Slide pressurizing mechanism used in slide pressurizing continuous solid-liquid separating machine

The technology of a solid-liquid separator and a pressurizing mechanism is applied in the directions of presses, filtration separation, separation methods, etc., which can solve the problems of material side slip and feeding difficulties, inconvenient separation of stick-slip materials, and difficulty in uniform distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

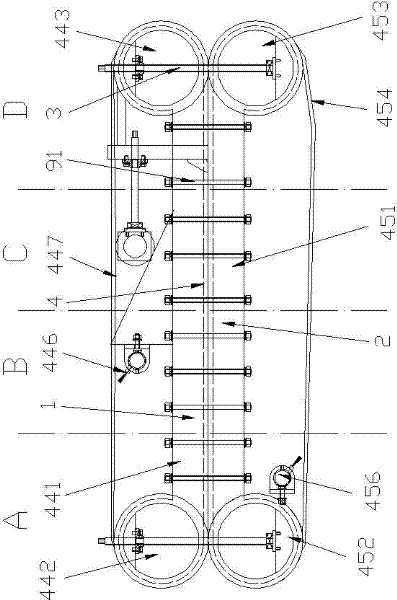

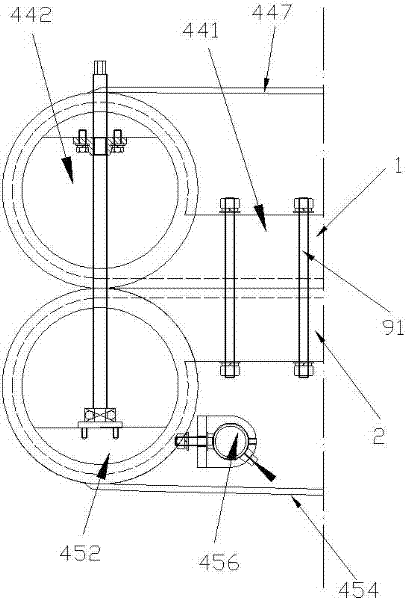

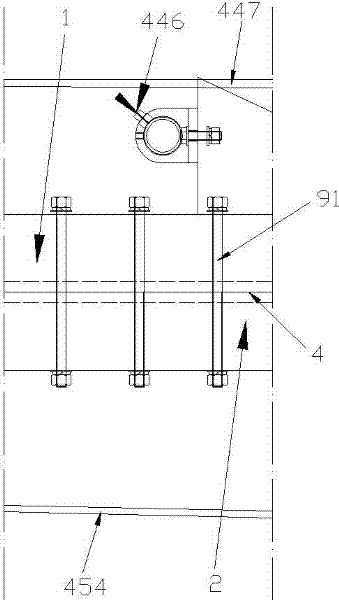

[0031] see Figure 1 to Figure 5 , the sliding pressurization mechanism used in the sliding pressurization continuous solid-liquid separator in this embodiment includes an upper pressing device 1 , a lower pressing device 2 and a pressing block distance adjusting device 3 .

[0032] The upper pressing device 1 in this embodiment is composed of an upper pressing unit, and the upper pressing unit includes an upper pressing block 441, an upper left pressing roller 442, an upper right pressing roller 443, an upper lubricating mechanism and an upper sliding tape 447, wherein the upper The two ends of the pressing block 441 are arc-shaped structures, and the upper pressing block 441 is located between the upper left pressing roller 442 and the upper right pressing roller 443, and the upper sliding tape 447 is wrapped around the upper left pressing roller 442, the upper pressing block 441 and the upper pressing block 441. Outside the upper right pressure roller 443. In this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com