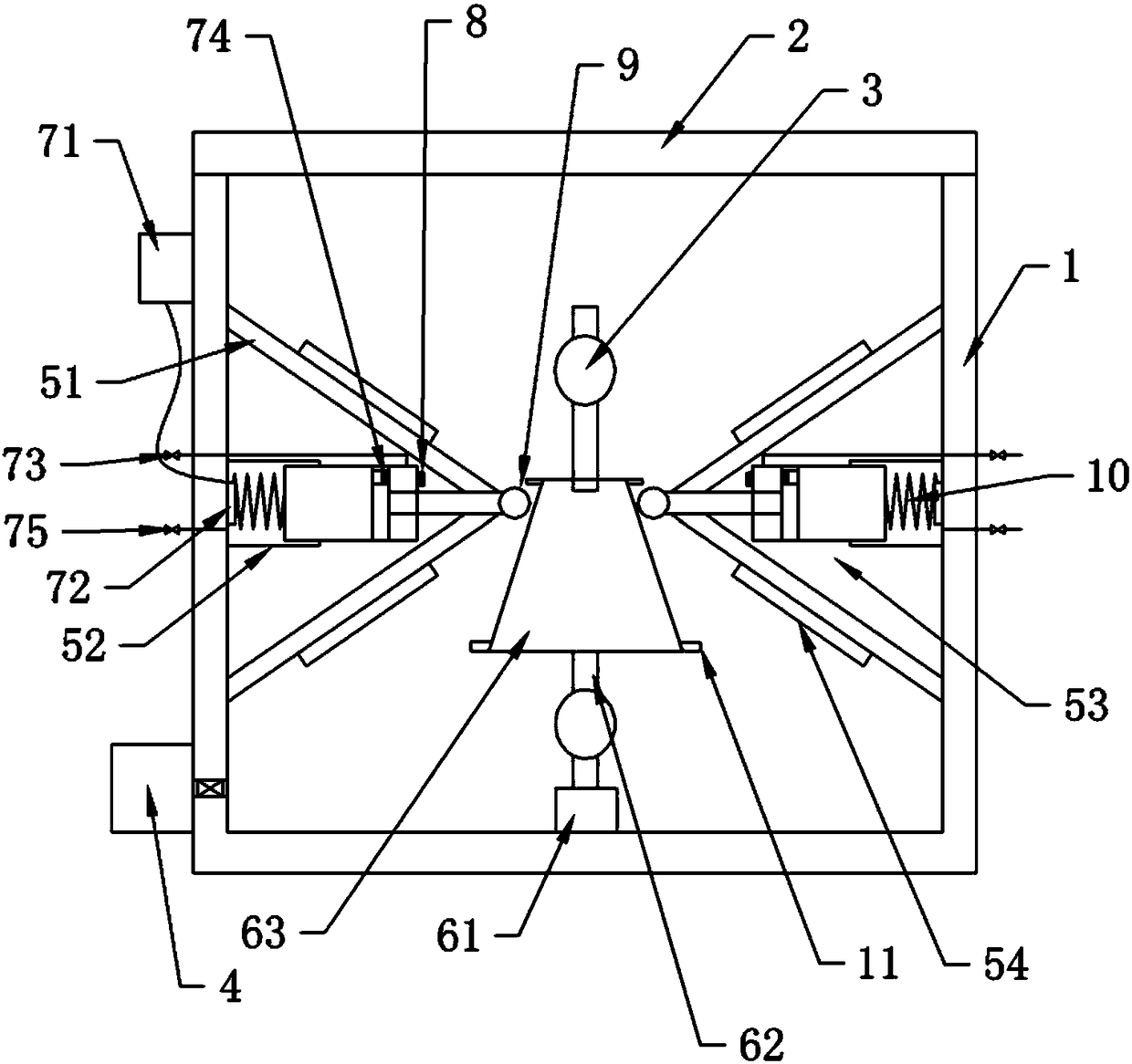

Assembling device for rectangular frame and assembling method of assembling device

PendingCN109227086AAchieve clamping positioningSimple structureMetal working apparatusHigh volume manufacturingEngineering

The invention discloses an assembling device for a rectangular frame and an assembling method of the assembling device. The assembling device comprises a rack, a rotary frame driven by a first power device is rotationally mounted on the rack, and short frame clamping and locating mechanisms driven by a driving device are slidingly mounted at the two ends of the rotary frame. Long frame clamping and locating mechanisms are fixedly mounted on the two sides of the rotary frame. By means of the assembling device for the rectangular frame, mechanical and automatic assembling of the rectangular frame is achieved, the effect of mass production of the rectangular frame is achieved, the assembling efficiency and production efficiency of the rectangular frame are greatly improved, the assembling effect is good, and the forming quality of the rectangular frame is high. Meanwhile, the labor intensity of workers is reduced, the number of the needed workers is reduced, and then the labor cost is reduced.

Owner:JIANGSU HAGONG PHARMA MACHINE TECH CO LTD

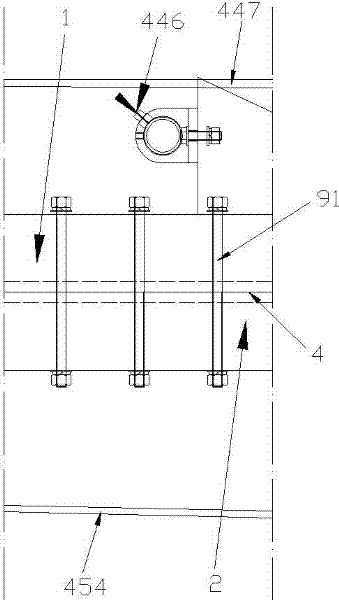

Rust-removing and flexibly-fixed paint spraying device for iron tower maintenance

The invention discloses a rust-removing and flexibly-fixed paint spraying device for iron tower maintenance. The device comprises a paint spraying panel, a device box body and fixing clamping grooves,wherein the device box body is located at the center position of the lower bottom surface of the paint spraying panel, the device box body is fixed to the paint spraying panel in a welded mode, the fixing clamping grooves are located on two sides of the paint spraying panel, the fixing clamping grooves are slidingly connected with the paint spraying panel, and the number of the fixing clamping grooves is four. By utilizing the cooperation of an arranged paint box and an arranged conveying pump, the conveying of paint to be sprayed is realized, and under the control of the conveying pump, thepaint is input into a paint spraying opening through a paint conveying pipeline so as to realize paint spraying of an iron tower.

Owner:潍坊华高信息科技有限公司

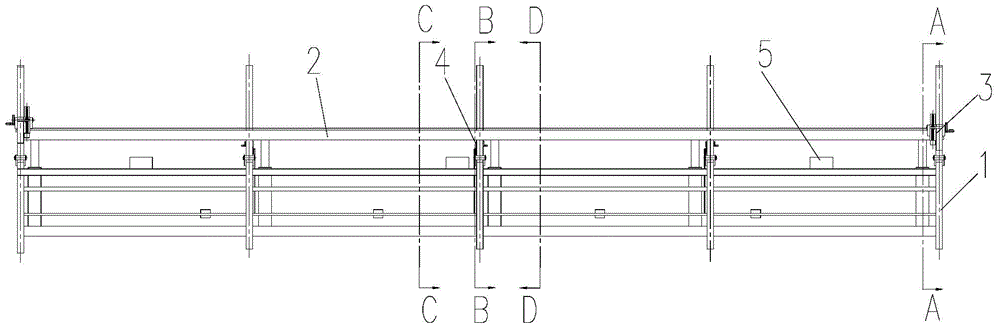

Exposure machine for printing

InactiveCN108132586AUniform drying board operationQuick inhalationPhotomechanical exposure apparatusMicrolithography exposure apparatusElectricitySlide plate

The invention discloses an exposure machine for printing. The exposure machine comprises a cabinet body, ultraviolet lamps, a vacuum pump and a sealing cover for covering the cabinet body, a pipelineis provided with a unidirectional-gas discharging one-way valve, the machine also comprises an exposure plate part, a driving part and a control part, the exposure plate part includes four slide plates, slide seats, gas suction members and exposure plate units, one ends of the slide plates are slidably connected to the sidewall of the cabinet body, and the gas suction parts are slidably connectedto the slide seat through springs; the driving part includes a power source, telescopic rods and a driving part, the driving part is connected to the telescopic rods and is used for driving the gas suction members to move, and the telescopic rods are provided with the ultraviolet lamps; and the control part comprises a controller, pressure sensors and first electronic control valves, the gas suction members are provided with gas discharging tubes, the first electric control valves are arranged on the gas discharging tubes, and the power source, the pressure sensors and the first electric control valves are respectively electrically connected with the controller. The exposure machine can ensure the uniformity of an exposure plate, and can avoid generated harmful gases from escaping in orderto ensure the health of operators.

