Device and method for testing adhesive force between metal coating and organic coating

A technology of organic coating and metal coating, which is applied in the field of metal parts, can solve the problems that the metal coating of the surface coating cannot be guaranteed to be scratched, the force of scratching can not be accurately controlled, and the adhesion between layers cannot be accurately reflected. Achieve the effects of avoiding scratches, ensuring dimensional accuracy, and sufficient cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

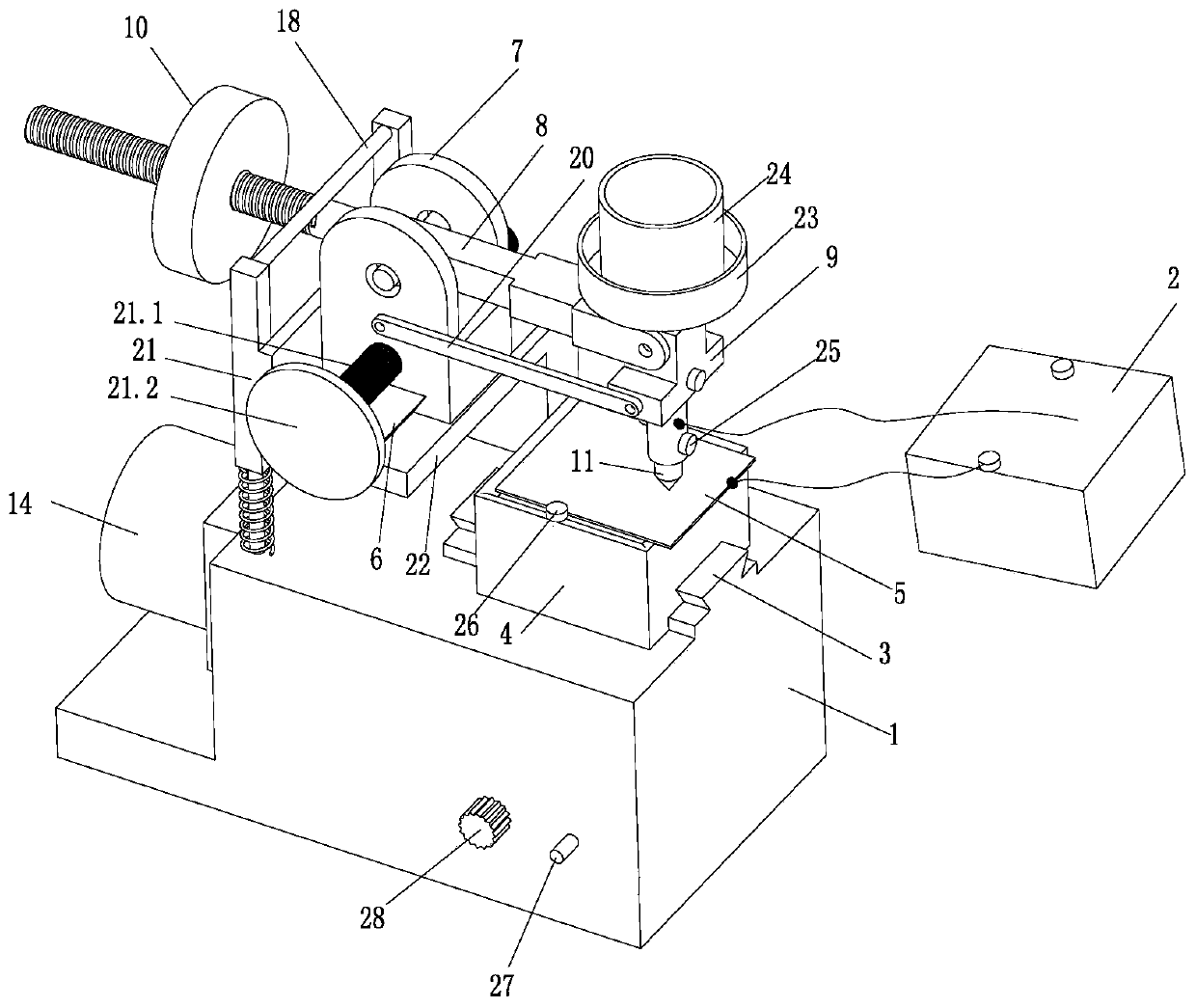

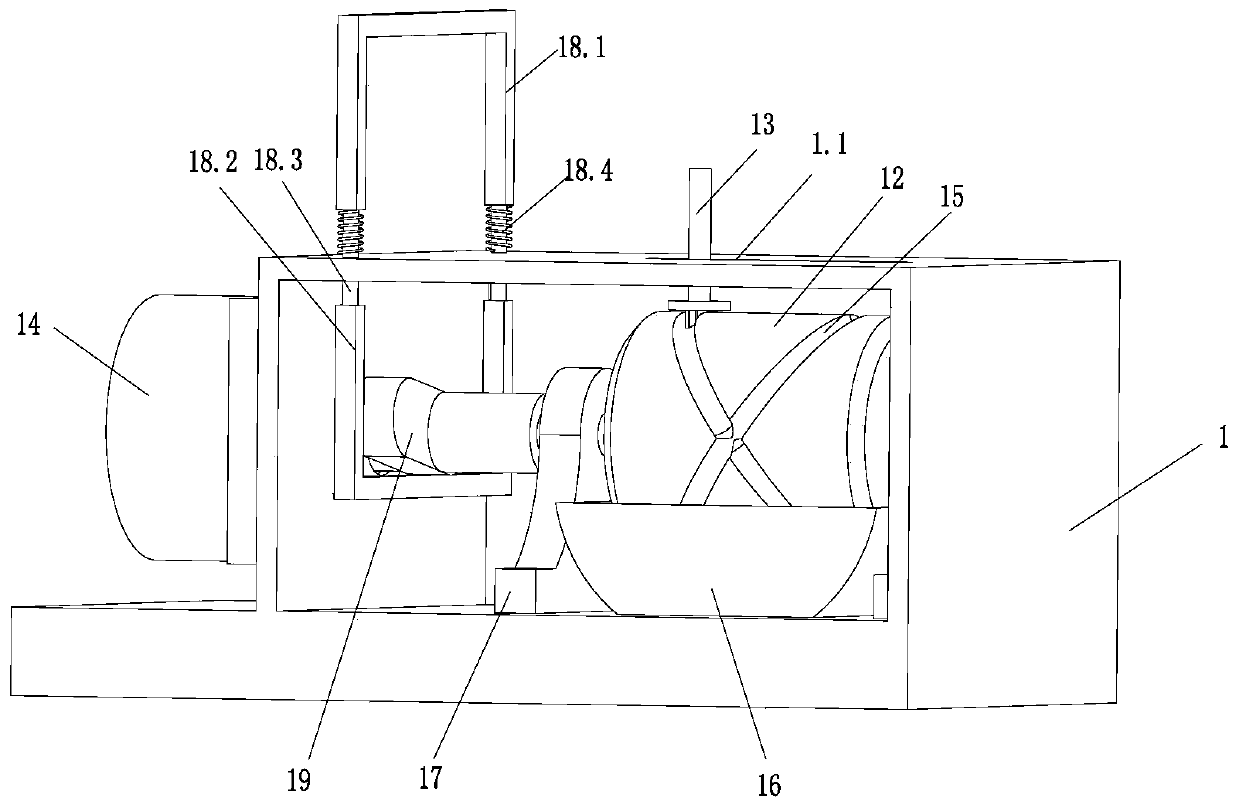

[0036] like figure 1 As shown, the adhesion test device between the metal coating and the organic coating of the present embodiment includes a base 1 and an electrification indicating device 2, the base 1 is provided with an X-direction slide rail 3, and the X-direction slide rail 3 is provided with There is an X-direction sliding seat 4 that can slide along it, and the X-direction sliding seat 4 is used to install the sample block 5 to be tested. The base 1 is also provided with a device for driving the X-direction sliding seat 4 to slide along the X-direction slide rail 3 The driving mechanism; the top two sides of the X-direction sliding seat 4 are provided with a fixed knob 26 for locking and fixing the sample block 5 to be te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com