Patents

Literature

114results about How to "Achieve clamping positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

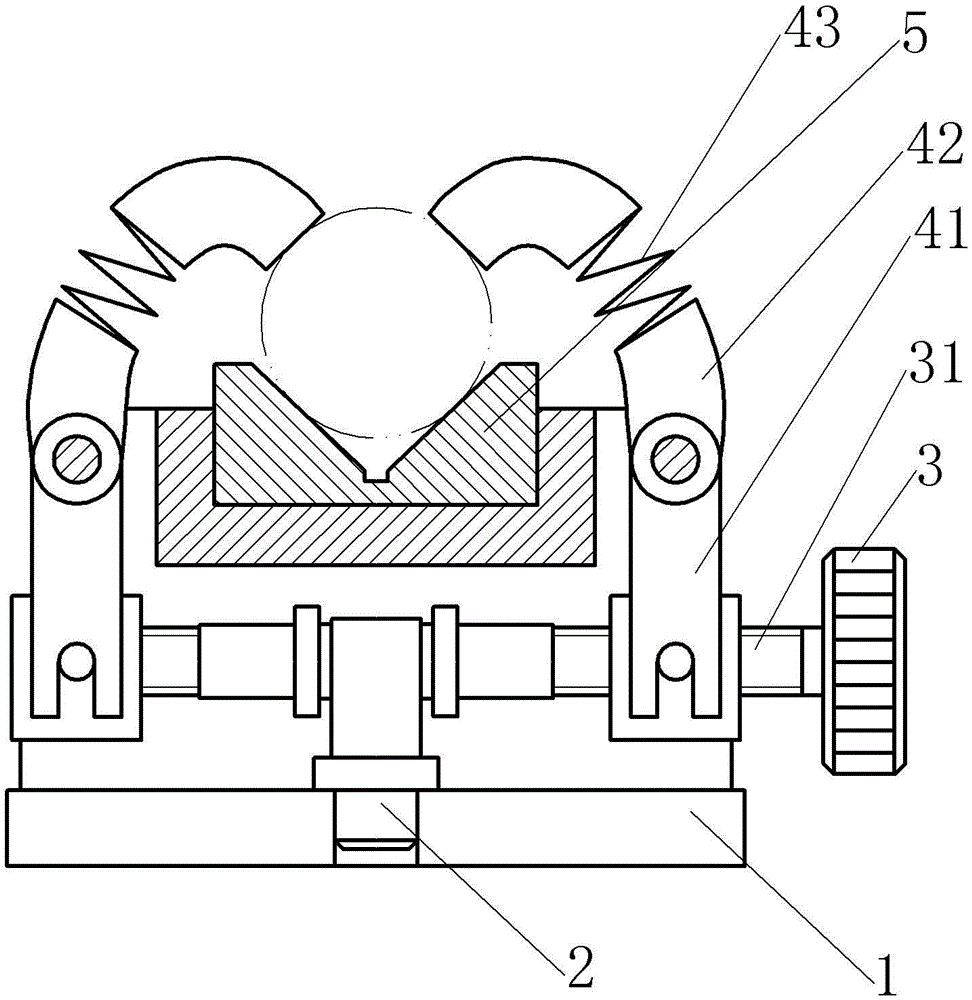

Clamping device for spring type accessory machining

InactiveCN105252301AAchieve clamping positioningFast processingJewelleryPositioning apparatusEngineeringScrew thread

The invention discloses a clamping device for spring type accessory machining. The clamping device comprises a base, a hinge support, a drive rod, clamping jaws and a V-shaped block. A strip-shaped groove is formed in the upper portion of the base. The V-shaped block is fixed into the strip-shaped groove and is a V-shaped rubber block. The two clamping jaws are distributed on the two sides of the V-shaped block respectively and symmetric about the V-shaped block. Each clamping jaw comprises a movable portion, a spring, a connection portion and a swing arm which are in linkage with one another in sequence from top to bottom. The swing arms and the connection portions are integrally formed. The upper ends of the swing arms are hinged to the upper portion of the base. The bottom end of the hinge support is connected to the bottom of the base in a treaded manner. The drive rod sequentially comprises a first thread segment, a smooth segment and a second thread segment in the horizontal direction. The smooth segment is in rotational linkage with the hinge support. The first thread segment and the second thread segment are in the opposite screwing directions. The first thread segment and the second thread segment are both connected with sliding sleeves in a threaded manner. Protruding columns are welded to the outer walls of the sliding sleeves. Opening grooves are formed in the lower ends of the swing arms and clamped to the protruding columns.

Owner:CHONGQING CHANGSHOU YIMEI ACCESSORIES PROCESSING MILL

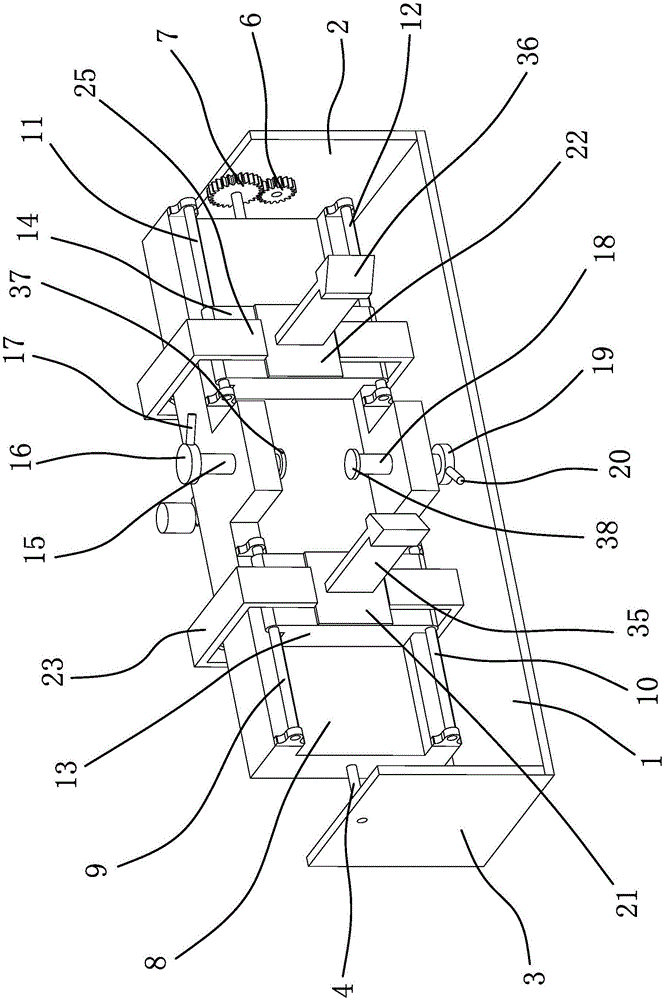

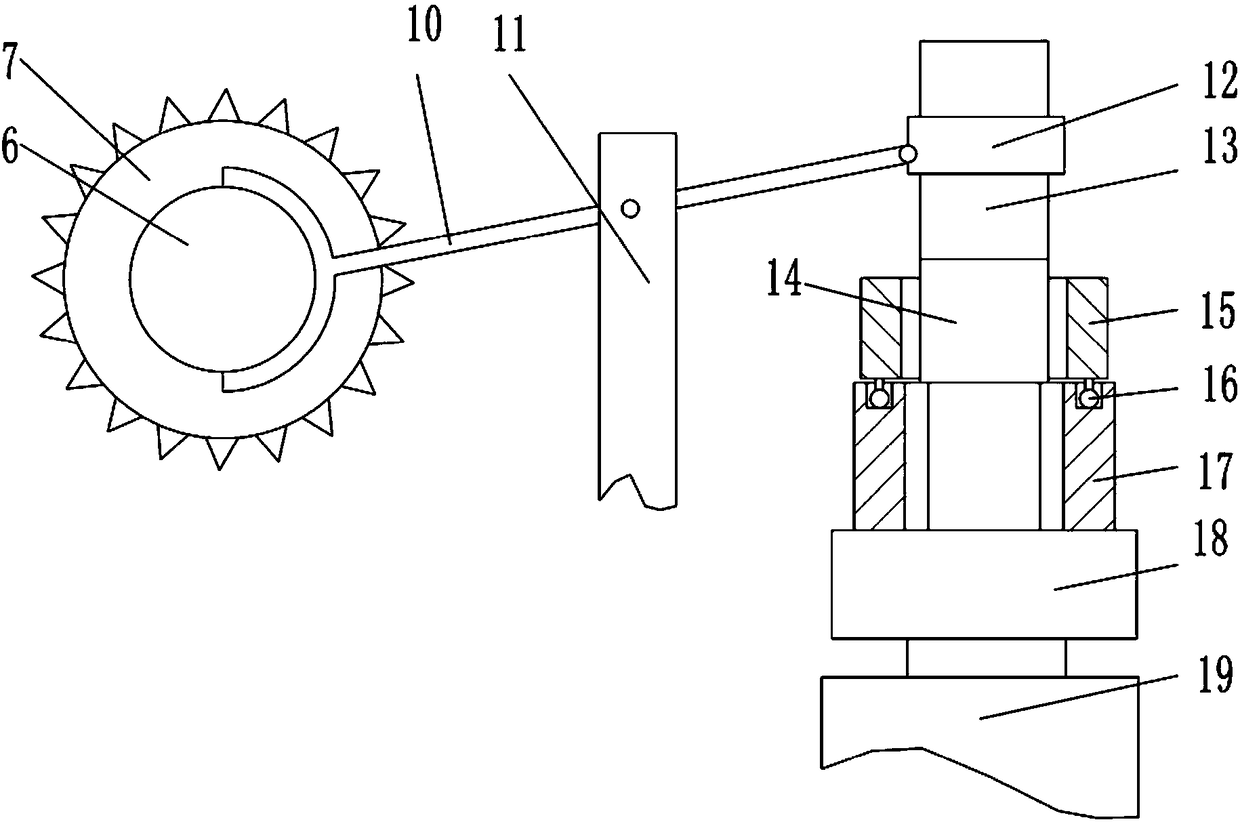

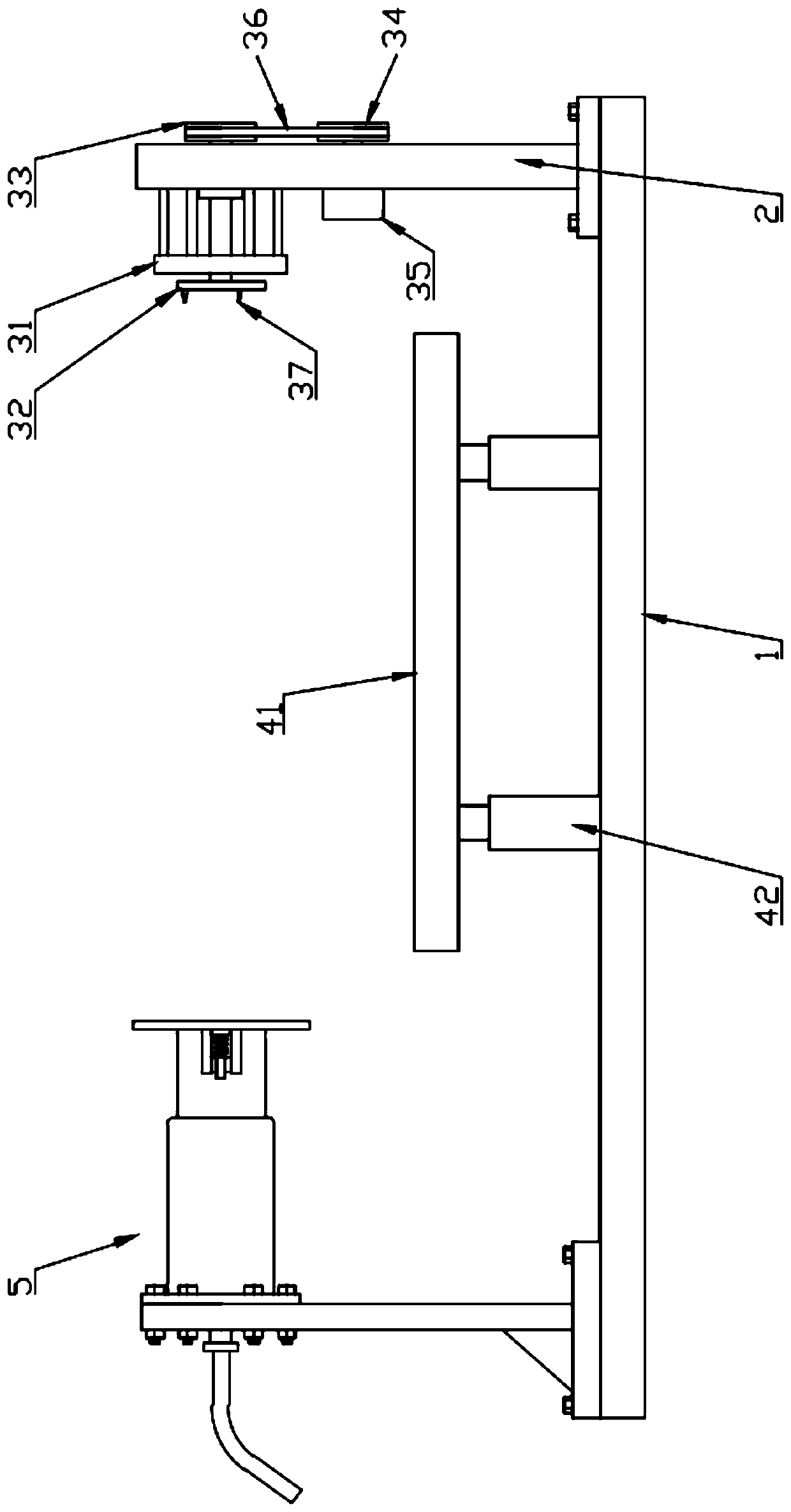

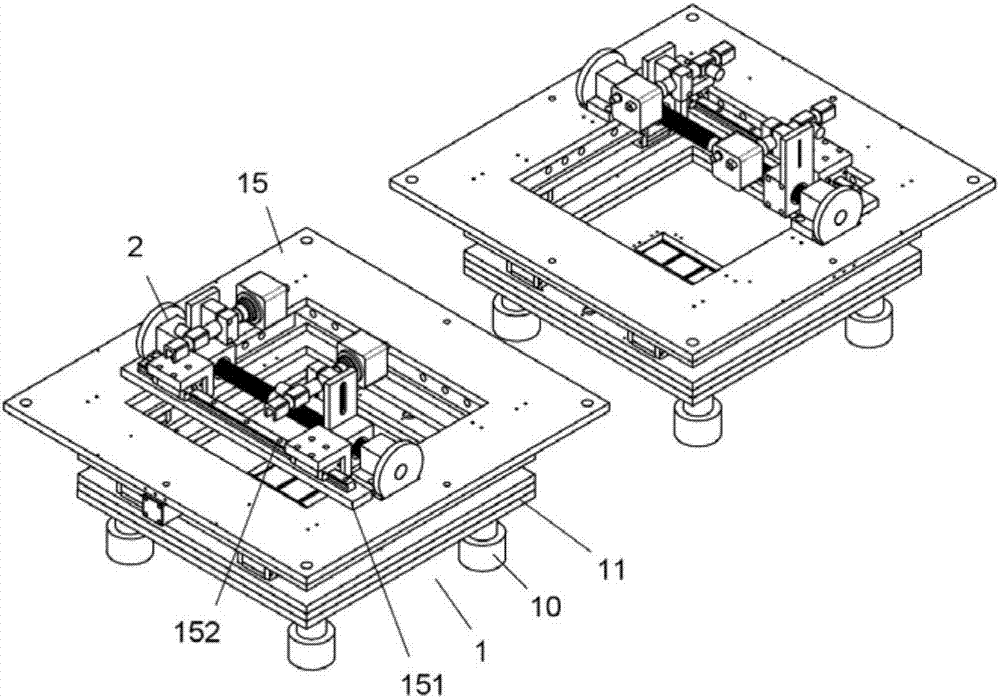

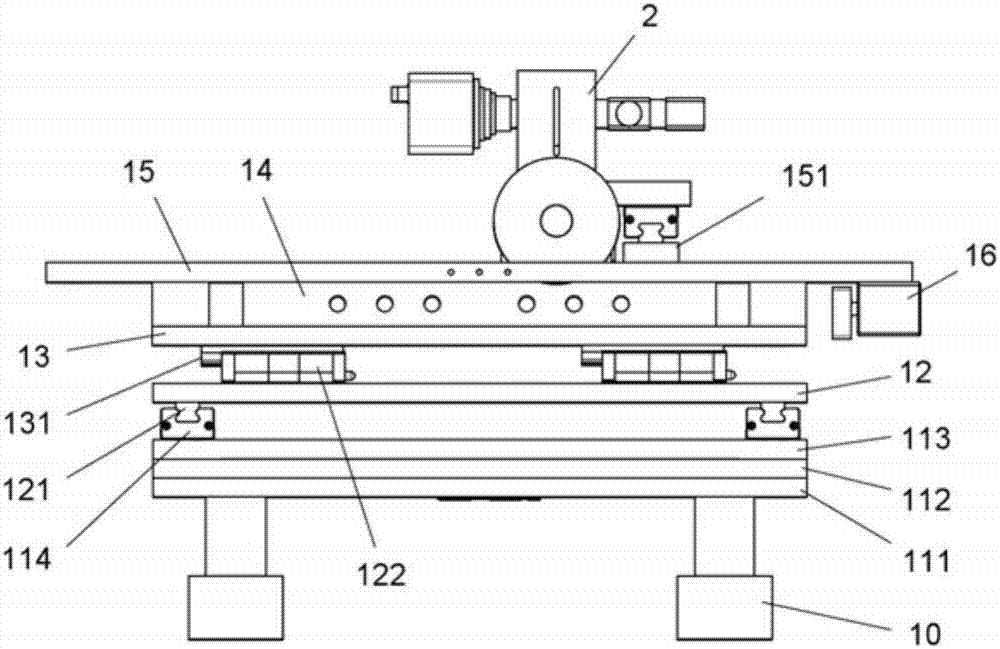

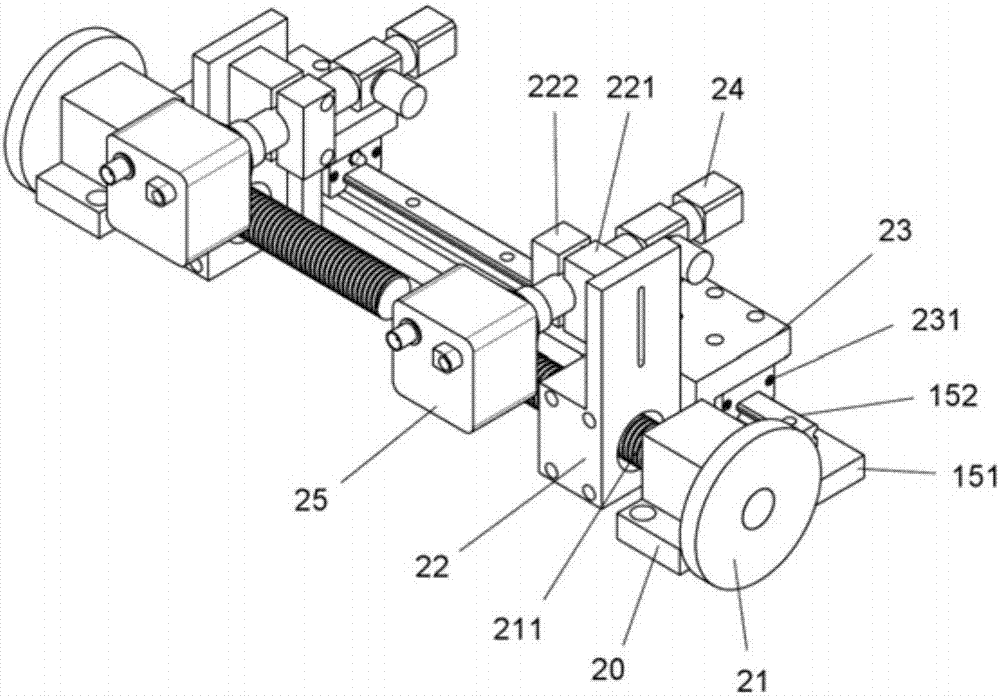

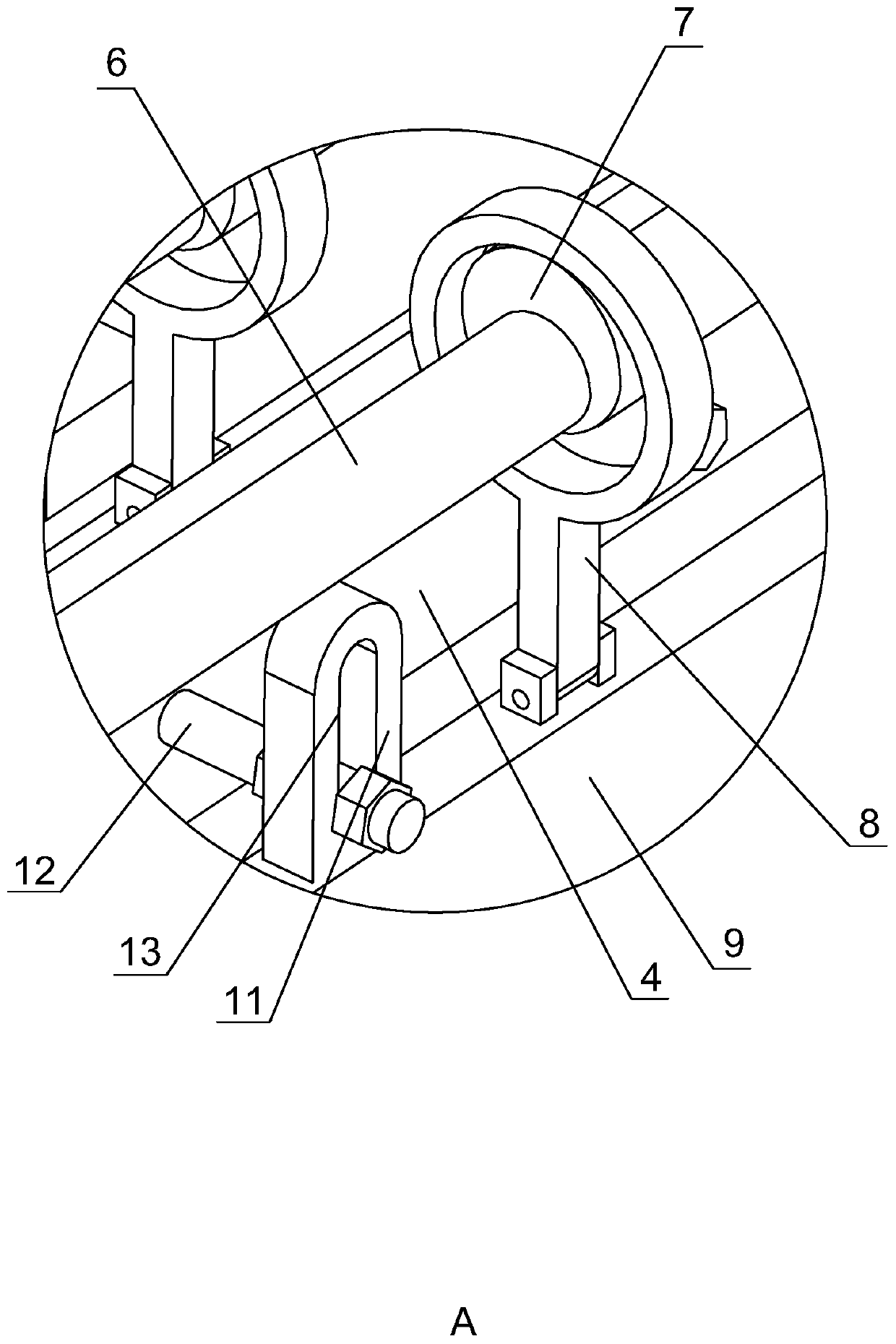

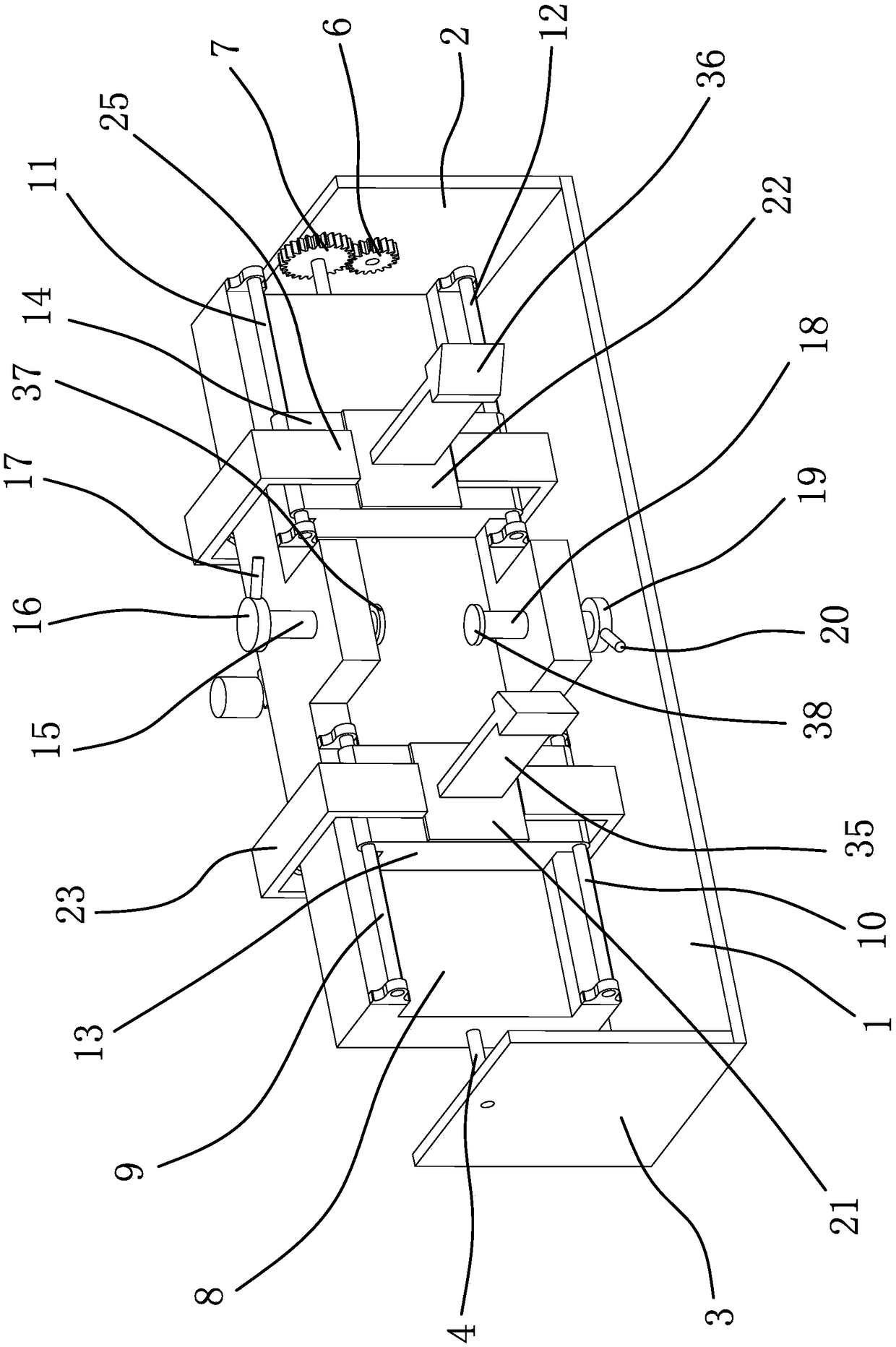

Connecting rod drive type clamp

ActiveCN106514332AAchieve positioningPrecise positioningPositioning apparatusMetal-working holdersEngineeringIndustrial engineering

The invention provides a connecting rod drive type clamp, and belongs to the technical field of machines. The connecting rod drive type clamp comprises an outer frame, a first clamping block, a second clamping block, a third clamping block and a fourth clamping block. The outer frame comprises a bottom plate, a first vertical plate and a second vertical plate, and a rotating mechanism is arranged on the first vertical plate. A locating frame is fixed to a rotating shaft. A first sliding rod, a second sliding rod, a third sliding rod and a fourth sliding rod are arranged on one side face of the locating frame. A first sliding block is arranged on the first sliding rod and the second sliding rod, and a second sliding block is arranged on the third sliding rod and the fourth sliding rod. A connecting rod drive mechanism is further fixed to the locating frame. A first locating plate is fixed to the locating frame and provided with a first screw. A first rotating disc is fixed to the first screw. The third clamping block is fixed to the lower surface of the first screw. A second locating plate is fixed to the locating frame and provided with a second screw. A second rotating disc is fixed to the second screw. The fourth clamping block is fixed to the lower surface of the second screw. The connecting rod drive type clamp has the beneficial effect of being capable of clamping a to-be-machined workpiece more effectively.

