Roller shutter

A technology of roller blinds and reels, which is applied in the field of curtains, can solve problems such as repositioning, and achieve the effect of convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

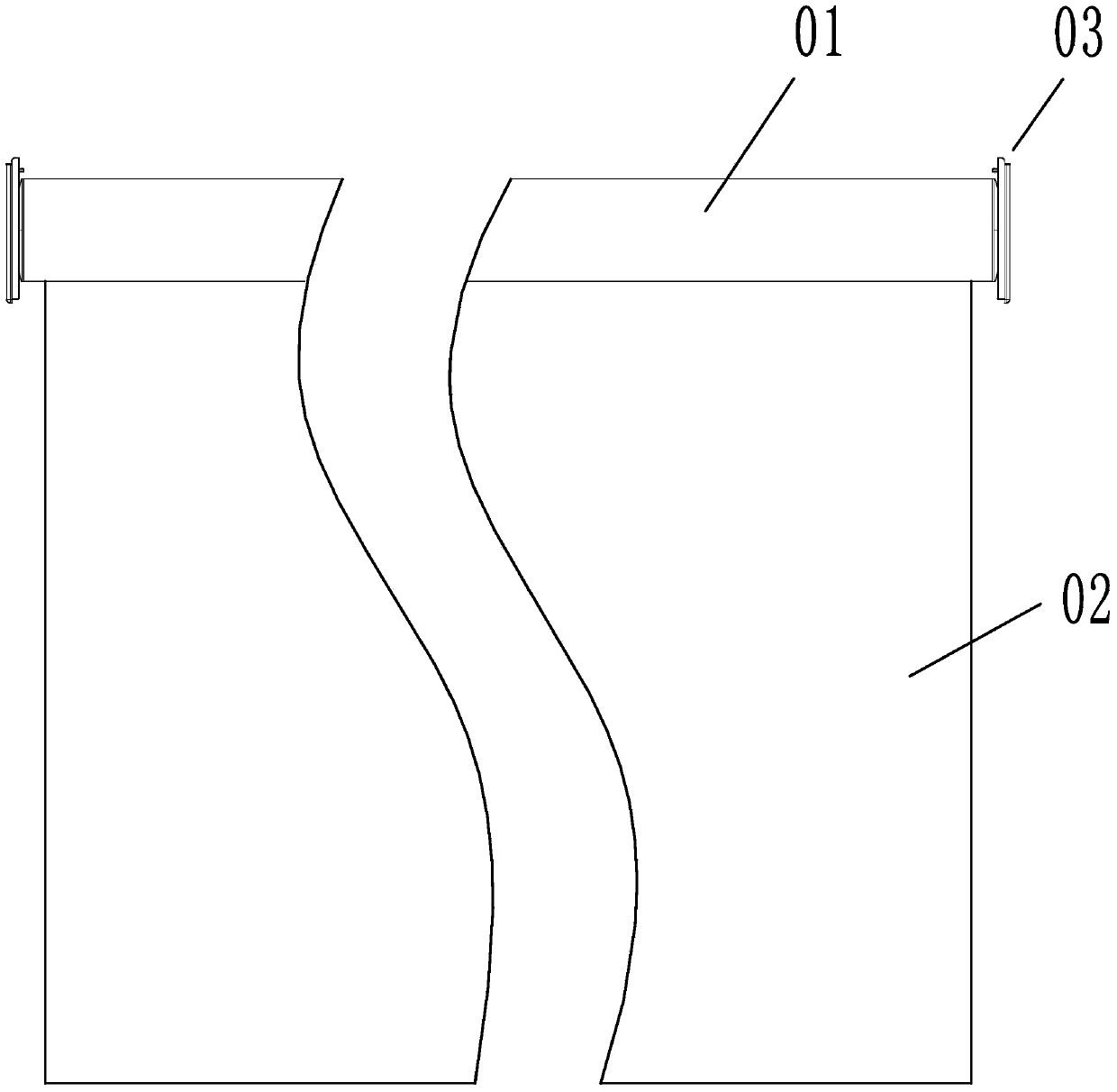

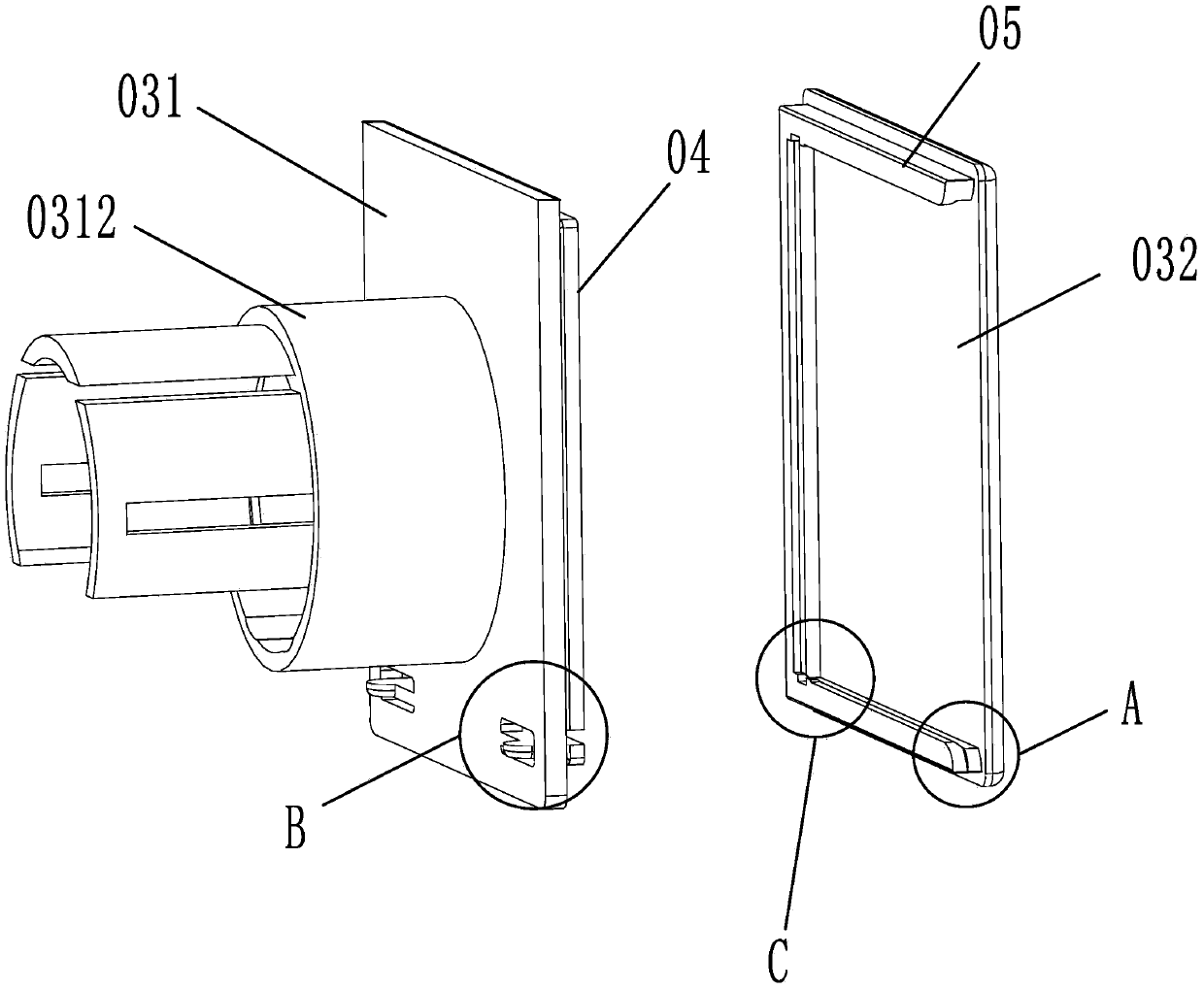

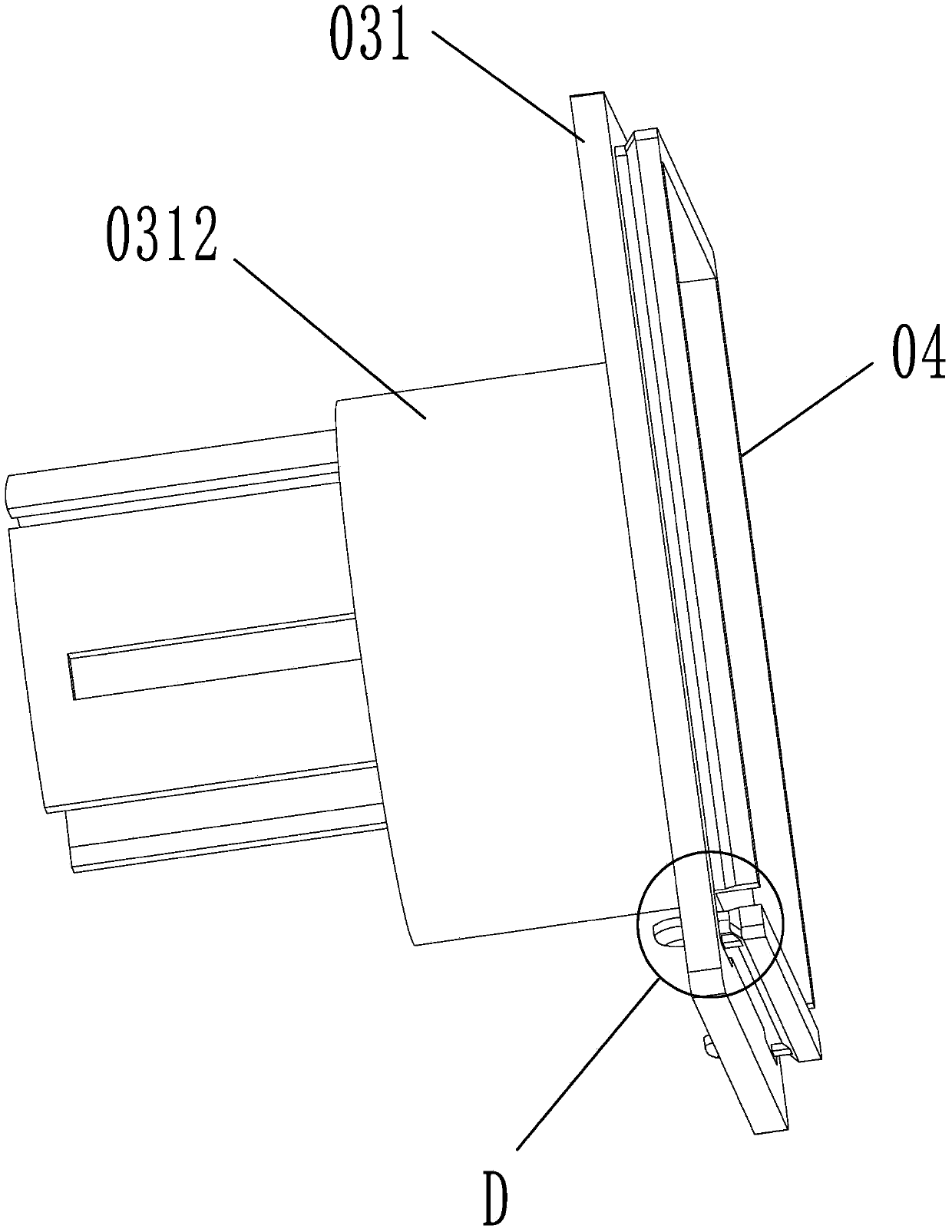

[0035] Embodiment 1: as figure 1 As shown, a roller blind includes a reel 01 and a curtain body 02 wound on the reel, and fixing seats 03 are installed at both ends of the reel 01 . Such as figure 2 As shown in ,, 3, and 4, the fixed base 03 includes a support plate 031 and a fixed end plate 032. One end surface of the support plate 031 is perpendicular to the axis of the reel 01 and is connected to the end of the reel through the bracket 0312. The support plate 031 The size is larger than the diameter of the reel 01, and the outer surface of the bracket 0312 on the support plate is connected with the inner surface of the reel 01 in cooperation. The fixed end plate 032 is detachably connected to the other end surface of the support plate 031, and