Owner:启东市启秀蔬果专业合作社

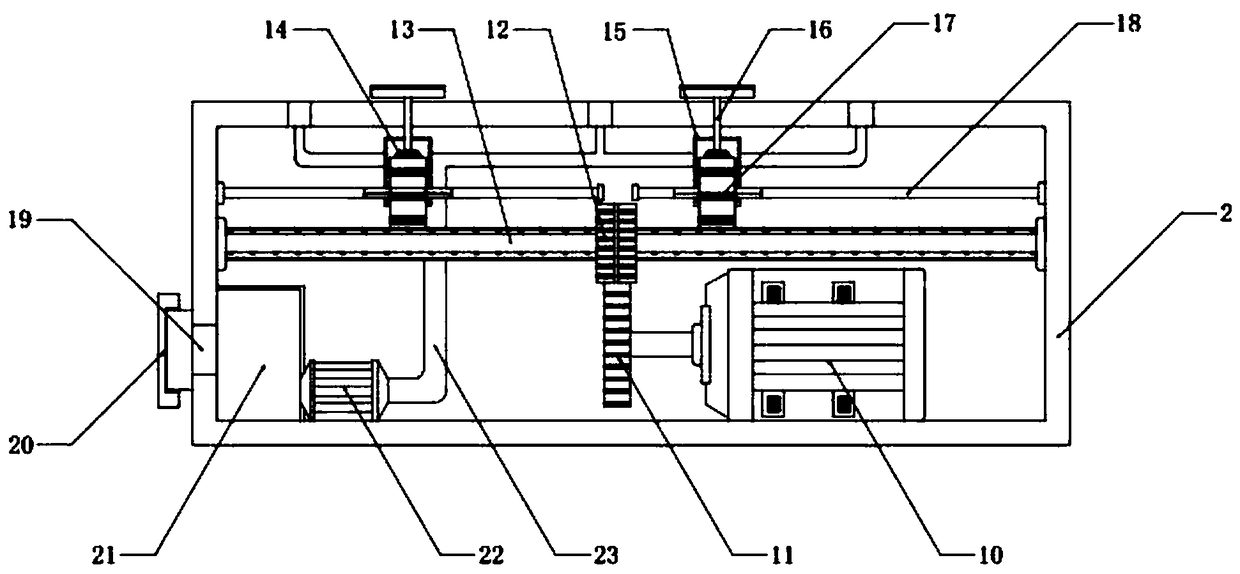

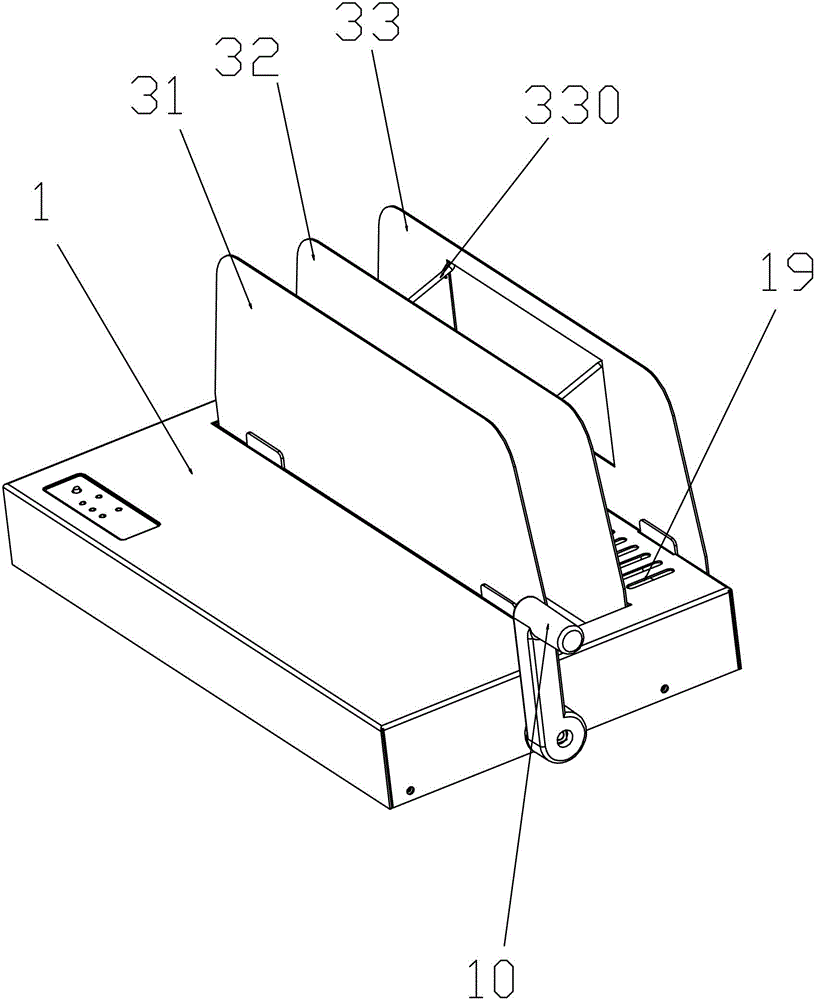

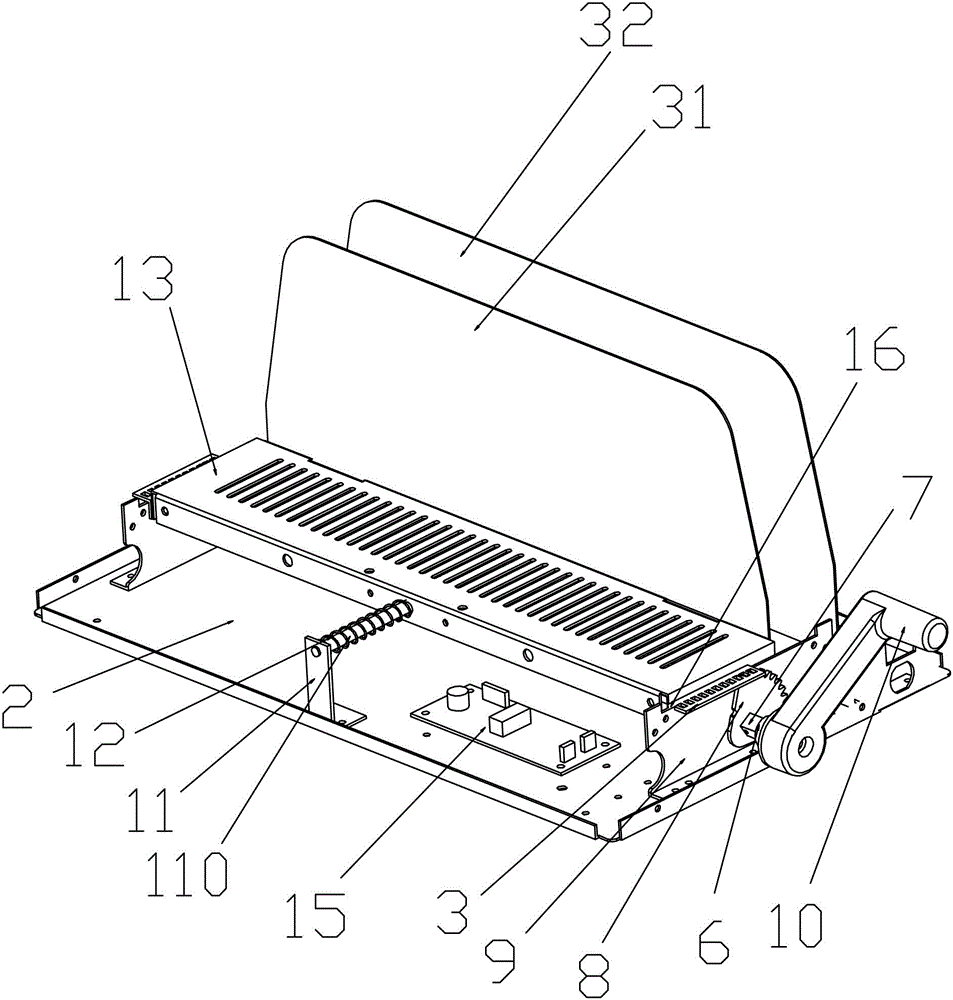

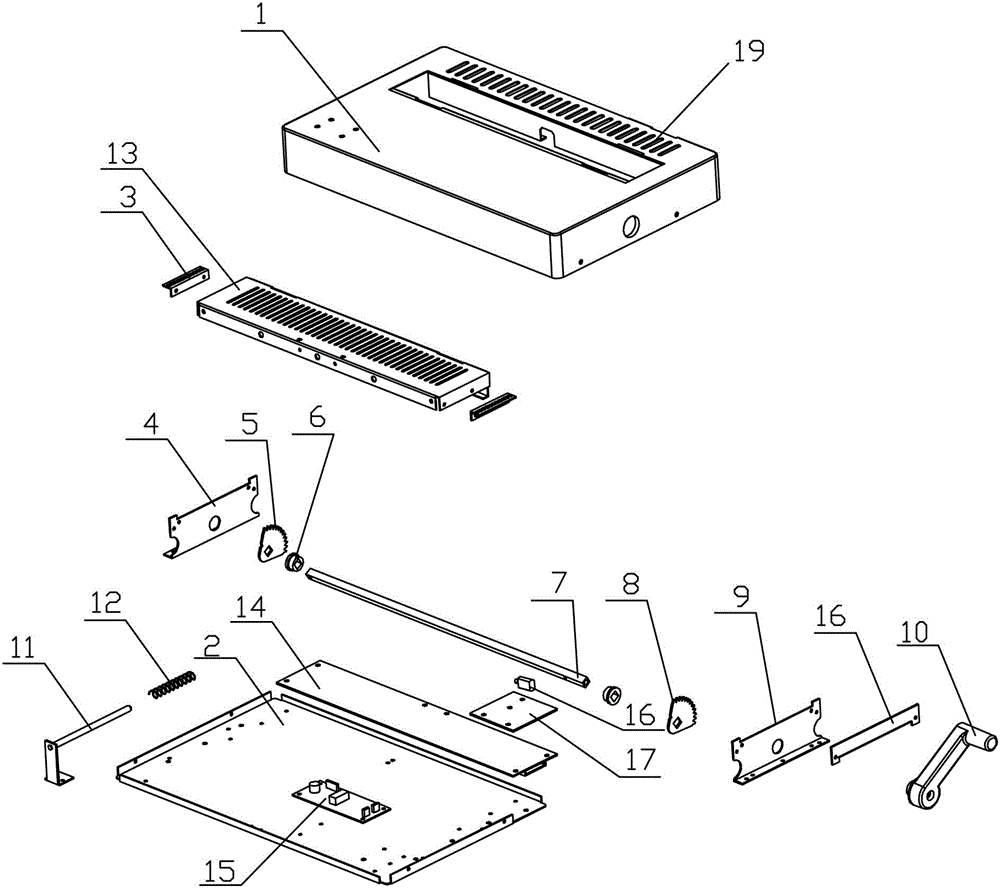

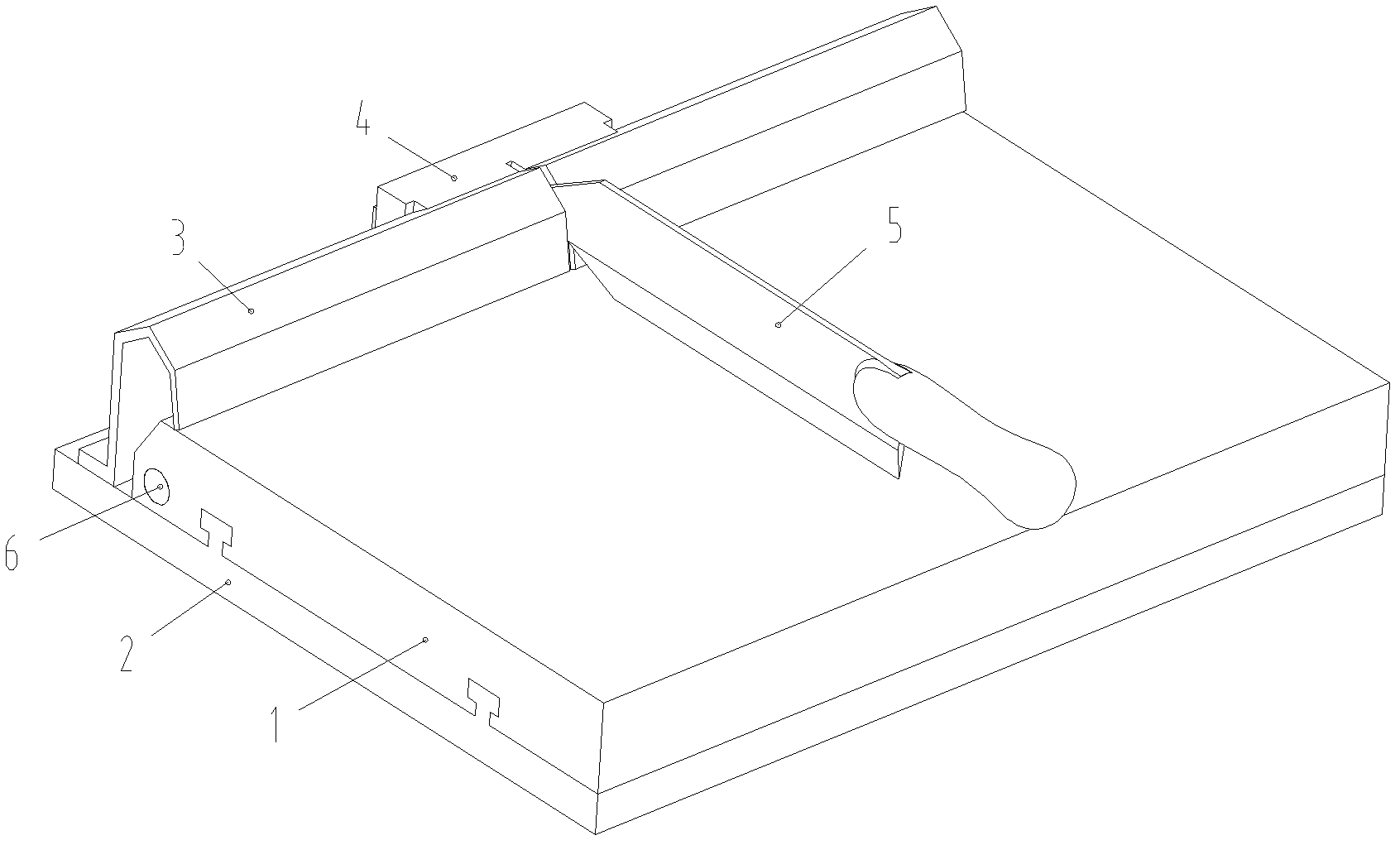

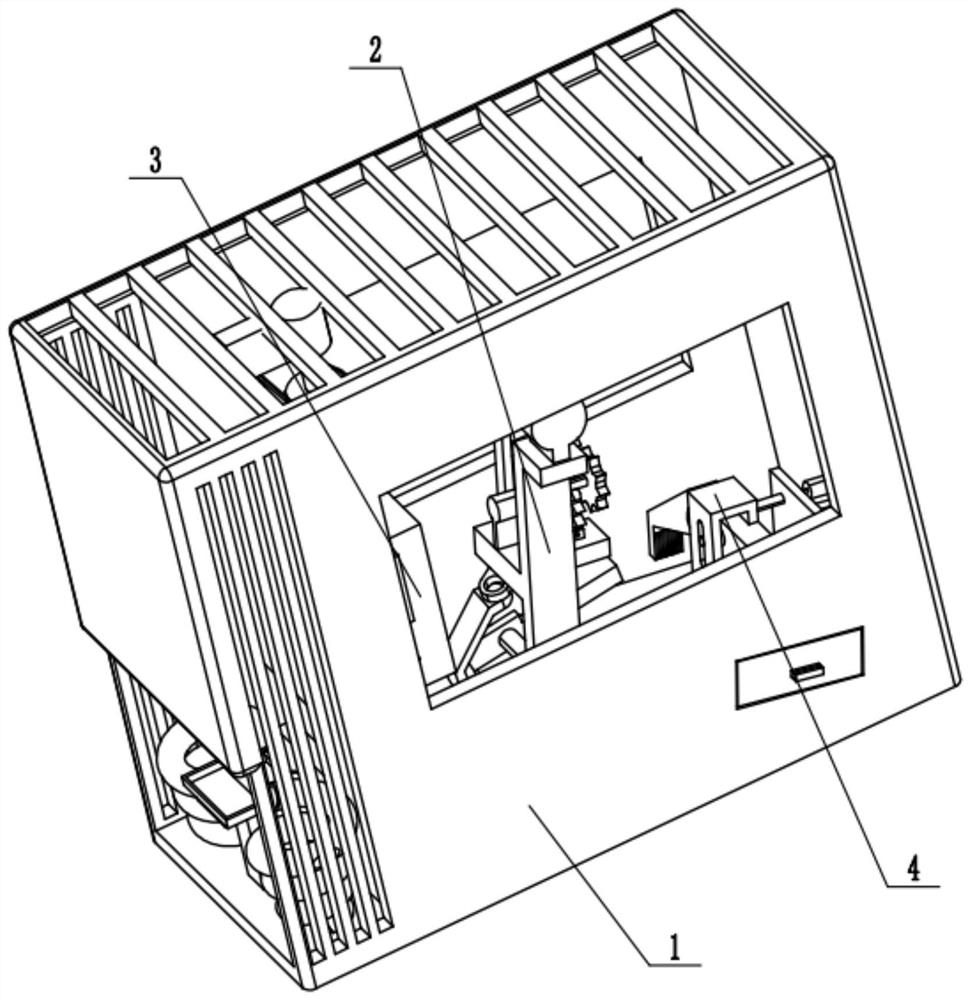

Hot melt cementing machine

The invention discloses a hot melt cementing machine which comprises a base, a shell and a sliding mechanism, wherein the sliding mechanism is mounted on the base; the shell is mounted on the sliding mechanism; the hot melt cementing machine further comprises a detachable paper baffle structure, a heating plate and a controller; the sliding mechanism comprises a sliding plate, brackets, a transmission shaft, gears, sliding racks and a spring bracket; the brackets are fixed on the base; the transmission shaft penetrates through the brackets at the two ends of the base respectively; the sliding racks are arranged at the two ends of the sliding plate and are mounted in inner slots of the brackets at the two ends; the transmission shaft penetrates through the gears; the gears are meshed with the sliding racks; the transmission shaft drives the gears; the gears drive the sliding racks to slide in the inner slots of the brackets; the heating plate and the controller are mounted on the base; the controller is electrically connected with the heating plate; the spring bracket is mounted on the base; the detachable paper baffle structure comprises three detachable paper baffles; the three detachable paper baffles are respectively mounted on the shell and the sliding plate.