Owner:嘉兴知酷客信息科技有限公司

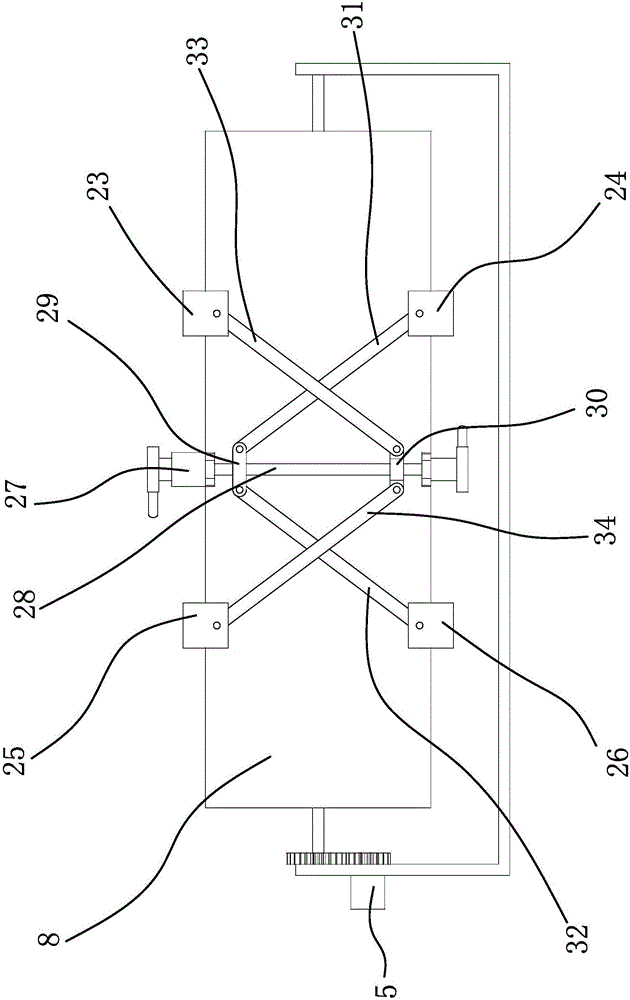

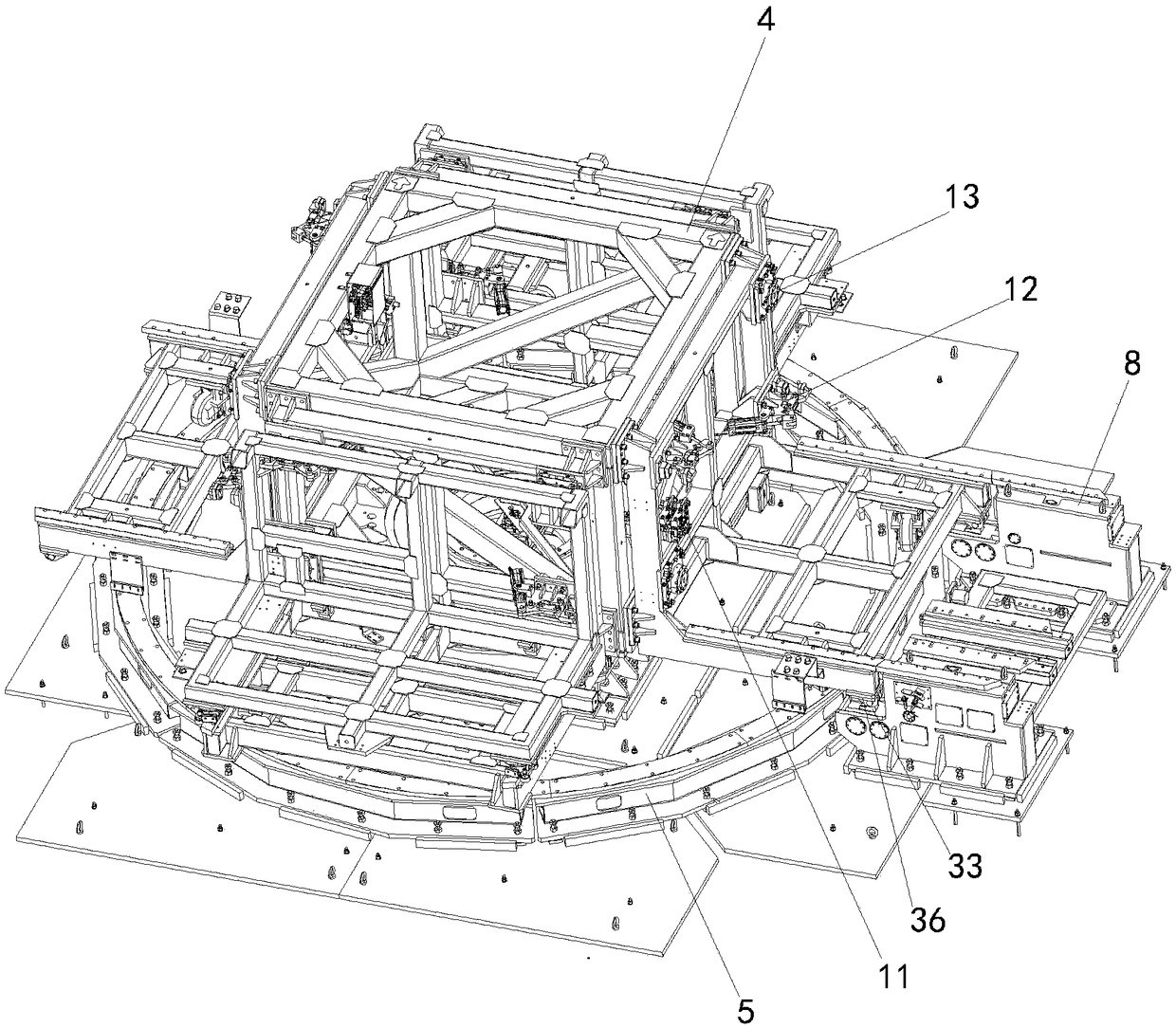

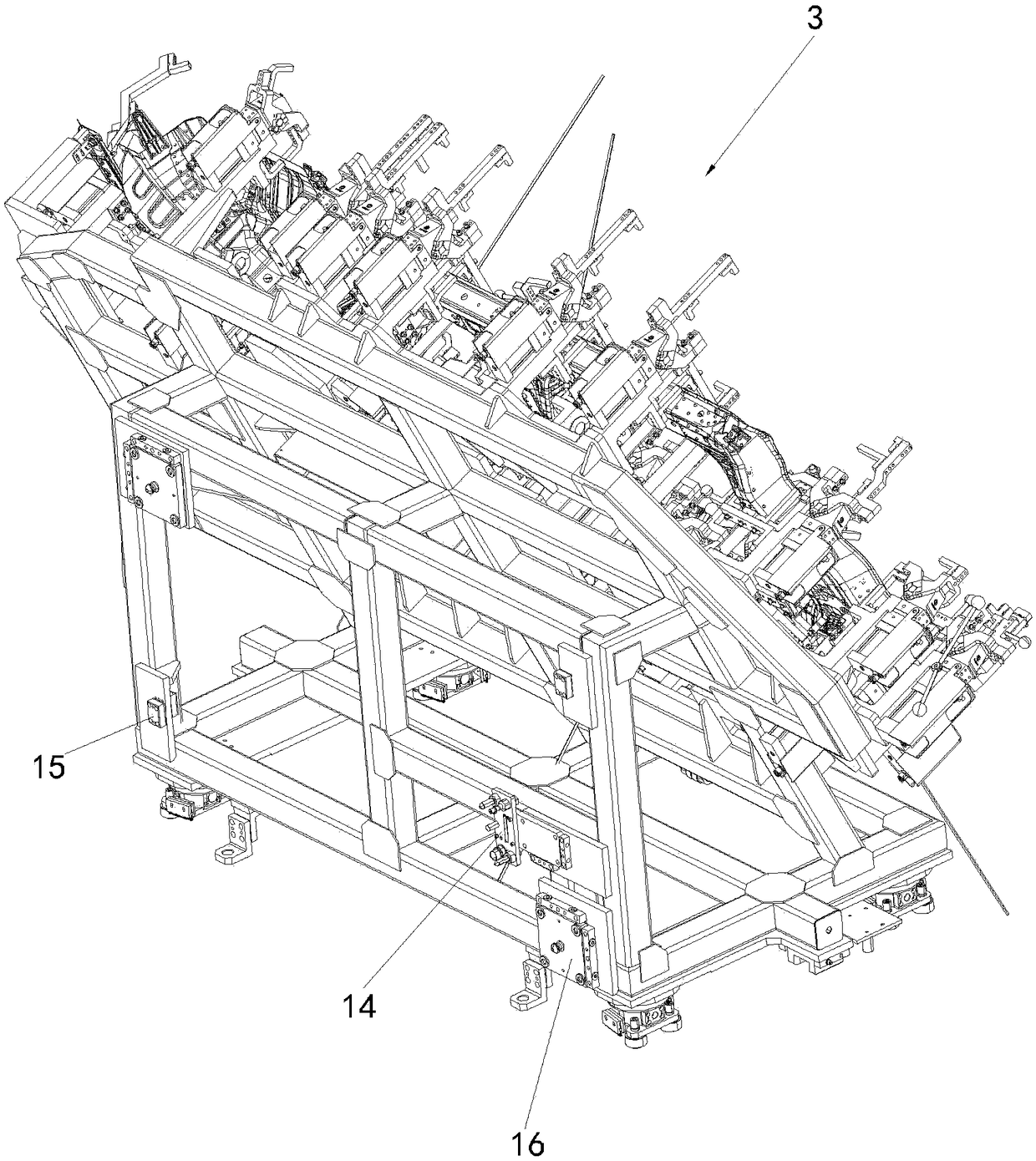

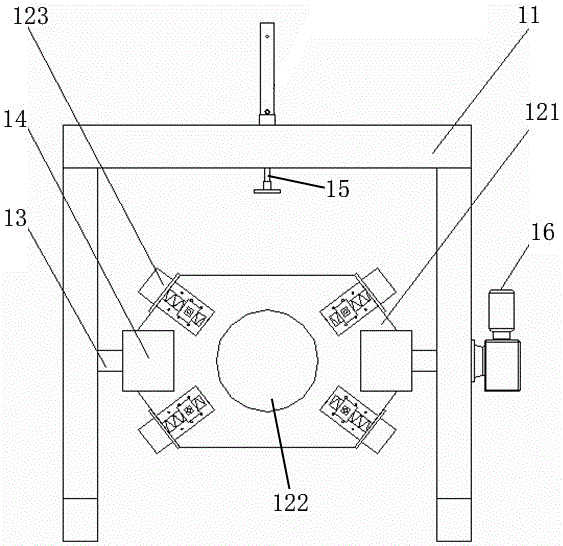

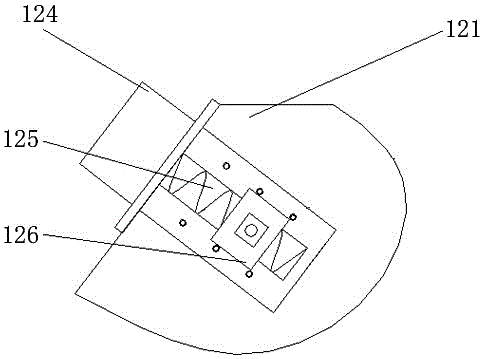

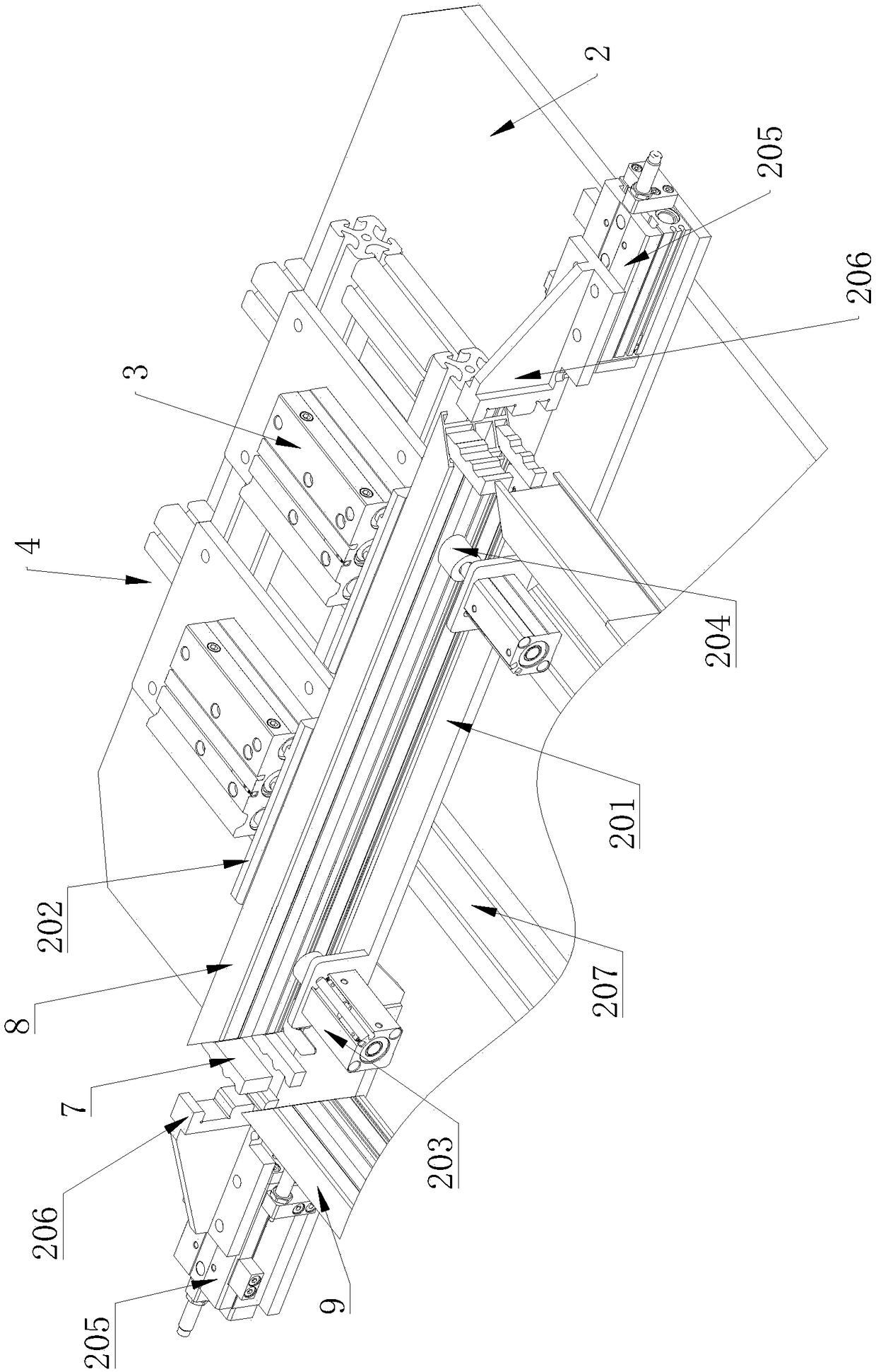

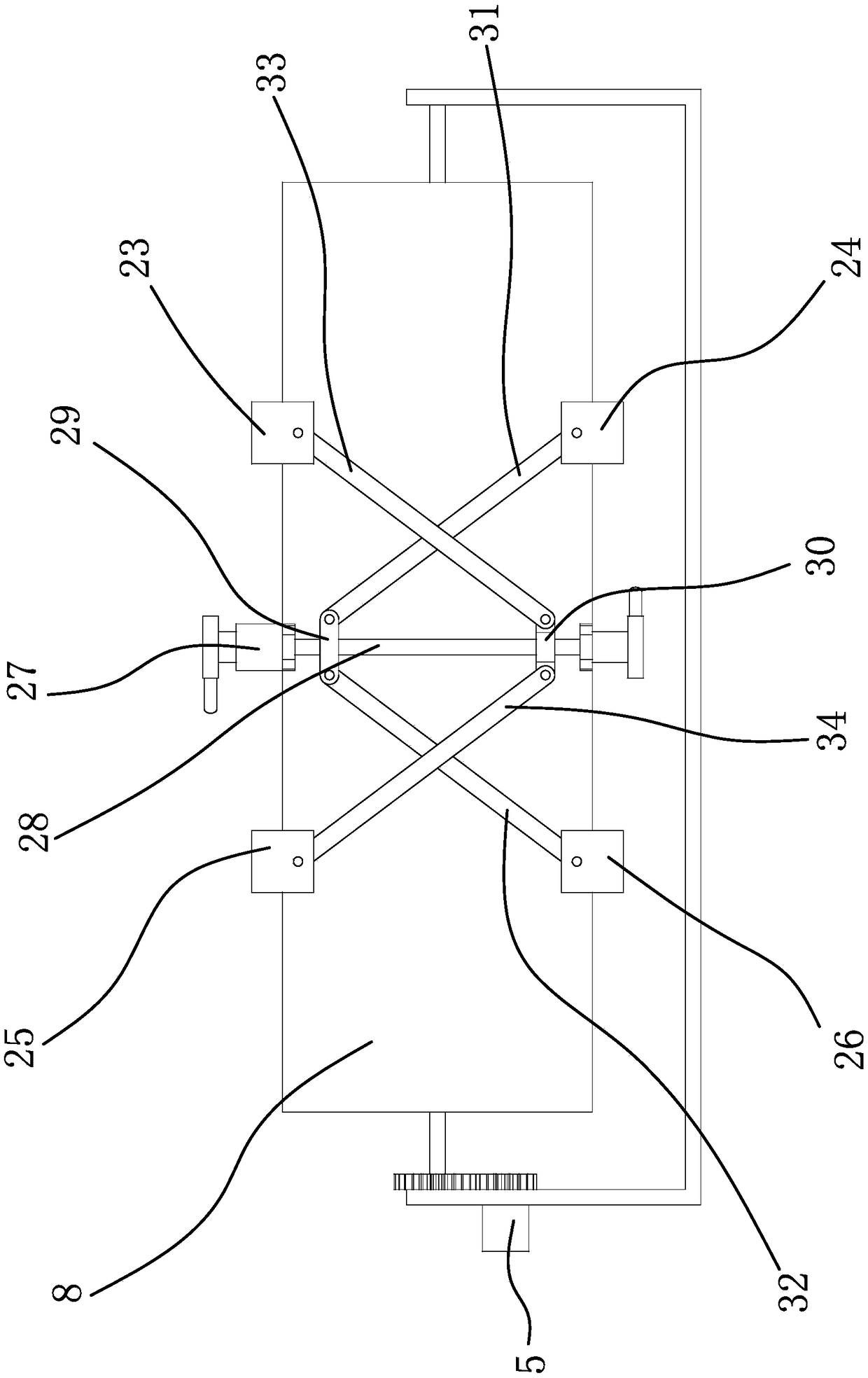

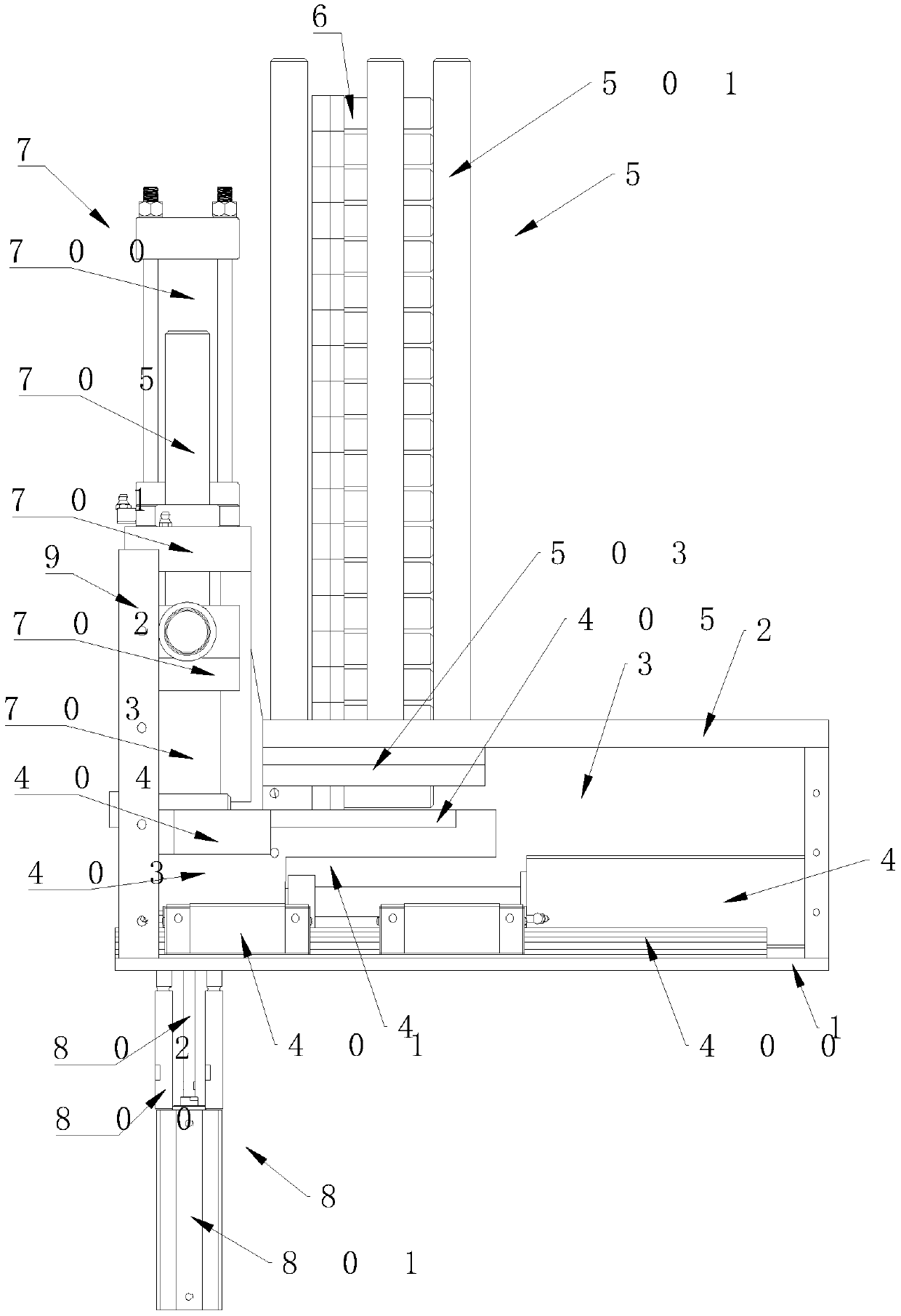

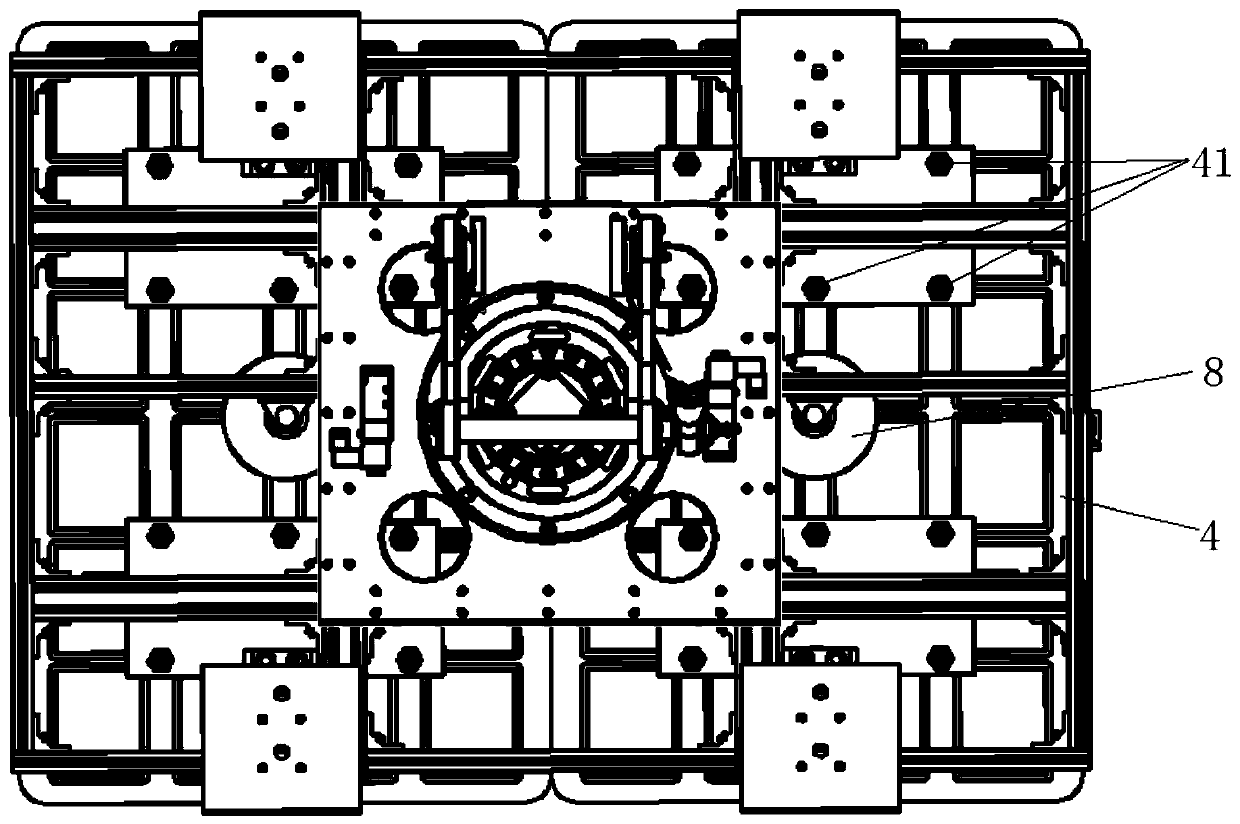

Multi-vehicle-type clamp switching warehouse system composed of tetrahedron rotary table and cross-shaped sliding table

ActiveCN108724049AReduce space footprintHigh degree of flexibilityWork holdersManufacturing efficiencyEngineering

The invention provides a multi-vehicle-type clamp switching warehouse system composed of a tetrahedron rotary table and a cross-shaped sliding table. Four side clamps are arranged on an upper tetrahedron frame of the tetrahedron rotary table in a center symmetry manner. A lower rotary table of the tetrahedron rotary table can rotate around the middle axis. Any side clamp can be switched to the butt joint position right opposite to a track butt joint device through rotation of the lower rotary table. A longitudinal sliding rail of the cross-shaped sliding table is in butt joint with a track ofthe track butt joint device, a plurality of transverse tracks are longitudinally arranged at intervals and are crossed with the longitudinal sliding rail in a cross manner, the various cross intersection positions on the cross-shaped sliding table are waiting positions, the side clamp located at the butt joint position is dragged by a traction trolley on the track butt joint device to run to one waiting position and is dragged by a traction trolley on the corresponding transverse track to run towards the left side or the right side to enter a warehouse. The multi-vehicle-type clamp switching warehouse system can meet the six-vehicle-type collineation production requirement, the equipment designing, machining, manufacturing, installing and maintaining difficulty is lowered, and the vehiclebody manufacturing efficiency is improved.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

