Guard bar cutting device

A cutting device and guardrail technology, which is applied in the direction of sawing machine, sawing machine accessories, metal sawing equipment, etc., can solve the problems of low cutting quality, different pipe materials, and pipe shaking, etc., so as to improve the cutting quality and cut the length accurately , Improve the effect of cutting precision

Active Publication Date: 2018-06-08

临沂经济开发有限公司

View PDF6 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The above solution can realize the fixed-length cutting of the pipe, but the length of the pipe required in actual production is often different; and the device directly cuts the pipe without clamping the pipe, which will cause the pipe to shake, so that the cutting quality is not high , may also lead to security issues

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

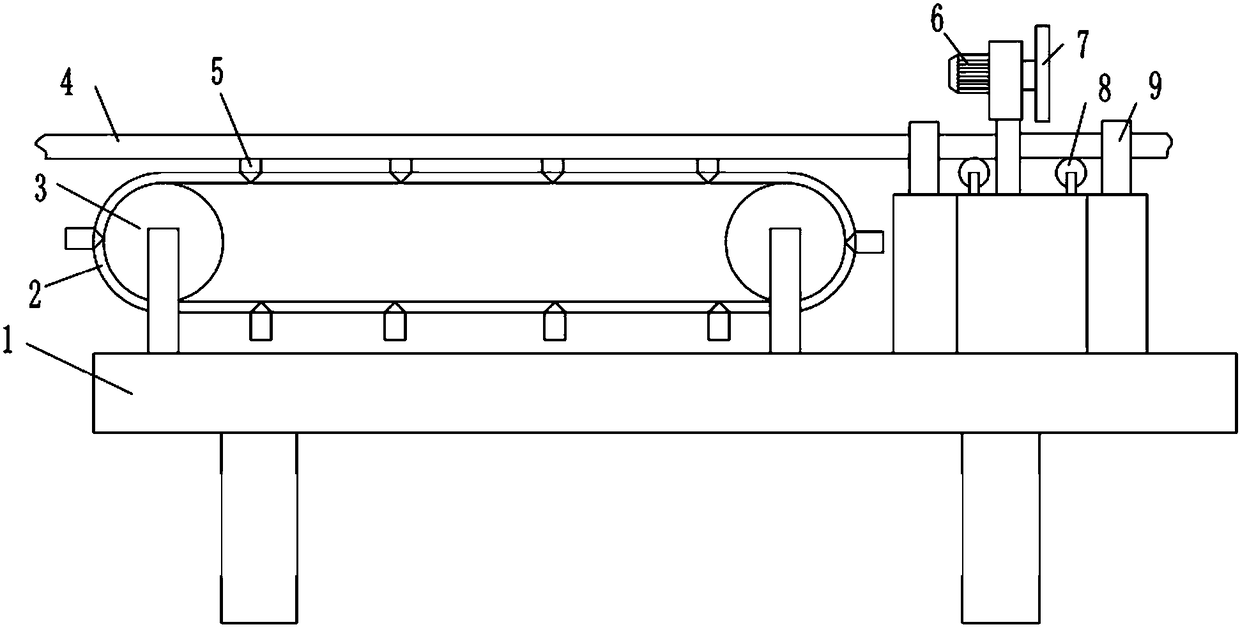

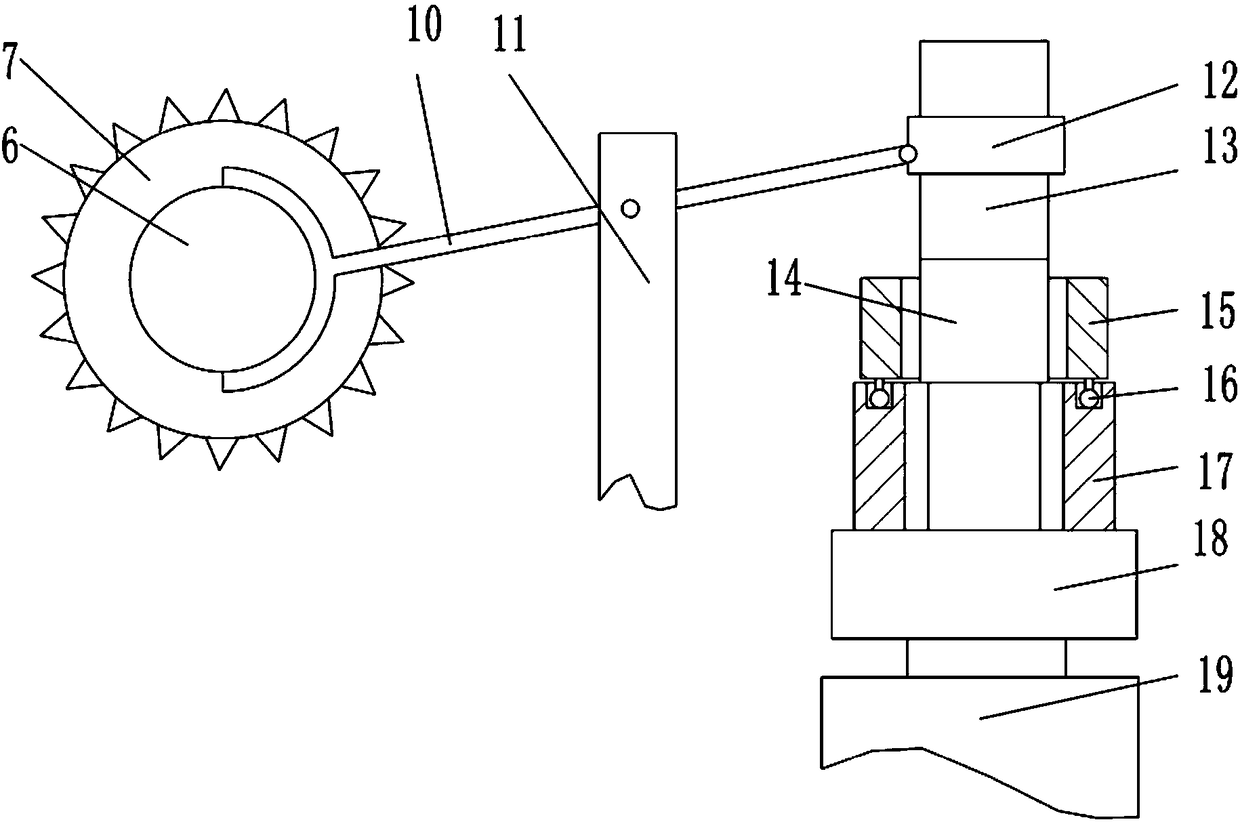

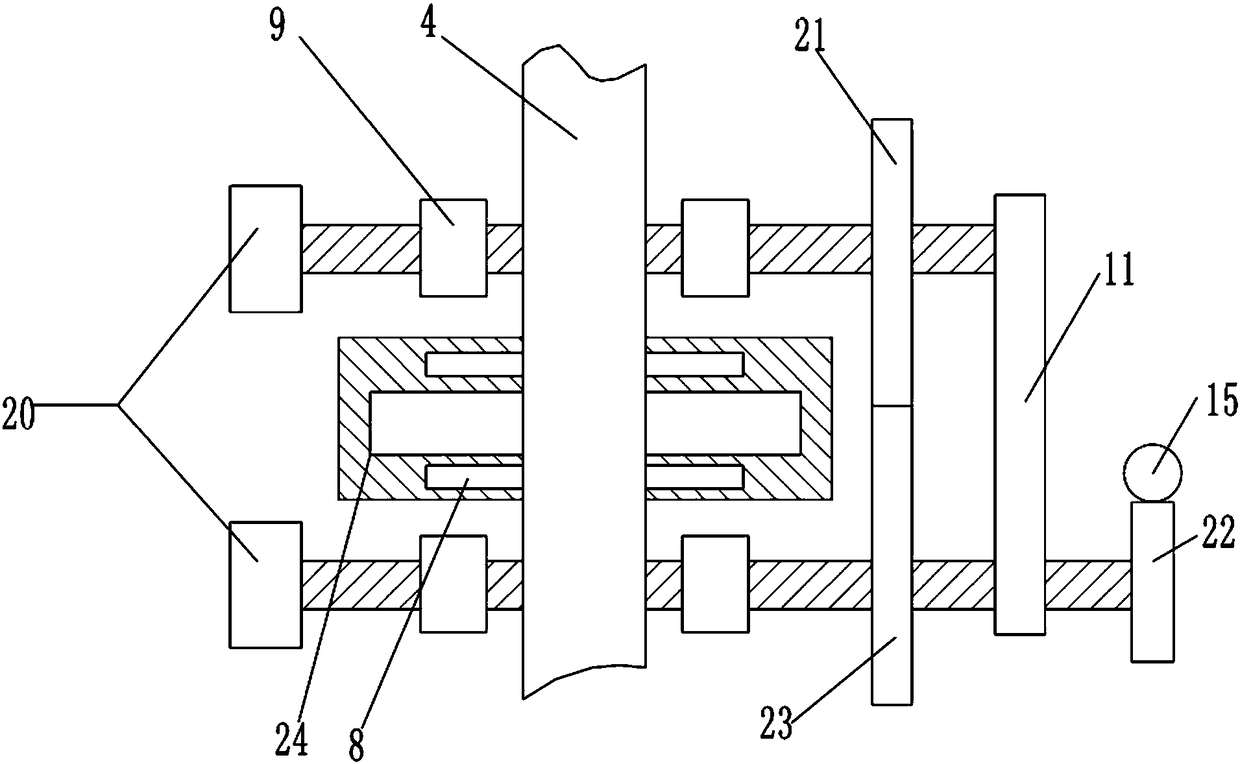