Owner:RAYSON ELECTRICAL MFG

Automatically-feeding manual vegetable chopping block

The invention relates to articles for daily use, in particular to a chopping block of cutting vegetables, which comprises a chopping block, a base, a vegetable cutting knife and a support. The base is movably connected with the chopping block, the support is fixedly connected on the base, the vegetable knife is arranged at the upper portion of the chopping block, a connection portion of the vegetable cutting knife is movably connected on the support, and the base is connected with a batch-type feeding mechanism. Food is arranged on the chopping block, and the chopping block remains fixed in a process that an operator presses down the vegetable cutting knife. When the operator raises the vegetable cutting knife, the chopping block is automatically fed into at a certain distance. Thus, tool marks at equal intervals are cut on food.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

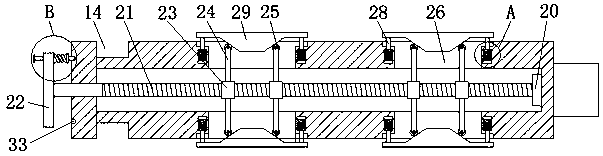

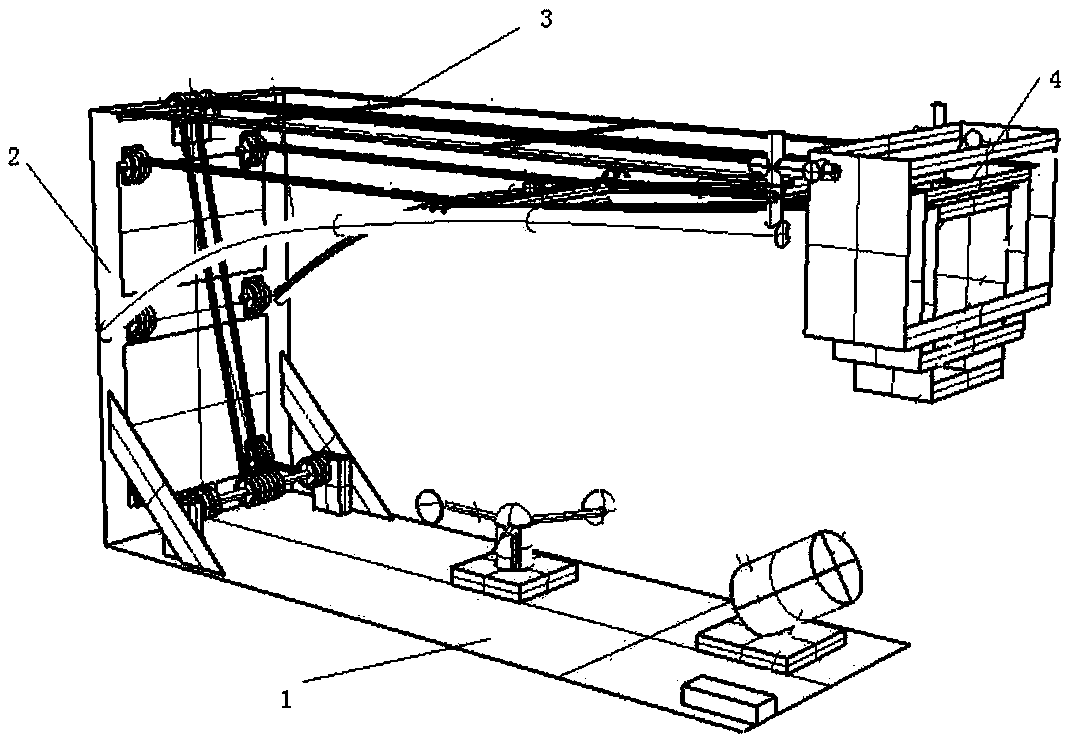

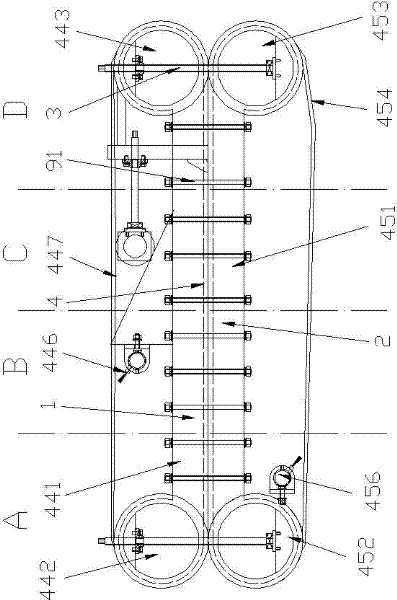

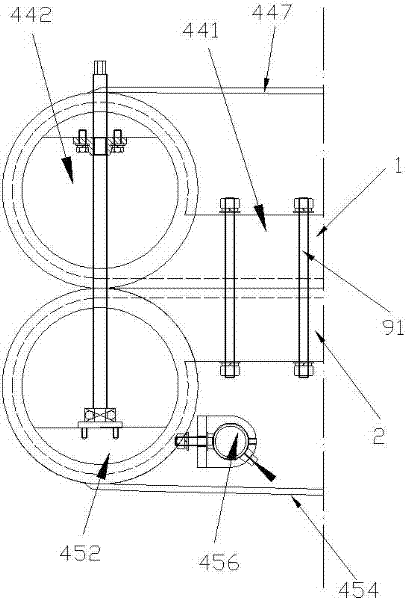

Slide pressurizing mechanism used in slide pressurizing continuous solid-liquid separating machine

InactiveCN102179093ASlide to achieveEffective squeezePressesMoving filtering element filtersAdhesiveEngineering

The invention relates to a slide pressurizing mechanism used in a slide pressurizing continuous solid-liquid separating machine, wherein no slide pressurizing mechanism has reliable performance at present. The slide pressurizing mechanism comprises an upper pressing device and a lower pressing device; the upper pressing device comprises at least one upper pressing unit; the upper pressing unit comprises an upper pressing block, an upper left pressing roller, an upper right pressing roller and an upper slide adhesive tape; the upper pressing block is positioned between the upper left pressing roller and the upper right pressing roller; the upper slide adhesive tape is twisted outside the upper left pressing roller, the upper pressing block and the upper right pressing roller; the lower pressing device comprises a lower pressing block, a lower left pressing roller, a lower right pressing roller and a lower slide adhesive tape; the lower pressing block is positioned between the lower left pressing roller and the lower right pressing roller; the lower slide adhesive tape is twisted outside the lower left pressing roller, the lower pressing block and the lower right pressing roller; the upper pressing device is positioned right above the lower pressing device; a gap is formed between the upper pressing device and the lower pressing device; and the gap height is gradually reduced from the inlet to the outlet. The slide pressurizing mechanism has reasonable structure design and high solid-liquid separation efficiency, and is applicable to the dewatering of sticky and smooth materials with continuous operation.