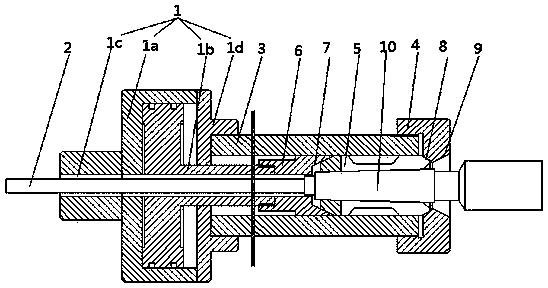

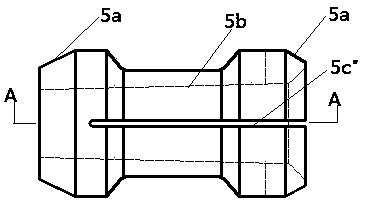

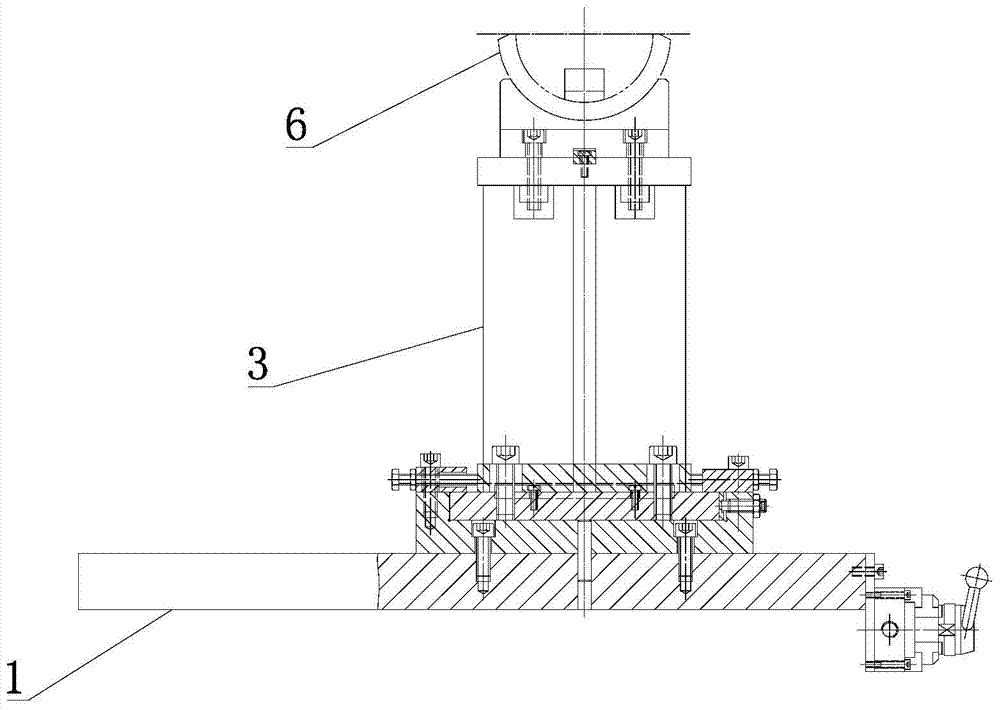

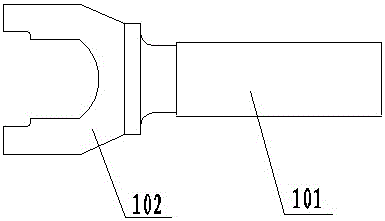

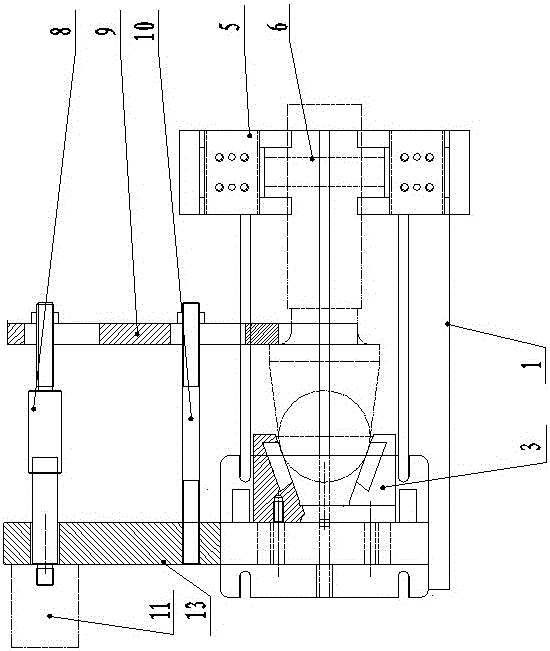

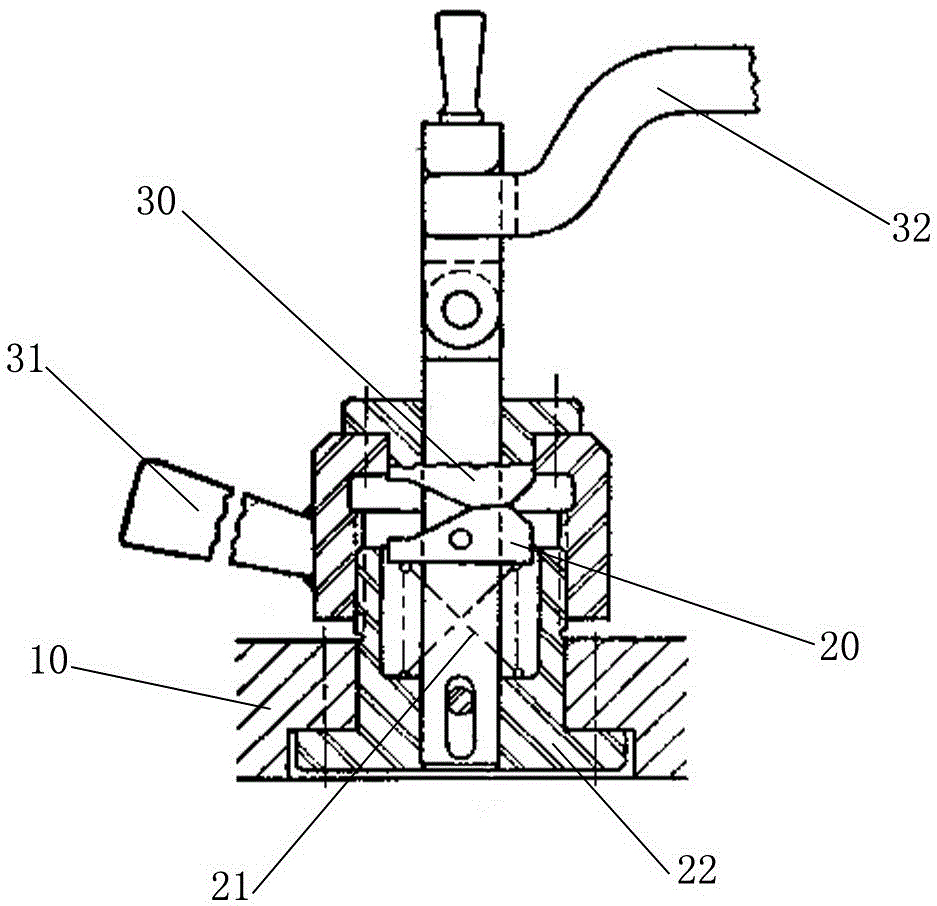

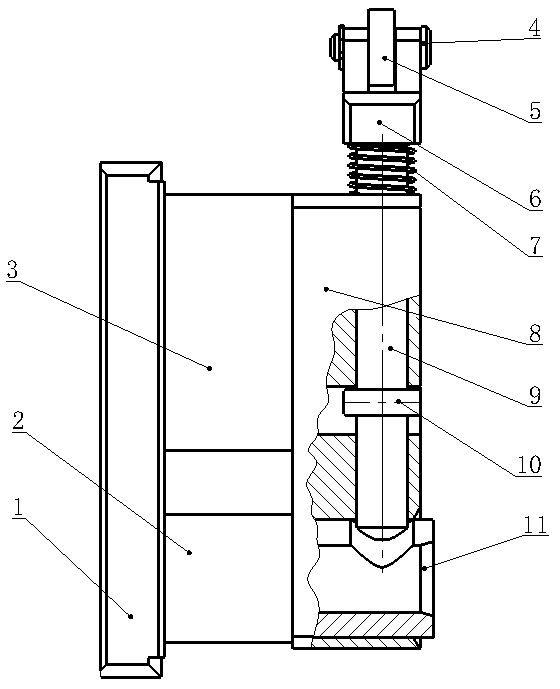

Taper shank automatic clamping device

ActiveCN103659391AAchieve clamping positioningEnsure consistencyPositioning apparatusMetal-working holdersMachiningFront cover

The invention discloses a taper shank automatic clamping device. The taper shank automatic clamping device comprises an air cylinder, a push rod, a main shaft, a front cover and a spring clamp sleeve, wherein the air cylinder comprises a cylinder body and an ejection rod, the ejection rod is provided with an axial through hole, the push rod is arranged inside the axial through hole of the ejection rod, the main shaft is a hollow shaft, the ejection rod is arranged inside the main shaft, the head end of the ejection rod is fixedly connected with a locking sleeve, a taper hole is formed in the head end of the locking sleeve, a front cover is arranged at the head end of the main shaft, a taper hole is formed in the inner side face of the front cover, the spring clamp sleeve is arranged inside the main shaft and located between the front cover and the locking sleeve, two end surfaces of the spring clamp sleeve are provided with taper faces respectively matched with the locking sleeve taper hole and the front cover taper hole, a taper hole is formed inside the spring clamp sleeve, and the spring clamp sleeve is provided with a plurality of axial grooves, so that the two ends of the spring clamp sleeve are of a multi-petal structure. The taper shank automatic clamping device can achieve automatic clamping and releasing motions of a taper shank, does not need to carry out fine machining on the taper shank, and is favorable for automatic production.

Owner:常熟量具刃具厂

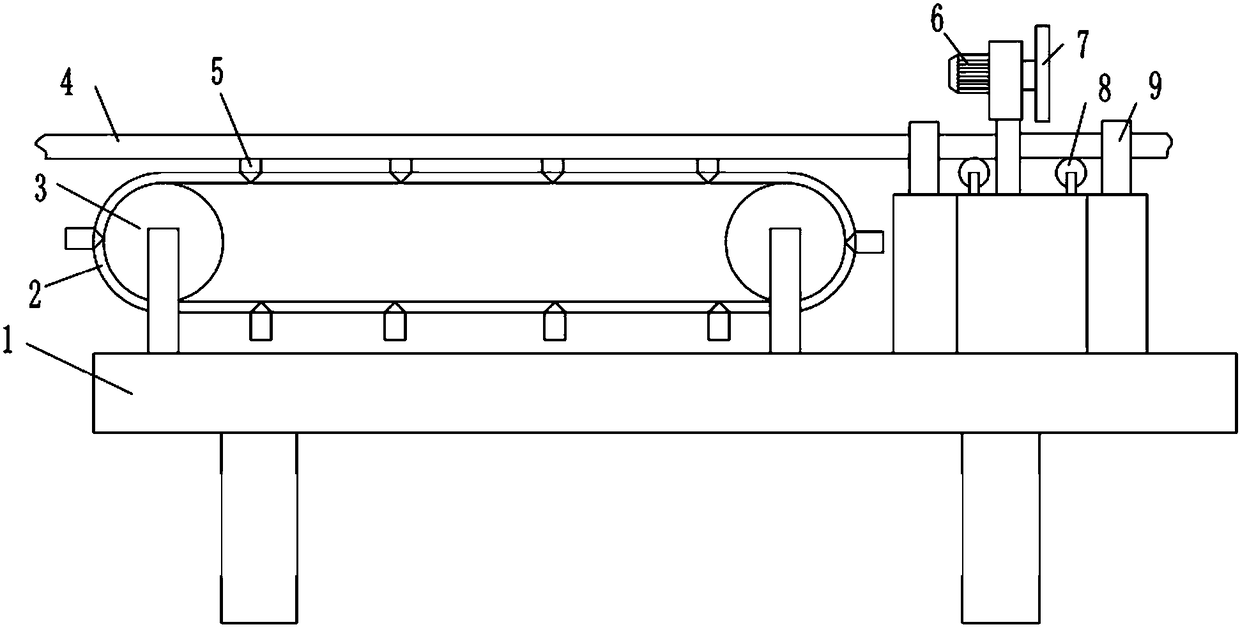

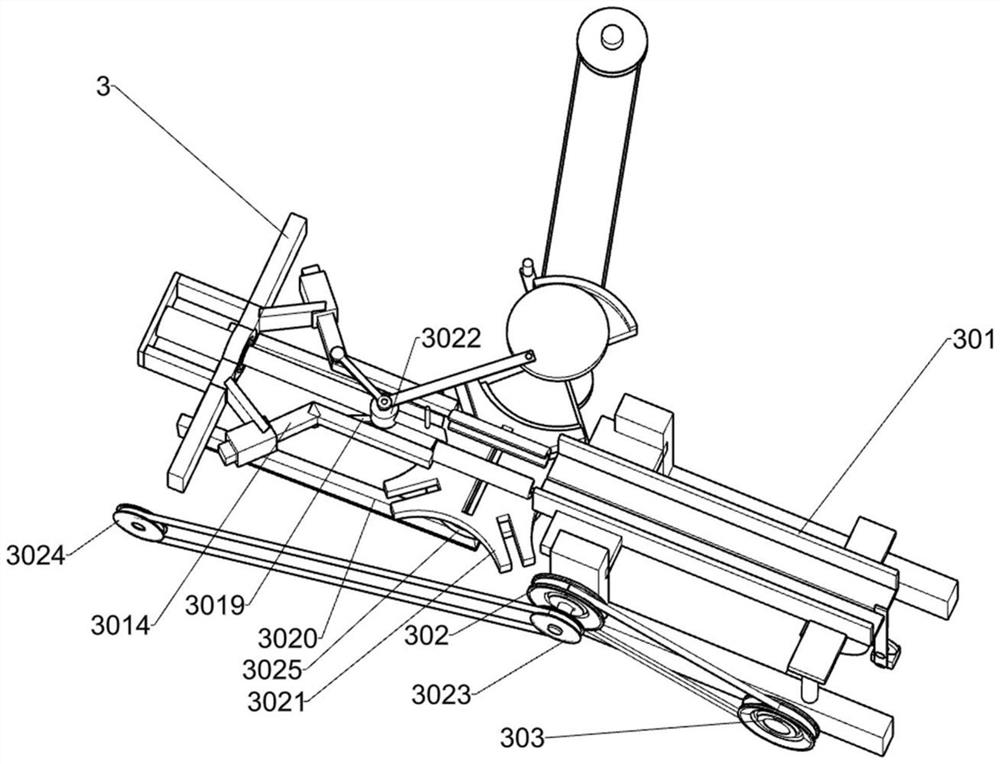

Guard bar cutting device

ActiveCN108127179ARealize automatic clampingImprove cut qualityMetal sawing devicesMetal sawing accessoriesEngineeringMachining

The invention belongs to the technical field of guard bar machining, and particularly discloses a guard bar cutting device. The device includes a worktable, and a conveying mechanism used for conveying pipe materials and a cutting mechanism used for cutting the pipe materials are arranged on the worktable. The conveying mechanism includes a conveyor belt, multiple V-shape locating blocks are movably connected to the conveyor belt, and each V-shaped locating block is provided with an approaching switch. The cutting mechanism includes a supporting frame and a second motor, an output shaft of thesecond motor is fixedly provided with an air expanding shaft, and a worm sleeves the air expanding shaft. A first lead screw is arranged on the air expanding shaft, and a first nut support is screwedwith the first lead screw. A connecting rod is hinged to the first nut support and the supporting frame and provided with the cutting mechanism. A worm gear is meshed with the worm, a bidirectional lead screw is connected to the center of the worm gear, second nut supports are screwed at both ends of the bidirectional lead screw, and clamping blocks are connected to both the two second nut supports. According to the scheme, cutting of the pipe materials can be achieved according to different length demands, and high cutting quality is ensured.

Owner:临沂经济开发有限公司

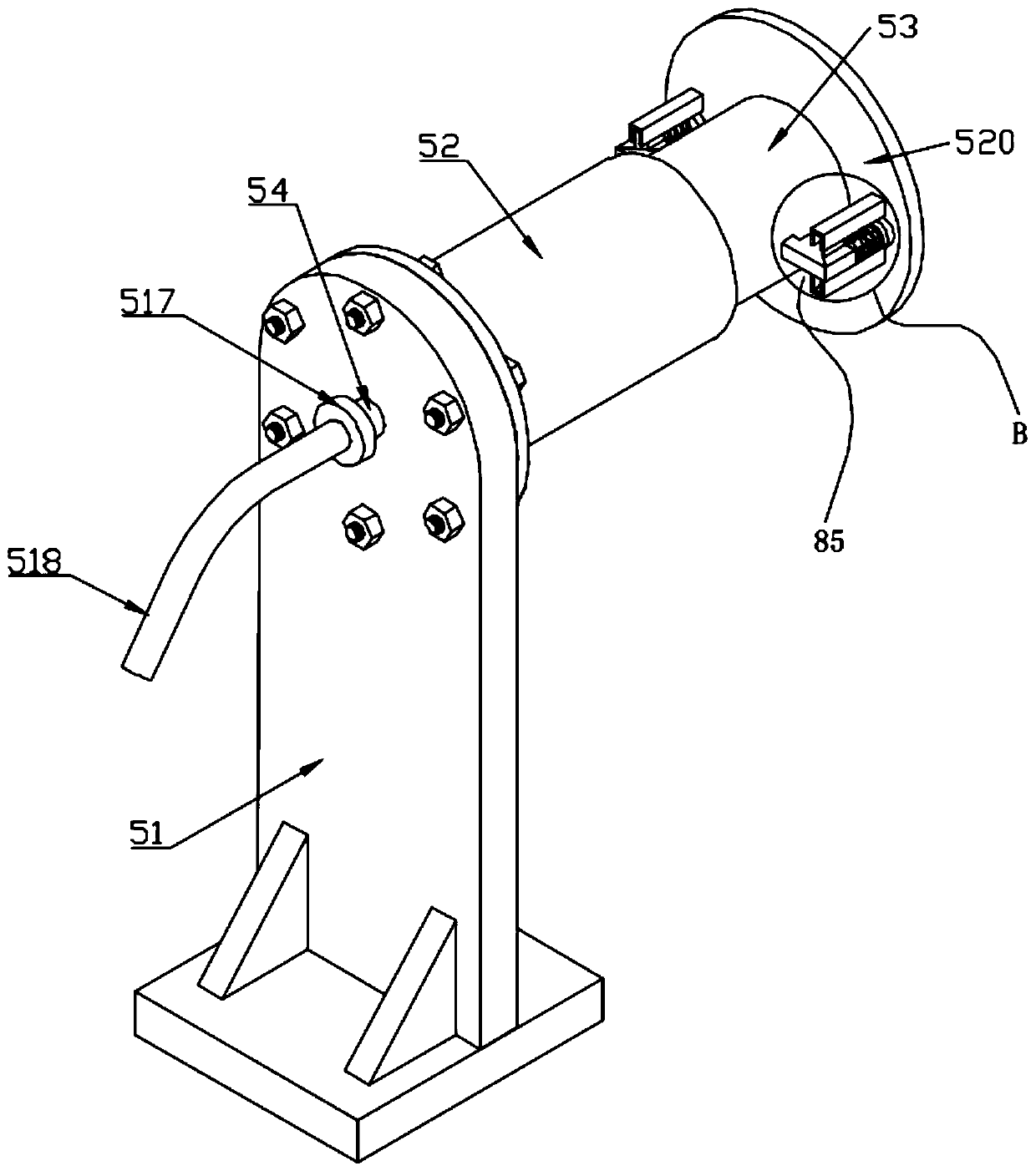

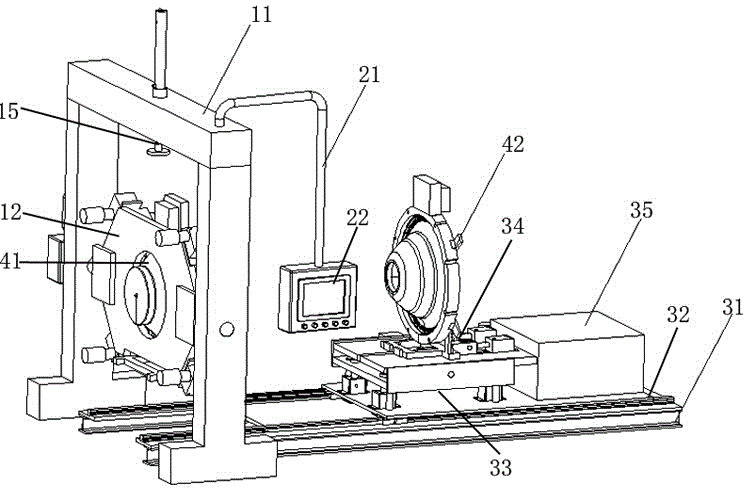

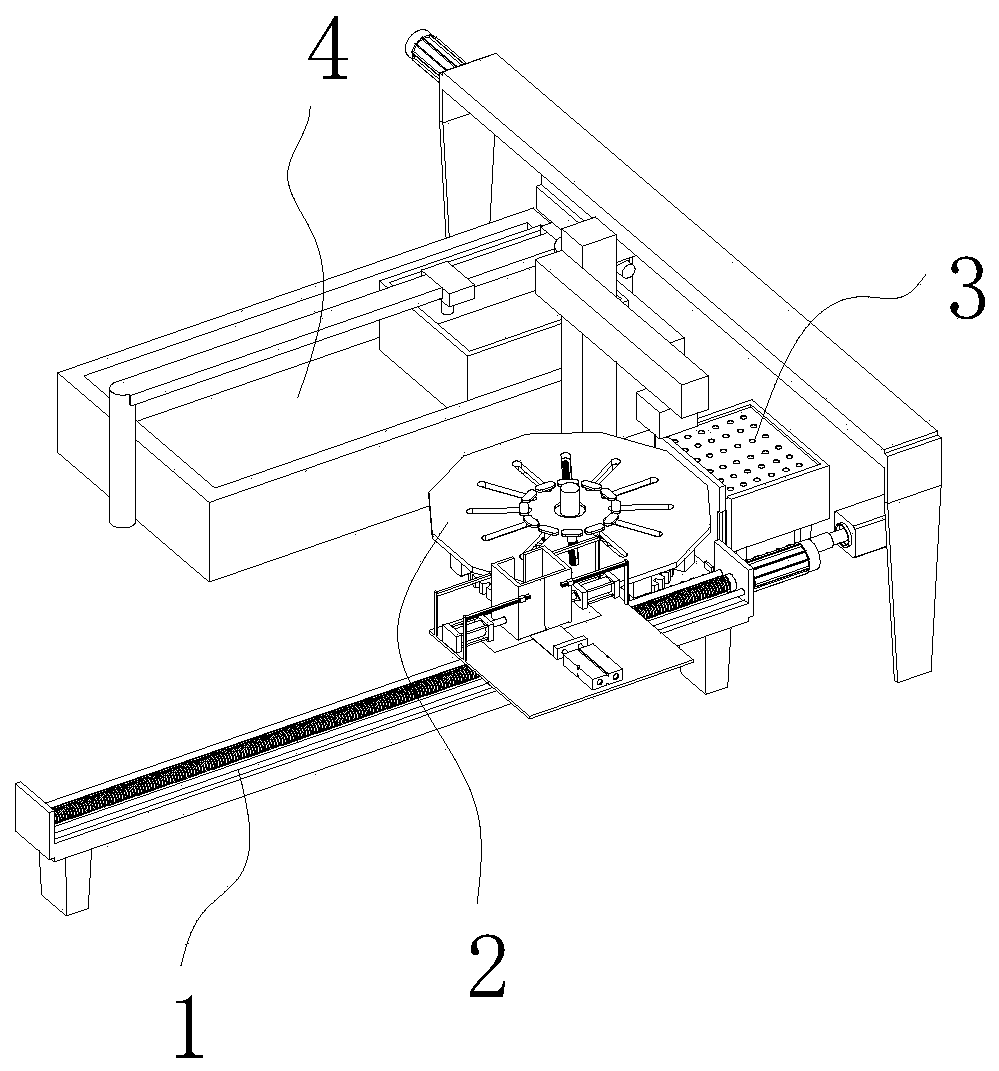

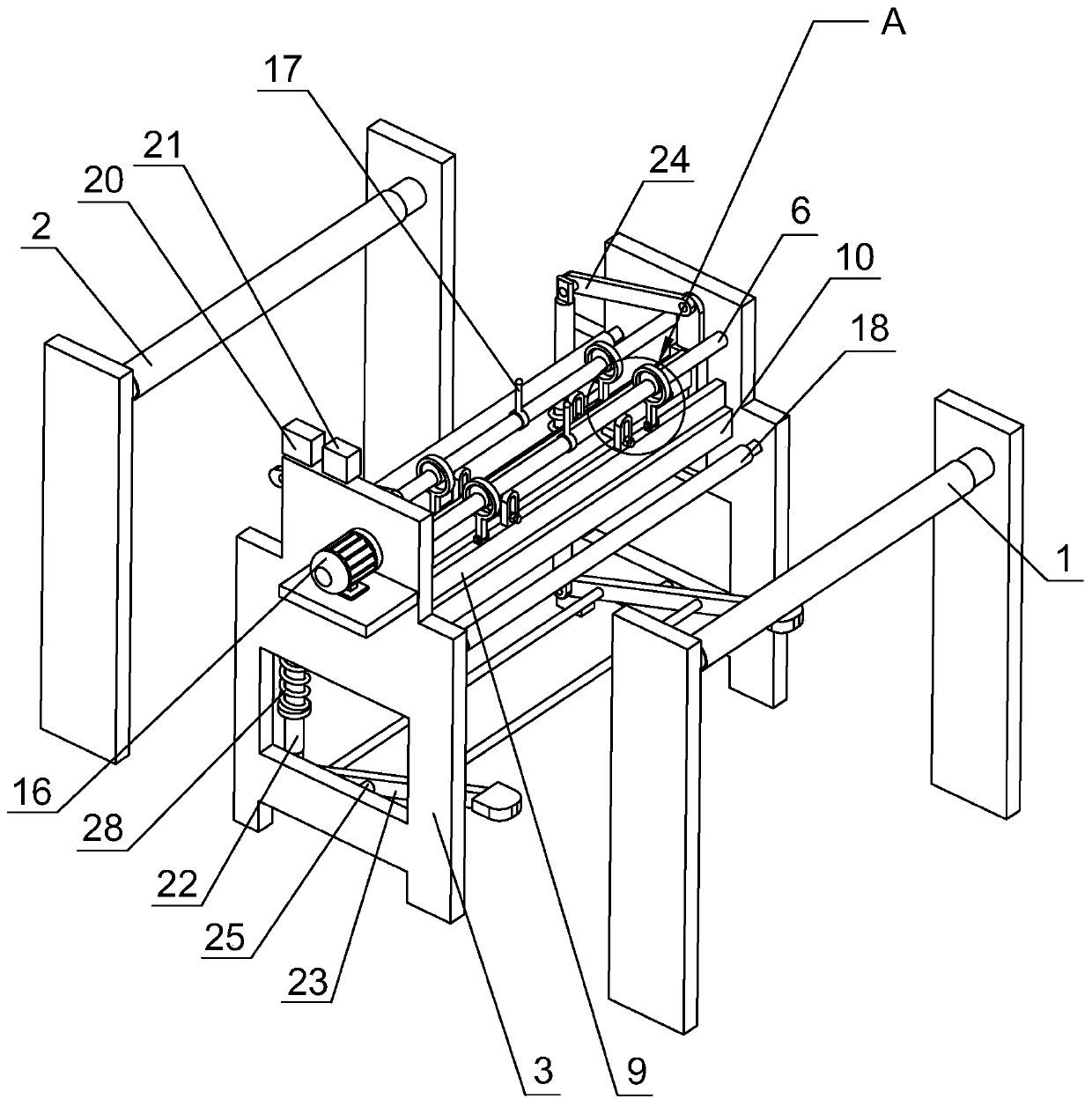

Large-size round timber processing facility for agriculture and forestry

ActiveCN110712254AAchieve axial positioningPrecise positioningMulti-purpose machinesGrinding work supportsAgricultural scienceAgricultural engineering

The invention discloses a large-size round timber processing facility for agriculture and forestry, and relates to the technical field of wood processing. The large-size round timber processing facility for the agriculture and forestry comprises a base, a machine frame, a power assembly, a lifting platform and a locating mechanism. The machine frame and the locating mechanism are installed at thetwo ends of the base correspondingly. The power assembly is installed on the machine frame, cooperates with the locating mechanism and drives a piece of round timber to rotate around the axis of the power assembly. The lifting platform is installed between the machine frame and the locating mechanism and used for achieving feeding and discharging operation of the round timber. By the adoption of the large-size round timber processing facility for the agriculture and forestry, the surface processing treatment work of the large-size round timber is achieved, namely, a driving motor drives the round timber to rotate, the locating mechanism cooperates with a driving disc to achieve the axial locating of the round timber, the clamping and locating operation of one end of the round timber is achieved in the mode that a supporting frame is fixed, and an inner sleeve moves, the process can be achieved under the condition that only the hydraulic oil needs to be fed into the facility, the locating process is simplified, the manpower is saved, the clamping force is more accurate, and the effect of avoiding the round timber rotation situation which happens due to the fact that the torque is excessively high is also achieved.

Owner:芜湖文青机械设备设计有限公司

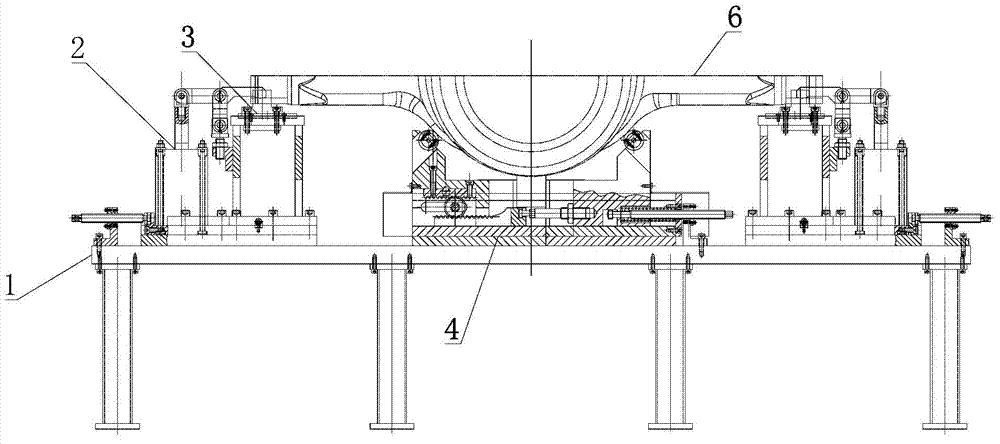

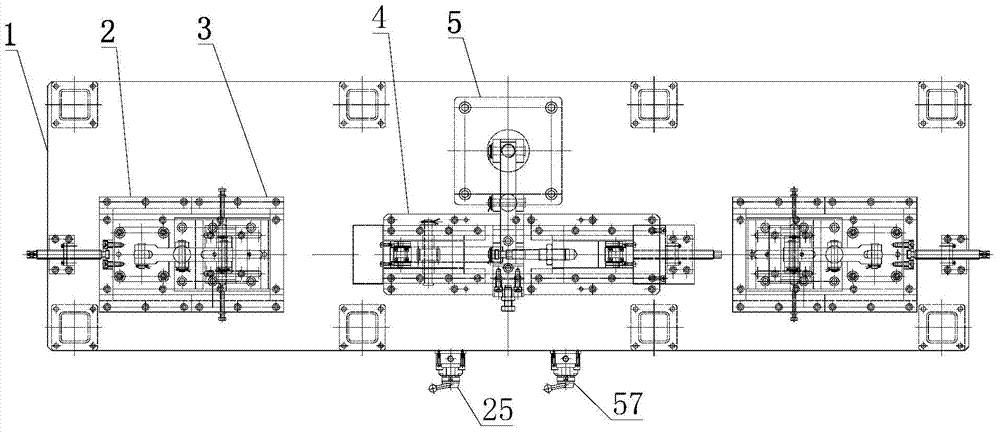

Work fixture for cutting groove at axle housing midpiece

ActiveCN103692133APrevent bouncing up and downPrevent radial movementWelding/cutting auxillary devicesAuxillary welding devicesAgricultural engineeringCushion

The invention discloses a work fixture for cutting a groove at an axle housing midpiece. The work fixture comprises a platform, a supporting structure and a clamping structure, wherein the supporting structure comprises end shaft supporting structures arranged at the two sides of the platform and a middle supporting structure arranged between the end shaft supporting structures, each end shaft supporting structure comprises a pedestal, a cushion block support arranged on the pedestal and a cushion block arranged on the cushion block support, the end face of each cushion block is provided with an arc-shaped inner groove, the middle supporting structure comprises a base, and a first supporting block and a second supporting block arranged at the left and right sides, the base is provided with a self-centering positioning mechanism for ensuring the synchronous movement of the first supporting block and the second supporting block, and the clamping structure comprises end shaft clamping mechanisms arranged at the two ends of an axle housing and used for clamping the two ends of the axle housing and a middle clamping mechanism for clamping the middle part of the axle housing. Through supporting and clamping the two ends and the middle of the axle housing midpiece for positioning, the positioning is accurate, the clamping is firm, the adjusting is convenient, and clamping and positioning for axle housing midpieces of different specifications and models can be realized.

