Patents

Literature

63results about How to "Cut to exact length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

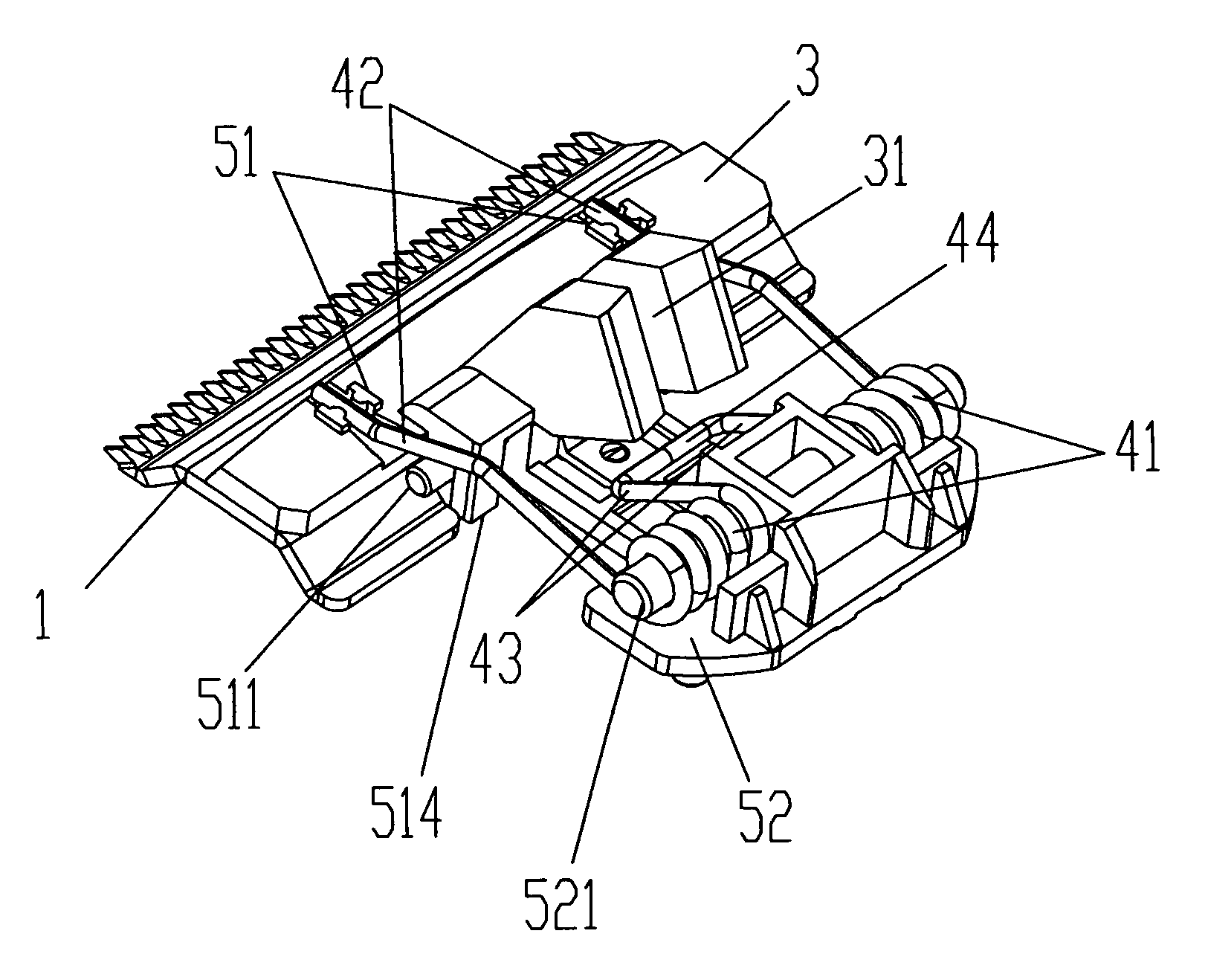

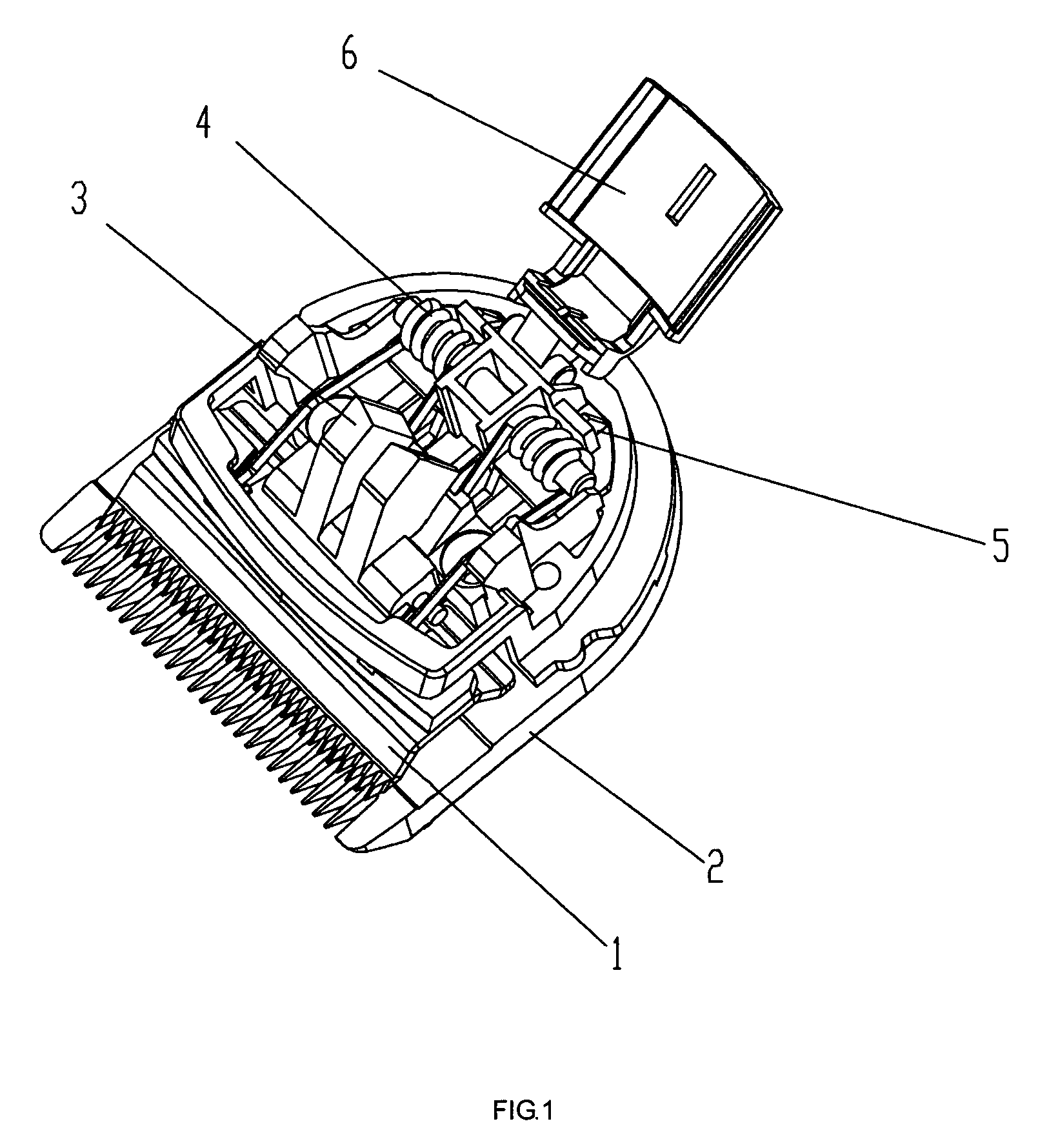

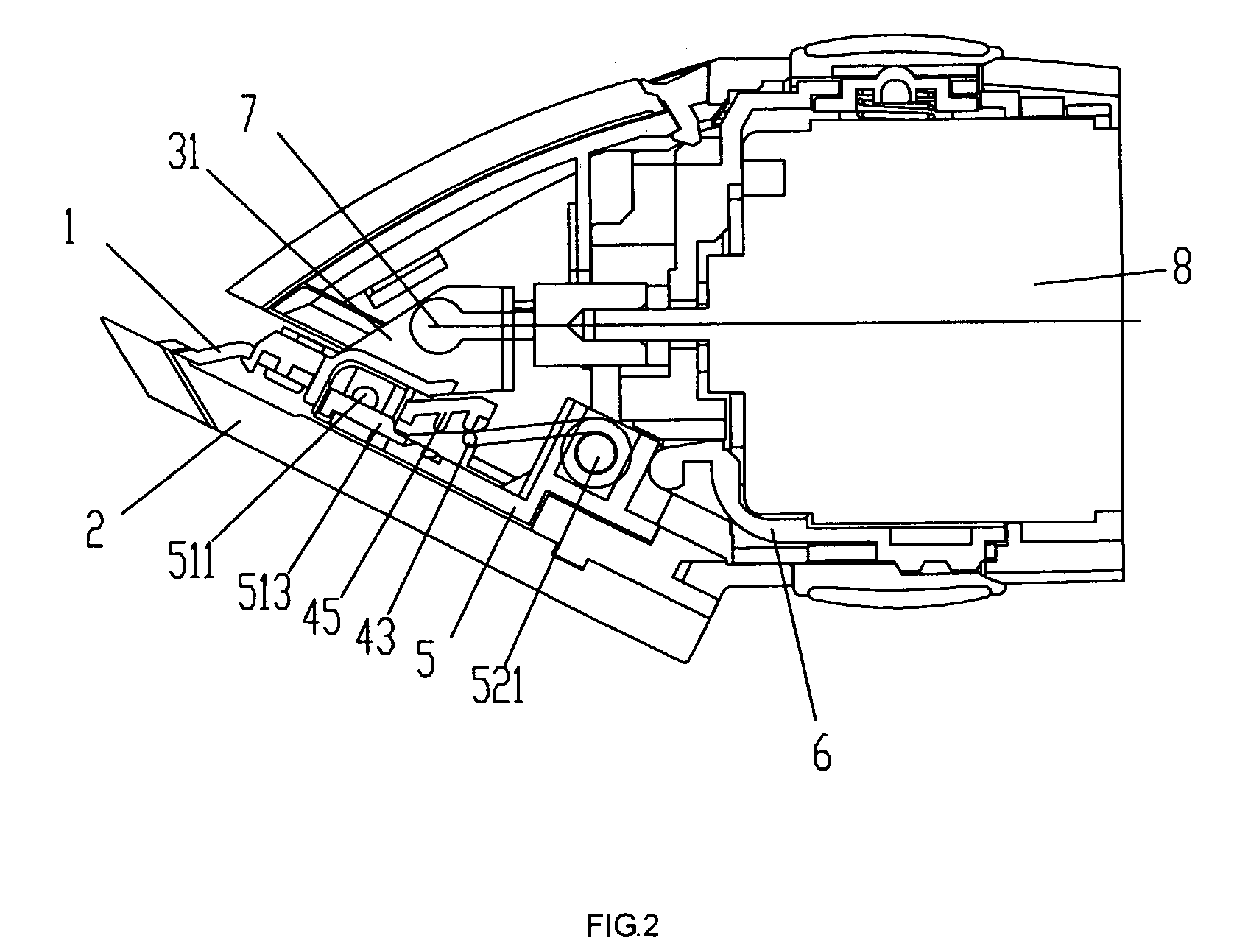

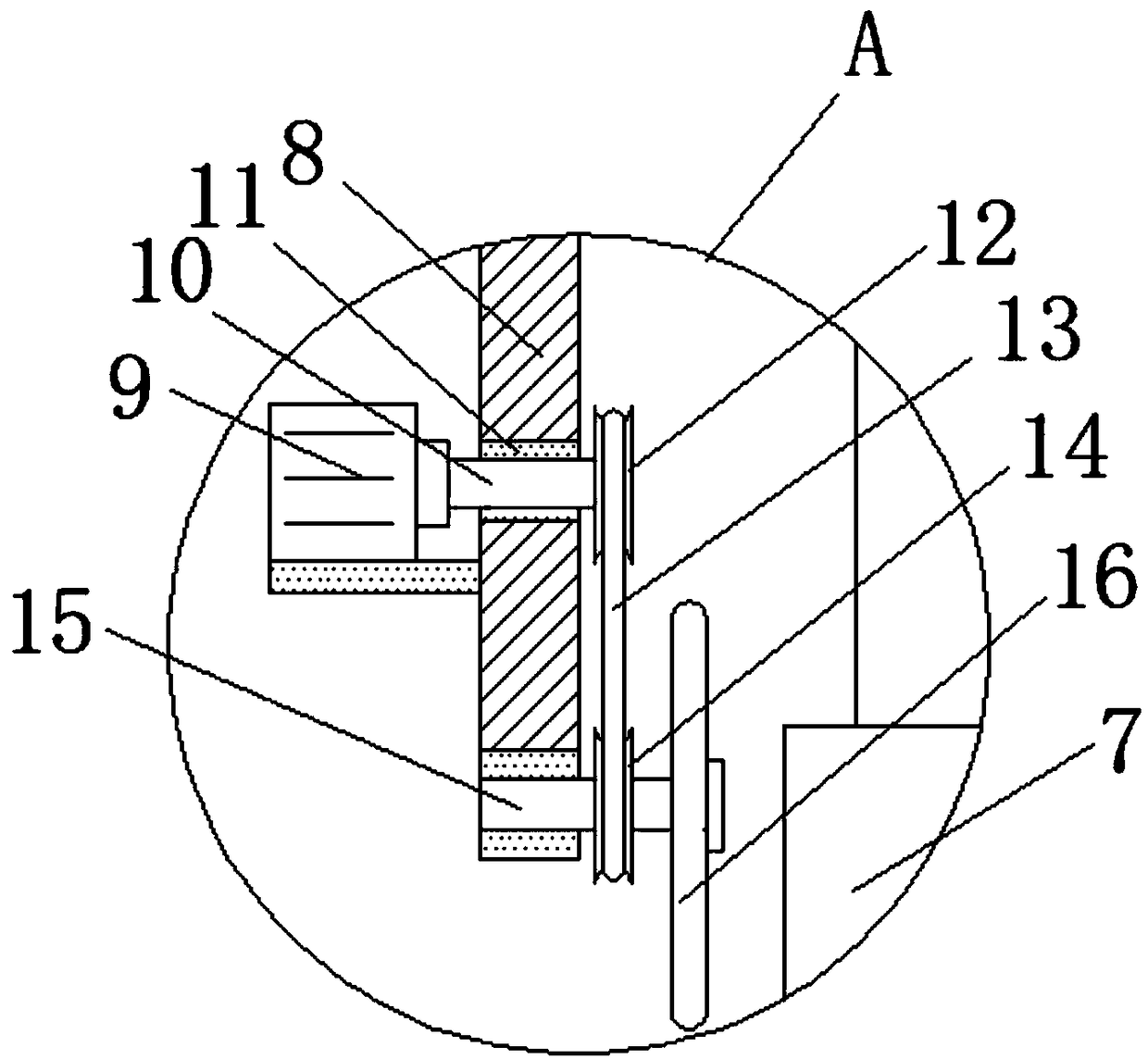

Blade driving assembly for an adjustable hair clipper

InactiveUS7703210B2Simple structureCut to exact lengthMetal working apparatusKnife bladesHair clipper

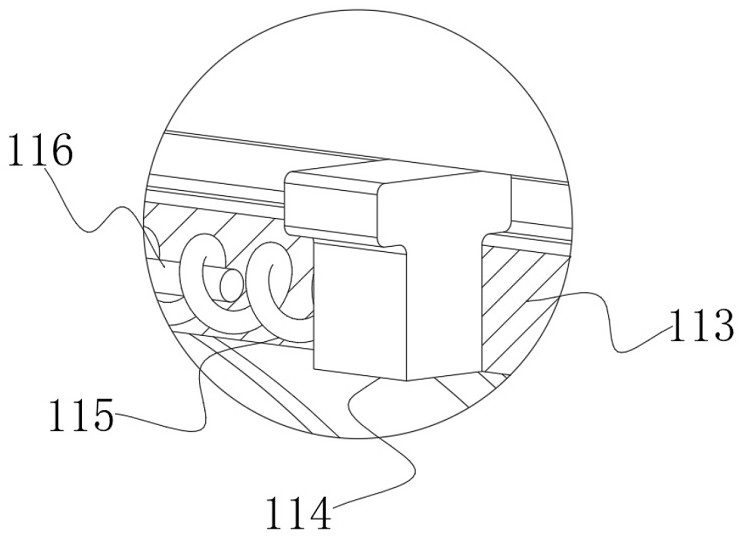

A blade driving assembly for an adjustable hair clipper of the present invention comprises a movable blade holder, a spring, a spring holder and a push lever. The spring is disposed with a coiled portion secured on the spring holder, a first portion which exerts pressure upon the movable blade holder to bias the movable blade towards the stationary blade and a second portion which biases the spring holder towards a retracted position. The push lever is driven to move forward or backward by an external force, and a front end of the push lever abuts against the rear end of the spring holder in such a way to push the spring holder forward when the push lever is driven forward, and when the push lever is driven backward, the spring holder is biased by the spring to retract until the rear end thereof abuts against the push lever.