the middle part of the support plate 031 has an installation hole 0311, and the installation hole 0311 is coaxial with the reel. Four first locking protrusions 04 are integrally connected to one end surface of the support plate 031...

Embodiment 2

[0037] Embodiment 2: The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that, as Figure 9 , 10 As shown, one side edge of the support plate 031 is integrally connected with a top plate pin 10, and the top plate pin 10 is vertically connected with the support plate 031 to form an "L" shape. A roller blind top plate 11 is installed between the two support plates at both ends of the reel, as shown in FIG. Figure 11 As shown, there are two draw-in grooves 112 for fixing the curtain body on the roller blind top plate 11, the two draw-in grooves 112 are parallel to the roller blind top plate 11, and there are two top plate pins 10 on the support plate 031, and the top plate pins 10 and the card The slot 112 is plugged in.

[0038] One edge of the support plate is provided with top plate pins, the top plate pins are vertical to the support plate and the roller shutter top plate is arranged between the two support plates, and the rolle...

Embodiment 3

[0039] Embodiment 3: The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that, as Figure 12 , 13 As shown, one side edge of the fixed end plate 032 is integrally connected with a connecting seat 13 for fixing the roller blind, and the connecting seat 13 is vertically connected with the fixed end plate to form an "L" shape. The connecting seat is vertically connected with the fixed end plate, and there are bolt mounting holes on the connecting seat, through which the entire roller blind can be fixed on the wall or the roof, that is, the fixed end plate is used to fix the roller blind. During maintenance, it is only necessary to disassemble the reel and support plate from the fixed end plate, without disassembling the fixed end plate, without changing the position of the fixed end plate, and there is no need to disassemble the reel and support plate during the maintenance process; after the maintenance is completed, just Reinstalli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com