Owner:GUANGDONG FUWA HEAVY IND

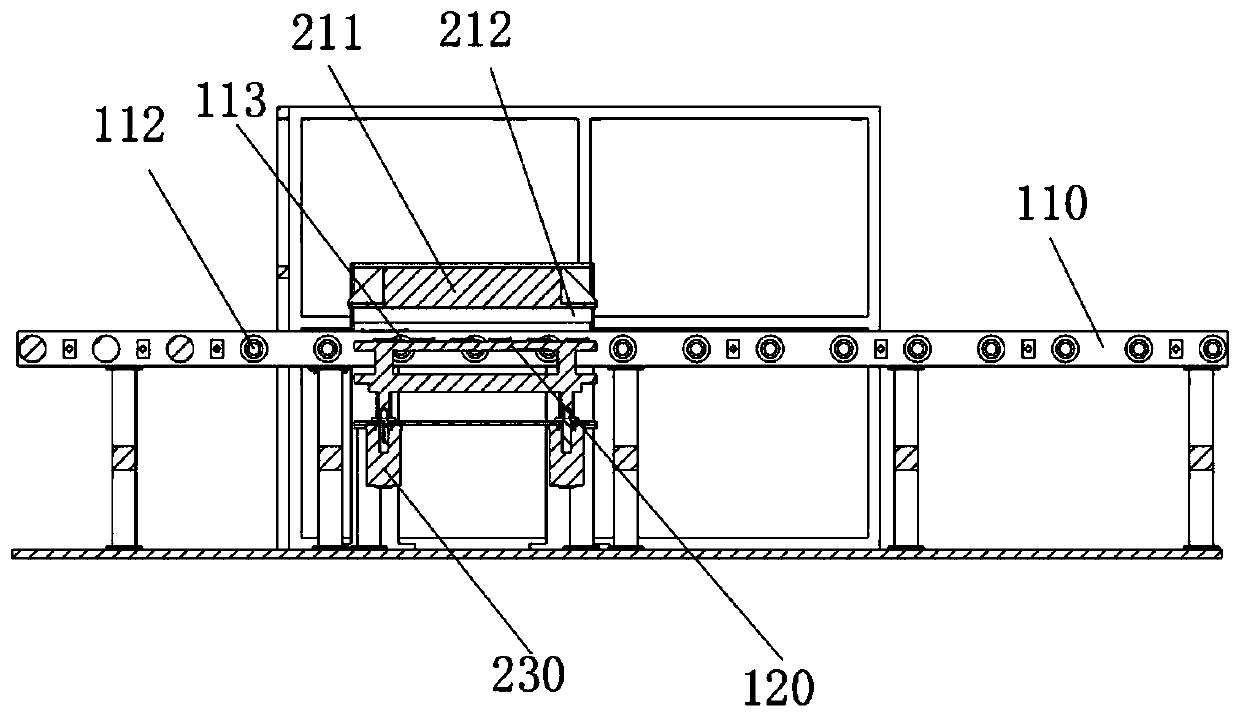

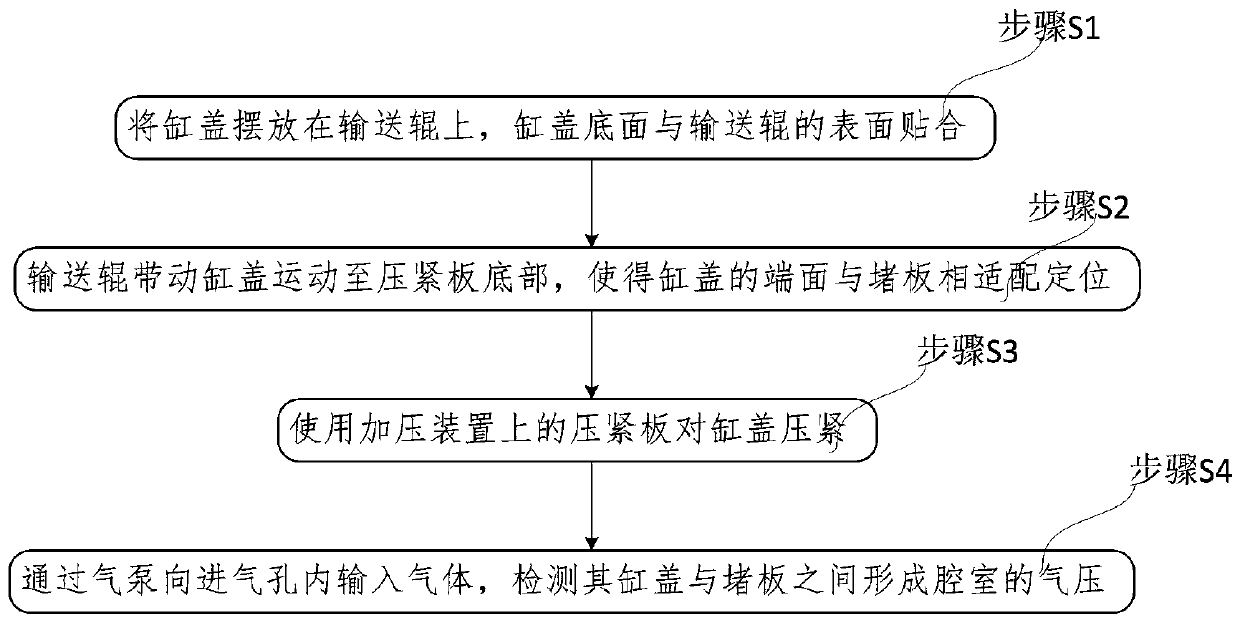

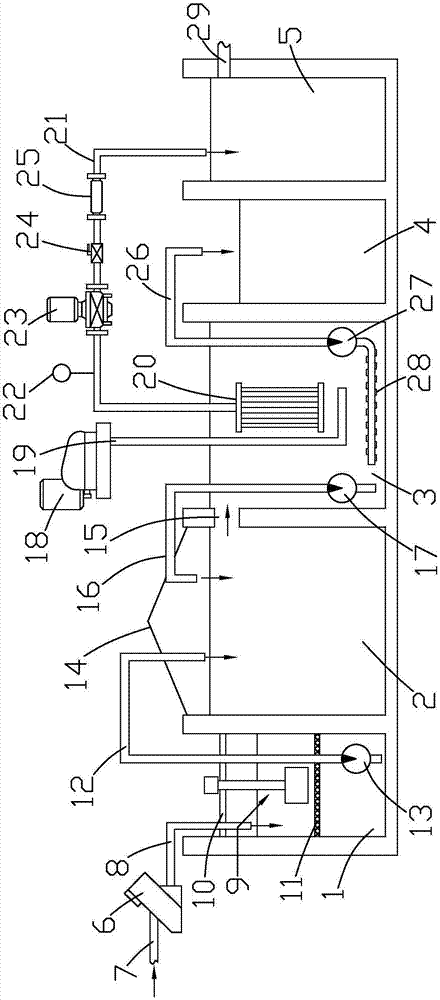

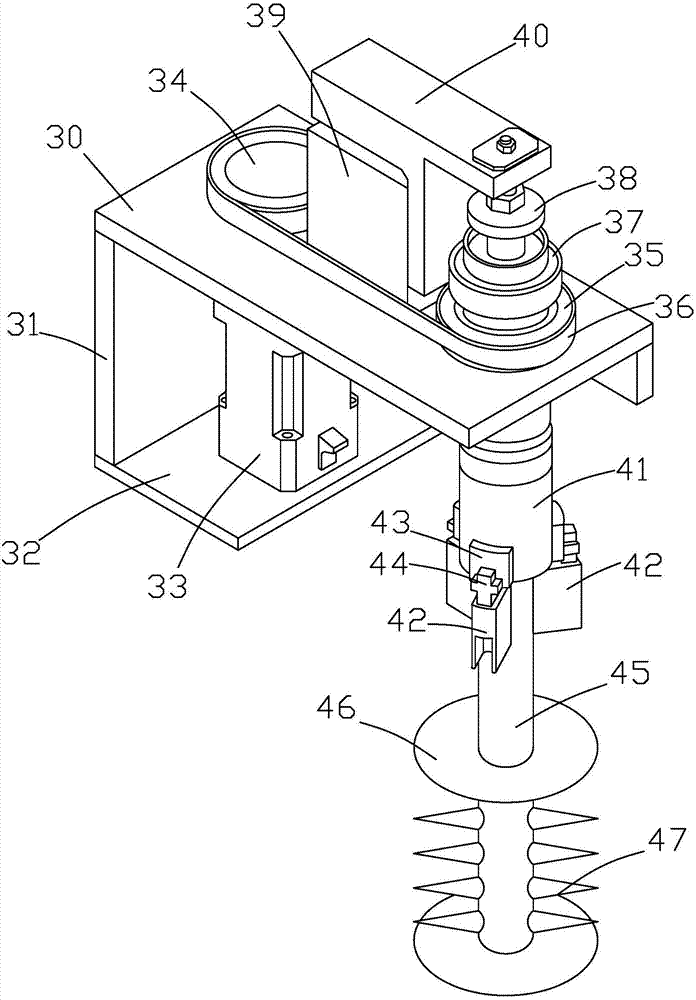

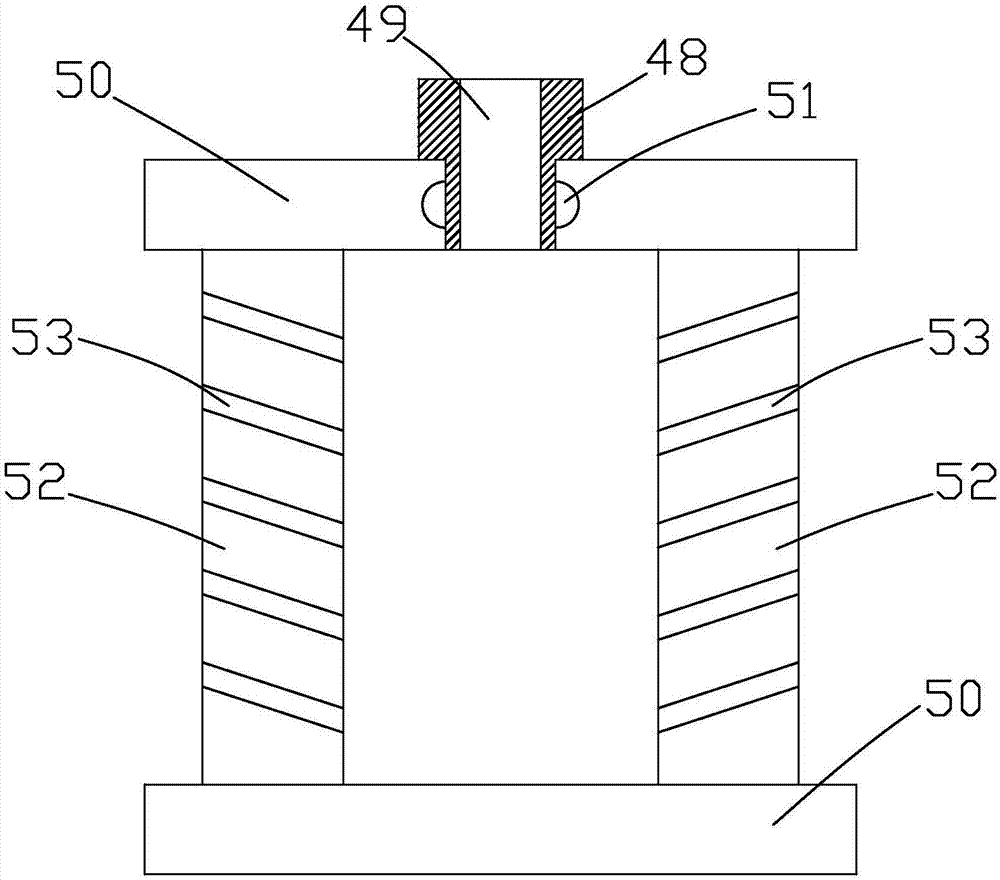

Air tightness detecting device for engine cylinder head and detecting method of air tightness detecting device

PendingCN109724757AEasy to fixGuaranteed accuracyMeasurement of fluid loss/gain rateCylinder headEngineering

The invention discloses an air tightness detecting device for an engine cylinder head and a detecting method of the air tightness detecting device. The air tightness detecting device includes a conveying roller bed and a pressurizing device, the conveying roller bed includes a conveying frame and conveying rollers, and the conveying rollers are installed parallel to each other at intervals on theconveying frame. According to the air tightness detecting device for the engine cylinder head and the detecting method of the air tightness detecting device, through use of the conveying rollers, automatic conveying of the engine cylinder head can be realized, clamping and positioning of a blocking plate are realized through the action of a locking cylinder and a locking head arranged on the conveying frame, and meanwhile, the height of the blocking plate can be adjusted through a lifting cylinder; and when a to-be-tested engine cylinder head is conveyed to the blocking plate at the locking cylinder under the action of the conveying rollers, the requirements of sealing and air intake can be met through an air inlet and a plug on the blocking plate, locking of the engine cylinder head can be realized through a compressing plate on an installation frame, and air tightness detection of the engine cylinder head is realized through air-entrapping of an air pump.

Owner:湖北襄发动力科技有限公司

Distributed type sewage treatment method

ActiveCN107285554ARelieve pressureEffective protectionSpecific water treatment objectivesTreatment involving filtrationSludgeReclaimed water

The invention discloses a distributed type sewage treatment method which comprises the following steps: (1) constructing a regulating reservoir; (2) constructing an anoxic pond; (3) constructing a membrane biological reaction pond; (4) constructing a sludge tank and a reclaimed water pool; and (5) treating the sewage. The sewage treatment method disclosed by the invention is simple in steps, not only can reduce the pressure of urban centralized pipeline sewage treatment but also directly utilizes the reclaimed water acquired after the treatment, effectively protects the water resource, reduces the operation cost and is convenient for management and maintenance.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

Fixing device for grinding of rear axle shaft sealing cover

InactiveCN105415186ASmooth rotationMove quicklyEdge grinding machinesGrinding work supportsEngineeringScrew thread

The invention discloses a fixing device for grinding of a rear axle shaft sealing cover. A round blind hole is formed in a machine frame in the vertical direction, and a square blind hole is formed in the machine frame in the horizontal direction. A cylindrical pull rod slides in the round blind hole, and a cuboid sliding block slides in the square blind hole. A first through hole is formed in the middle of the pull rod, a first wedged face is arranged on the lower inner wall of the first through hole, and a second wedged face is correspondingly arranged in the middle of the sliding block. A screw rod is integrally arranged at the outer end of the sliding block, one end of a threaded cover is connected with the screw rod through threads, and the end face of the end of the threaded cover abuts against the side wall of the machine frame; the other end of the threaded cover is fixed to a handle, a positioning block is embedded into the upper end of the round blind hole, and a second through hole for the pull rod to slide is formed in the center of the positioning block; a pressing plate is connected to the upper end of the pull rod in a sleeving mode, and the pressing plate and the pull rod are locked through a nut. A spring is fixed between the bottom of the square blind hole and the bottom of the pull rod. By means of the fixing device, a workpiece can be clamped and positioned and can be quickly clamped, so that efficiency is greatly improved.

Owner:CHONGQING FENGHUIDA METAL FORGING CO LTD

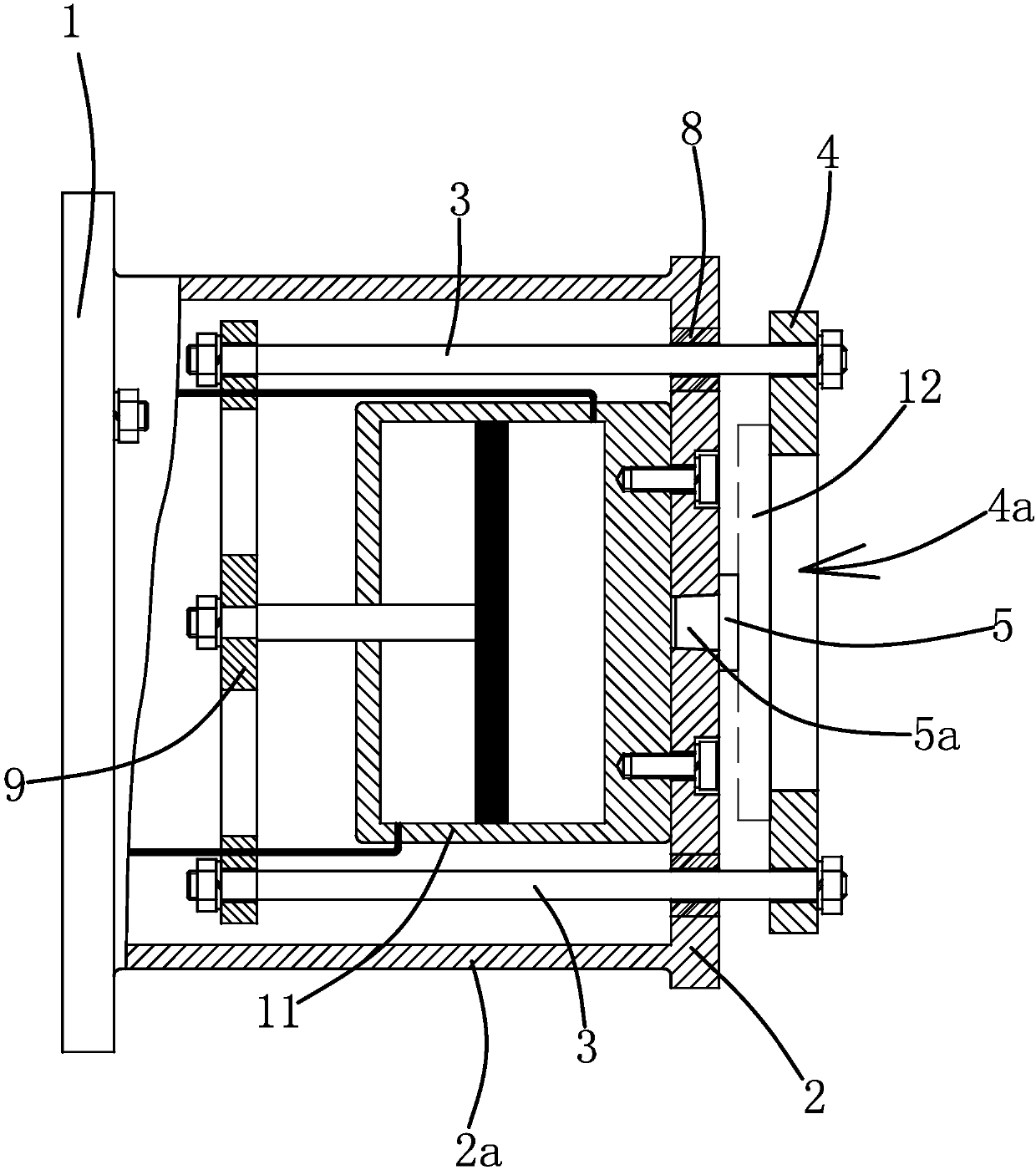

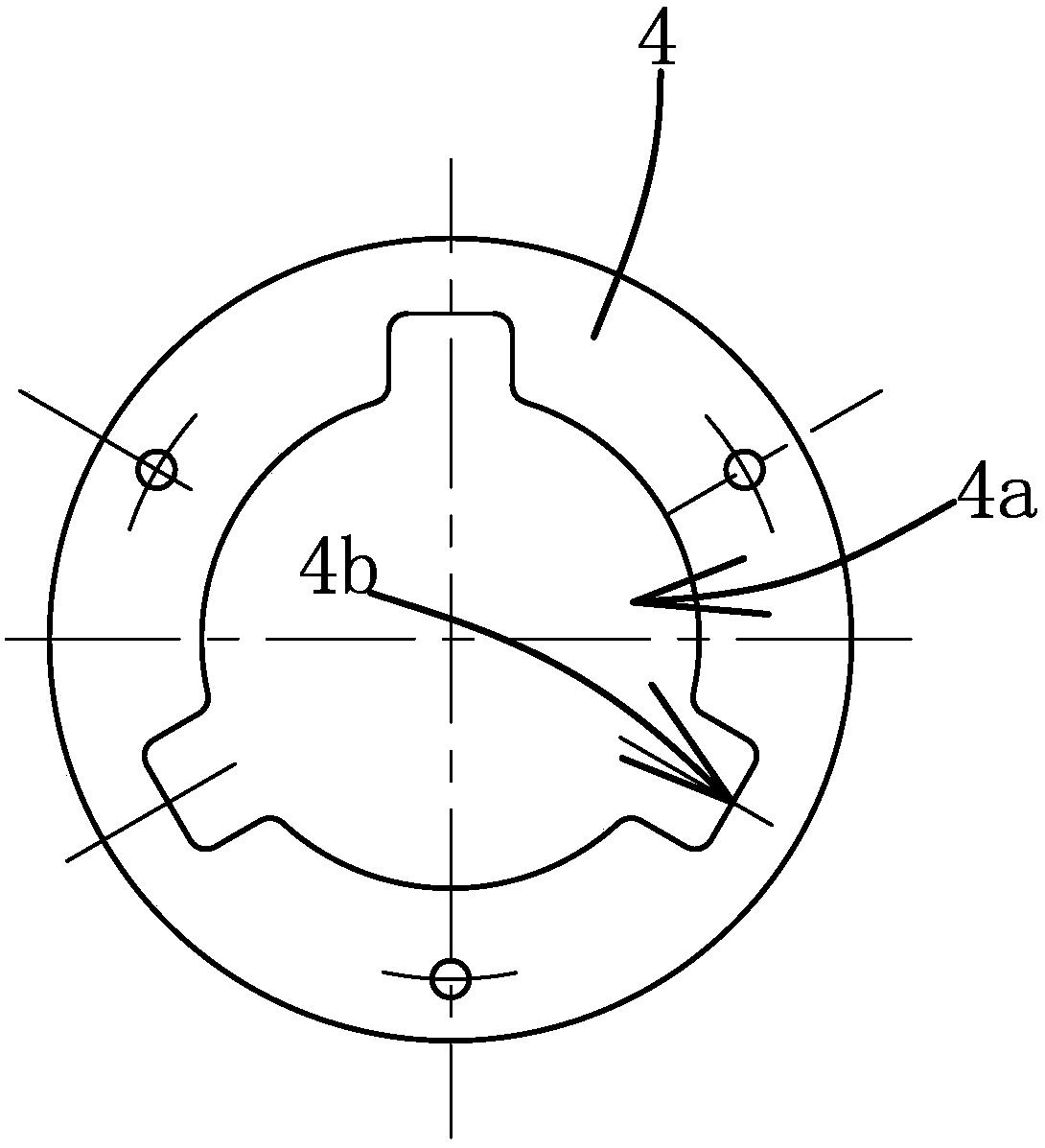

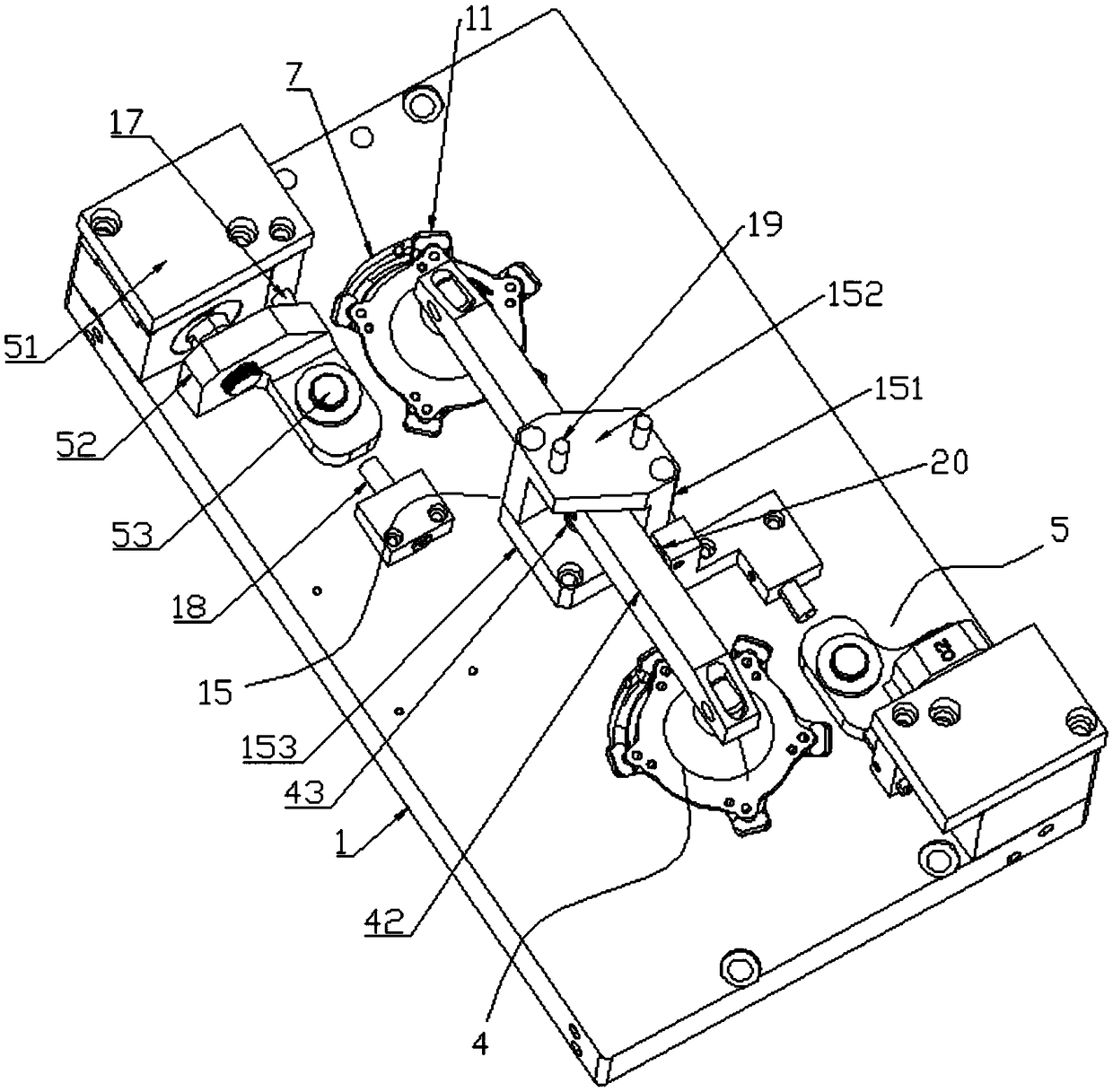

Die clamping and stripping device for epoxy resin casting workpiece

The invention discloses a die clamping and stripping device for an epoxy resin casting workpiece. The die clamping and stripping device comprises a female die clamp and a male die clamp which are relatively arranged forwards and backwards; the female die clamp is rotationally assembled on a female die supporting seat around an axis extending leftwards and rightwards; the male die clamp is movably assembled on a male die supporting seat along the guiding of front-back direction; the female die clamp and / or the male die clamp is an adjustable clamp; the adjustable clamp comprises more than two clamping bodies for clamping corresponding dies; and a clamping driving device is in driving connection with each clamping body. Therefore, when a female die and / or a male die is clamped, all the clamping bodies can clamp the corresponding dies by relatively closing and loosen the corresponding dies by relatively keeping away, so that when the female die and / or the male die of the die is clamped, the clamping and positioning of the female die and / or the male die can be realized after all the clamping bodies are relatively closed as long as a part to be clamped is positioned in a space between every two clamping bodies, and further the die clamping and stripping device has the advantages of convenience and reliability in clamping.

Owner:HENAN PINGGAO ELECTRIC +2

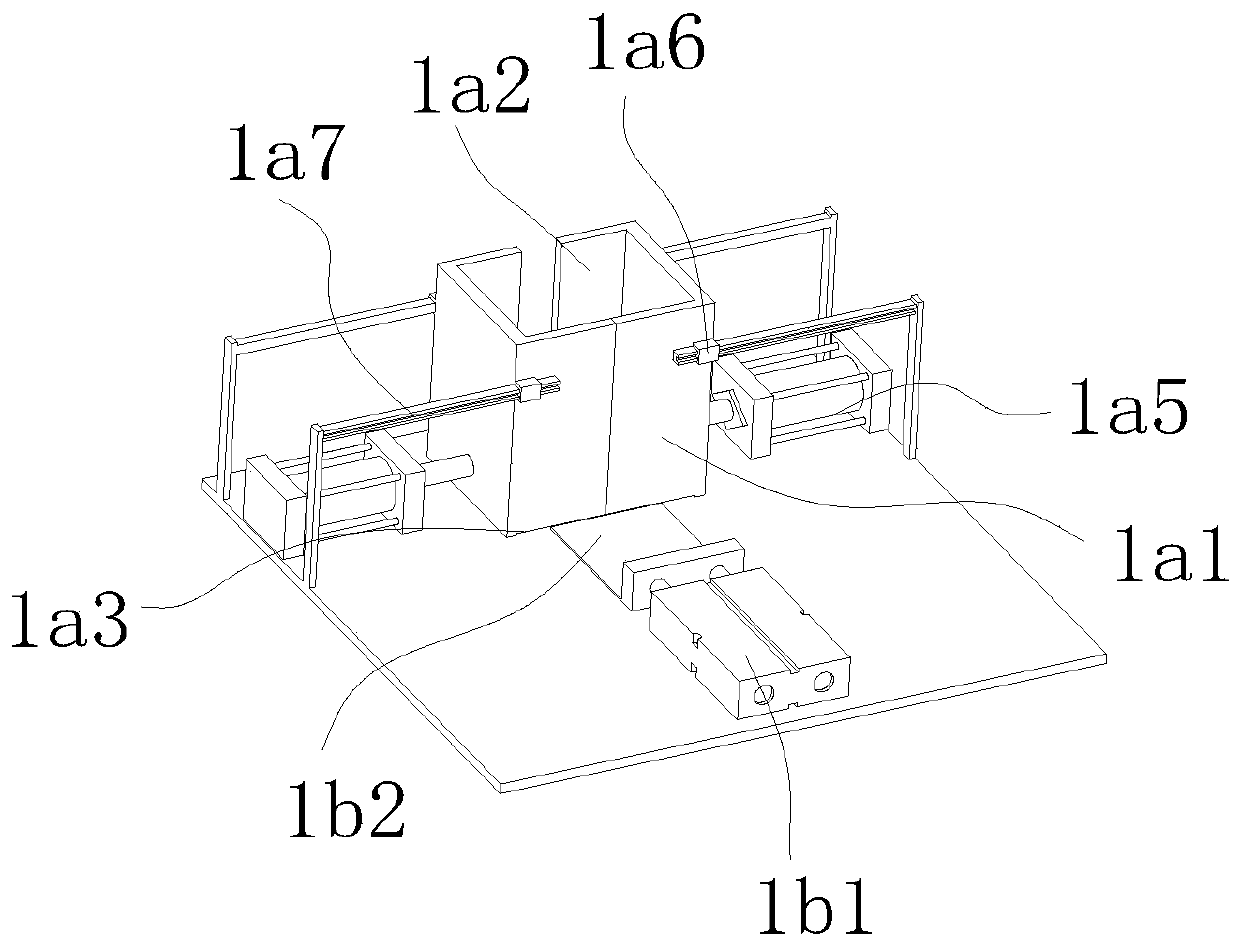

Assembly jig

The invention discloses an assembly jig comprising two fixture units arranged oppositely. The two fixture units are same in structure and each comprise four vertical columns. A glass base is fixed to the upper portions of the vertical columns. An upper substrate is fixed on the glass base seat. A longitudinal sliding groove fixing plate is fixed on the upper portion of the upper substrate. Longitudinal sliding grooves are arranged on the upper portion of the longitudinal sliding groove fixing plate. Longitudinal sliding blocks are slidably arranged in the longitudinal sliding grooves. A lower supporting plate is fixedly connected to the longitudinal sliding blocks. Transverse sliding grooves are arranged on the lower supporting plate. Transverse sliding blocks are arranged in the transverse sliding grooves. An intermediate supporting plate is fixed to the upper portions of the transverse sliding blocks. A supporting frame is fixed to the four upper edges of the intermediate supporting plate. By means of the two fixture units arranged oppositely, an assembly workpiece is clamped and positioned; the assembly jig is simple in structure and high in automation degree, can adjust and position from multiple dimensionalities and is more convenient, rapid and efficient.