Owner:SPECIALIFE INDS

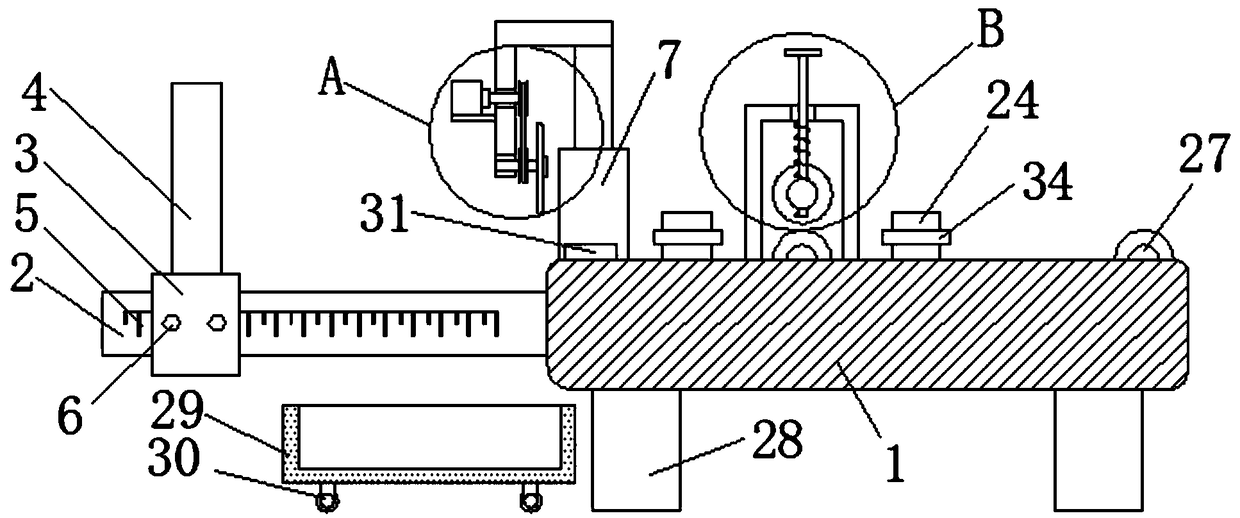

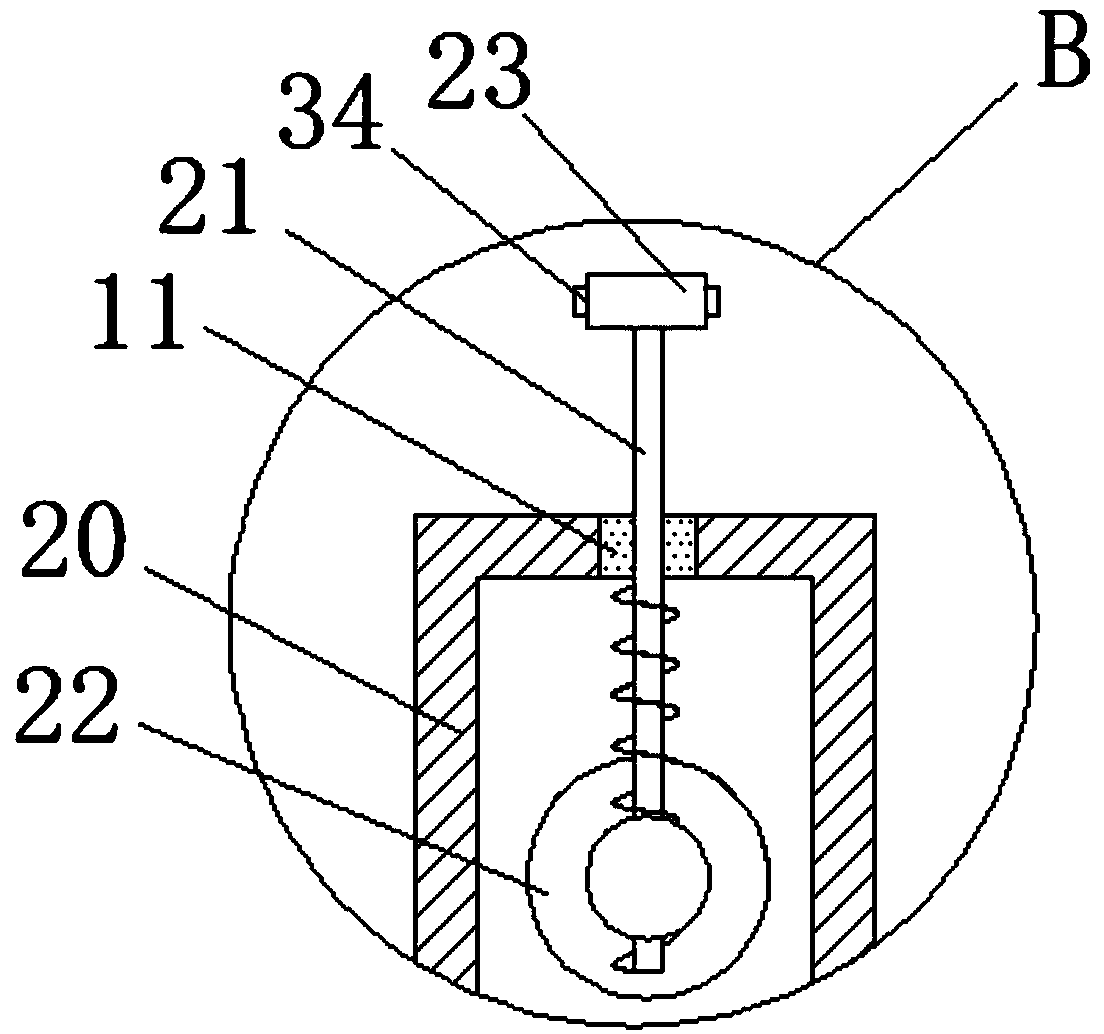

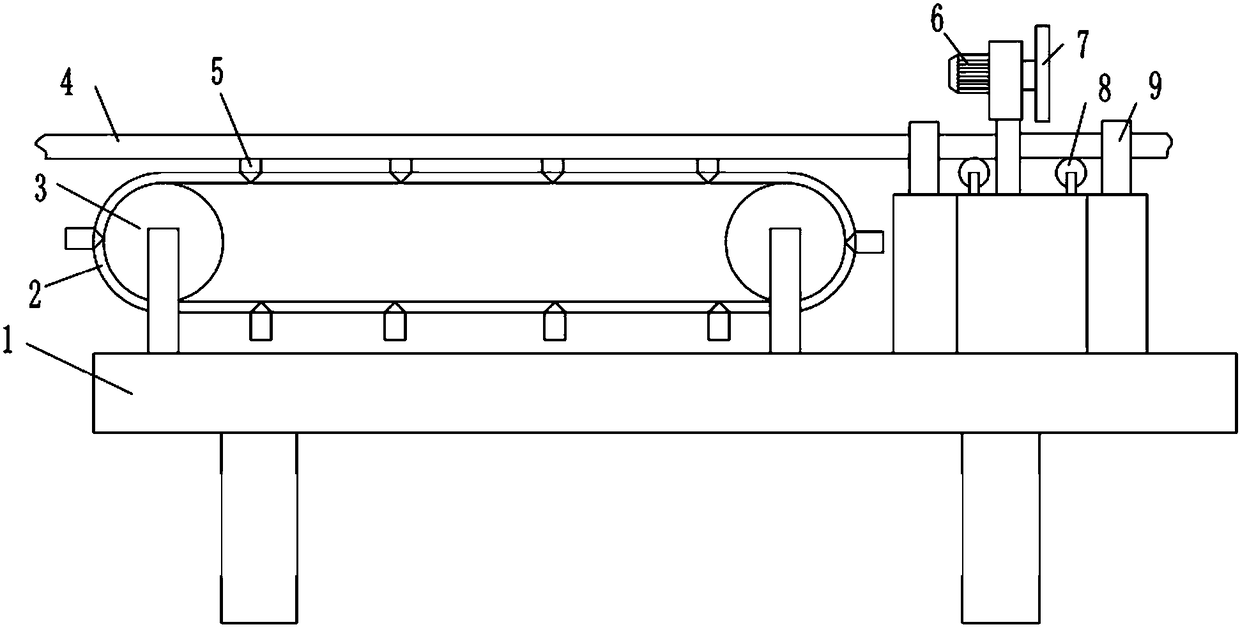

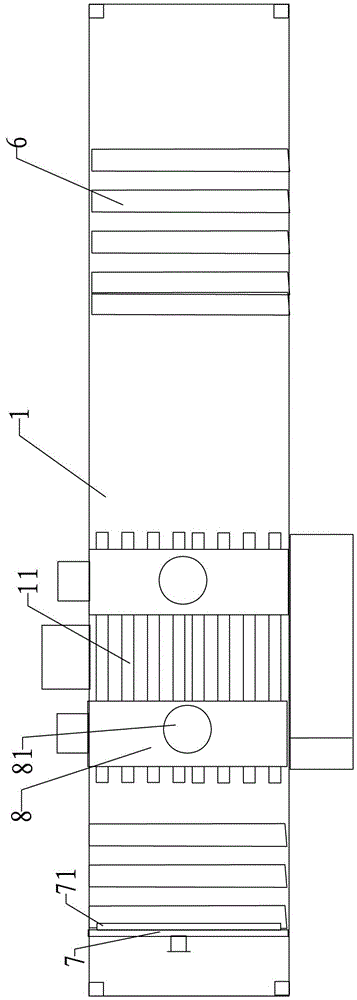

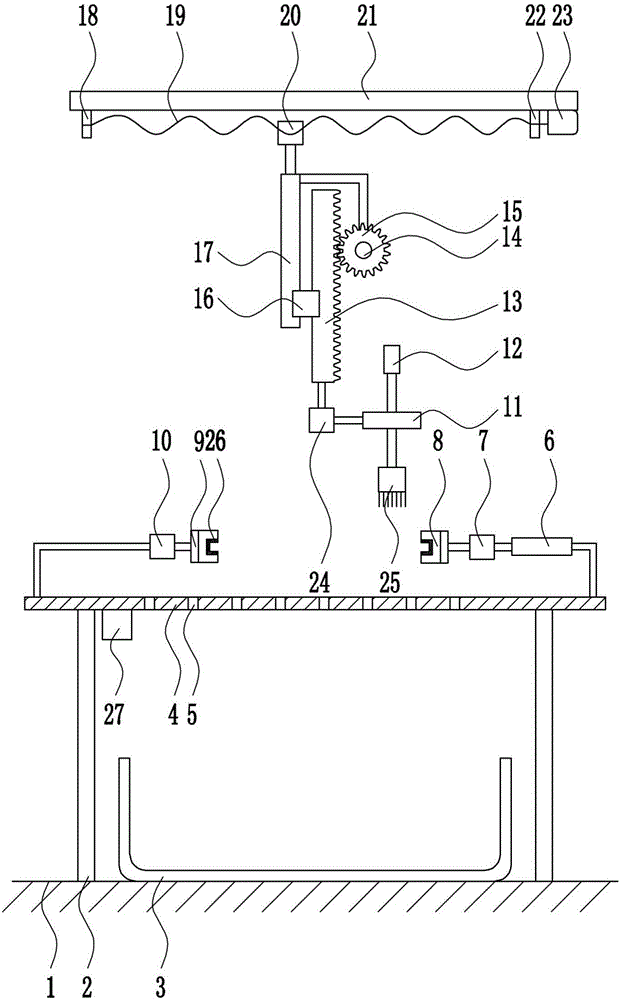

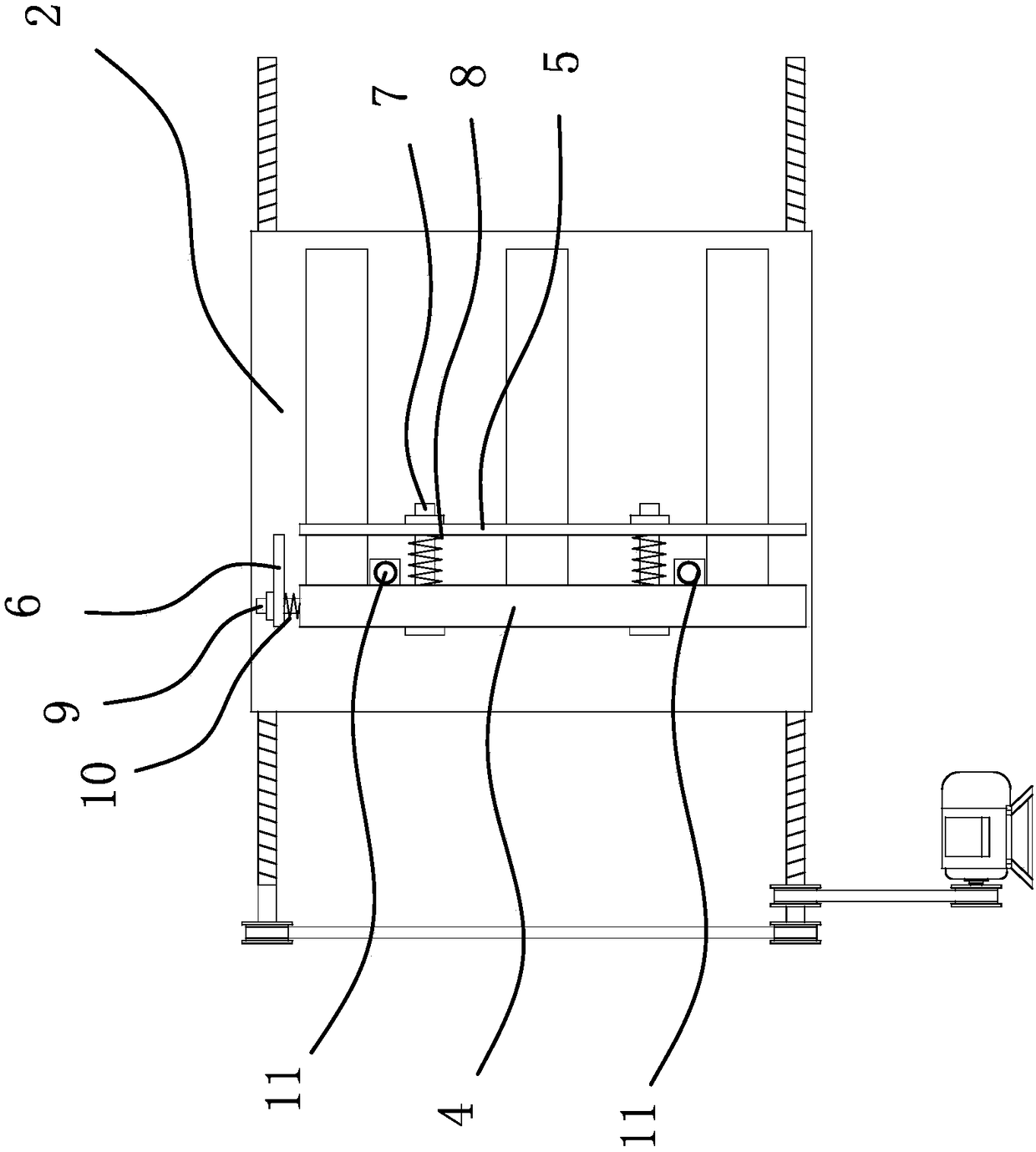

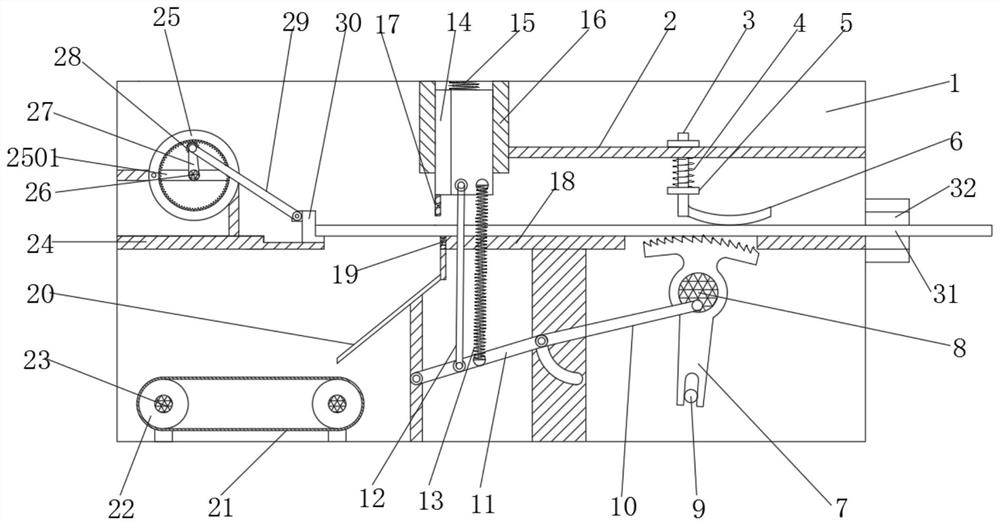

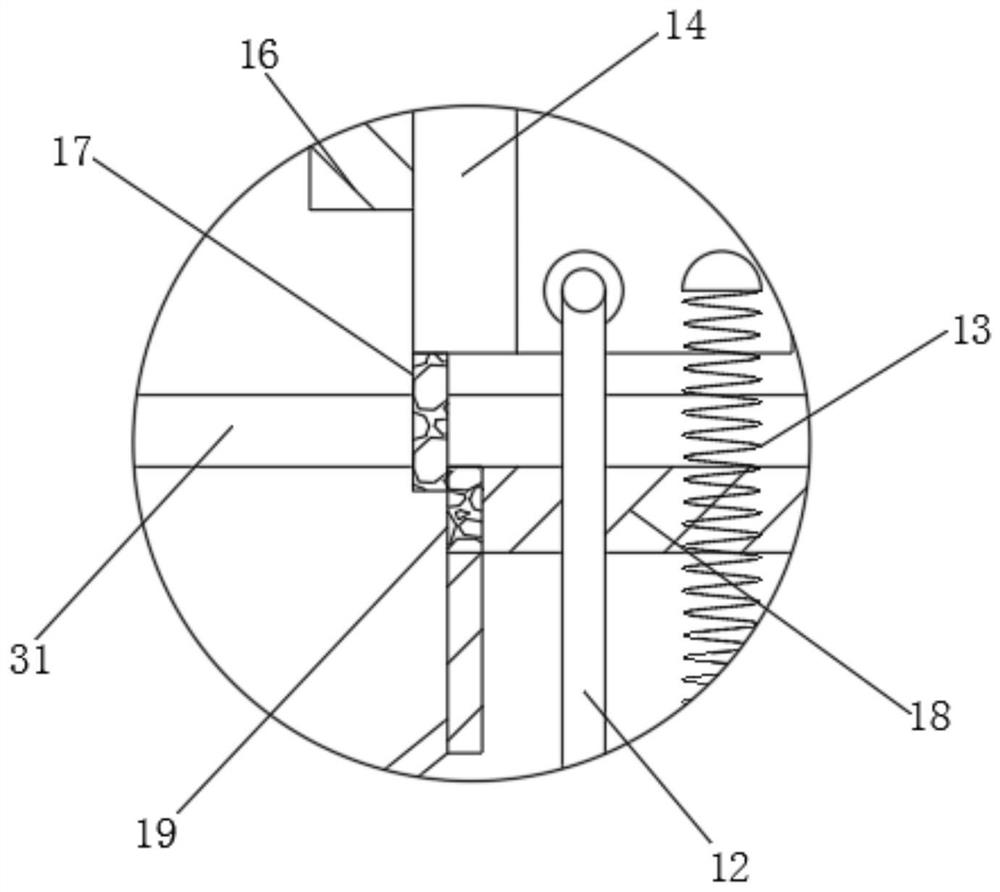

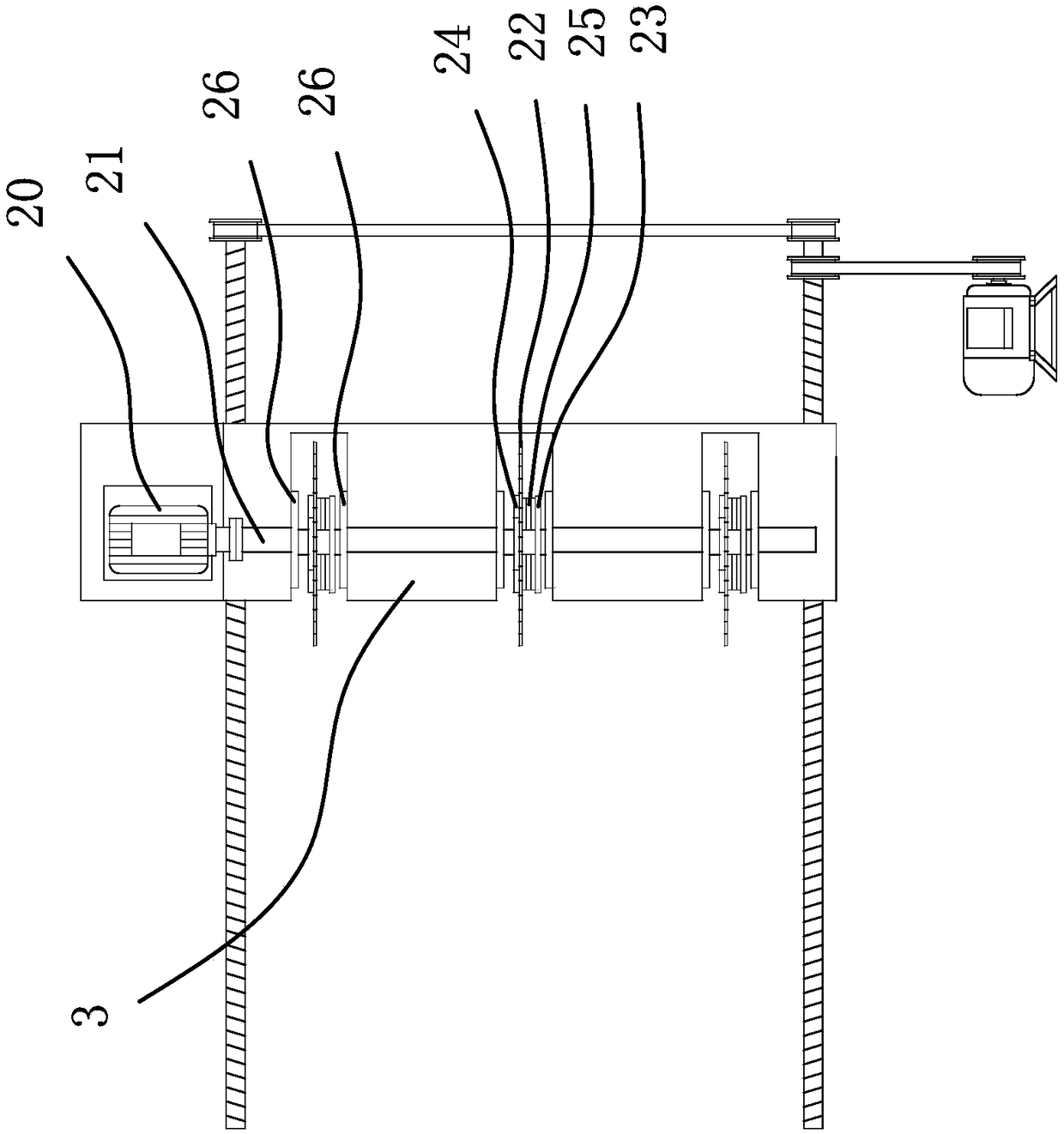

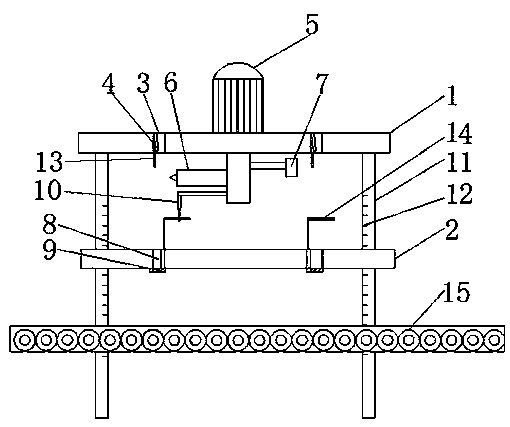

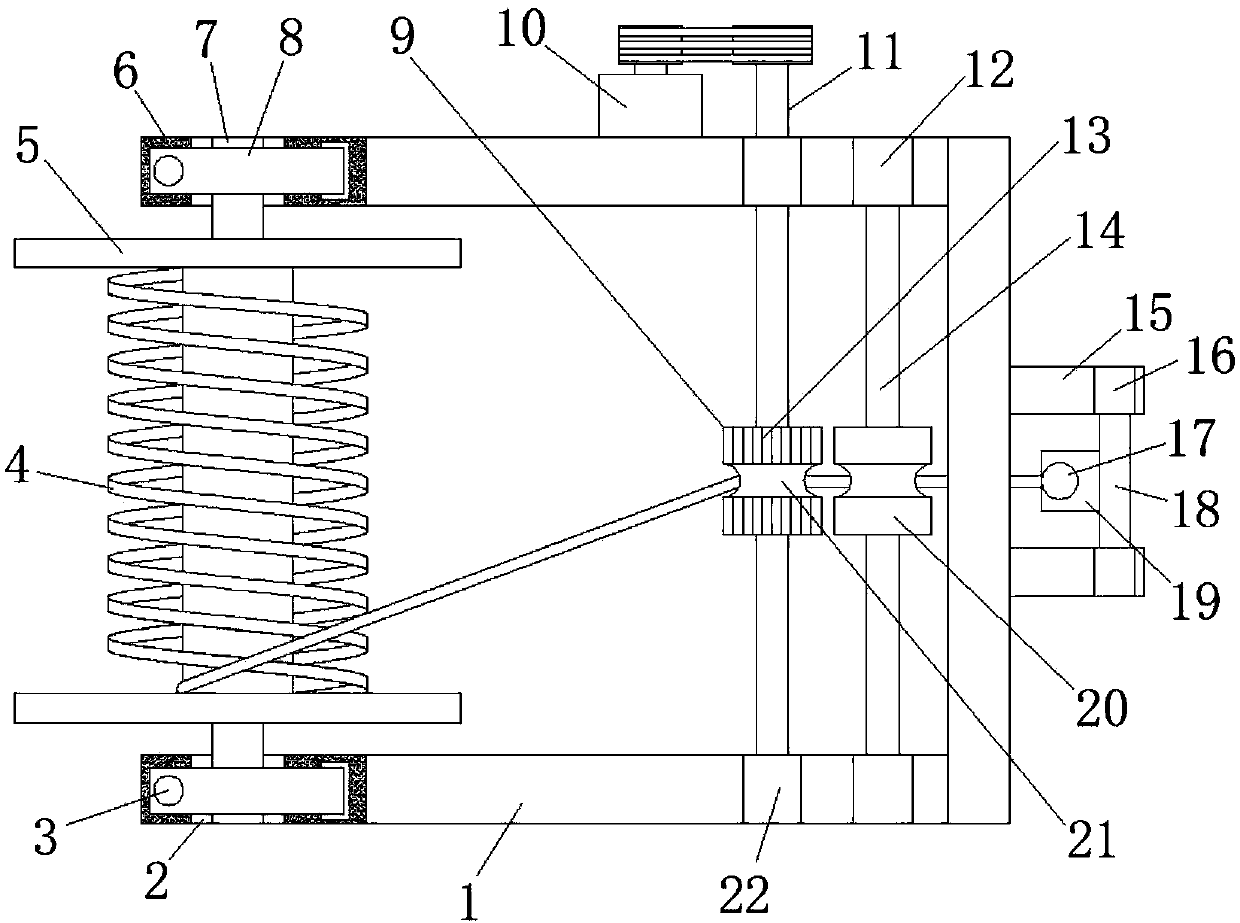

Steel bar cropping machine with cropping size precisely-adjusting function for construction industry

InactiveCN108971394AEasy to moveControl cutting lengthMetal working apparatusArchitectural engineeringRebar

The invention discloses a steel bar cropping machine with a cropping size precisely-adjusting function for the construction industry. The steel bar cropping machine comprises a base, one end of the base is fixedly connected with two sets of sliding rails, a first motor is mounted on one side of the lower end of an L-shaped fixing plate, a first rotating shaft is fixedly connected to an output shaft of the first motor, and the first rotating shaft is mounted on one side of the L-shaped fixing plate through a bearing; and the interior of a fixing block is in threaded connection with a second lead screw, and a clamping plate is mounted at one end of the second lead screw through a bearing. The two sets of sliding rails are mounted at one end of the base, and thus a baffle can slide on the sliding rails through sliding blocks; the sliding blocks are fixed to the sliding rails through screws, and meanwhile, moving of the sliding blocks is also facilitated; and the sliding blocks are moved through a graduated scale on one side of the corresponding sliding rail according to the steel bar cutting length, thus the baffle can abut a steel bar, the cutting length of the steel bar is controlled, and thus the cutting length of the steel bar is more precise.