Owner:ZHEJIANG HUAZHANG TECH

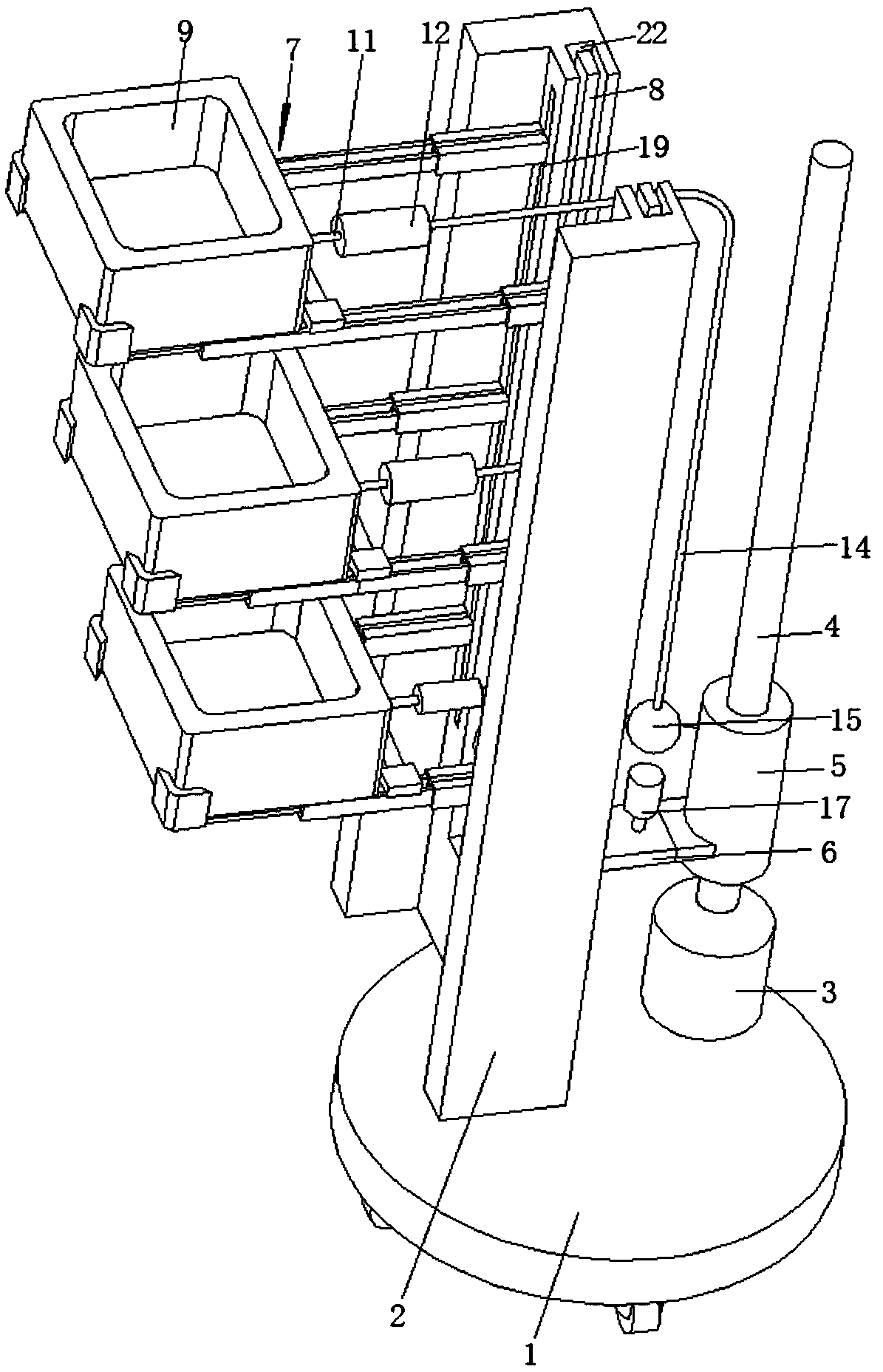

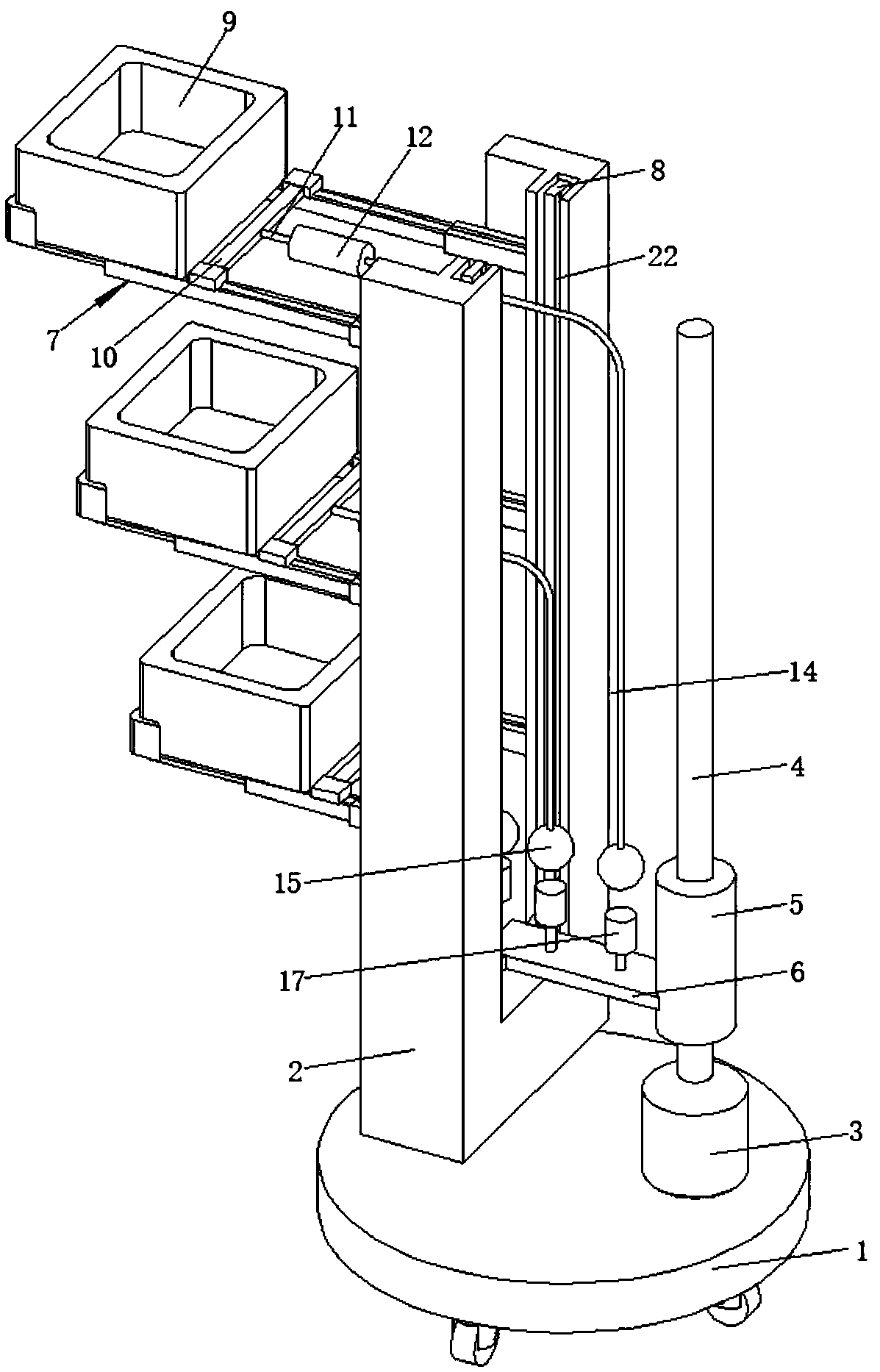

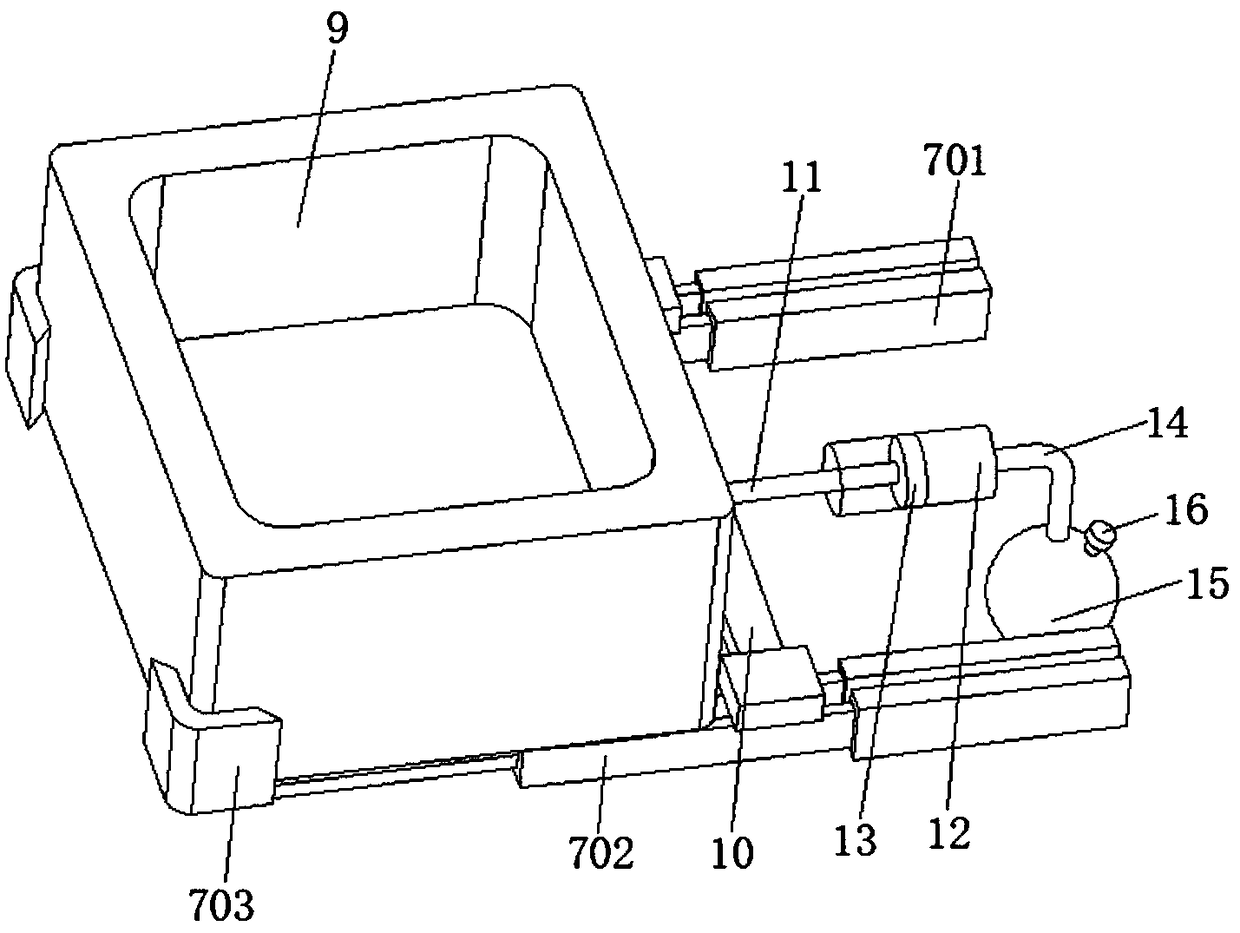

Transfer device for packaging of automobile components

InactiveCN109455208AEasy accessEasy to slide up and downSupporting partsHand carts with multiple axesEngineeringMechanical engineering

The invention discloses a transfer device for packaging of automobile components and belongs to the field of packaging of automobile components. The transfer device for packaging of the automobile components comprises a base and a support rod, wherein the support rod is fixedly connected to the top of the base; the support rod is slidably connected with a plurality of supports arranged on different layers, the end, away from the support rod, of each support is provided with a transfer box, the tops of the supports are connected with blocking rods slidably, and the end, away from the corresponding transfer box, of each blocking rod is connected with a sealing pipe through a piston rod; the end, away from the corresponding blocking rod, of each sealing pipe is connected with a negative pressure ball through a connecting air pipe; the top of a supporting plate is fixedly connected with a plurality of touch pressing rods matched with the negative pressure balls, and the touch pressing rodsare distributed in a stepped pattern in the direction away from lead screw nuts. According to the transfer device, the transfer boxes arranged on different layers can ascend and descend so that components in the transfer box at the bottom layer can be conveniently taken and placed; the multi-layer transfer boxes can be layered and staggered, and components in the transfer box on a specific layercan be taken and placed conveniently.