Owner:ZHEJIANG JINYUAN IND CO LTD

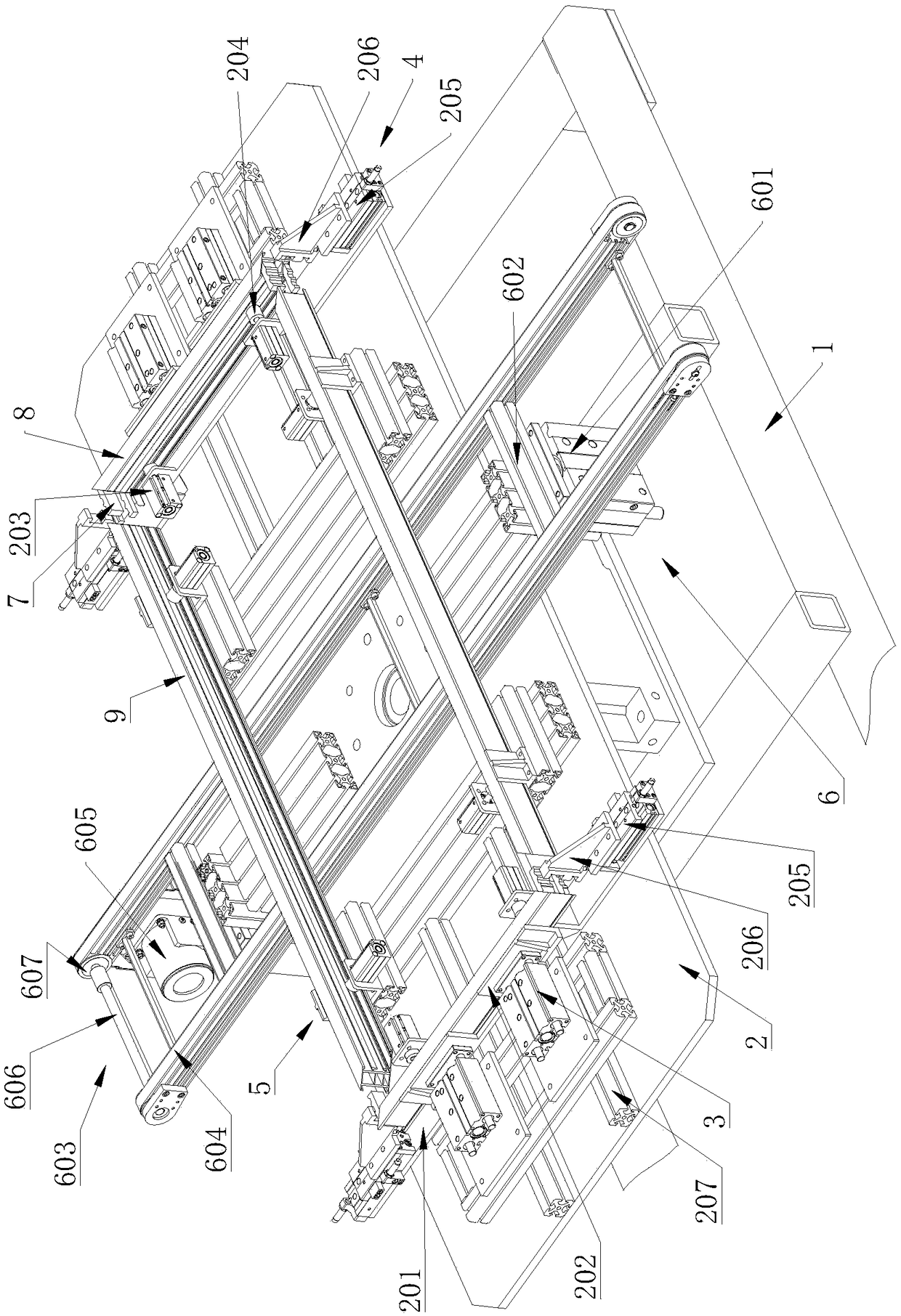

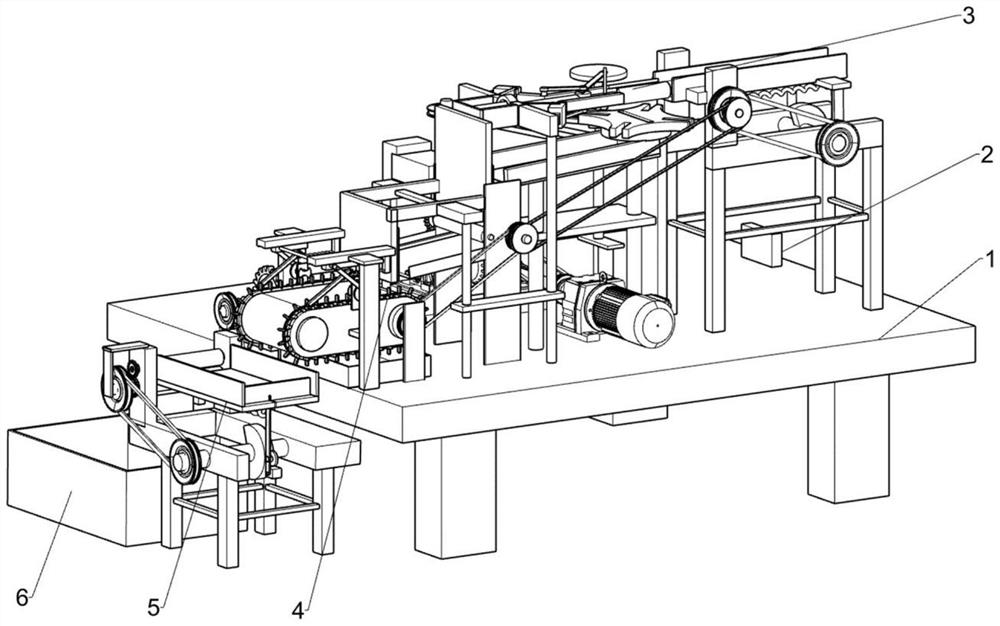

Assembling device for rectangular frame and assembling method of assembling device

PendingCN109227086AAchieve clamping positioningSimple structureMetal working apparatusHigh volume manufacturingEngineering

The invention discloses an assembling device for a rectangular frame and an assembling method of the assembling device. The assembling device comprises a rack, a rotary frame driven by a first power device is rotationally mounted on the rack, and short frame clamping and locating mechanisms driven by a driving device are slidingly mounted at the two ends of the rotary frame. Long frame clamping and locating mechanisms are fixedly mounted on the two sides of the rotary frame. By means of the assembling device for the rectangular frame, mechanical and automatic assembling of the rectangular frame is achieved, the effect of mass production of the rectangular frame is achieved, the assembling efficiency and production efficiency of the rectangular frame are greatly improved, the assembling effect is good, and the forming quality of the rectangular frame is high. Meanwhile, the labor intensity of workers is reduced, the number of the needed workers is reduced, and then the labor cost is reduced.

Owner:JIANGSU HAGONG PHARMA MACHINE TECH CO LTD

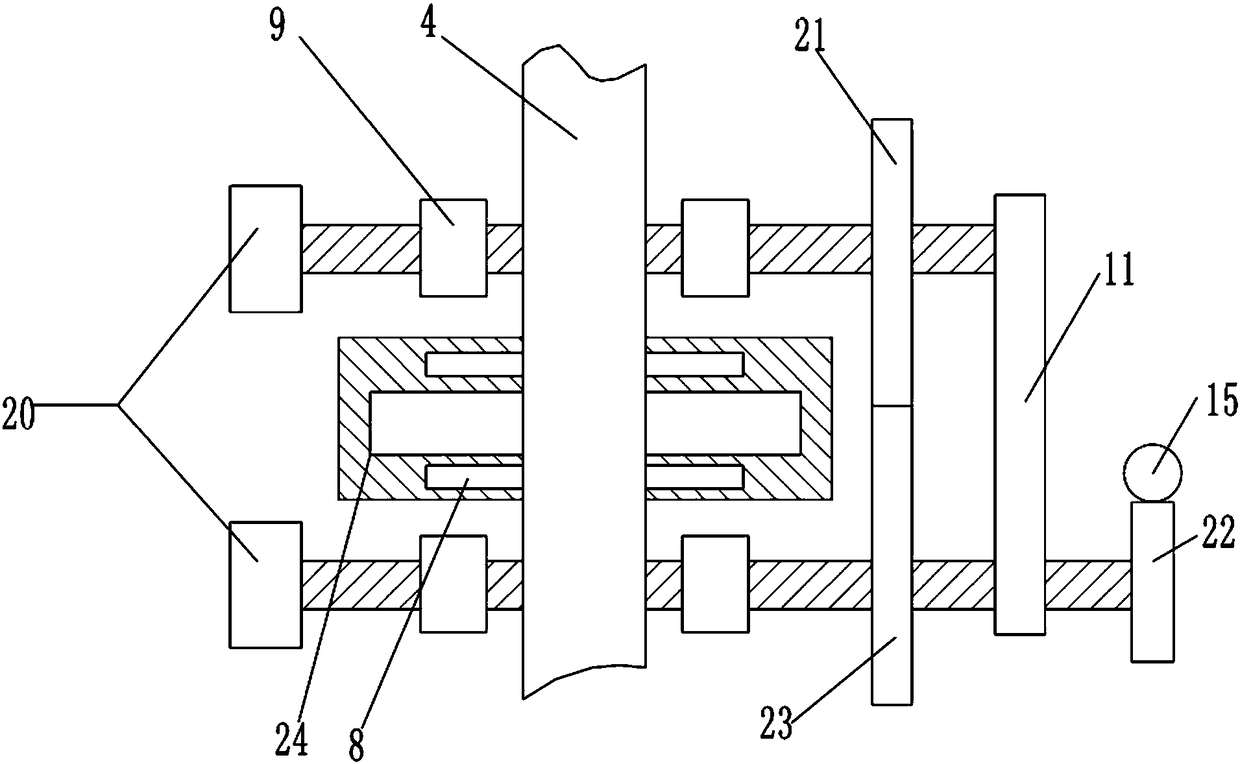

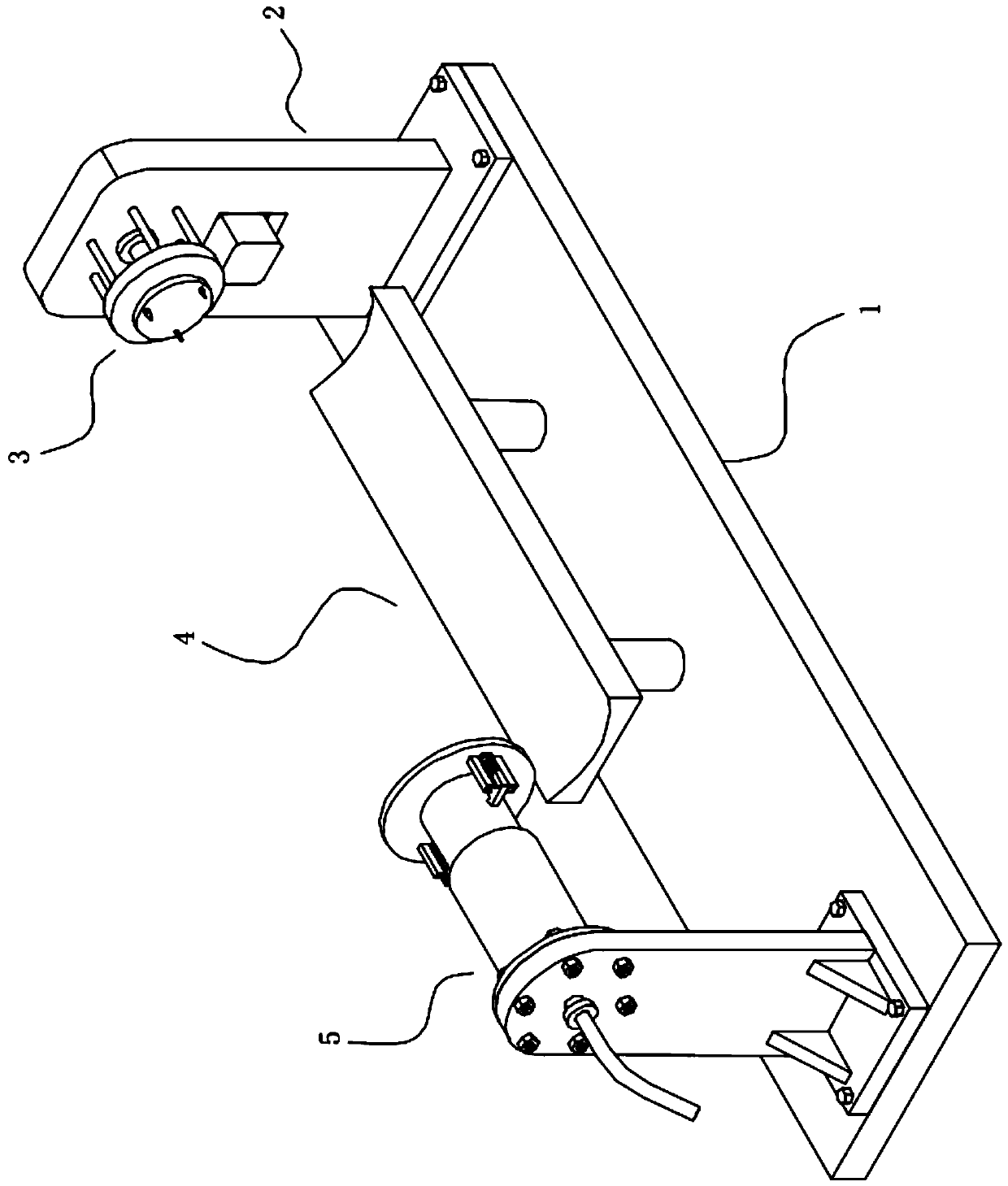

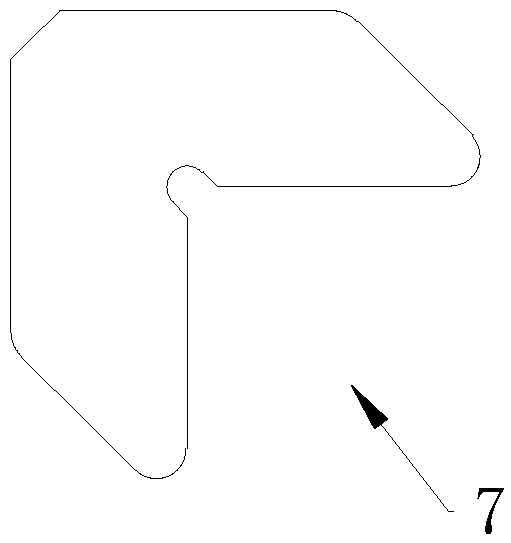

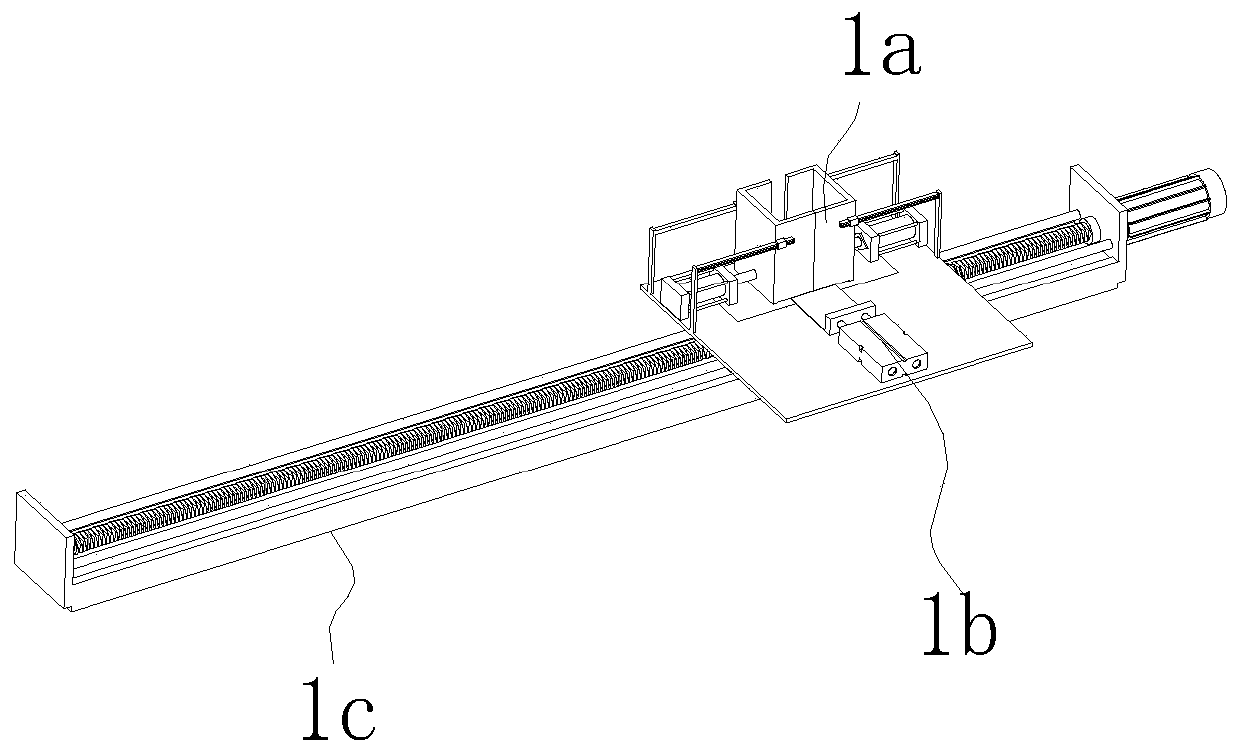

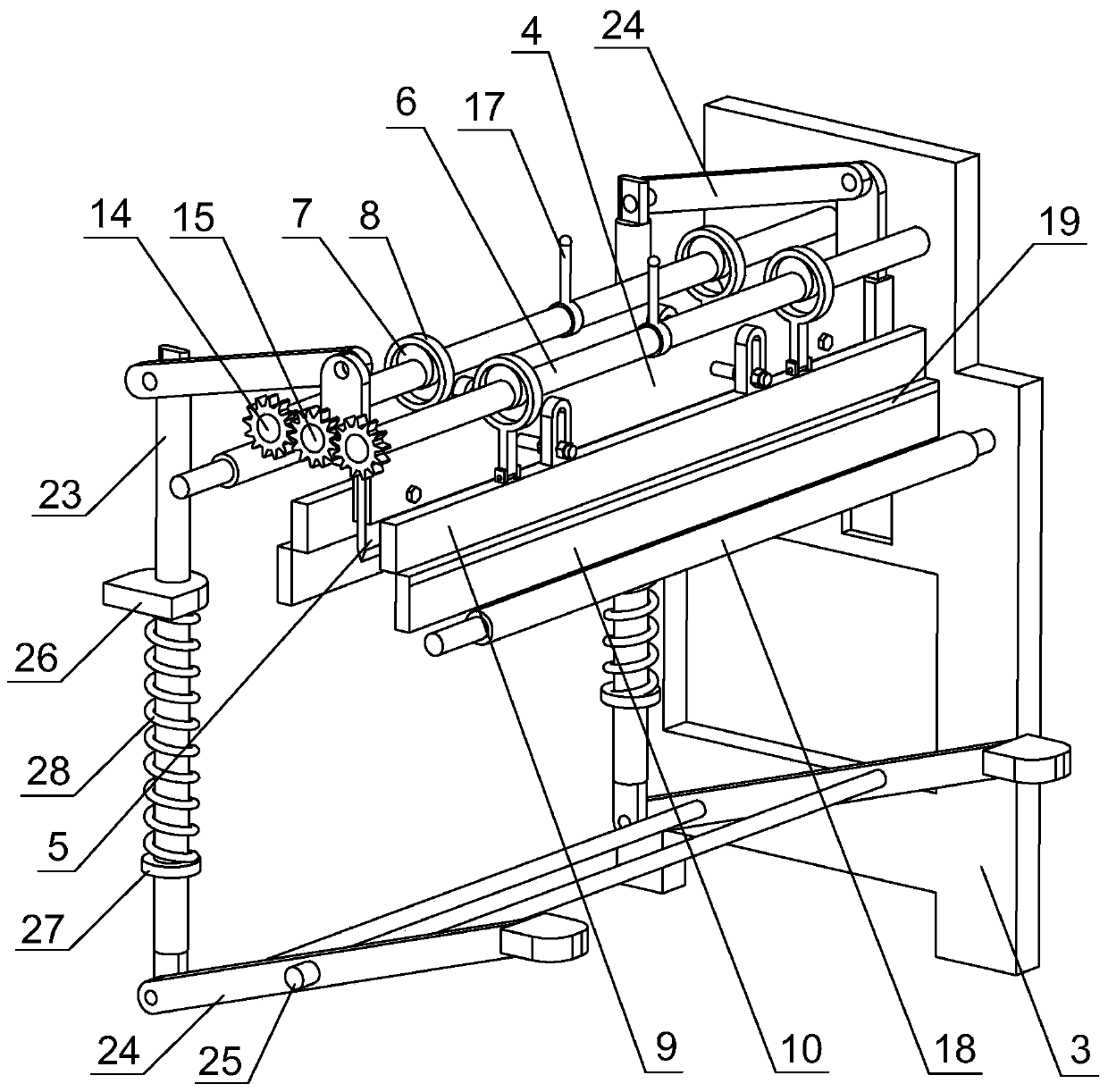

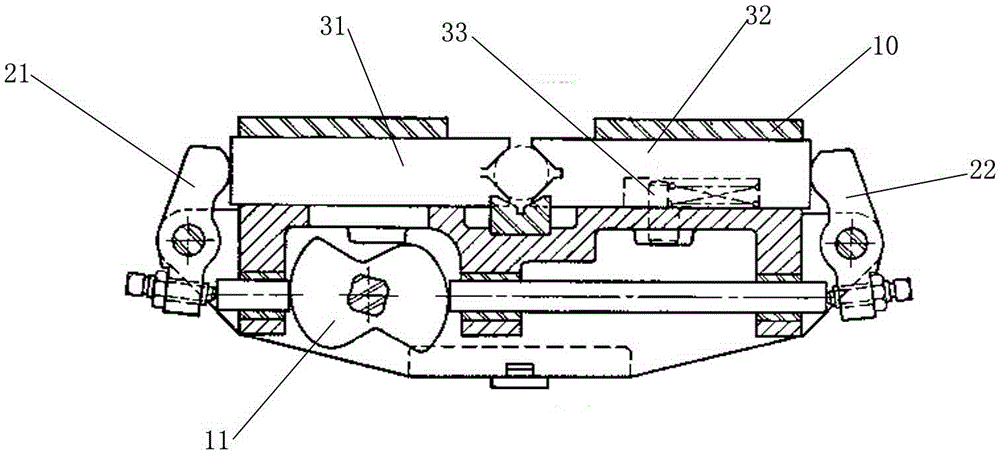

Clamping tool for transmission shaft spline shaft fork

ActiveCN106736731AAchieve clamping positioningImprove clamping efficiencyPositioning apparatusMetal-working holdersDrive shaftEngineering

The invention discloses a clamping tool for a transmission shaft spline shaft fork. The clamping tool comprises a bottom plate. The bottom plate is provided with a fork part positioning mechanism and a shaft part clamping mechanism from left to right. The fork part positioning mechanism comprises a clamp body fixedly connected with the bottom plate. Two vertically symmetrical positioning V-shaped blocks are fixedly arranged on the clamp body. A spring jacking device is arranged between the two positioning V-shaped blocks. The shaft part clamping mechanism comprises s guide rail fixedly connected with the bottom plate. Two sliding blocks are arranged on the guide rail in a matched mode. Each sliding block is provided with a clamping V-shaped block, and V-shaped notches of the clamping V-shaped blocks on the two sliding blocks are oppositely formed. A bidirectional threaded rod penetrates through the two sliding blocks in sequence. The forward thread part of the bidirectional threaded rod is in threaded connection with one of the sliding blocks, and the reverse thread part of the bidirectional threaded rod is in threaded connection with the other sliding block. According to the clamping tool for the transmission shaft spline shaft fork, clamping and positioning of the transmission shaft spline shaft fork are achieved, the clamping efficiency of the transmission shaft spline shaft fork is improved, and the product machining quality is improved.

Owner:河南中轴福漫锻造有限公司

Stamping device for vehicle parts

ActiveCN108311603AAvoid safety hazardsCompression and extraction action is continuousMetal-working feeding devicesPositioning devicesEngineeringConveyor belt

The invention belongs to the technical field of production equipment for vehicle parts and particularly discloses a stamping device for vehicle parts. The stamping device for vehicle parts comprises arack and a fixing board; the rack is provided with a drive mechanism; the fixing board is connected with an upper stamping mold and an inclined board; the inclined board is of a hollow structure; theupper inclined end of the inclined board is closed, and a cover is hinged to the lower inclined end of the inclined board; the cover is provided with a first wedge block; a first cylinder is fixed tothe rack and connected with a second wedge block; the upper portion of the inclined board is in sliding connection with a suction and pressing device; the suction and pressing device comprises a plurality of hollow columns and a suction cup; the hollow columns are provided with a supporting board; one side of the supporting board is connected with the inclined board through a spring; a check block is arranged on the lower portion of the inclined board; a lower stamping mold is arranged under the suction cup; a feeding mechanism is arranged on one side of the lower stamping mold; and a discharging conveyor belt is arranged on the other side of the lower stamping mold and located under the lower inclined end of the inclined board. By adoption of the technical scheme, the problems that the production efficiency is low, the forming quality is poor, discharging is inconvenient and potential safety hazards exist are solved.