Owner:潍坊华高信息科技有限公司

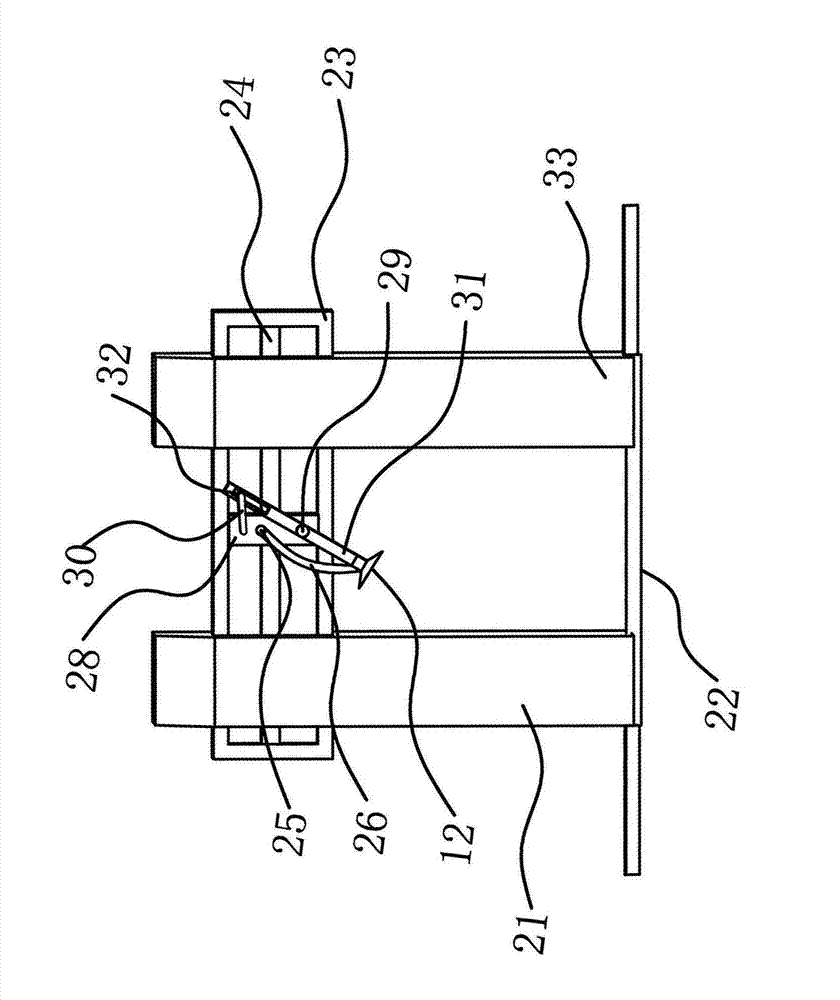

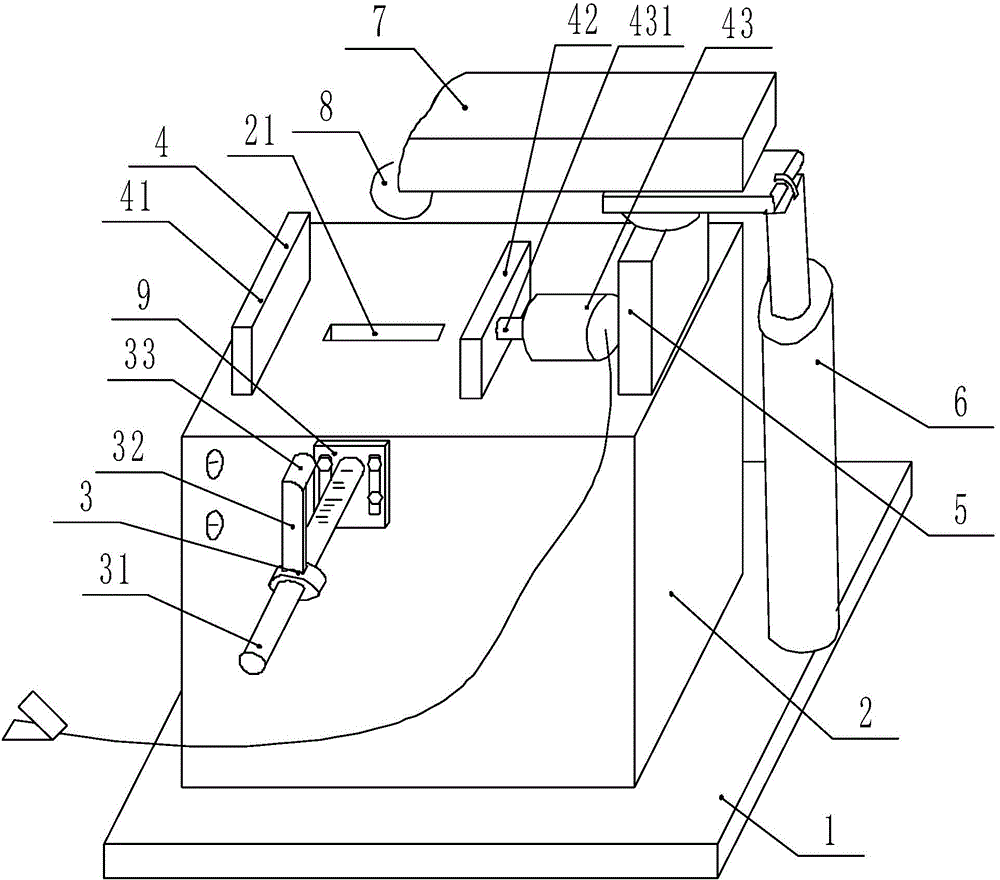

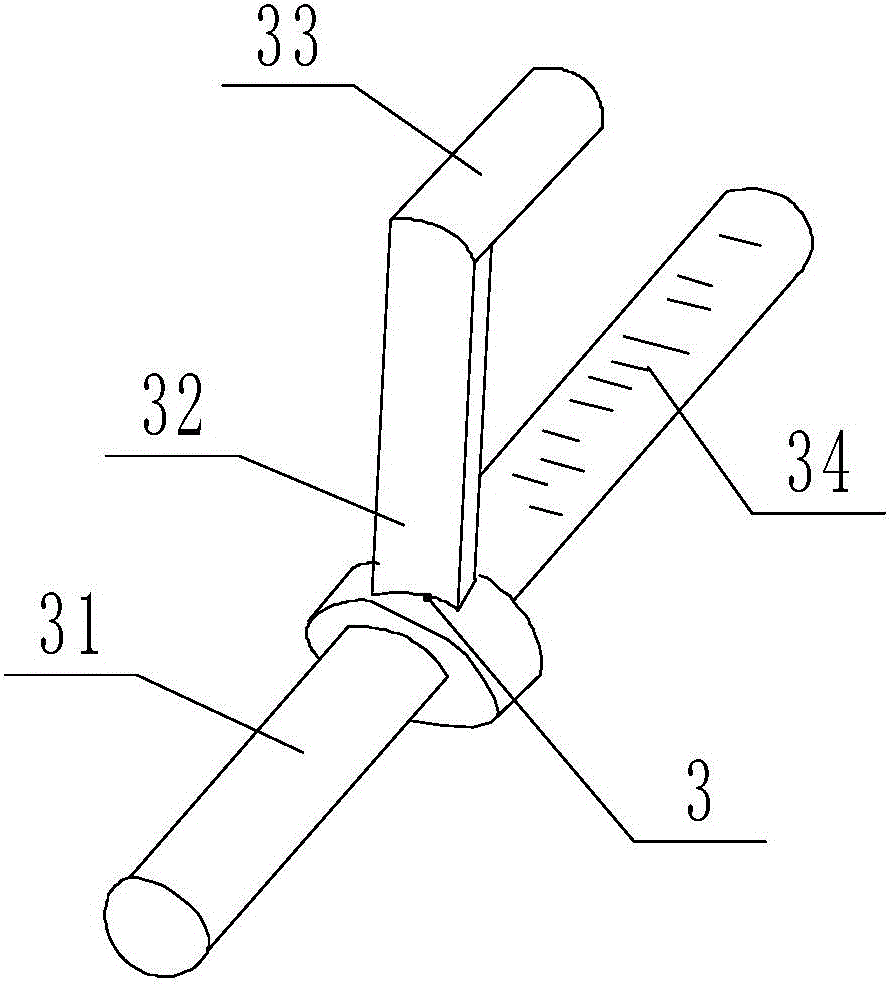