Owner:大连思博科技服务有限公司

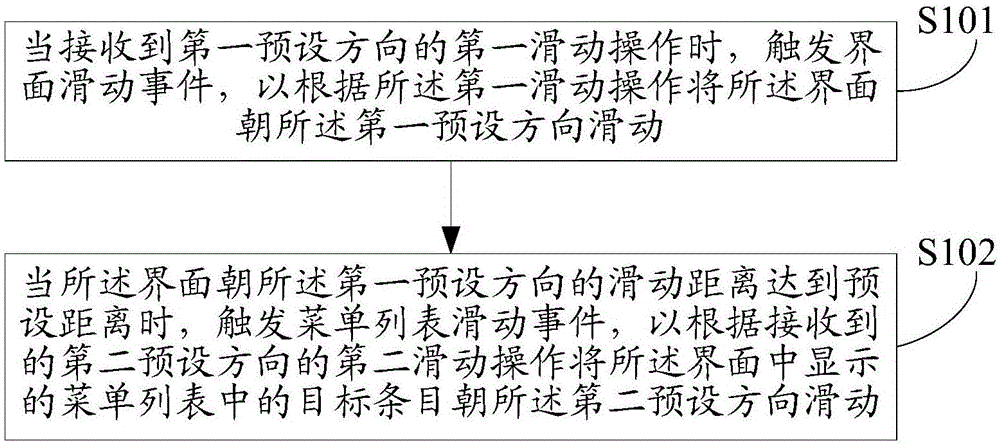

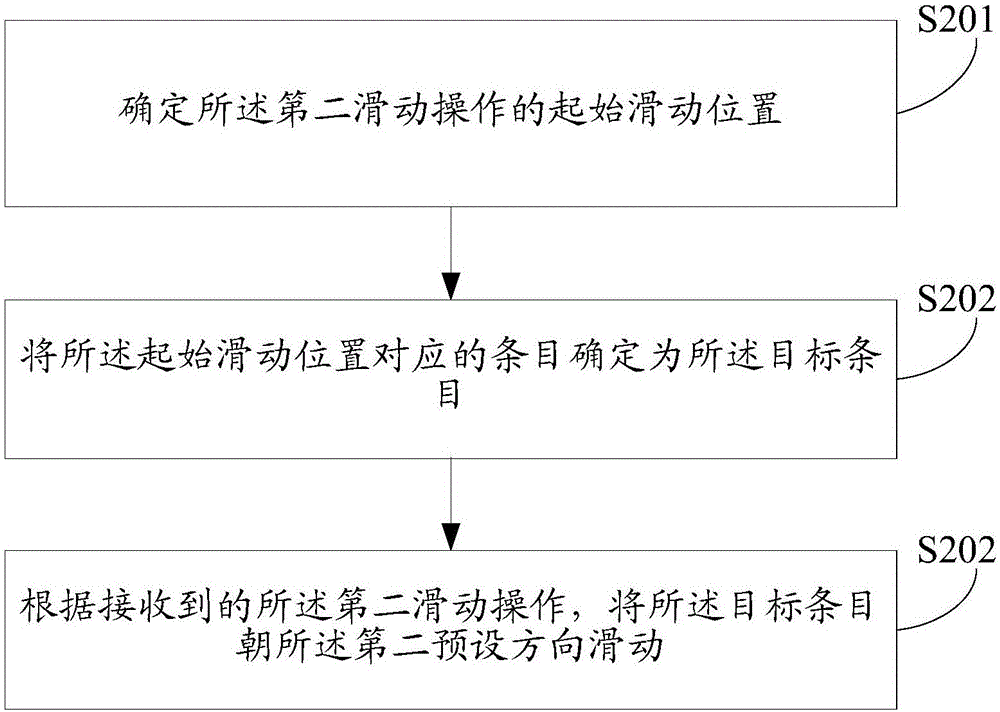

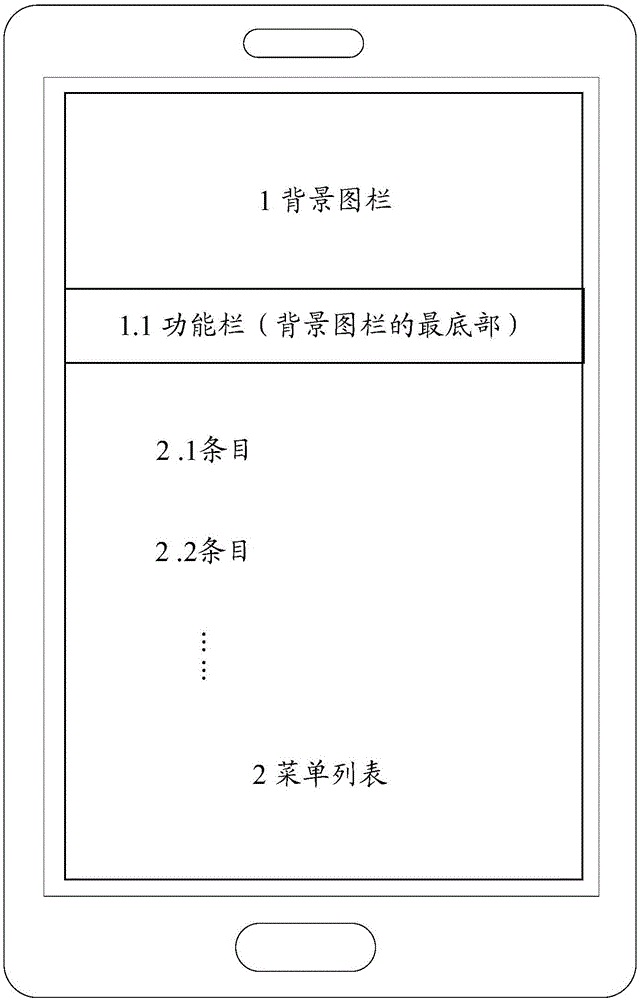

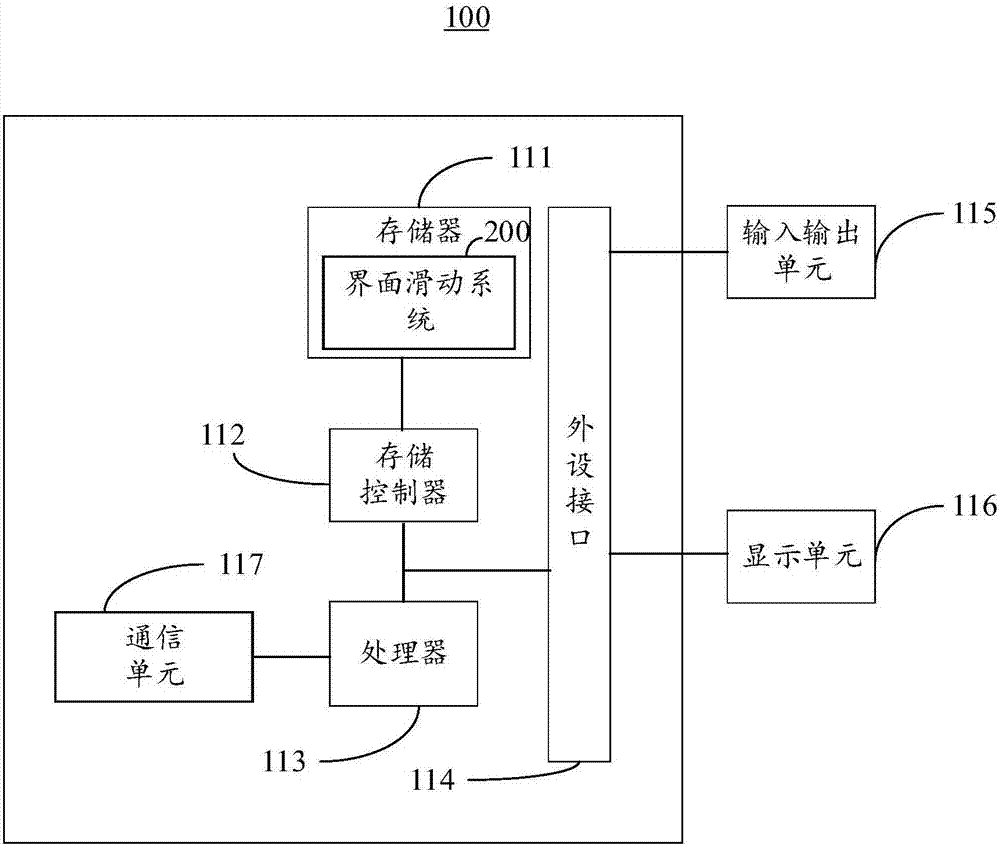

Interface treatment method and device

InactiveCN106648333ASlide to achieveOperation diversificationInput/output processes for data processingComputer engineering

The invention discloses an interface treatment method and a device. The method comprises the steps that an interface slide event is triggered when a first slide operation of a first preset direction is received, so that the interface is slid towards the first preset direction based on the first slide operation; a menu list slide event is triggered when the slide distance of the interface towards the first preset direction reaches a preset distance, so that the target entries of the menu list displayed in the interface are slid towards the second preset direction based on the received second slide operation of the second preset direction. By adopting the technical scheme, not only the sliding of interfaces is achieved, but also the target entries of the menu list displayed in the interface can be slid by the user, thereby user operations are enriched and great conveniences are provided for users.

Owner:TVMINING BEIJING MEDIA TECH

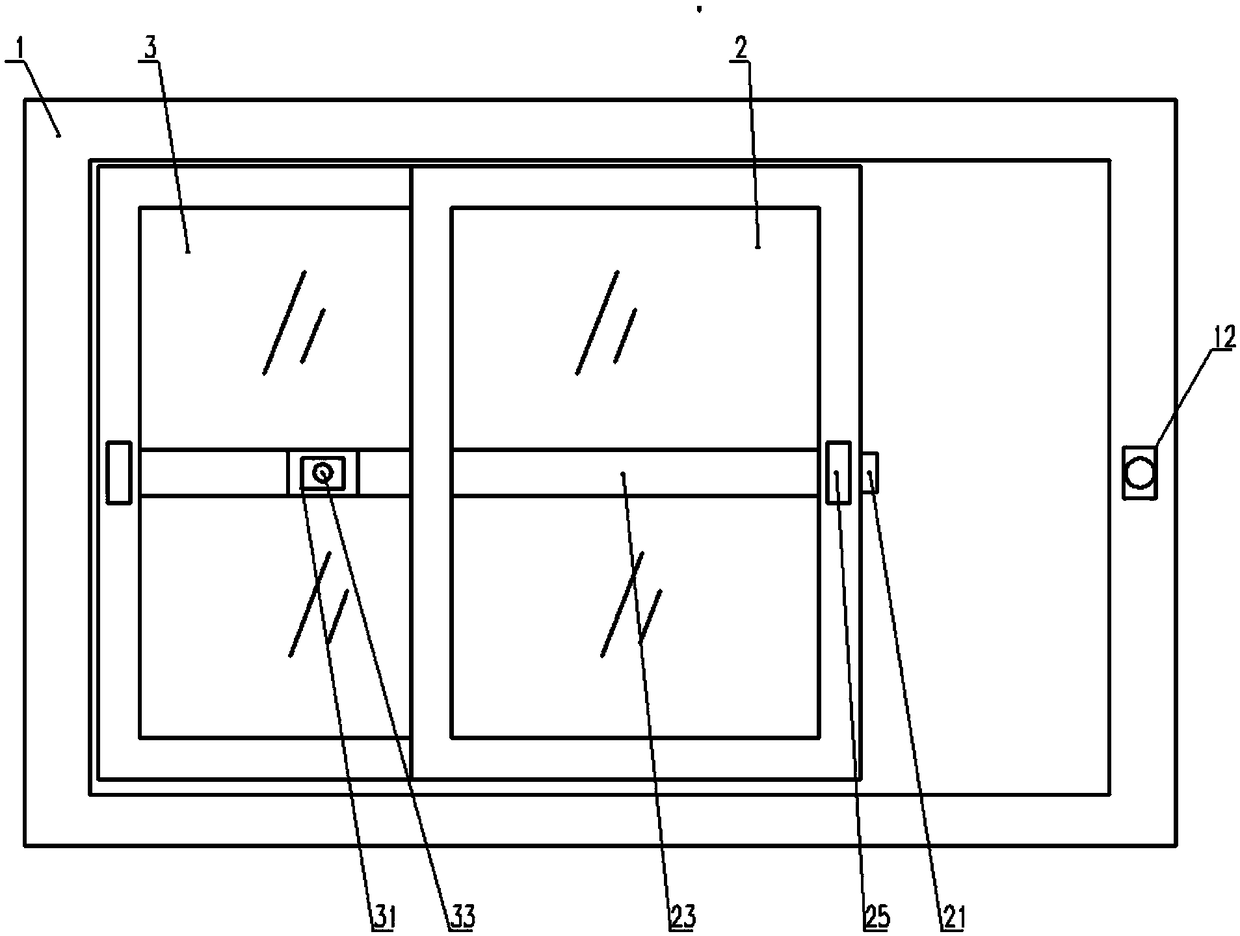

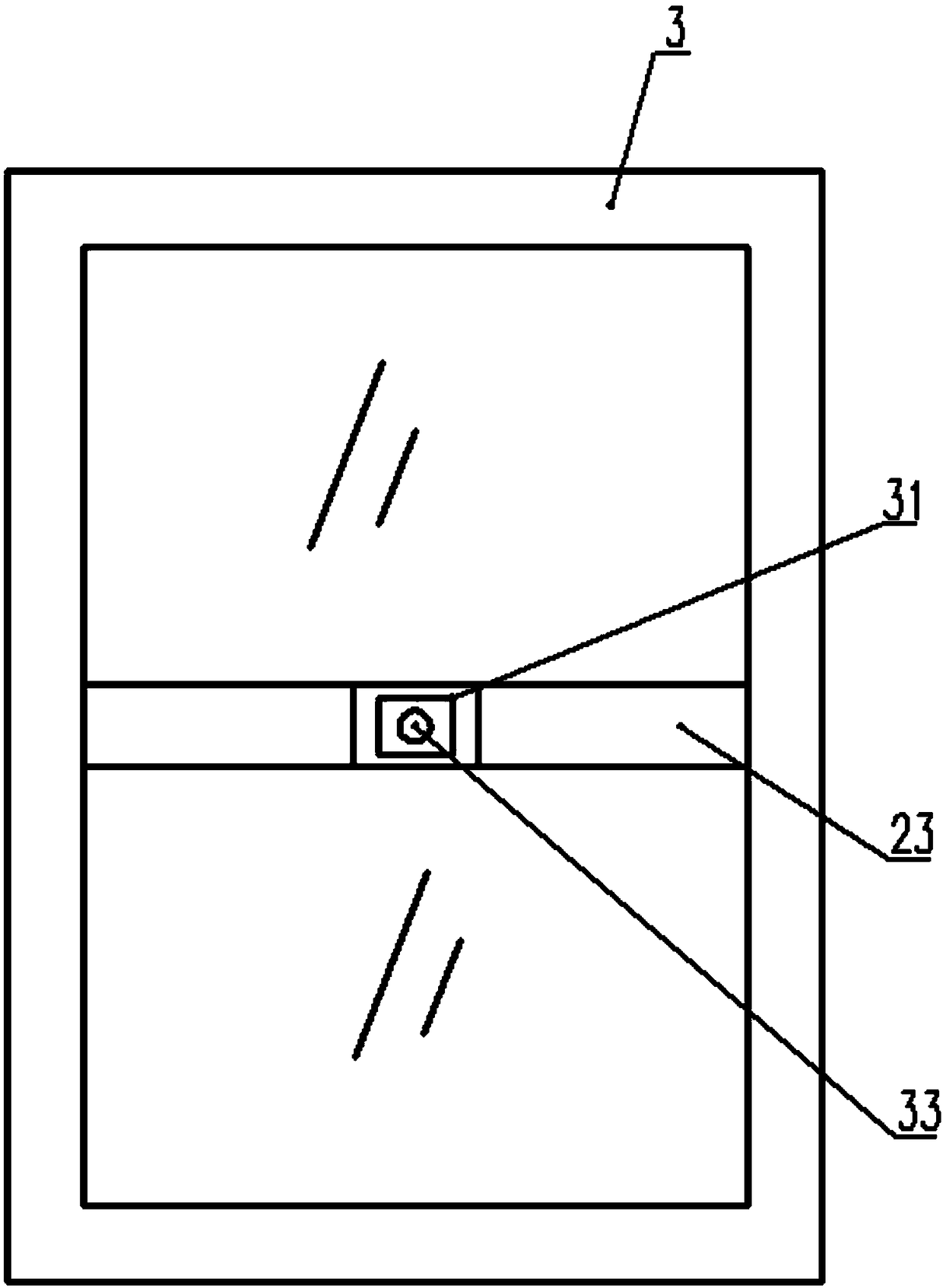

Aluminum alloy window convenient to push and pull

InactiveCN109386214ASlide to achieveDifficult to escapeWing arrangementsWing suspension devicesPush and pullSlide window

The invention discloses an aluminum alloy window convenient to push and pull, and relates to the field of building materials. The aluminum alloy window comprises a frame, an outer-layer sliding windowbody and an inner-layer sliding window body; the upper and lower ends of the frame are provided with two sliding rails front and back respectively, the upper and lower ends of the outer-layer slidingwindow body and the upper and lower ends of the inner-layer sliding window body are provided with sliding grooves, the outer-layer sliding window body is installed on the frame through the sliding rail at the back portion, and the inner-layer sliding window body is installed on the frame through the sliding rail at the front portion; the left and right sides of the frame are provided with lockingdevice respectively, the left side of the outer-layer sliding window body and the right side of the inner-layer sliding window body are provided with locking blocks, and the locking blocks correspondto the two locking devices respectively. The aluminum alloy window solves the problems that in the prior art, an aluminum alloy push-and-pull window is easily stuck during sliding, and when inner andouter window bodies are located at the same position, the window body at the outer layer cannot be pushed and pulled.