Owner:沛县奔腾工贸有限公司

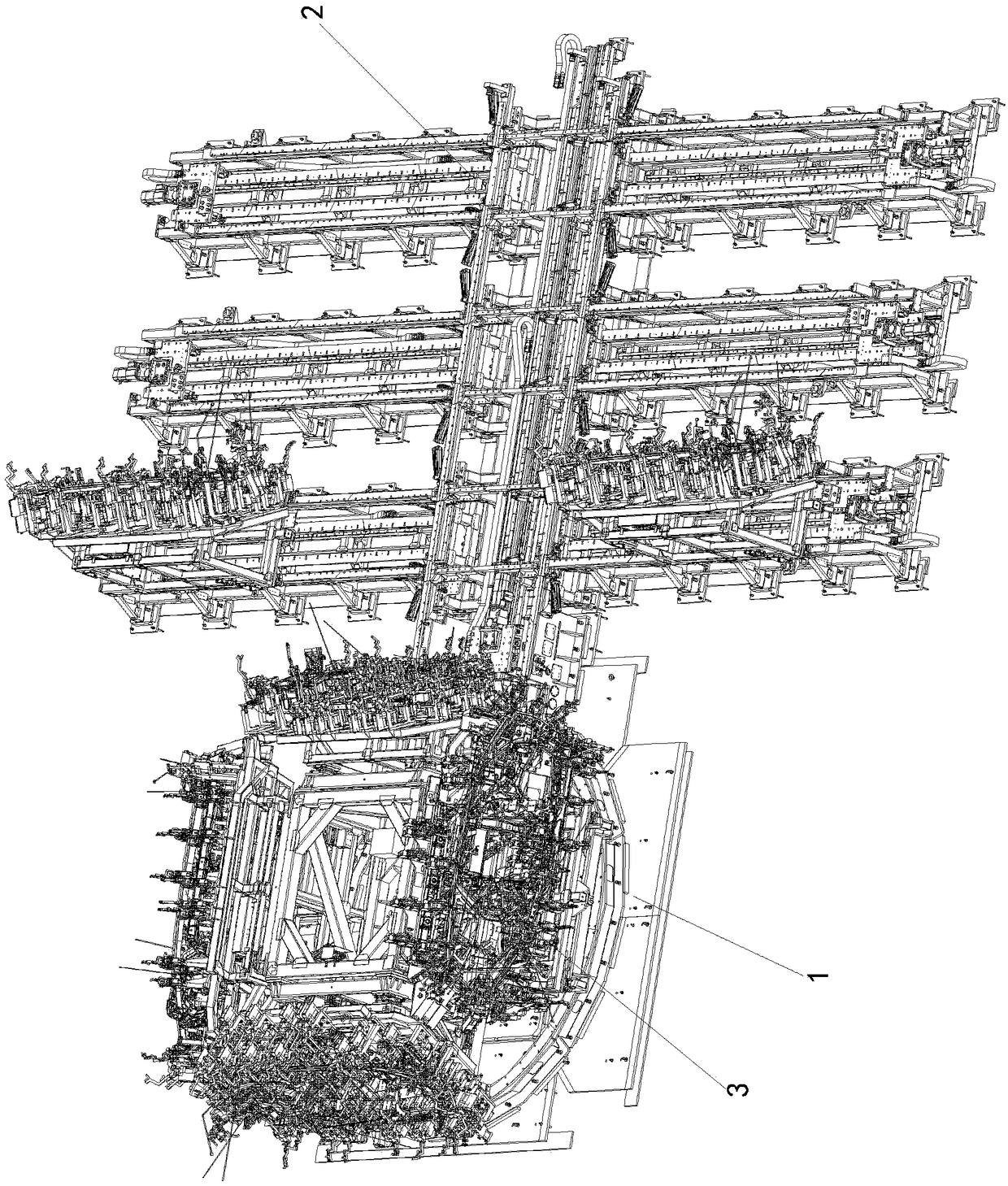

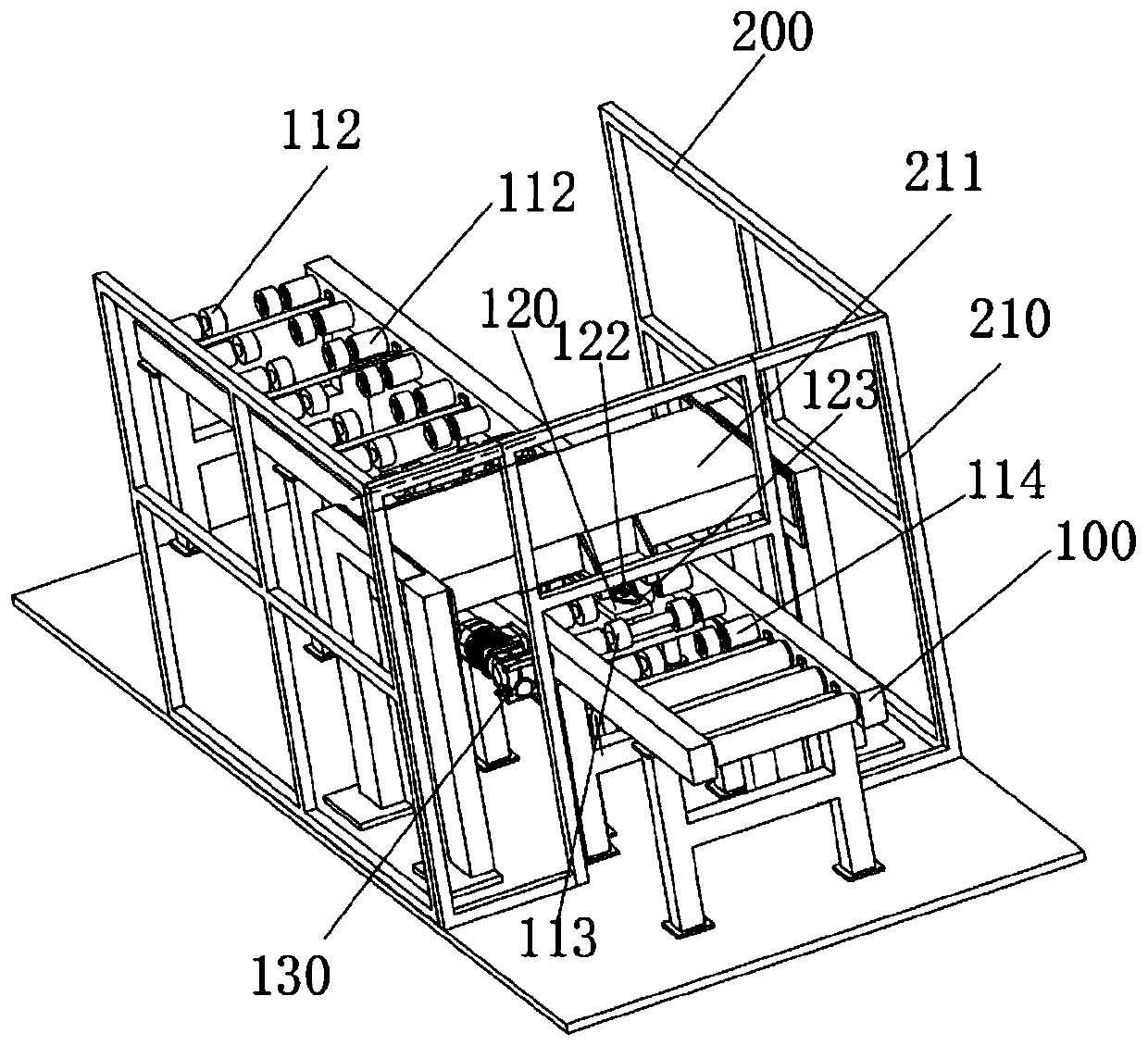

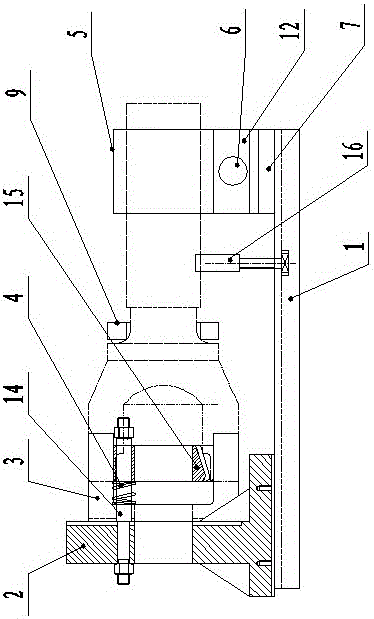

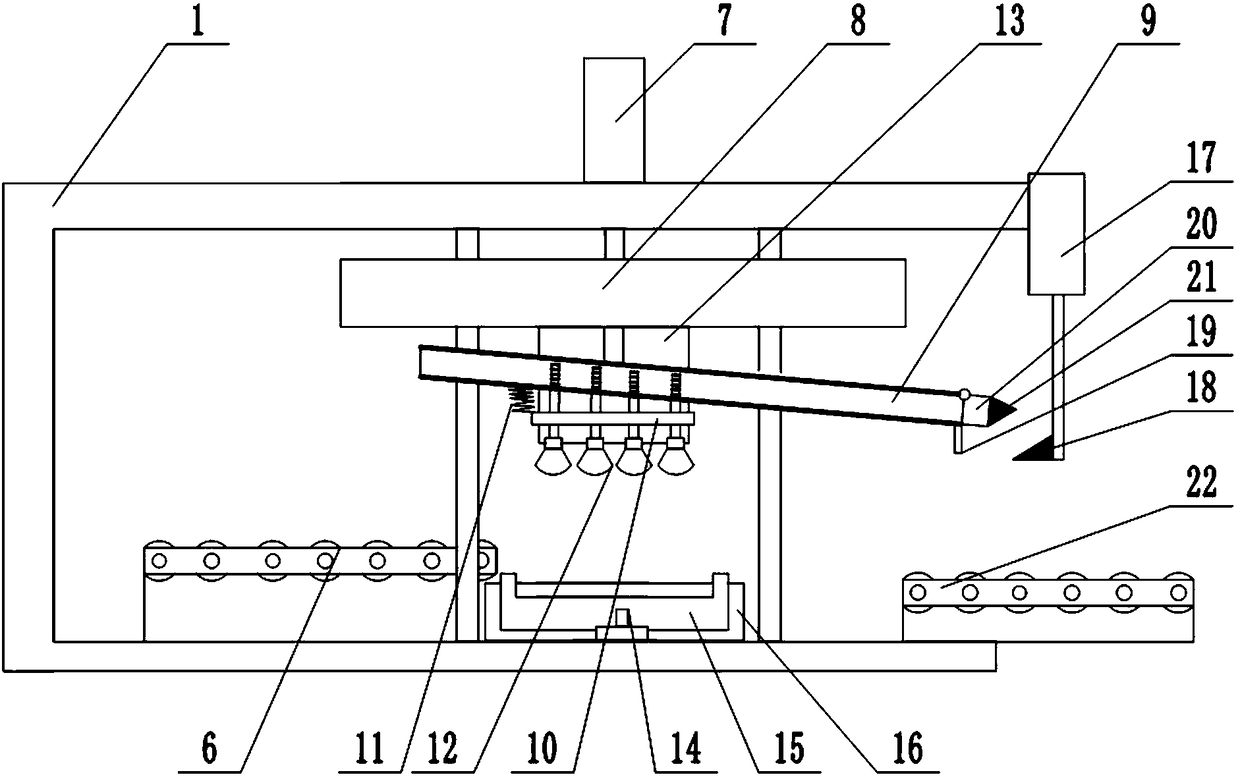

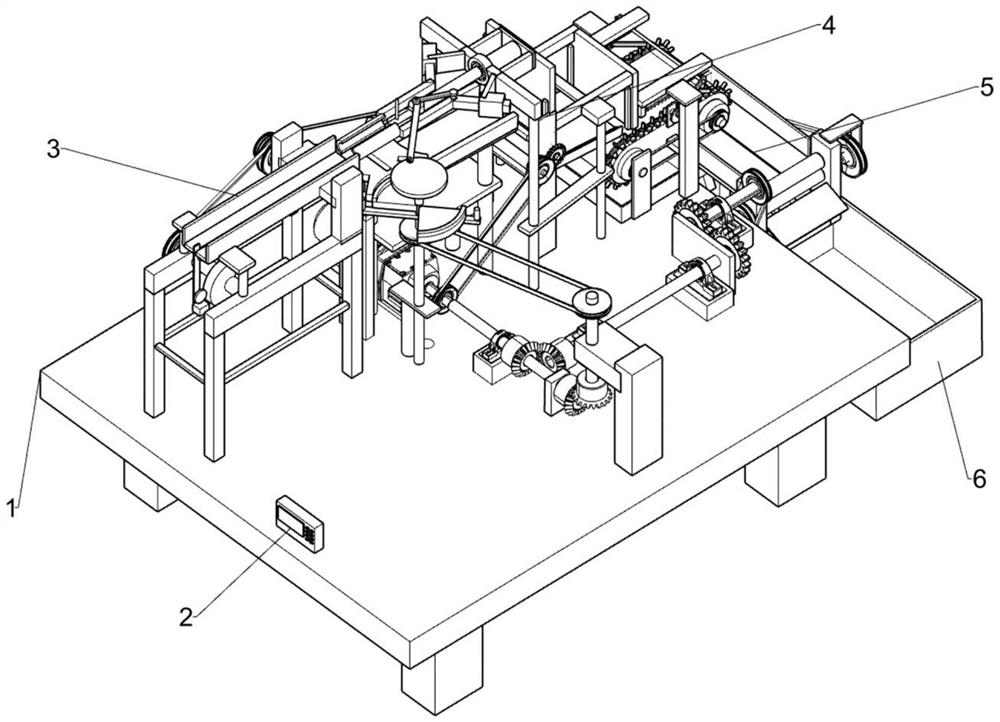

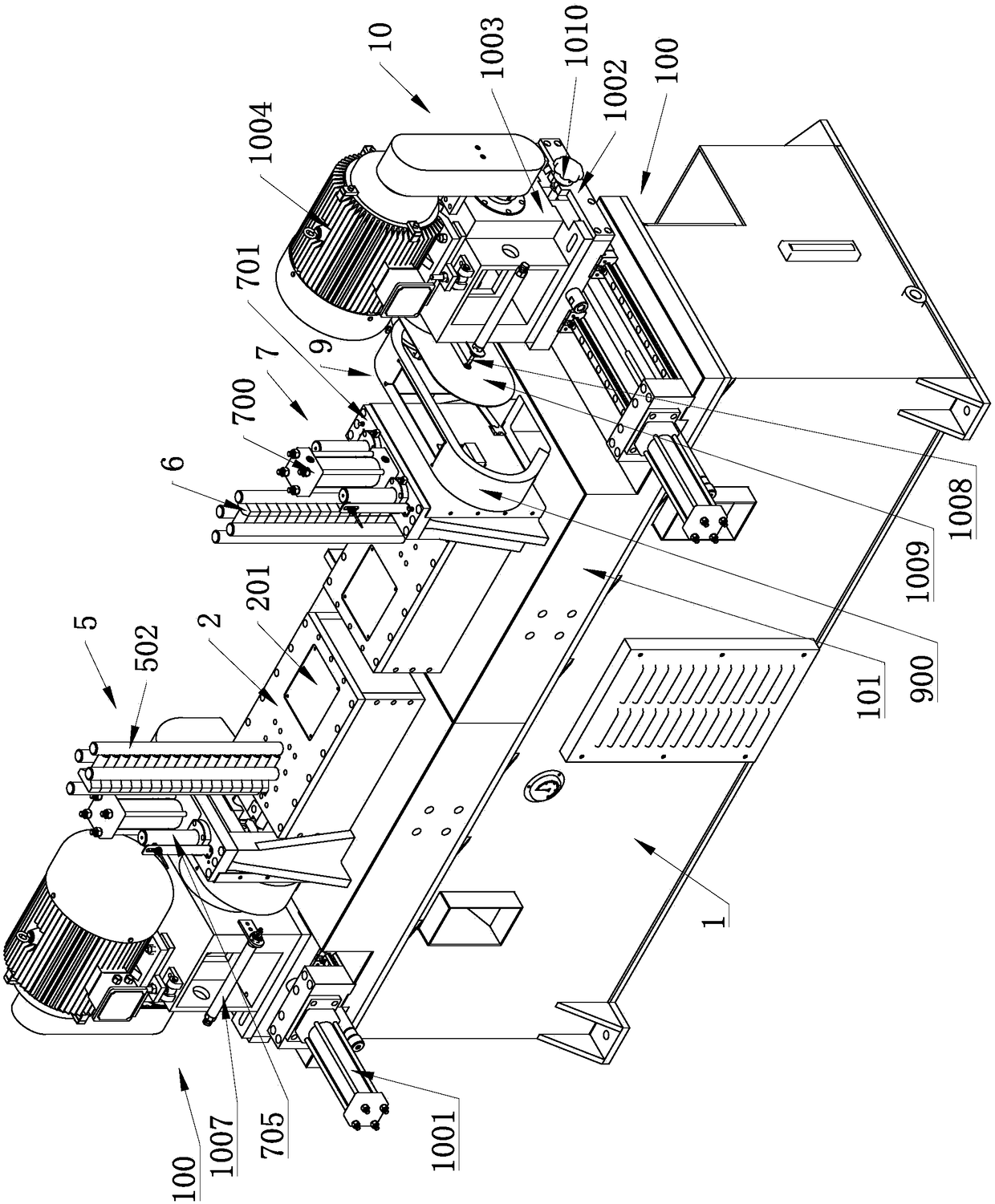

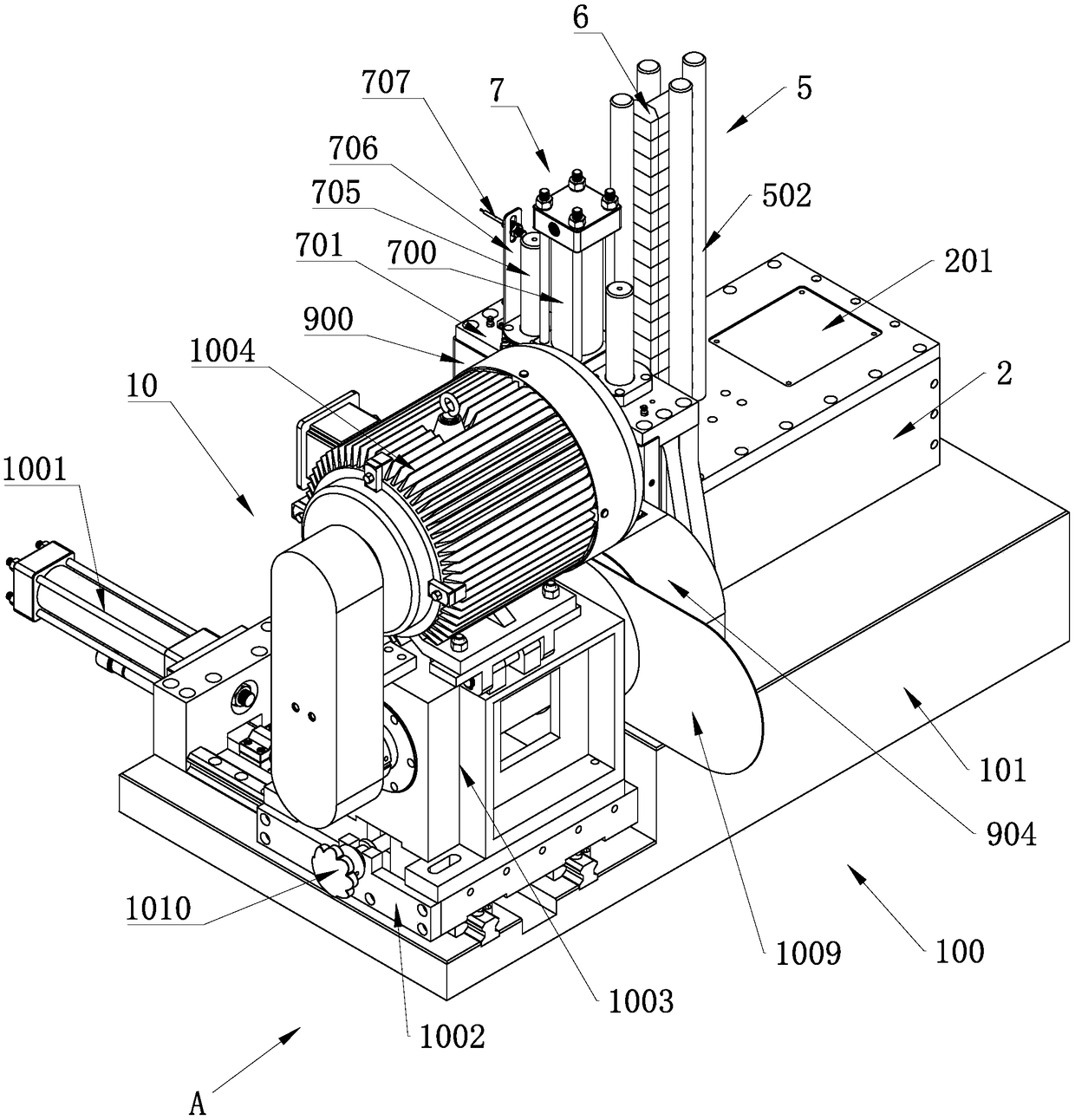

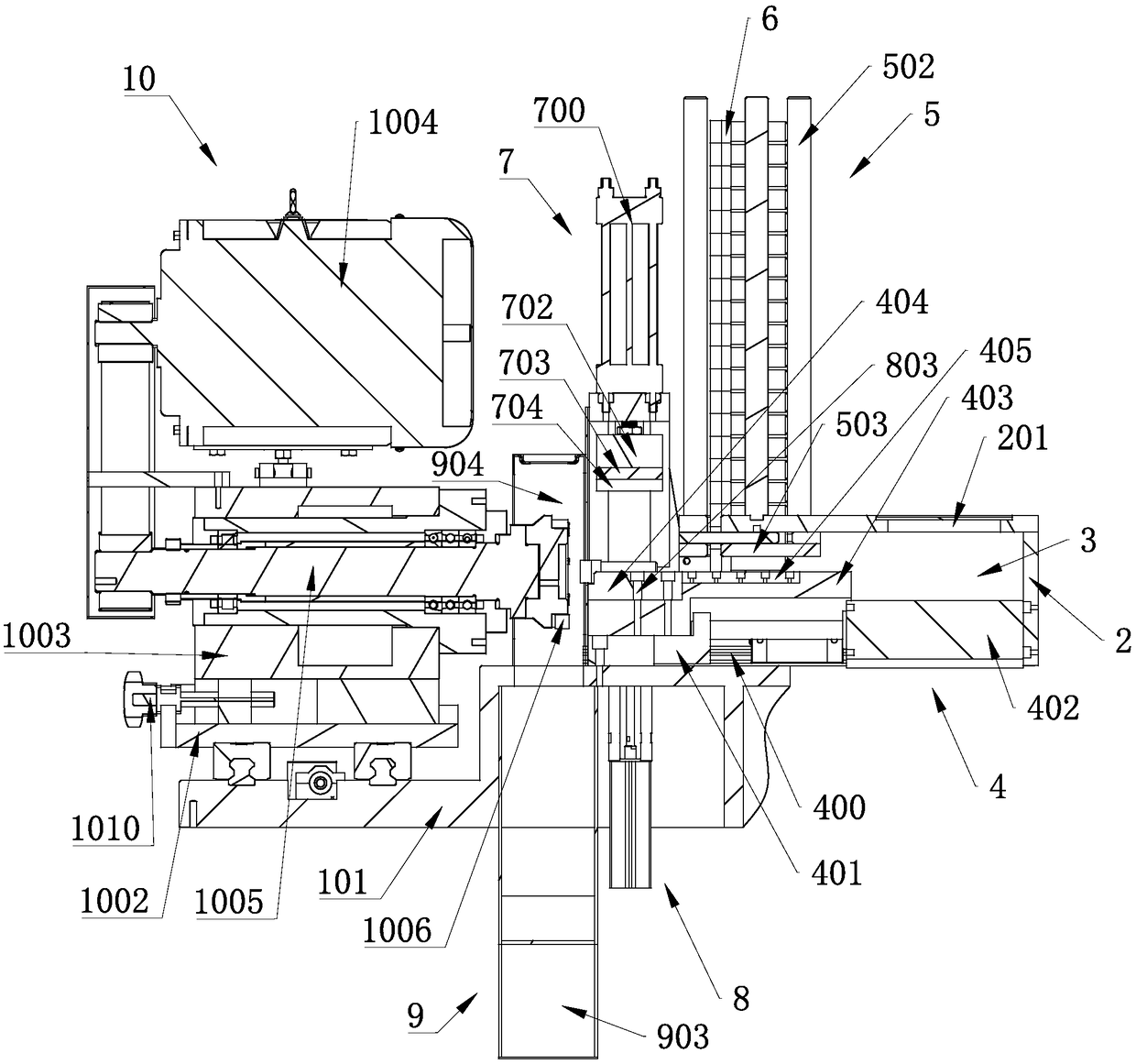

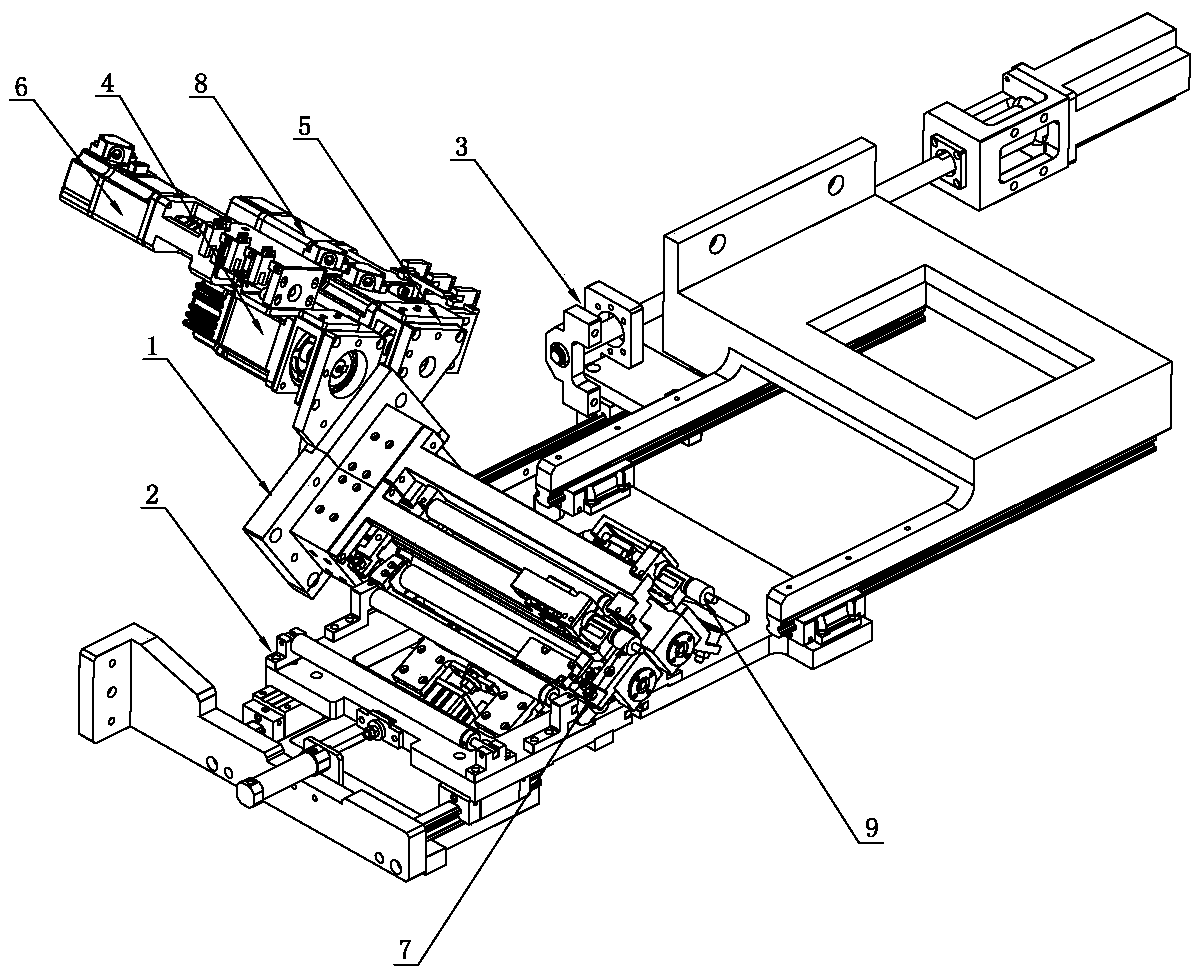

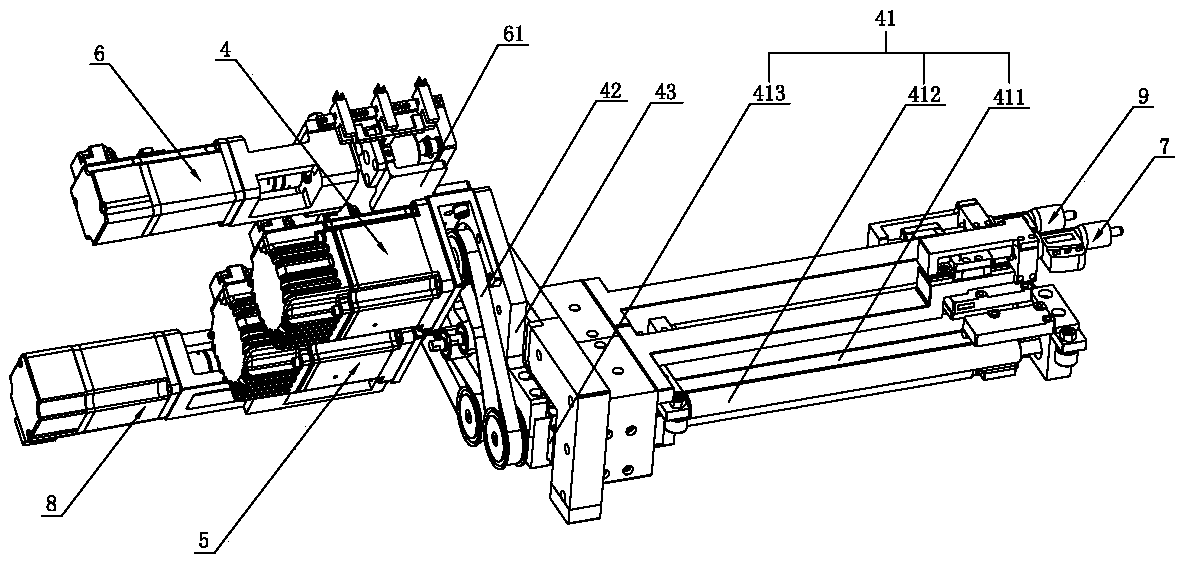

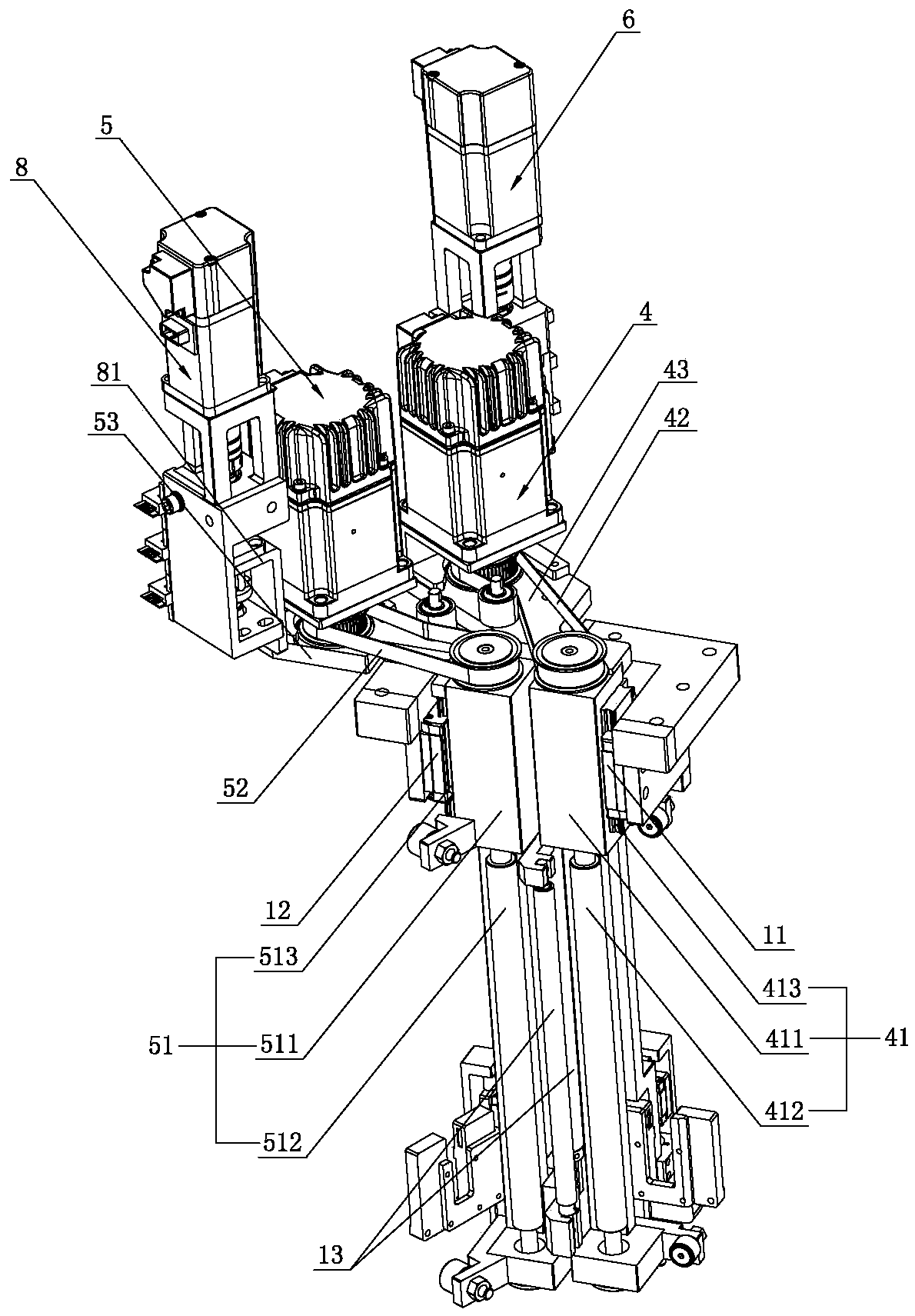

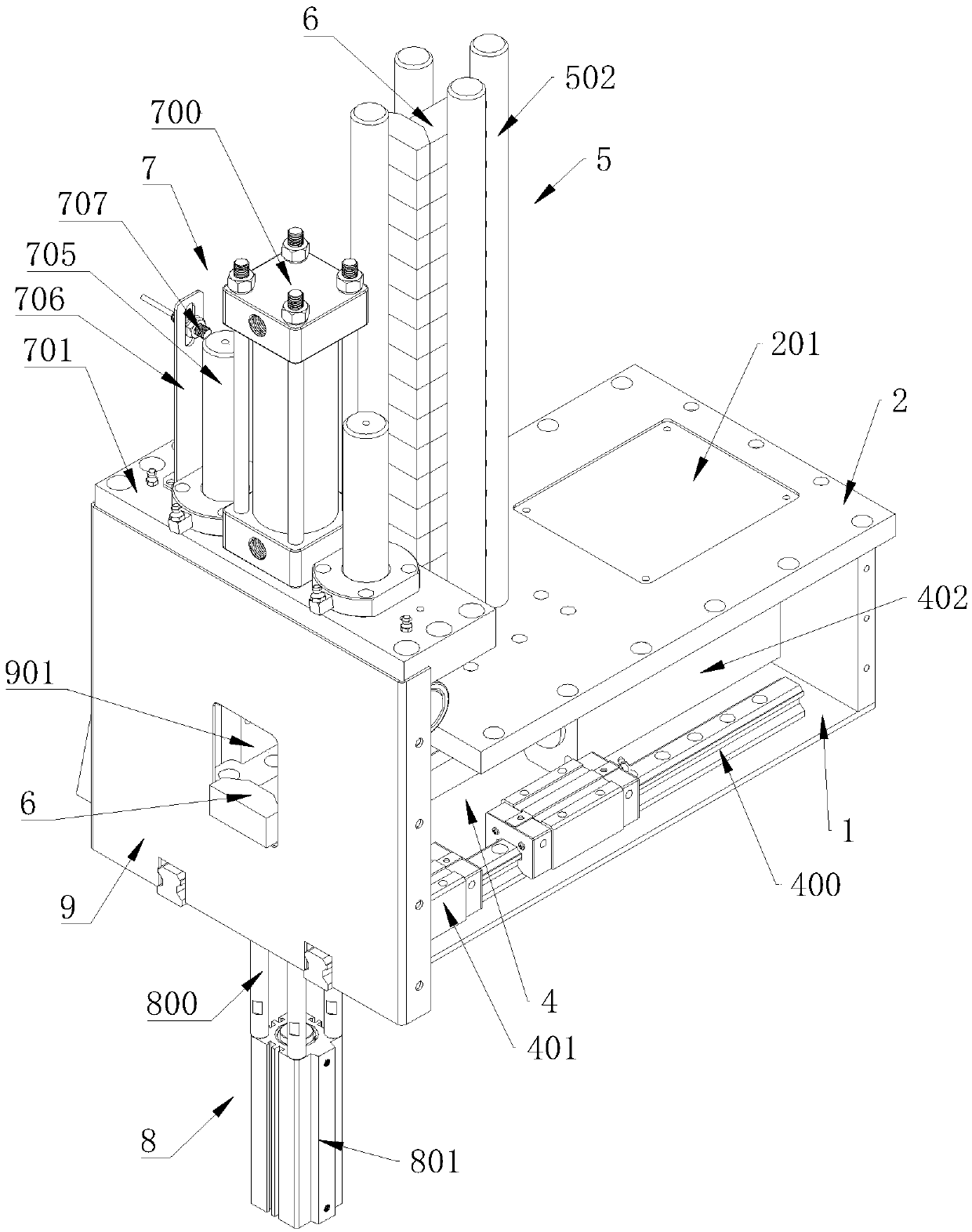

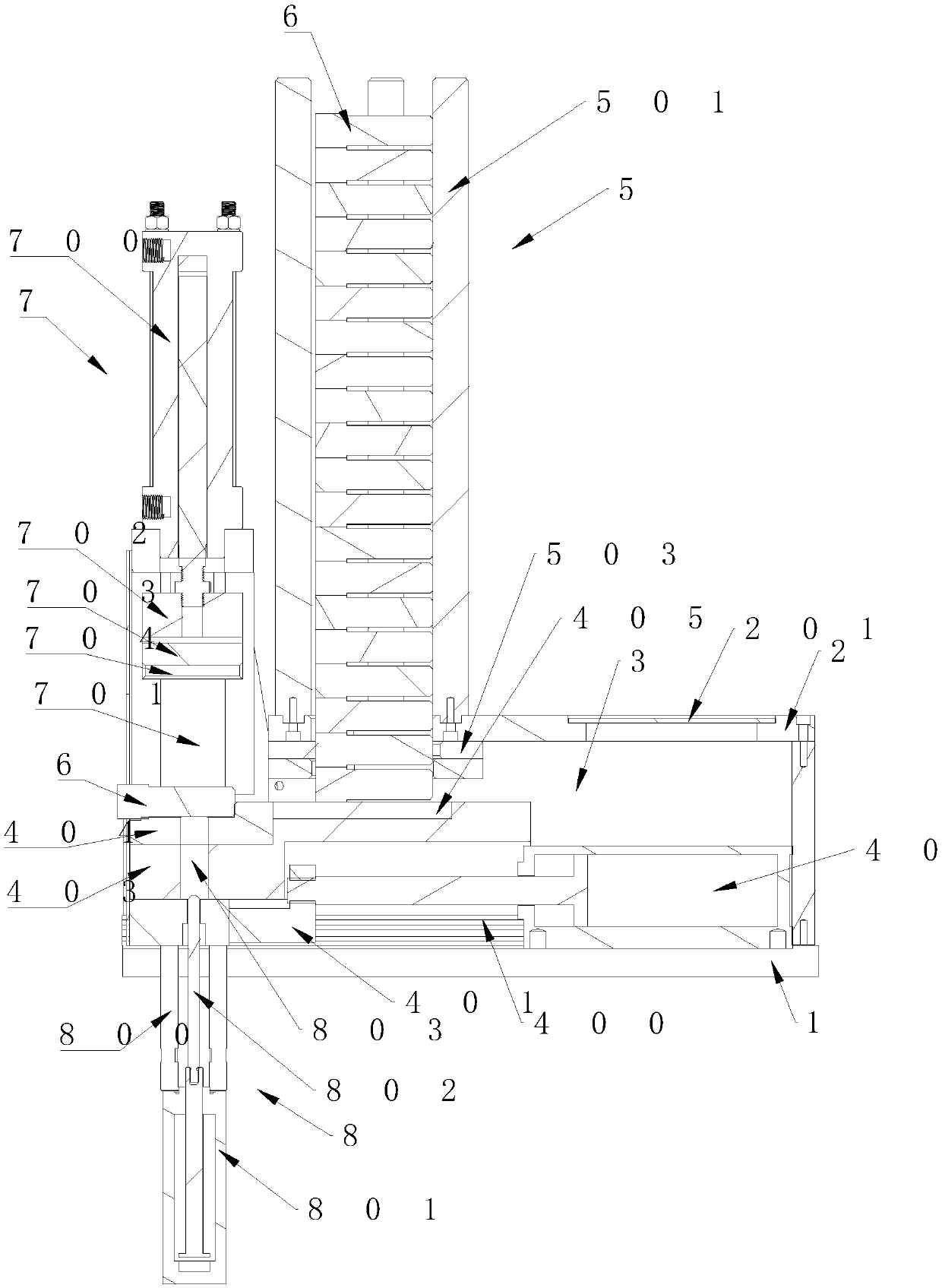

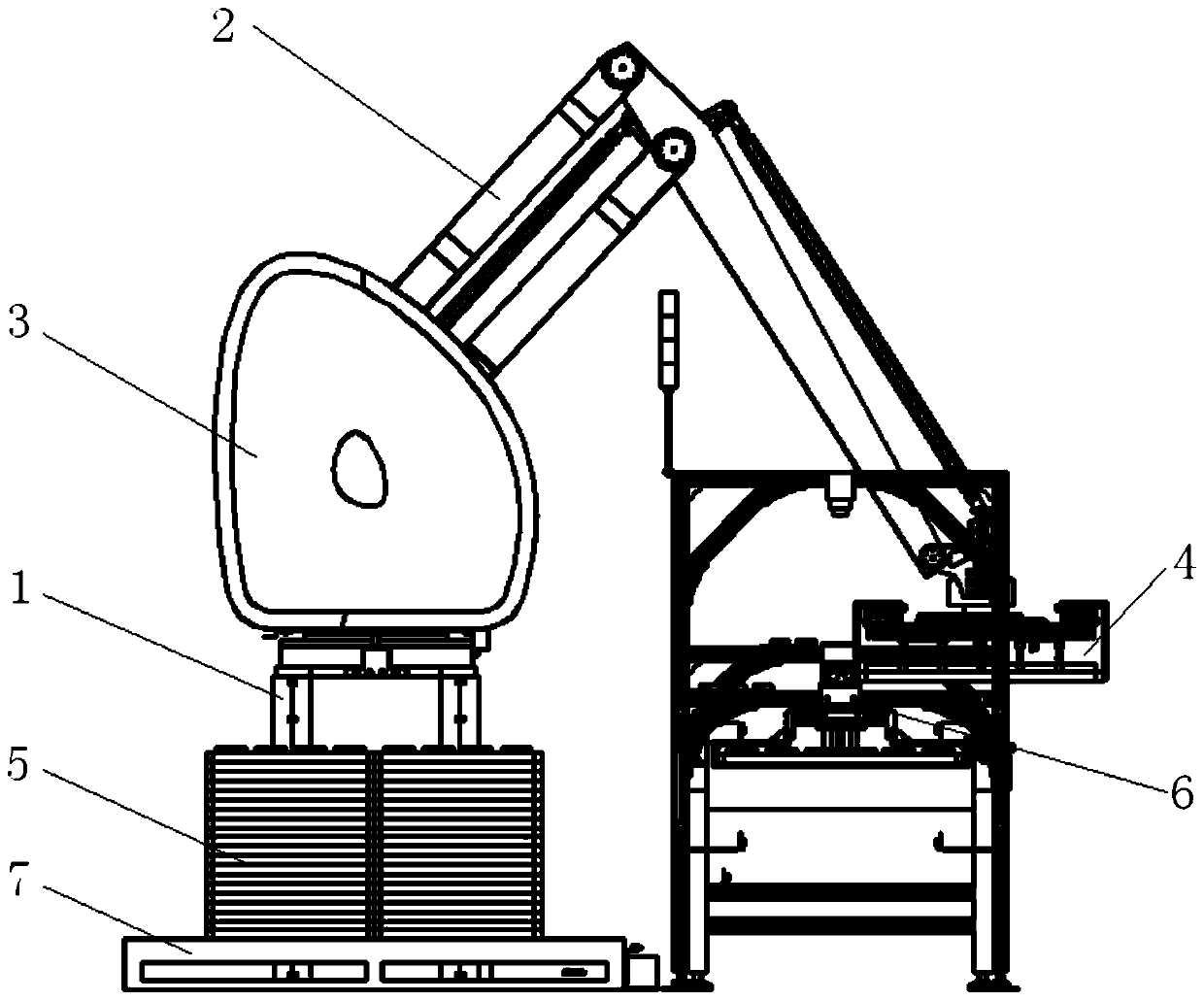

Drilling and copper deposition all-in-one equipment for processing via holes of circuit boards

ActiveCN111299867ARealize integrated processingAchieve clamping positioningPrinted circuit manufactureWelding/soldering/cutting articlesTransfer mechanismProcess engineering

The invention relates to the field of processing for circuit boards, in particular to drilling and copper deposition all-in-one equipment for processing via holes of circuit boards. The equipment comprises a feeding and discharging mechanism, a drilling mechanism, a transfer mechanism and a copper deposition mechanism. An output end of the feeding and discharging mechanism is connected with an input end of the drilling mechanism, an output end of the drilling mechanism is connected with an input end of the transfer mechanism, and an output end of the transfer mechanism is connected with an input end of the copper deposition mechanism. According to the drilling and copper deposition all-in-one equipment, the multiple circuit boards which are laminated in sequence are quickly and effectivelyfed and discharged through the feeding and discharging mechanism, and the equipment can be matched with the circuit boards different in size through the drilling mechanism so as to complete clampingpositioning and continuous drilling operation on the circuit boards. The circuit boards after being drilled are conveyed to the transfer mechanism, the transfer mechanism transfers the circuit boardsto the copper deposition mechanism to perform chemical copper deposition, and integrated processing of drilling and copper deposition for the via holes of the circuit boards is achieved.

Owner:赣州中盛隆电子有限公司

Device for recycling spray cans

InactiveCN111975381ADrilling and inflationAchieve clamping positioningOther manufacturing equipments/toolsProcess engineeringMechanical engineering

The invention relates to the field of recycling, in particular to a device for recycling spray cans. The invention has the technical implementation scheme that the device for recycling spray cans comprises a bottom frame, a controller, a drilling inflation mechanism, a grinding cutting mechanism, a can case compression mechanism and a storage box, wherein the controller is arranged at the upper side of the bottom frame; and the drilling inflation mechanism and the like are sequentially arranged above the bottom frame. The device for recycling spray cans has the advantages that a traditional spray can recycling mode is avoided; the valuable spray head position of the spray can body is specially treated; the defects that in the prior art, the recycling of the spray cans generally needs manual operation by labor, the efficiency is low, and the danger degree of manual operation is high are overcome; and the operation that a common mechanical device cannot conveniently treat deformed spraycans in batches and in a unified mode is completed.

Owner:李晓强

Plane winding machine