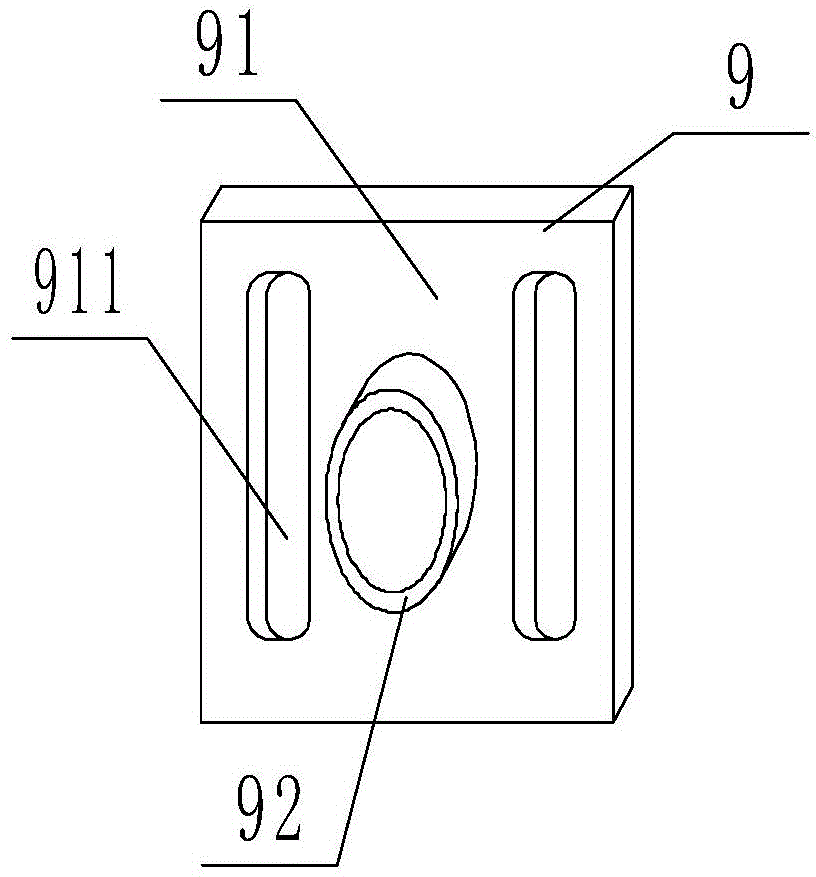

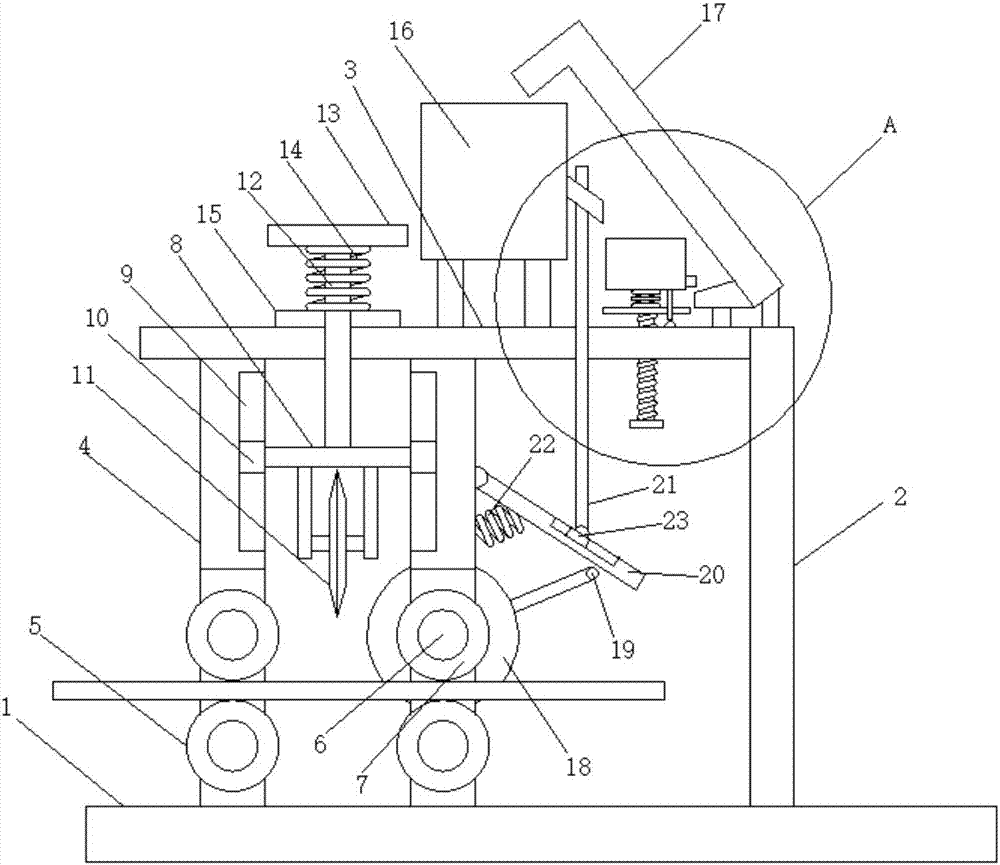

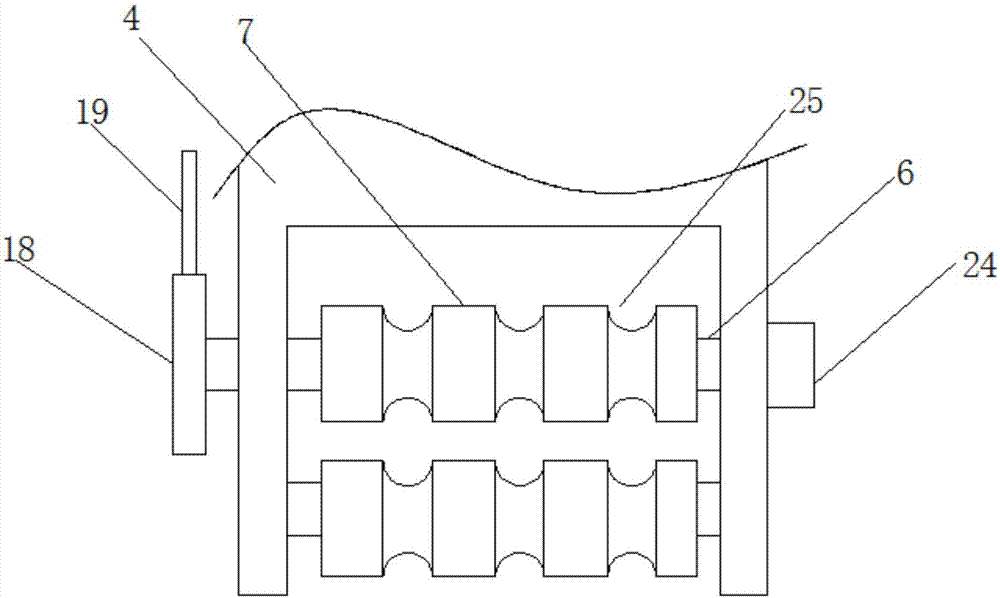

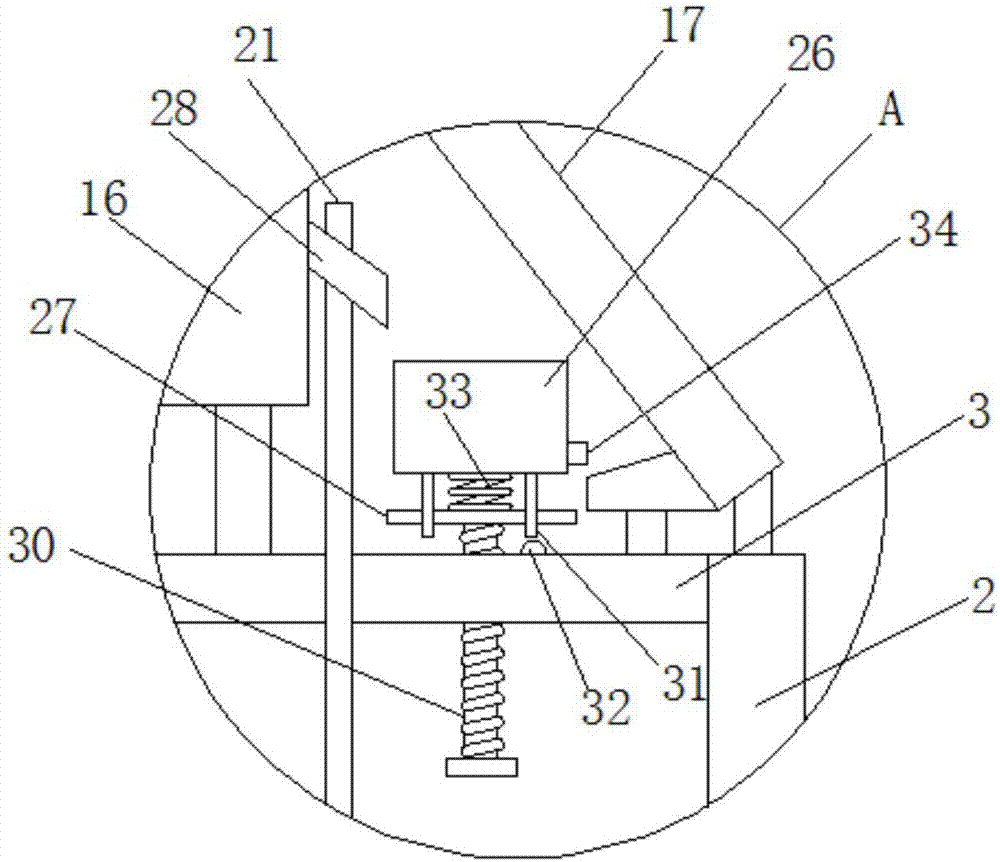

