Assembling device for rectangular frame and assembling method of assembling device

An assembly device and assembly method technology, applied in metal processing, metal processing equipment, manufacturing tools and other directions, can solve the problems of poor forming quality, high labor intensity of staff, low assembly efficiency, etc., and achieve high forming quality and save labor costs. , good positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below through specific embodiments.

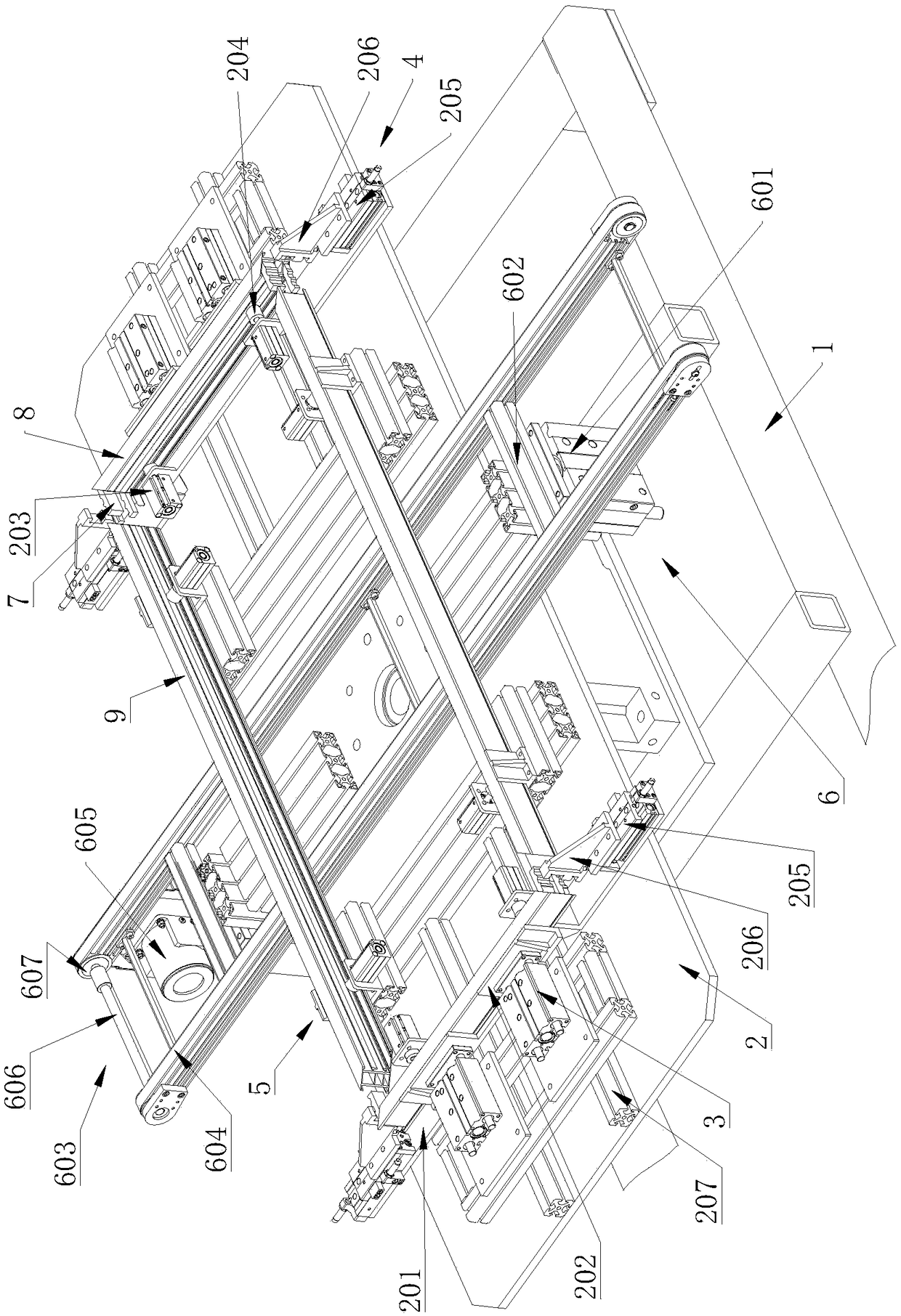

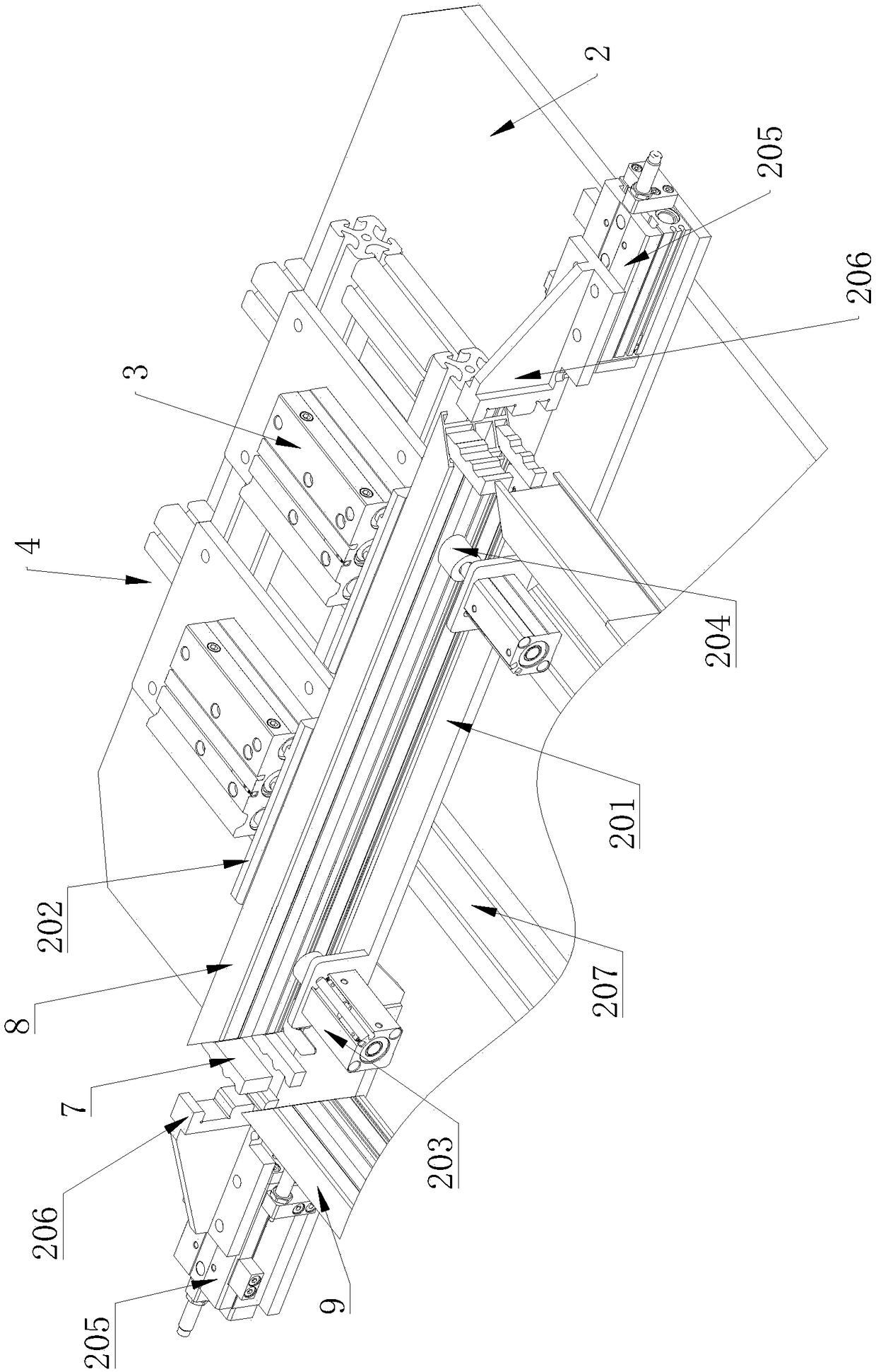

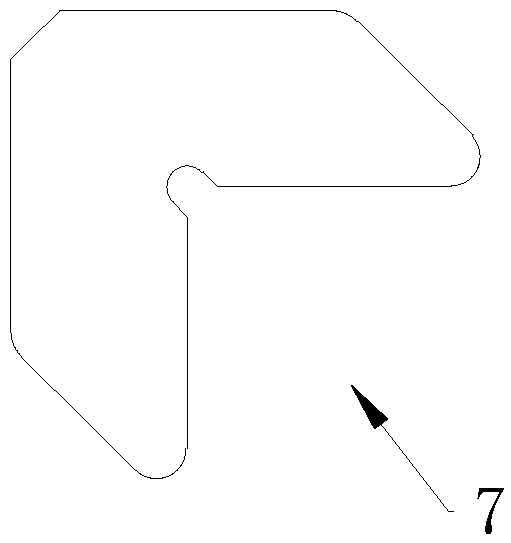

[0044] like figure 1 and figure 2 Commonly shown, an assembly device for a rectangular frame includes a frame 1 on which a rotating frame 2 driven by a first power device (not shown in the figure) is rotatably mounted. In this solution, the first The power device is a motor-driven cam divider; both ends of the rotating frame 2 are slidably installed with a short frame clamping and positioning mechanism 4 driven by the driving device 3, and both sides of the rotating frame 2 are fixedly installed with long frame clamping and positioning. When the mechanism 5 is in the initial state, the distance between the two short frame clamping and positioning mechanisms 4 is greater than the length of the long frame 9; the rotating frame 2 is also provided with a top for lifting and conveying the assembled rectangular frame. Lift the conveying mechanism 6.

[0045] Both the short fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com