The invention discloses a plane winding machine, and relates to the technical field of film winding equipment. The machine solves the problem that a large quantity of films are wasted because the films are not positioned and the cutting path is curved.. The plane winding machine comprises an unwinding roller and a winding roller for winding a film, wherein a rack is fixed between the unwinding roller and the winding roller; a cutter holder is arranged in the rack in a lifting manner; a cutter is fixedly arranged on one side of the cutter holder in an embedded manner; rotating rods are rotatably arranged on two sides of the cutter holder respectively; cams are connected to two ends of each rotating rod fixedly and coaxially; a press rod sleeves the peripheral side of each came, and two of the press rods are jointly hinged with an upper positioning plate; a lower positioning plate is fixed in the rack; a guiding assembly is arranged between the upper positioning plate and the cutter holder. According to the plane winding machine, the upper positioning plate and the lower positioning plate are combined, so that the film can be conveniently positioned and clamped; with the film is cutby the cutter, the cutting speed is high, so that the surface of the film is flatter and attractive, waste of film resources is reduced, and production efficiency is improved.

Owner:浙江达尔美塑胶有限公司

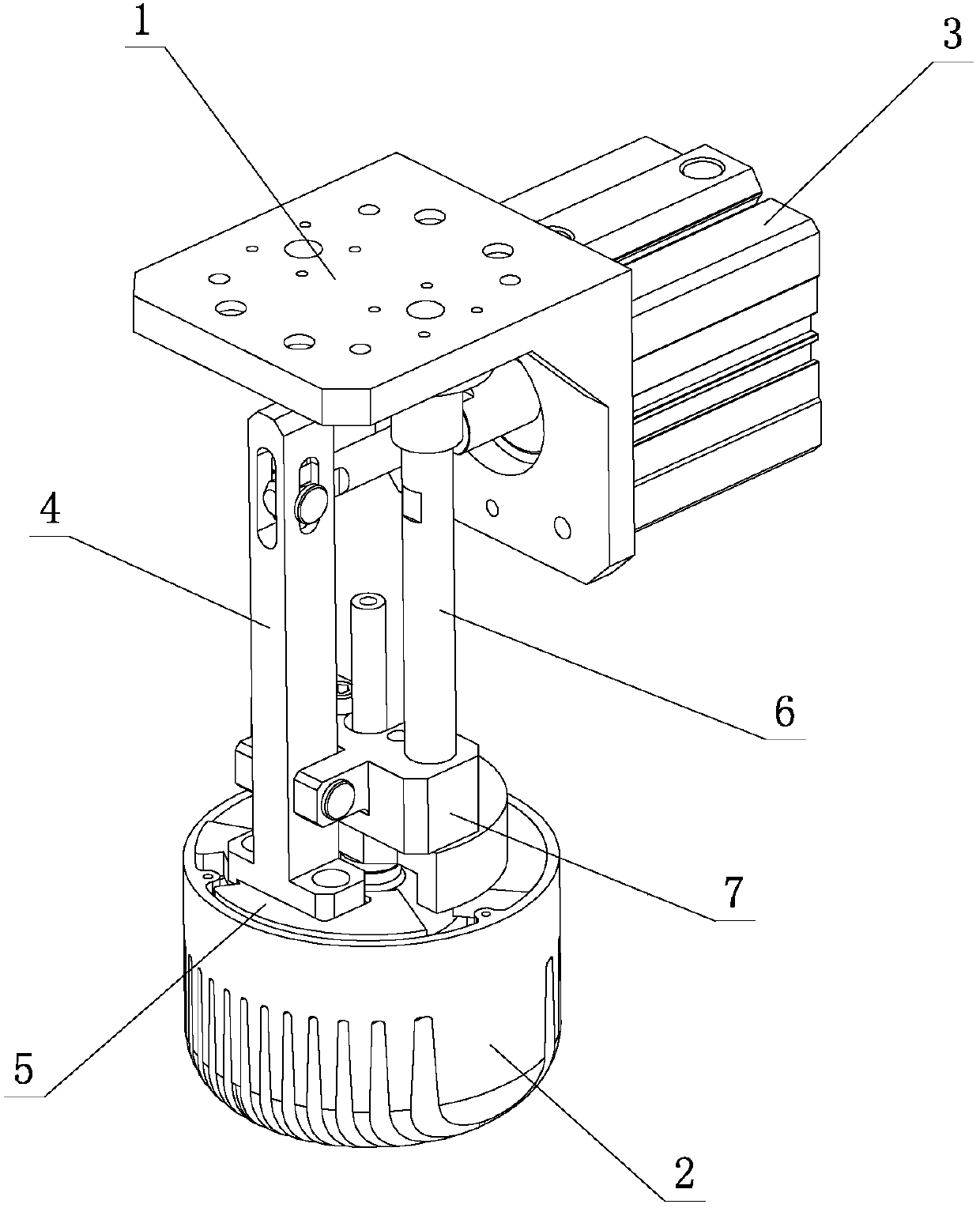

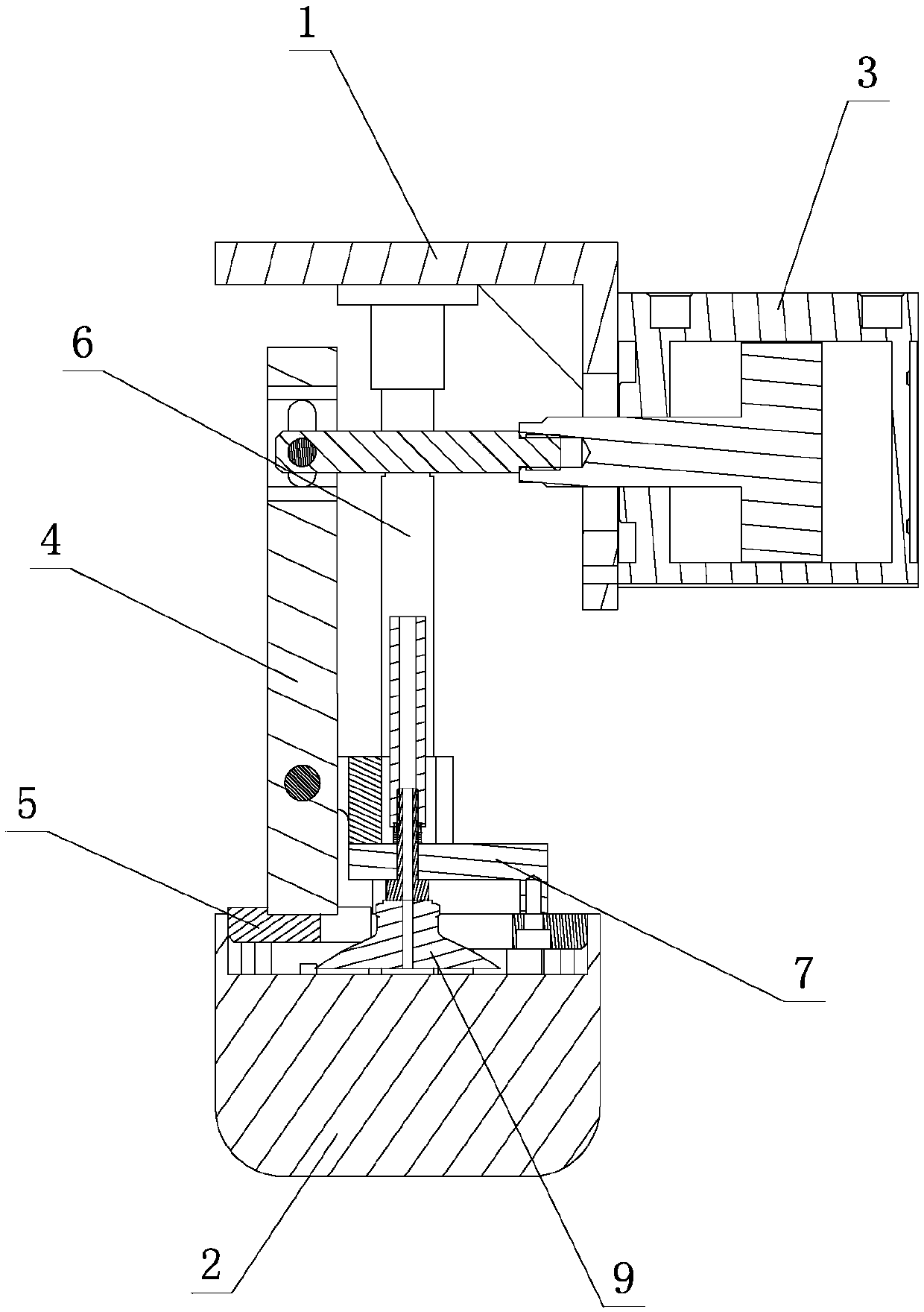

Pneumatic clamp

PendingCN107825194AAchieve clamping positioningEasy to hold the workpieceWork clamping meansPositioning apparatusEngineeringMechanical engineering

The invention provides a pneumatic clamp and belongs to the technical field of machines. The pneumatic clamp solves the problem that a workpiece cannot be conveniently clamped by an existing pneumaticclamp. The pneumatic clamp comprises a base; a workbench is arranged on the base; the outer end face of the workbench is a positioning face for the workpiece to abut against; a plurality of pulling rods and a cylinder driving the pulling rods to synchronously and horizontally move in the axial direction in a reciprocating manner are vertically arranged on the workbench; the outer ends of the pulling rods are all fixedly connected with annular pressing blocks; the pressing blocks are arranged on the outer side of the workbench in parallel; and the middle portion of each pressing block is provided with an inner hole for the workpiece to pass through. The pneumatic clamp has the beneficial effects that workpiece clamping is convenient, and using is convenient.

Owner:浙江青霄科技股份有限公司

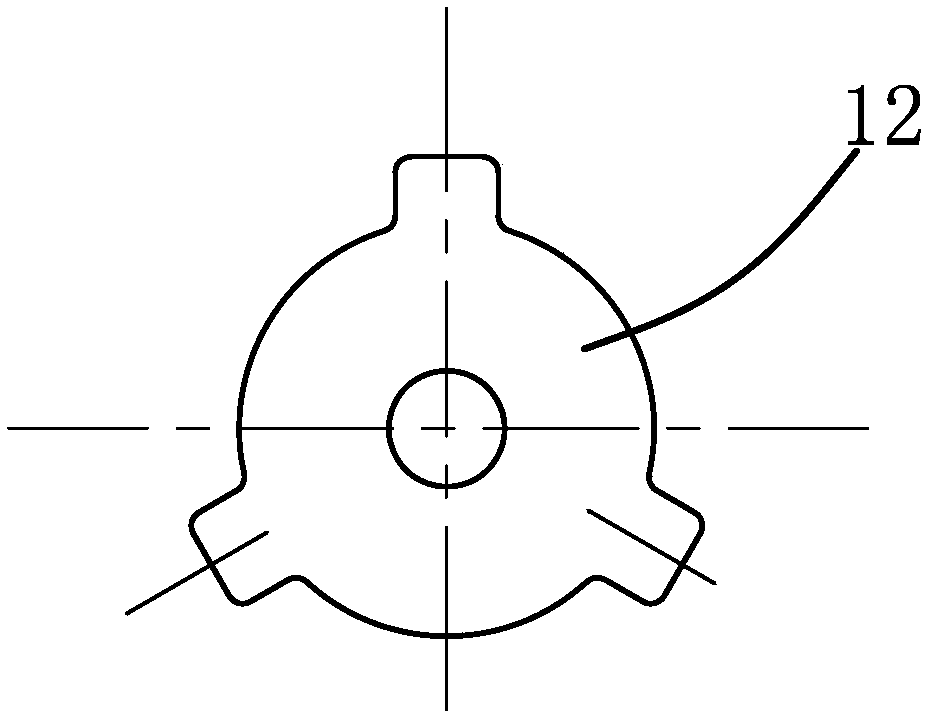

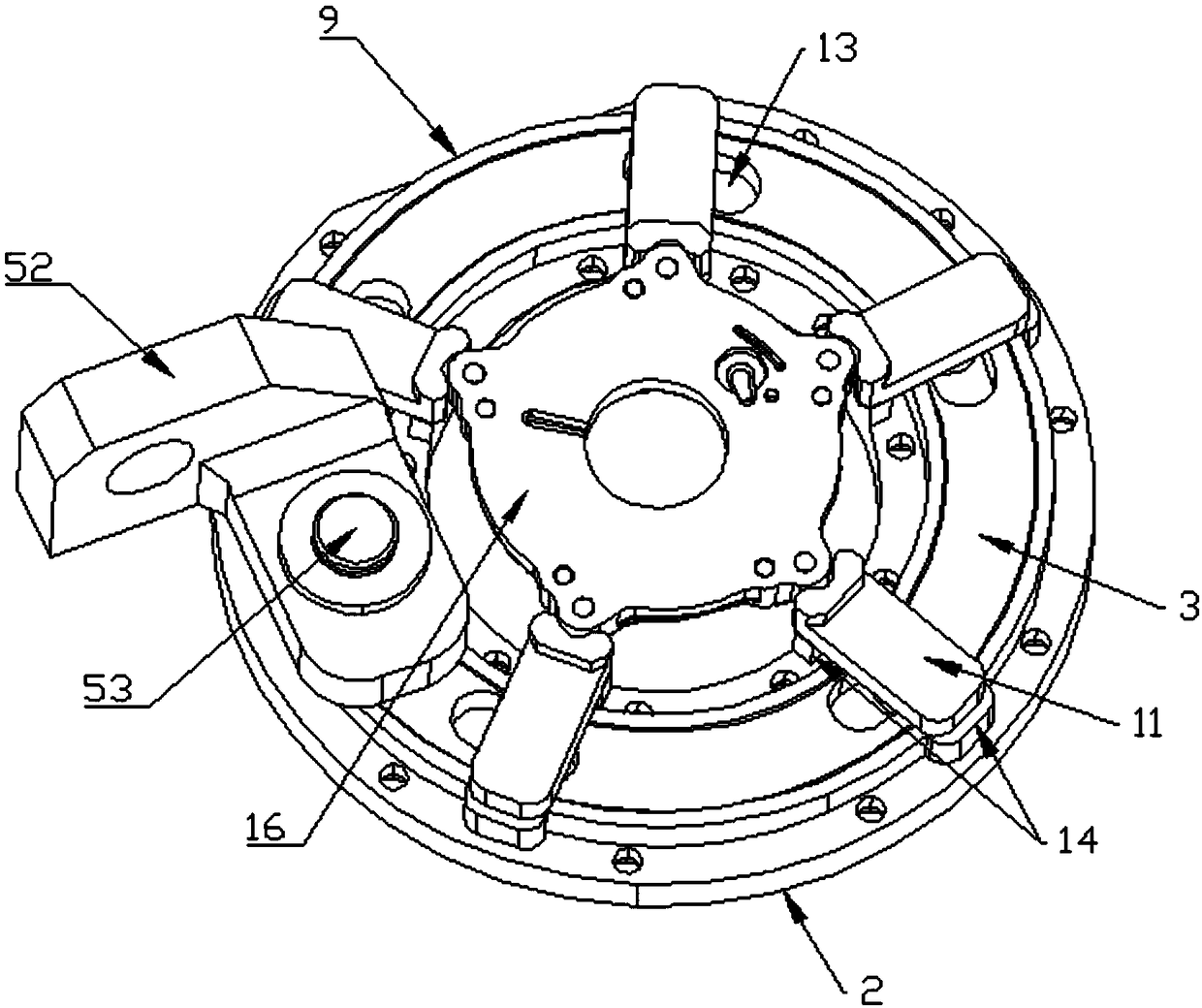

Five-claw self-centering clamping tool with detecting function

The invention discloses a five-claw self-centering clamping tool with a detecting function and relates to the technical field of aluminum alloy pressure casting. The five-claw self-centering clampingtool comprises a bottom plate, a clamping assembly and an air pressure detecting assembly. The clamping assembly comprises a rotary disc seat, a rotary disc, a compressing assembly and a pushing assembly. The air pressure detecting assembly comprises a first air pressure detecting head, a second air pressure detecting head, a third air pressure detecting head and a fourth air pressure detecting head. The five-claw self-centering clamping tool is simple in structure and convenient to operate, a placed product is pre-located firstly through the compressing assembly, then the rotary disc is pushed to rotate through the pushing assembly, and a chuck moves inwards under the action of a track groove to clamp the protruding portion around a lock cover, and clamping and locating of the product areachieved.