Owner:广信铝业股份有限公司

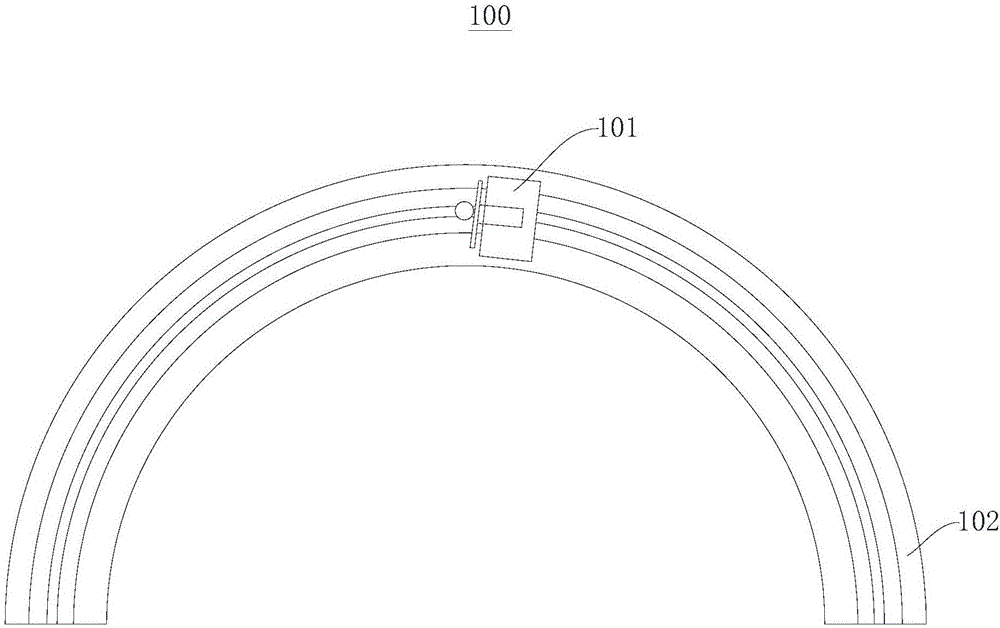

Toy basketball stand and physical exercise toy

The invention provides a toy basketball stand and a physical exercise toy. The toy basketball stand comprises a basketball stand body and a semicircular guide rail component. The basketball stand body comprises a backboard, a backboard stand column and a base. The two ends of the backboard stand column are connected with the backboard and the base respectively. The base is provided with sliding wheels. The sliding wheels are provided with wheel grooves. The guide rail component comprises a guide rail panel, guiding sliding strips and guiding sliding grooves, wherein the guiding sliding strips and the guiding sliding grooves are arranged on the guide rail panel, the guiding sliding strips are arranged inside the guiding sliding grooves and protrude out of groove bottom plates of the guiding sliding grooves. The sliding wheels are embedded into the guiding sliding grooves. The guiding sliding strips are embedded into the wheel grooves. The physical exercise toy comprises the toy basketball stand. The toy basketball stand is matched with the guide rail component through the basketball stand body, so that the static basketball stand body is replaced with a dynamic and movable basketball shooting basketball stand body; accordingly, interestingness of the toy basketball stand is enhanced, and a child is not tired of playing the toy basketball stand for a long time.

Owner:YANCHENG INST OF TECH

Rotary table type clamping device

The invention provides a rotary table clamping device, and belongs to the technical field of machining. The rotary table clamping device comprises a rotary disc, an annular guide rail, a clamping assembly and a positioning ring. The rotary disc is rotationally arranged on a bearing support. The annular guide rail is fixed to the rotary disc. Elevating bosses are arranged on the annular guide rail at equal intervals. A fixed disc is arranged on the bearing support through a disc support. The positioning ring is fixed to the outer side of the fixed disc. A fixed support lug of the clamping assembly is fixed to a fixed supporting column. One end of a first connecting rod is hinged to the fixed support lug, and the other end of the first connecting rod is hinged to one end of a second connecting rod. The other end of the second connecting rod is hinged to one end of an ejector rod. The ejector rod is arranged on an ejector rod support in a sliding manner. Sliding column bearings are fixed to the fixed disc. Sliding columns are arranged on the sliding column bearings in a vertical sliding manner. The upper ends of the sliding columns are connected with one end of the second connecting rod, and the lower ends of the sliding columns are attached to the annular guide rail. By means of the rotary table clamping device, multiple workpieces can be synchronously clamped, and the workpiece production efficiency is effectively improved.

Owner:TONGXIANG HUIQUAN TEXTILE CO LTD

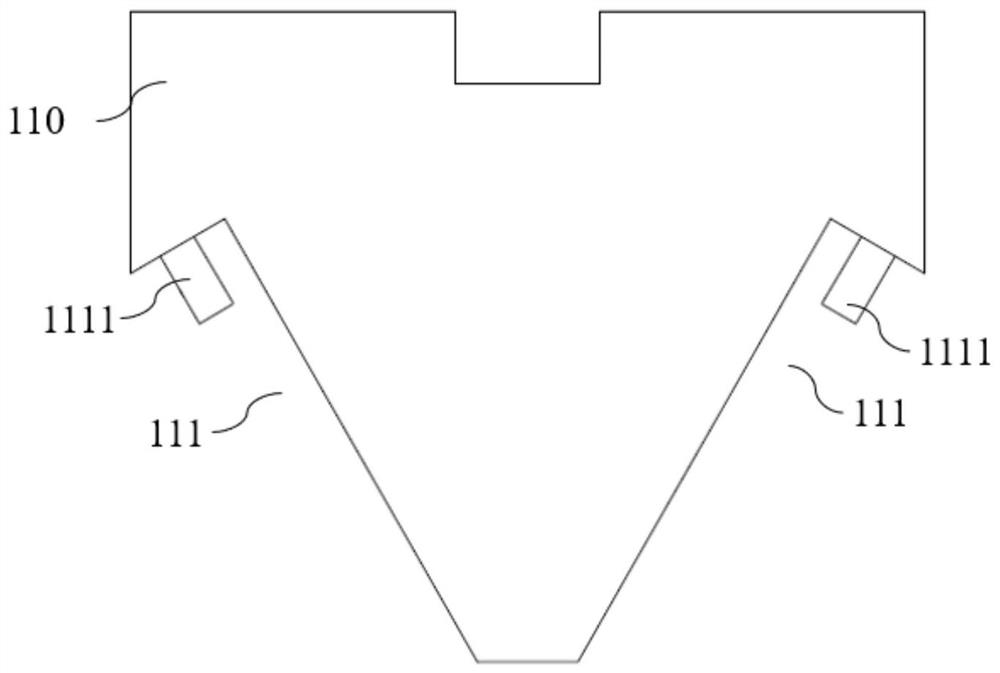

Machining method for bending large plate into multi-edge-angle workpiece in one step

ActiveCN112496104AReduce chanceRealize the reset functionMetal-working feeding devicesPositioning devicesStructural engineeringManufacturing engineering

The invention discloses a machining method for bending a large plate into a multi-edge-angle workpiece in one step, and belongs to the technical field of machining equipment. The multi-edge-angle workpiece is formed by one-step bending through an automatic forming die; the automatic forming die comprises an upper die part and a lower die part; the machining method comprises the steps that S1, theplate-shaped workpiece is placed on the upper surface of a lower die part of the automatic forming die; an upper die part descends for stamping, and when the die is closed, a male die of the upper diepart is attached to the upper surface of a workpiece to form a plurality of edges; a first female die of the lower die part is attached to the lower surface of the workpiece to form two obtuse edge angles; meanwhile, a second female die and a third female die of the lower die part are attached to the lower surface of the workpiece to form a plurality of edge angles respectively; S2, the upper diepart ascends; the male die is away from the upper surface of the workpiece; and a multi-edge-angle workpiece is obtained. By means of the machining method, the multi-edge-angle workpiece can be formed in one step.

Owner:ANHUI LIYUAN NUMERICAL CONTROL CUTTING TOOL & PATTERNS MFG

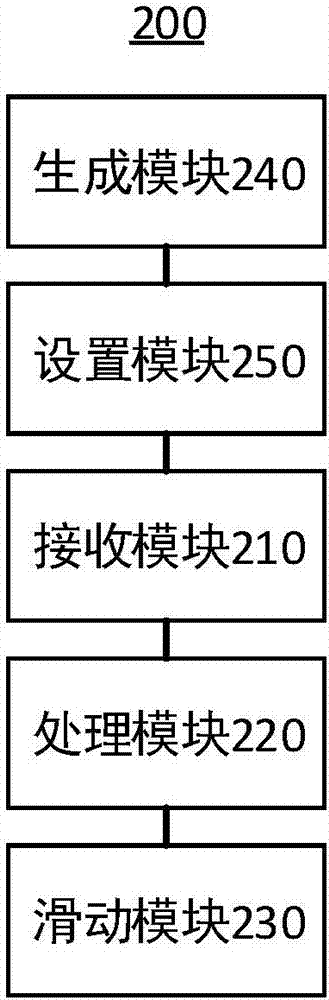

Interface sliding method and system

ActiveCN107153502AImplement the click functionSlide to achieveInput/output processes for data processingIntermediate pointComputer engineering

The invention provides an interface sliding method and an interface sliding system, and relates to the field of interface sliding. A sliding track corresponding to a sliding operation is acquired through the sliding operation starting from a certain point of a user on a display interface, a starting point, an intermediate point and an end point of the sliding are acquired according to the sliding track, a plurality of displacement vectors are generated according to the starting point, the intermediate point and the end point, a content displayed in the display interface slides at the preset times of the length of the displacement vector in the direction opposite to the displacement vector, then the display interface slides, the display content on the end position of the sliding is clicked when the sliding is finished, the parameters of the specific point, like the existence place, the transparency, the shape, the size, preset times and the display mode, are set according to the requirement of the user, and the function of clicking an area hard to touch and control by the user in the display interface is realized.