The invention belongs to the technical field of guard bar machining, and particularly discloses a guard bar cutting device. The device includes a worktable, and a conveying mechanism used for conveying pipe materials and a cutting mechanism used for cutting the pipe materials are arranged on the worktable. The conveying mechanism includes a conveyor belt, multiple V-shape locating blocks are movably connected to the conveyor belt, and each V-shaped locating block is provided with an approaching switch. The cutting mechanism includes a supporting frame and a second motor, an output shaft of thesecond motor is fixedly provided with an air expanding shaft, and a worm sleeves the air expanding shaft. A first lead screw is arranged on the air expanding shaft, and a first nut support is screwedwith the first lead screw. A connecting rod is hinged to the first nut support and the supporting frame and provided with the cutting mechanism. A worm gear is meshed with the worm, a bidirectional lead screw is connected to the center of the worm gear, second nut supports are screwed at both ends of the bidirectional lead screw, and clamping blocks are connected to both the two second nut supports. According to the scheme, cutting of the pipe materials can be achieved according to different length demands, and high cutting quality is ensured.

Description

technical field [0001] The invention belongs to the technical field of guardrail processing, and in particular relates to a guardrail cutting device. Background technique [0002] Guardrails are mainly used for the protection and protection of equipment and facilities in factories, workshops, warehouses, parking lots, commercial areas, public places and other occasions. Guardrails can be seen everywhere in our lives. The columns of the guardrail are fixed to the ground by expansion bolts. It is usually installed on both sides of the logistics channel, around the production equipment, in the corner of the building, on both sides of the door and the edge of the cargo platform, etc. Effectively reduce the damage to equipment and facilities caused by accidental impact when transporting equipment back and forth. Guardrail materials include: aluminum alloy, malleable steel (ductile iron), carbon steel (sprayed or galvanized), stainless steel, plastic steel, zinc steel, PVC and ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23D47/02B23D59/02B23Q17/00

Inventor 周强周琪

Owner 临沂经济开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com