Owner:WUHU JINYI MACHINERY

End face machining method of bolts and end face machining machine achieving method

PendingCN109352044AImprove push effectEasy to replaceMilling equipment detailsMetal working apparatusEngineeringOperation safety

The invention discloses an end face machining method of bolts and an end face machining machine achieving the method. The method comprises the following steps that bolts to be machined are guided andconveyed one by one; the guided and conveyed bolts to be machined are pushed to the machining station, and in the pushing process, a pushing mechanism used for pushing the bolts to be machined to abutagainst next bolts to be machined; the to-be-machined bolts pushed to the machining station are located and clamped; composite end face machining is carried out; an end face machining device used formachining the end face and a clamping mechanism used for clamping are reset; the machined bolts are conveyed in an ejected manner; the bolts conveyed in an ejected manner are conveyed; and the pushing mechanism is reset to push the next bolts to be machined. According to the method, assembly automatic guiding, conveying, pushing, clamping, locating and machining of the bolts, and ejected conveying and outputting of the machined bolts are achieved, the potential safety hazards in the operation of the bolt clamping process and labor intensity of personnel are reduced, and meanwhile the work continuity and the working efficiency are improved greatly.

Owner:张家港市润泰机械有限公司

Fixing device for rear axle shaft sealing cap

ActiveCN105500198AAchieve clamping positioningQuick clampingGrinding work supportsEngineeringCenter of mass

Owner:CHONGQING YIZHU MACHINERY MFG

A link-driven clamp

ActiveCN106514332BAchieve clamping positioningAchieve releasePositioning apparatusMetal-working holdersEngineeringIndustrial engineering

The invention provides a connecting rod drive type clamp, and belongs to the technical field of machines. The connecting rod drive type clamp comprises an outer frame, a first clamping block, a second clamping block, a third clamping block and a fourth clamping block. The outer frame comprises a bottom plate, a first vertical plate and a second vertical plate, and a rotating mechanism is arranged on the first vertical plate. A locating frame is fixed to a rotating shaft. A first sliding rod, a second sliding rod, a third sliding rod and a fourth sliding rod are arranged on one side face of the locating frame. A first sliding block is arranged on the first sliding rod and the second sliding rod, and a second sliding block is arranged on the third sliding rod and the fourth sliding rod. A connecting rod drive mechanism is further fixed to the locating frame. A first locating plate is fixed to the locating frame and provided with a first screw. A first rotating disc is fixed to the first screw. The third clamping block is fixed to the lower surface of the first screw. A second locating plate is fixed to the locating frame and provided with a second screw. A second rotating disc is fixed to the second screw. The fourth clamping block is fixed to the lower surface of the second screw. The connecting rod drive type clamp has the beneficial effect of being capable of clamping a to-be-machined workpiece more effectively.

Owner:嘉兴知酷客信息科技有限公司

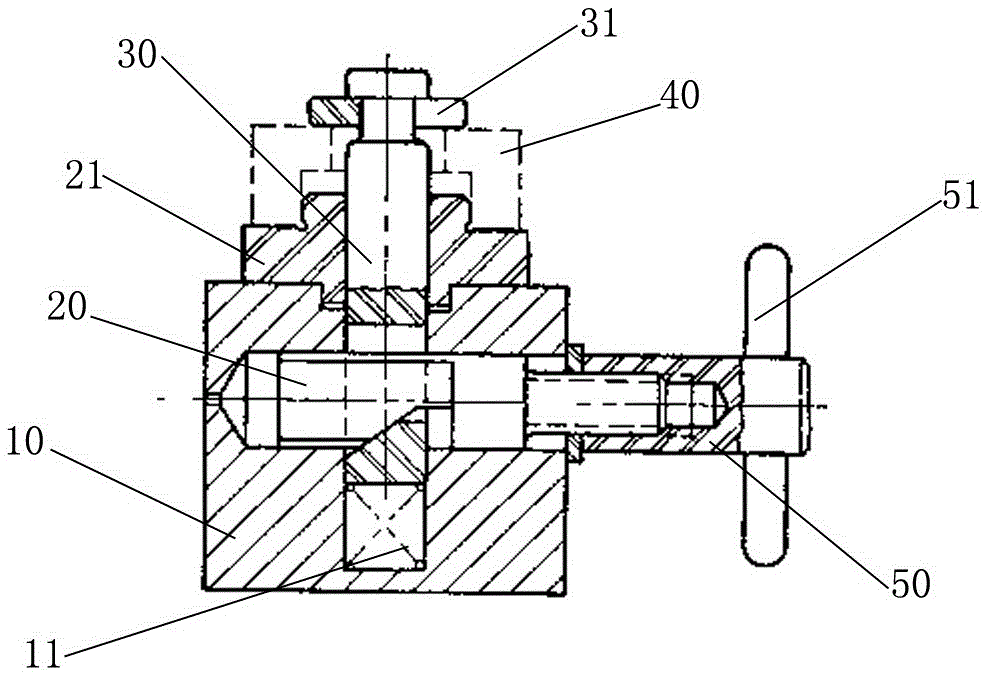

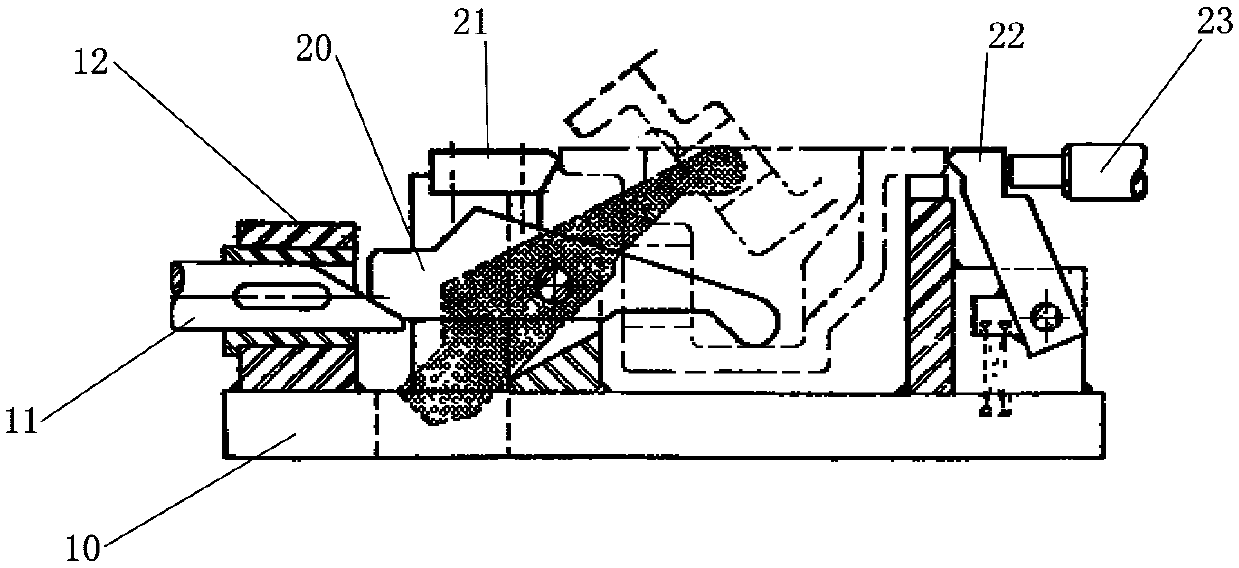

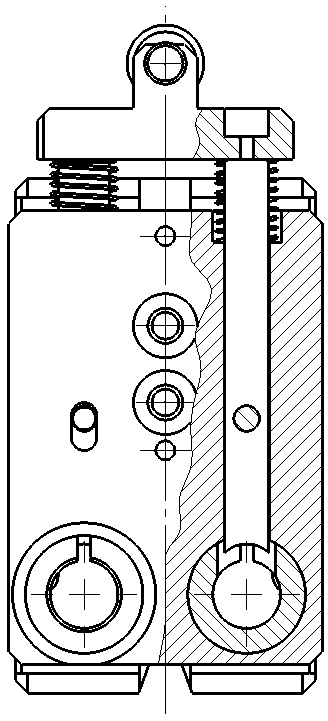

Fixing device for motorcycle engine end cover machining

InactiveCN105458920AAchieve clamping positioningQuick clampingGrinding work supportsArchitectural engineeringMachining

The invention discloses a fixing device for motorcycle engine end cover machining. The fixing device comprises a machine frame and further comprises a pull rod, a gland, an upper lug, a thread cap, a lower lug, a spring and a fixed base, wherein the pull rod, the gland, the upper lug, the thread cap, the lower lug, the spring and the fixed base are sequentially arranged on the machine frame from top to bottom. A counter bore is formed in the bottom face of the machine frame. The fixed base is fixed into the counter bore. The fixed base and the counter bore are positioned through a pin. The upper end of the fixed base is sunken inwards to form a groove allowing the lower lug to slide therein. The lower lug is connected with the middle of the pull rod through a pin. The spring is fixed between the lower lug and the bottom face of the groove. An external thread is arranged on the outer wall of the fixed base. An internal thread matched with the external thread is arranged on the inner wall of the thread cap. A handle is fixed to the outer wall of the thread cap. The upper lug is connected to the middle of the pull rod in a sleeving mode. The lower end face of the upper lug abuts against the upper end face of the lower lug. The upper end of the upper lug is fixed to the thread cap through a bolt. By means of the fixing device, clamping and positioning of workpieces can be achieved, the workpieces can be clamped rapidly, and the efficiency is greatly improved.

Owner:CHONGQING QINGYING MOTORCYCLE PARTS CO LTD

Full-automatic battery winding and deviation rectification equipment

PendingCN108777325AAchieve clamping positioningAvoid deformationPrimary cell manufactureAssembling battery machinesElectrical batteryDrive motor

The invention relates to the technical field of lithium battery automatic winding equipment and in particular relates to full-automatic battery winding and deviation rectification equipment. The full-automatic battery winding and deviation rectification equipment comprises a main driving machine platform, wherein a first clamping mechanism and a second clamping mechanism are arranged at two sidesof the main driving machine platform respectively; the main driving machine platform is provided with a negative pole piece driving motor and a positive pole piece driving motor; a power output end ofthe negative pole piece driving motor is in driving connection with a negative pole piece driving assembly; a power output end of the positive pole piece driving motor is in driving connection with apositive pole piece driving assembly; a negative pole piece deviation rectification motor is arranged at one side of the negative pole piece driving motor; the main driving machine platform is provided with a negative pole piece edge detection sensor; a positive pole piece deviation rectification motor is arranged at one side of the positive pole piece driving motor; the main driving machine platform is provided with a positive pole piece edge detection sensor. According to the full-automatic battery winding and deviation rectification equipment, a diaphragm material and a pole piece materialare used for independently feeding respectively, and the pole piece material is initiatively driven to feed and wind, so that a feeding speed and a winding speed of the pole piece material are synchronous, and the alignment precision and production efficiency of a wound product are improved.

Owner:广东锦捷智能科技有限公司

Bolt pre-processing assembly

PendingCN109514334AImprove push effectEasy to replaceWork clamping meansPositioning apparatusEngineeringOperation safety

The invention discloses a bolt pre-processing assembly. The bolt pre-processing assembly comprises an installation body. A support body is arranged on the installation body. An installation cavity isformed between the support body and the installation body. A material pushing mechanism is slidably installed on the portion, positioned in the installation cavity, of the installation body. A bolt guiding mechanism communicated with the installation cavity is arranged on the support body. A clamping mechanism is arranged on the portion, at one end of the support body, of the installation body. The clamping mechanism is arranged in the pushing direction of the material pushing mechanism. A material jacking mechanism for jacking and conveying bolts pushed by the material pushing mechanism is arranged on the material pushing mechanism. By adopting the bolt pre-processing assembly, the mechanical guiding, pushing, clamping and positioning of the bolts and the jacking and conveying work afterthe bolt processing is completed are realized, and compared with a traditional manual bolt transferring and clamping mode, by the adoption of the bolt pre-processing assembly, the potential safety hazard of operation in the bolt clamping process is greatly reduced, and the labor intensity of workers is greatly reduced as well; and meanwhile the work continuity and work efficiency are effectively improved.

Owner:张家港市润泰机械有限公司

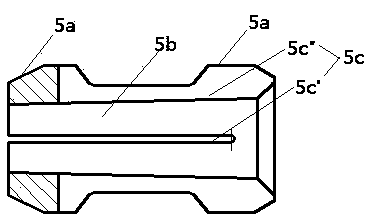

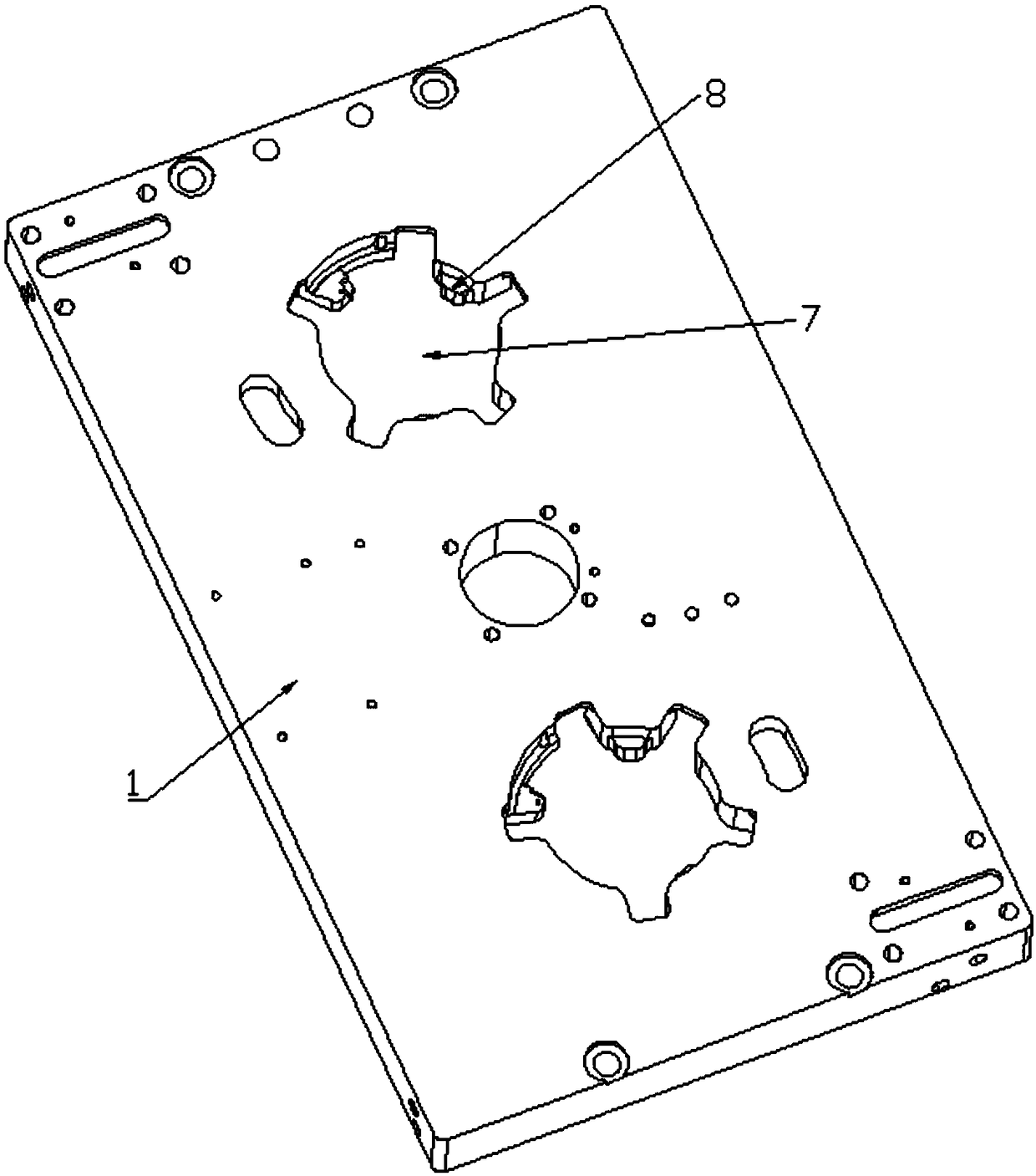

Elastic conveying carrier for cylindrical products

The invention discloses a elastic conveying carrier for cylindrical products. The elastic conveying carrier is characterized in that two round through holes and two U-shaped through holes are machinedin the front face of a carrier plate, two holes penetrating through the two round through holes in the front face are machined in one end face of the carrier plate, two spacer bushes are arranged inthe two round through holes in the front face of the carrier plate correspondingly, two ejector rods are arranged in the two holes in the end face of the carrier plate correspondingly, the end faces of the two ejector rods are connected with a push plate, the outer circular surfaces of the ejector rods are sleeved with springs, a hinge pin is arranged on the push plate, and a bearing is arranged on the hinge pin. The carrier is used for conveying and positioning the cylindrical products during production and detection in a chain conveying line, the products are placed in the carrier spacer bushes, when the products are conveyed to a station needing to be positioned, a cam or a wedge-shaped block installed on the station pushes a rolling wheel at the front end of the carrier, the push platemoves towards the carrier plate and compresses the spring, and the ejector rods are pushed to move towards the spacer bushes to press against the products in the spacer bushes, so that the products can be positioned, the carrier is simple in structure and free of power, and the cost of equipment is reduced.

Owner:苏州北杰星智能装备有限公司

Processing device for cleaning rear car axle shaft sealing cover

The invention discloses a processing device for cleaning a rear car axle shaft sealing cover. The processing device comprises a machine frame, a left swing arm, a left clamping jaw, a left ejector rod, a cam, a supporting block, a right ejector rod, a right clamping jaw and a right swing arm, wherein the left swing arm, the left clamping jaw, the left ejector rod, the cam, the supporting block, the right ejector rod, the right clamping jaw and the right swing arm are arranged on the machine frame from left to right. The cam is connected to the lower portion of the machine frame through a square shaft in a rotating mode. The upper portion of the machine frame is provided with a left slide way where the left clamping jaw slides and a right slide way where the right clamping jaw slides. The lower portion of the machine frame is provided with a left passageway where the left ejector rod slides and a right passageway where the right ejector rod slides. The right end of the left ejector rod abuts against the left end of the cam. The left end of the right ejector rod abuts against the right end of the cam. The left end of the left ejector rod abuts against the lower end of the left swing arm. The middle of the left swing arm is connected to the machine frame in a pivot mode. The upper end of the left swing arm abuts against the left end of the left clamping jaw. The middle of the right swing arm is connected to the machine frame in a pivot mode. The upper end of the right swing arm abuts against the right end of the right clamping jaw. The right end of the left clamping jaw and the left end of the right clamping jaw are both in a V shape, and the supporting block is arranged between the left clamping jaw and the right clamping jaw. The supporting block is fixed to the machine frame. The processing device can clamp and locate a workpiece and quickly clamp the workpiece, thereby greatly improving efficiency.

Owner:CHONGQING FENGHUIDA METAL FORGING CO LTD

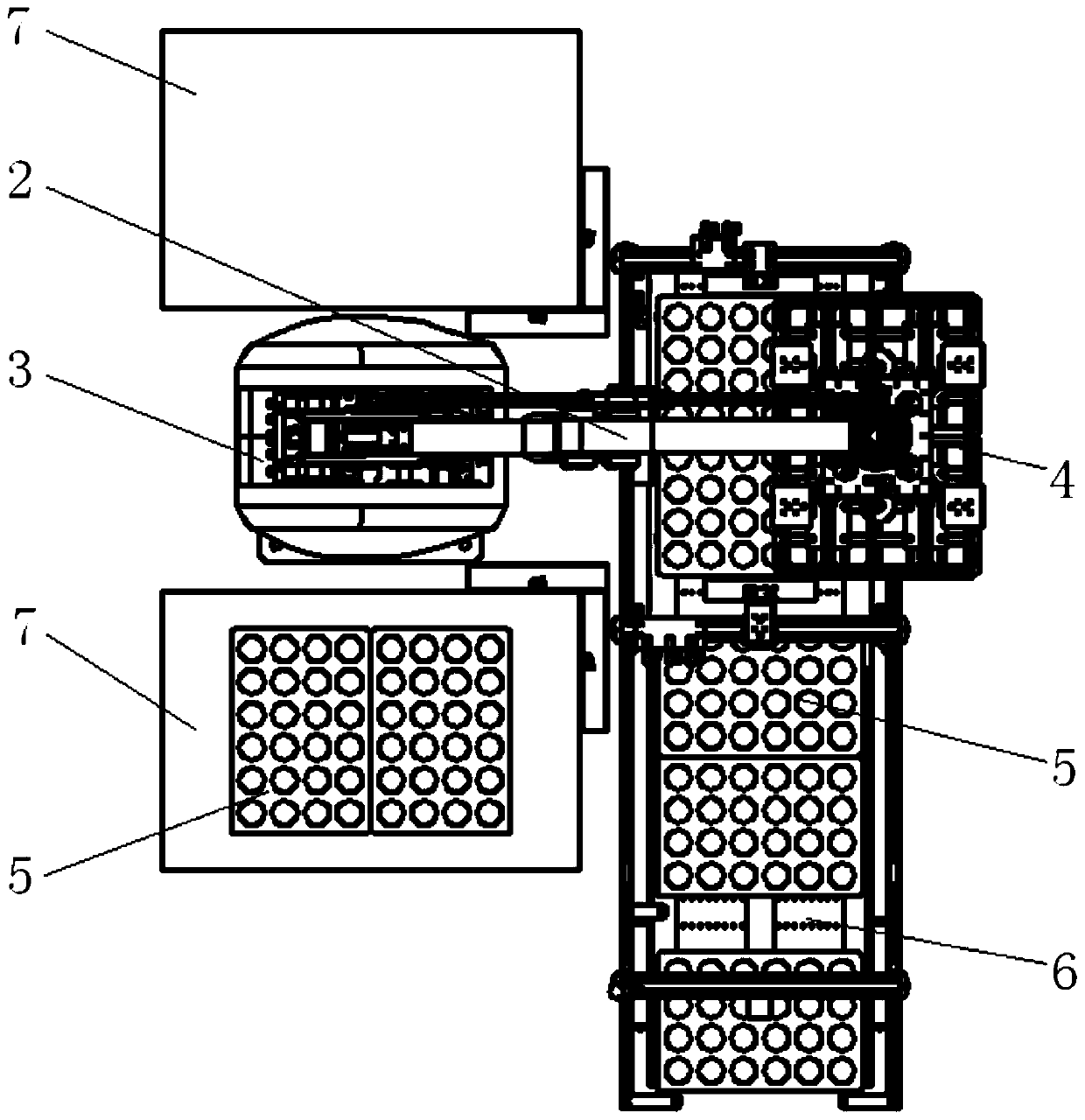

Tray grabbing mechanism of bread tray collecting machine and bread tray collecting machine

PendingCN110817431AImprove grasping accuracyImprove gripConveyorsControl devices for conveyorsEngineeringMechanical engineering

The invention discloses a tray grabbing mechanism of a bread tray collecting machine. The tray grabbing mechanism comprises a grabbing framework, a plurality of electromagnetic chucks are arranged onthe lower surface of the grabbing framework, and correspond to positions of protrusions on backs of trays, and separating air cylinders are furthermore arranged on the grabbing framework and used forachieving separation of the trays and the electromagnetic chucks when the electromagnetic chucks are powered off. At least one electromagnetic chuck set is arranged on the lower surface of the grabbing framework, and each electromagnetic chuck set corresponds to one tray, and comprises 12 chucks. The invention furthermore discloses the bread tray collecting machine. The bread tray collecting machine comprises the tray grabbing mechanism, a tray positioning and clamping device, a sensor detection mechanism and an abnormal tray monitoring mechanism. According to the tray grabbing mechanism, theelectromagnetic chucks correspond to the positions of the protrusions on the backs of the trays, and the tray grabbing precision is improved. Moreover, through the separating air cylinders, the problem that the trays cannot be quickly separated from the chucks due to the phenomenon of magnetic hysteresis is also effectively solved. The tray grabbing mechanism is precise in tray positioning, high in grabbing efficiency, capable of timely handling the occurrence of abnormal conditions, and high in automation degree.

Owner:北京市粮食科学研究院有限公司 +1

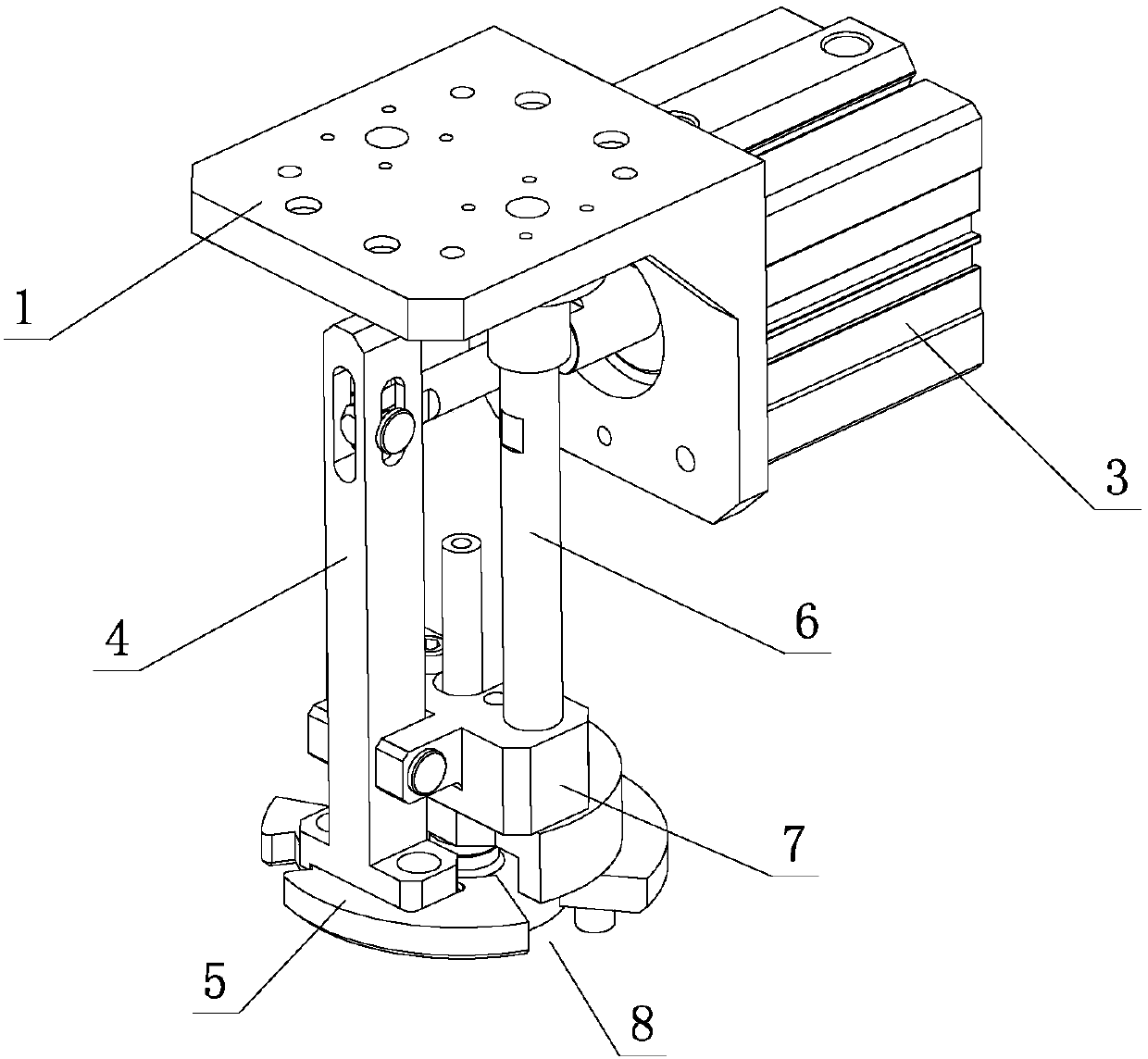

Grinding clamp for lamp cooling fin

ActiveCN107932323AAchieve clamping positioningAvoid dangerGrinding work supportsEngineeringHeat sink

A grinding clamp for a lamp cooling fin comprises a clamp body and a to-be-machined product. A power air cylinder, a connecting rod assembly and a positioning assembly are arranged on the clamp body.The power air cylinder and the connecting rod assembly are in driving connection. The connecting rod assembly is movably arranged on the clamp body through driving of the power air cylinder, and is matched with the positioning assembly during moving so that the to-be-machined product can be clamped or loosened. Through the above structure improvement, a movable piece is driven to swing into an empty part firstly, accordingly, the periphery size of the work position is smaller than that of the to-be-machined product, then, a suction cup is used for sucking the to-be-machined product, then, themovable piece is driven to swing to the empty part, the periphery of the work position is equivalent to the periphery size of the to-be-machined product, and accordingly, clamping and positioning of the to-be-machined product can be achieved. The grinding clamp has the beneficial effects that the structure is simple and reasonable, performance is excellent, operation is convenient, the manufacturing cost is low, production and achieving are easy, full automation and intelligence are achieved, the production efficiency is high, and safety and reliability are achieved; and practicability is high.

Owner:GUANGDONG LXD ROBOTICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com