Owner:深圳掌酷软件有限公司

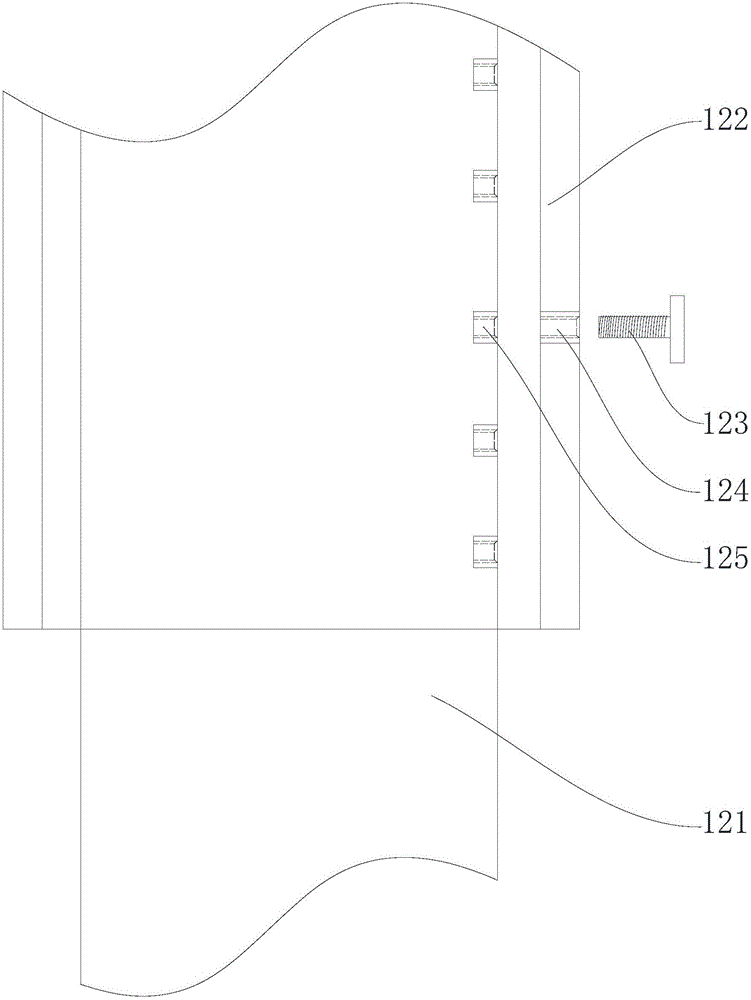

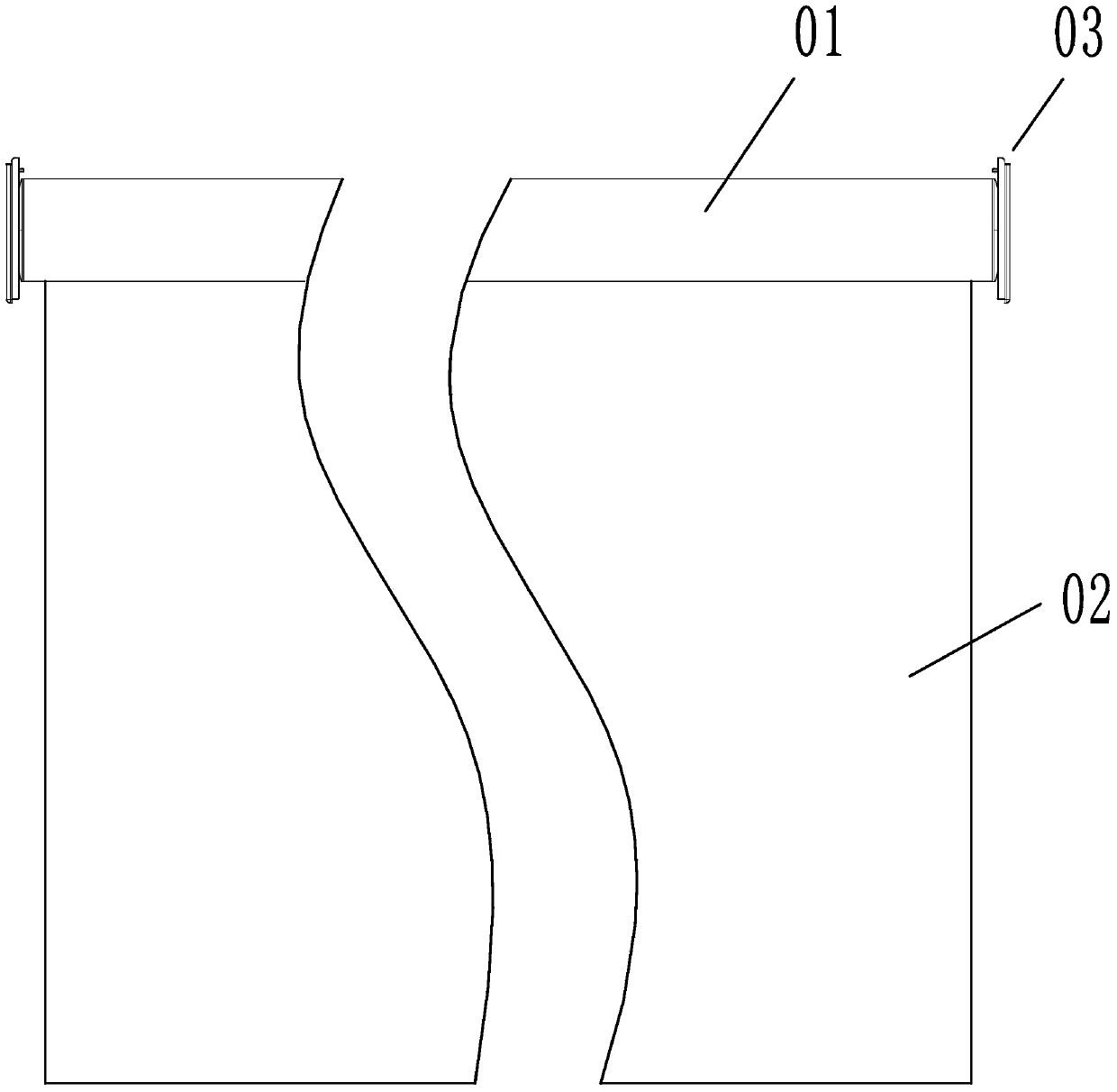

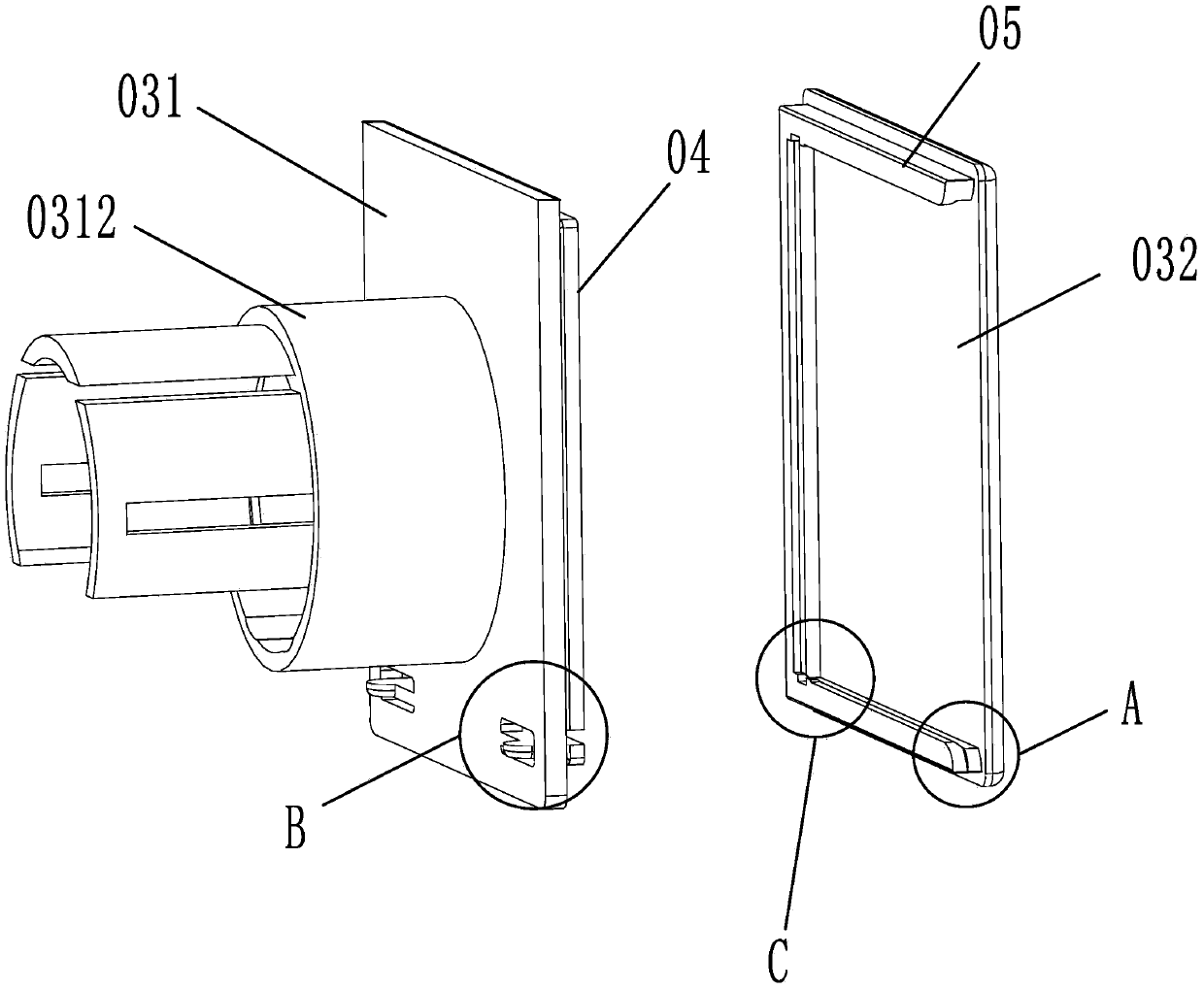

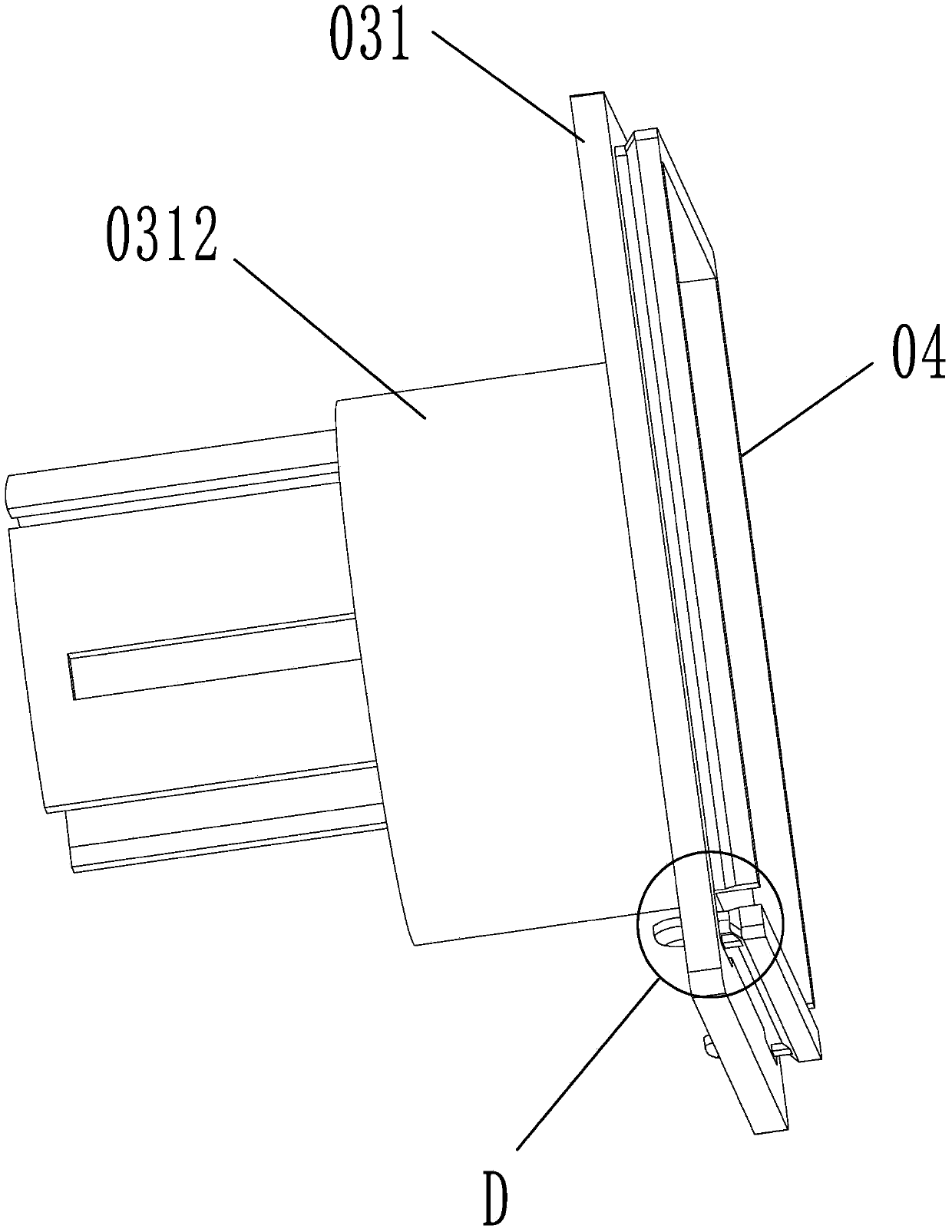

Roller shutter

ActiveCN103993821AEasy maintenanceSlide to achieveLight protection screensEngineeringMechanical engineering

The invention relates to a curtain, in particular to a roller shutter. The roller shutter comprises a winding drum and a shutter body winding around the winding drum. Fixing bases are arranged at the two ends of the winding drum. Each fixing base comprises a supporting plate and a fixing end plate. One end surfaces of the supporting plates are perpendicular to the axis of the winding drum and are connected with the end of the winding drum, the fixing end plates are detachably connected with the other end surfaces of the supporting plates, and installation holes are formed in the middle of the supporting plates. The roller shutter can be implemented manually or electrically. Meanwhile, the roller shutter has the advantages of being convenient to disassemble and assemble, simple in operation process and convenient to use, facilitating repair and maintenance of the interior of the winding drum, and the like, and it is not needed to locate the whole roller shutter again in the repair process.

Owner:HD4U SMART HOME CO LTD

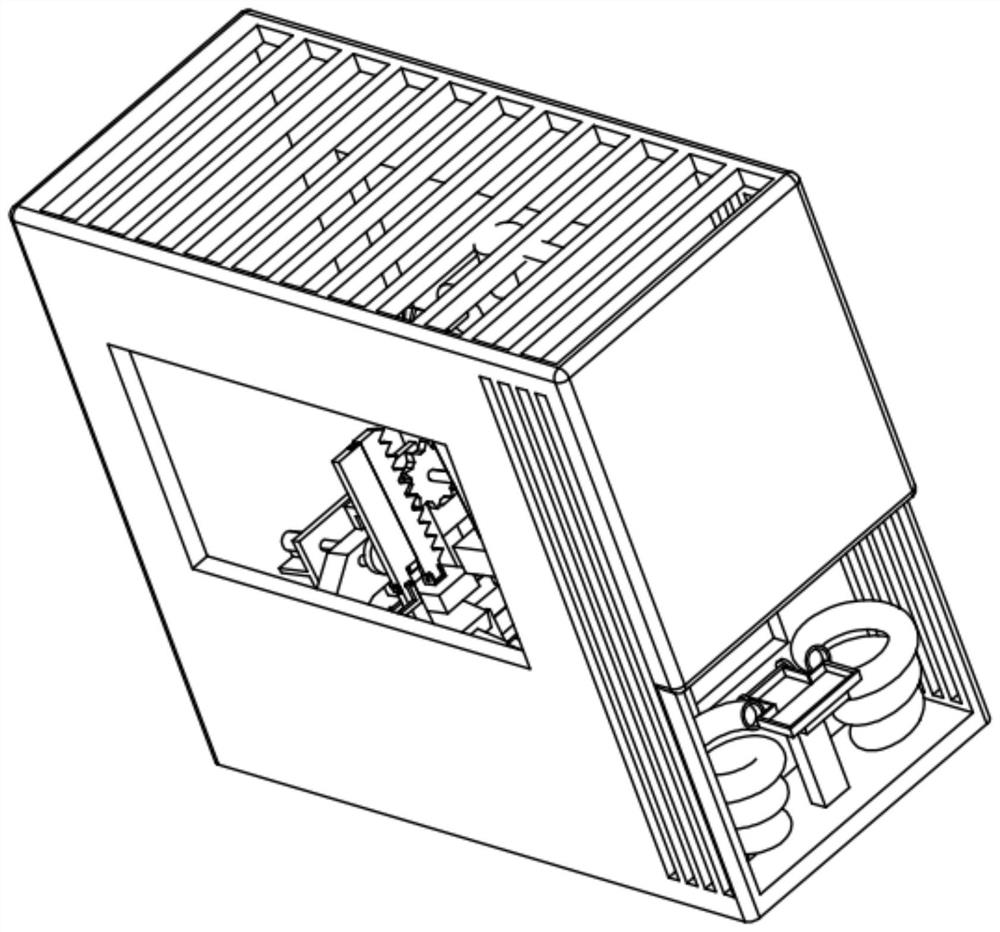

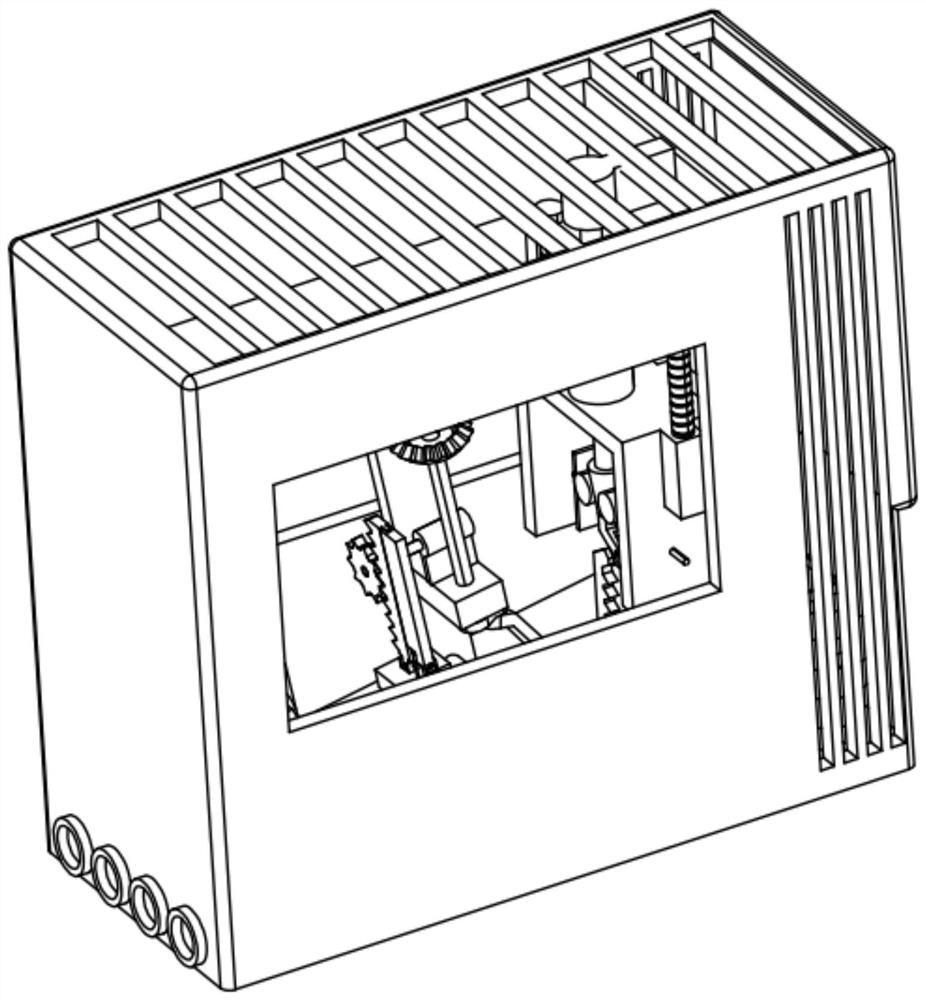

Intelligent mouse trapping cage

ActiveCN111713484AAvoid backtrackingRealize the temptationAnimal trapsElectric machineryStructural engineering

The invention provides an intelligent mouse trapping cage. The intelligent mouse trapping cage comprises a mouse cage mechanism, a knocking and trapping mechanism, a clamping and trapping mechanism and a collecting mechanism, wherein the mouse cage mechanism comprises a mouse cage box, a glass window, a ventilation port, a slope plate and a drawer; the knocking and trapping mechanism comprises a bottom plate, a counterweight mechanism and a knocking mechanism; the knocking mechanism is used for knocking a mouse; the counterweight mechanism is used for applying an impact force to the knocking mechanism; the clamping and trapping mechanism comprises a belt motor, a belt wheel, a screw rod and a slide block plate; the belt motor is fixedly mounted on a baffle plate on the inner side of the mouse cage box; a motor shaft of the belt motor is fixedly connected with the belt wheel; the rear end face of the slide block plate is fixedly connected with the baffle plate on the inner side of the mouse cage box; the screw rod is in thread fit with a thread on the slide block plate; the belt wheel is in rolling fit with the screw rod through a belt; the clamping and trapping mechanism is used for clamping the mouse; the collecting mechanism is fixedly mounted on the upper end face of the slope plate; and the collecting mechanism is used for cleaning the mouse sliding down from the slope plate.

Owner:西安天纵有害生物防治有限公司

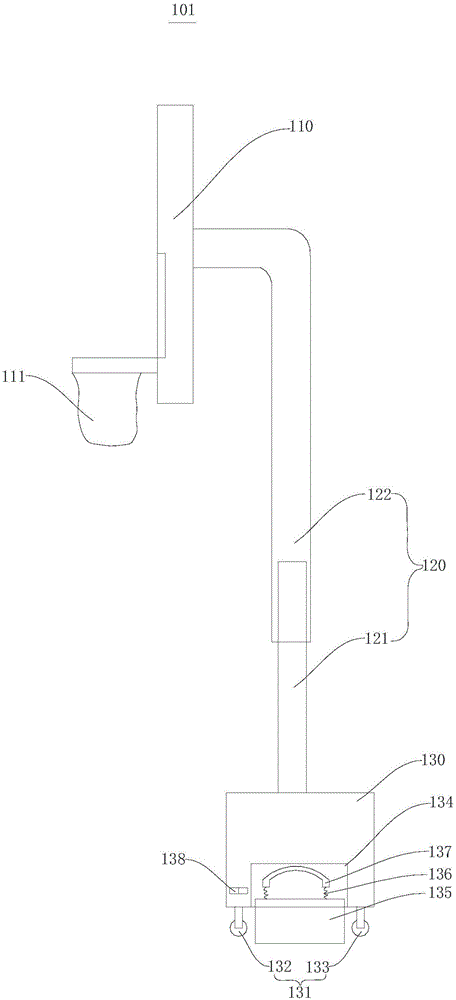

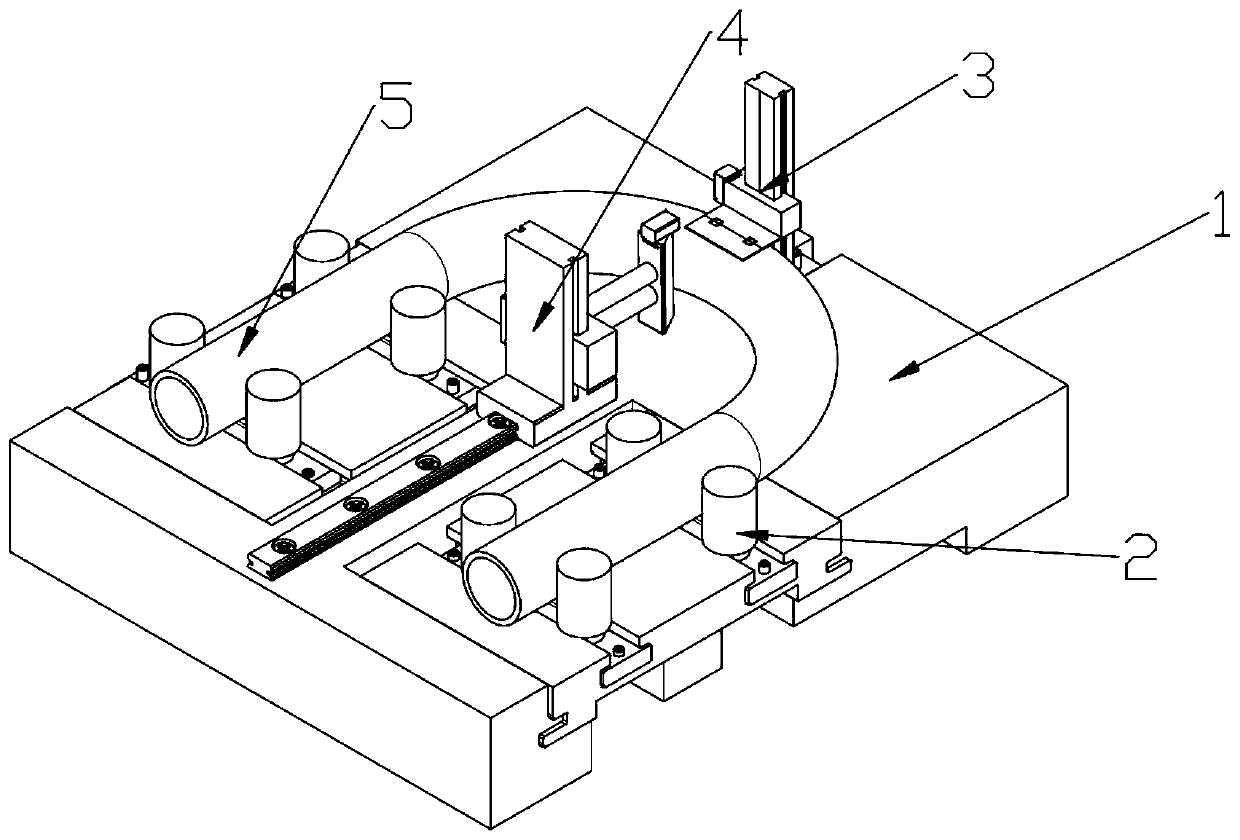

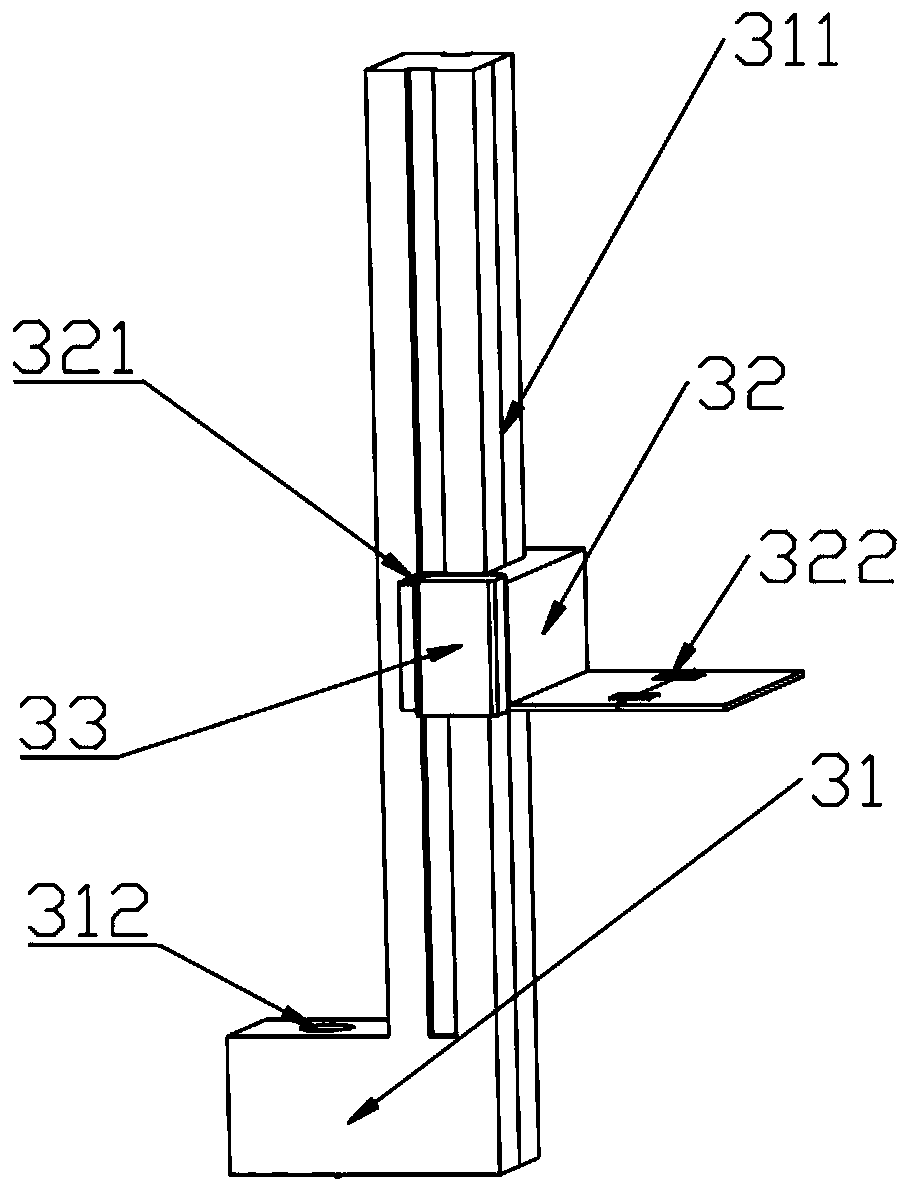

Bent tube section ovality manual measurement device

PendingCN109764825AEasy to measureAccurate measurementUsing optical meansLaser rangingMeasurement device

The invention discloses a bent tube section ovality manual measurement device. The device comprises a base, a fitting positioning module, a bent tube section long axis measurement module, and a bent tube section short axis measurement module; the bent tube section long axis measurement module, the bent tube section short axis measurement module and the fitting positioning module are arranged on the base, and then the fitting is placed on the fitting positioning module, the bent tube section long axis measurement module and the bent tube section short axis measurement module are adjusted, the measurement is performed after positioning, the section long axis and the section short axis of the bending center angle of the bent tube are respectively measured through laser range finders arrangedat the bent tube section long axis measurement module, the bent tube section short axis measurement module, thereby computing the ovality of the section. The measurement device disclosed by the invention is modular in design and strong in generality.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com