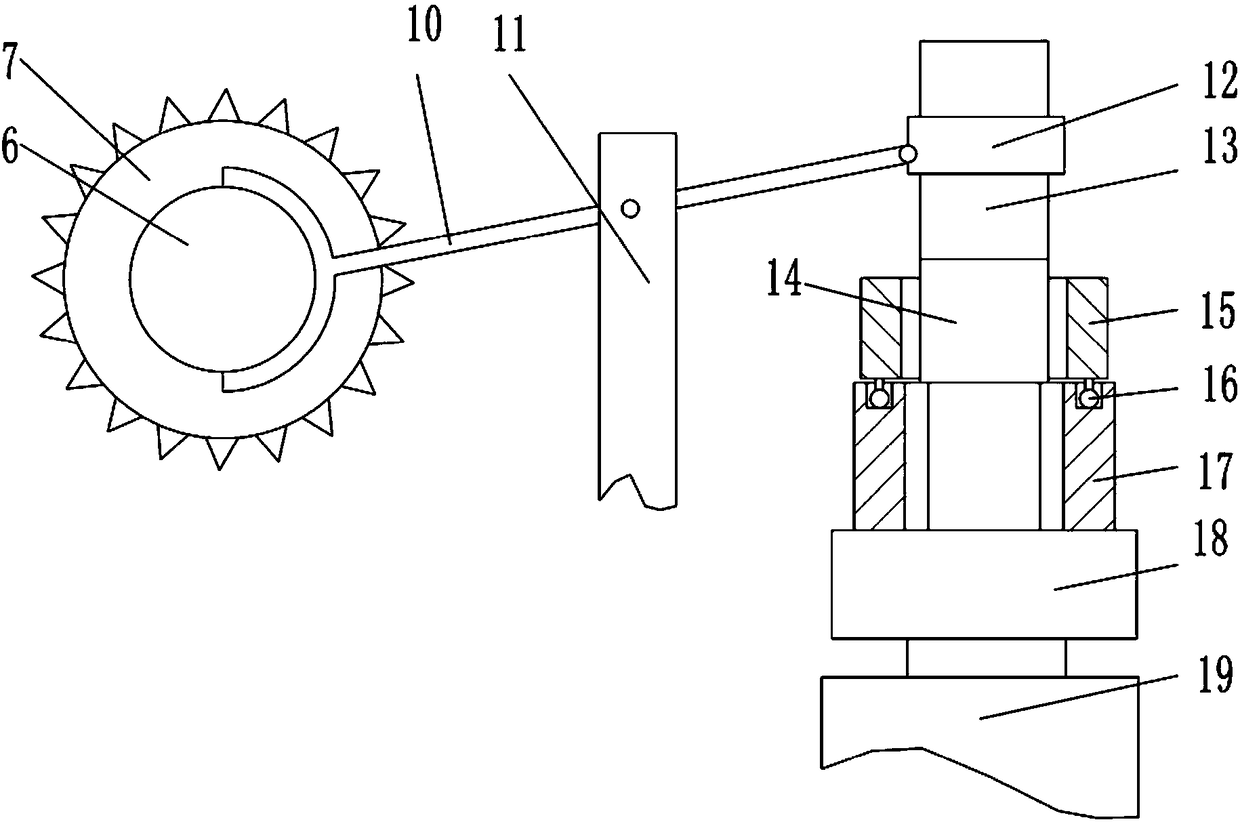

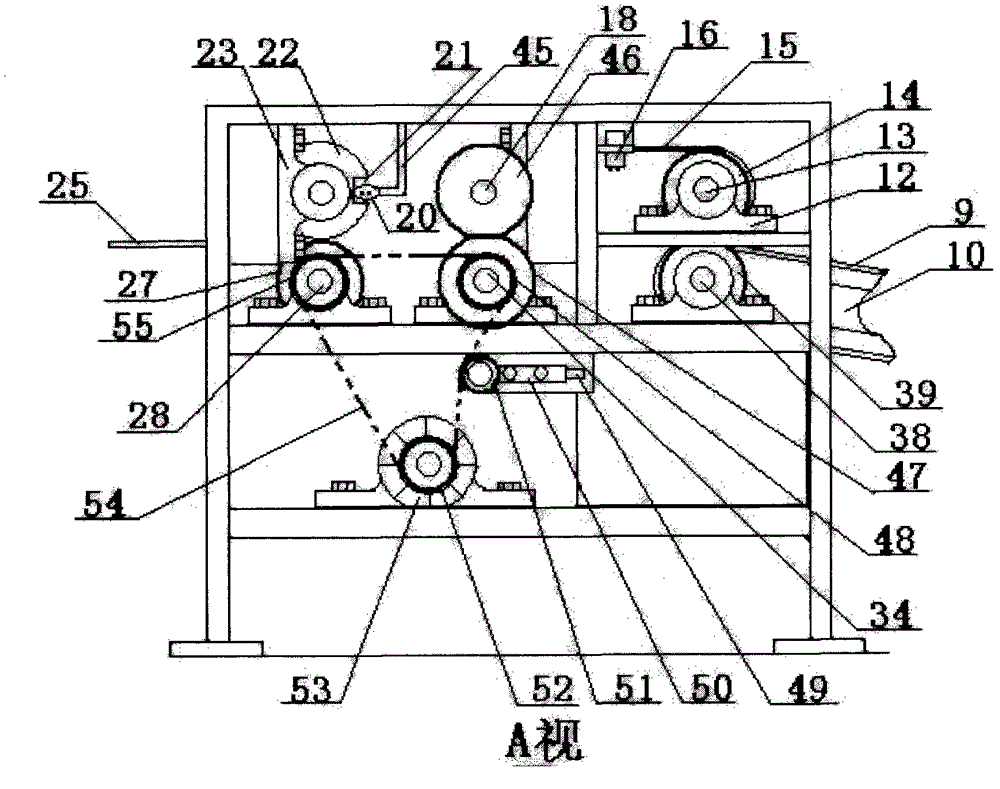

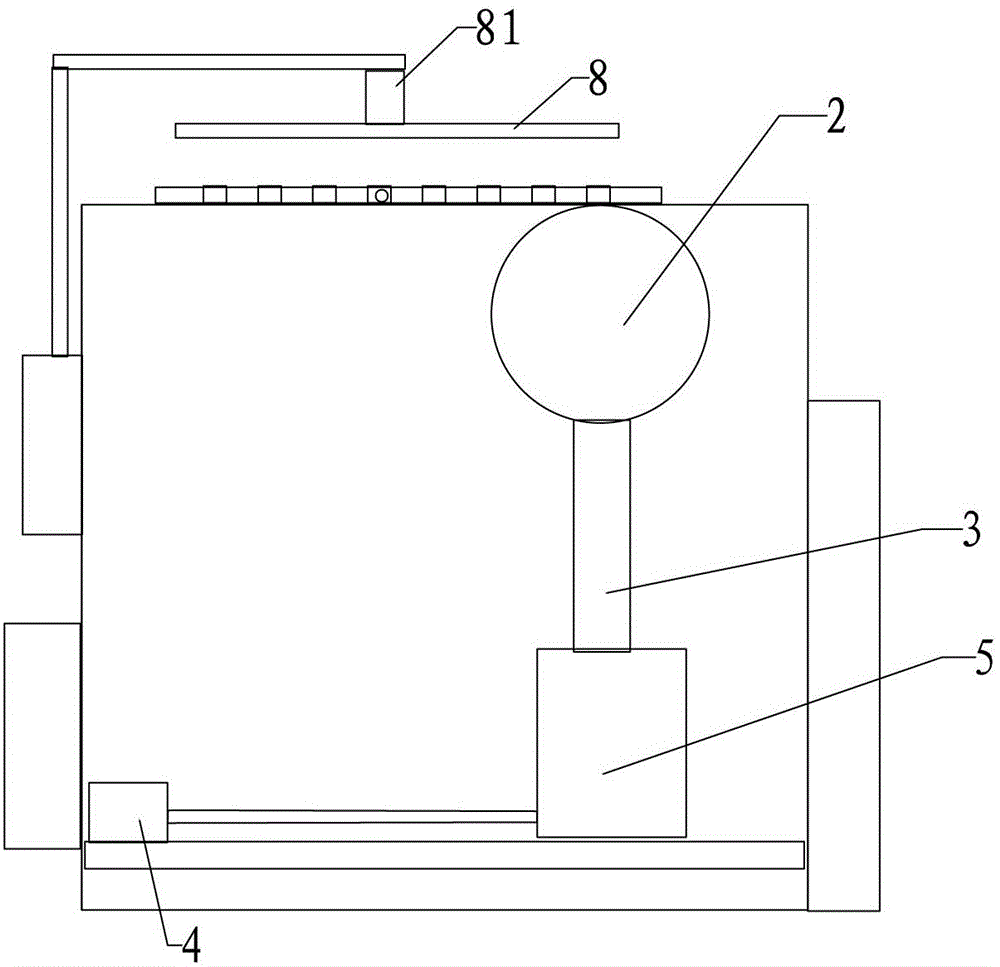

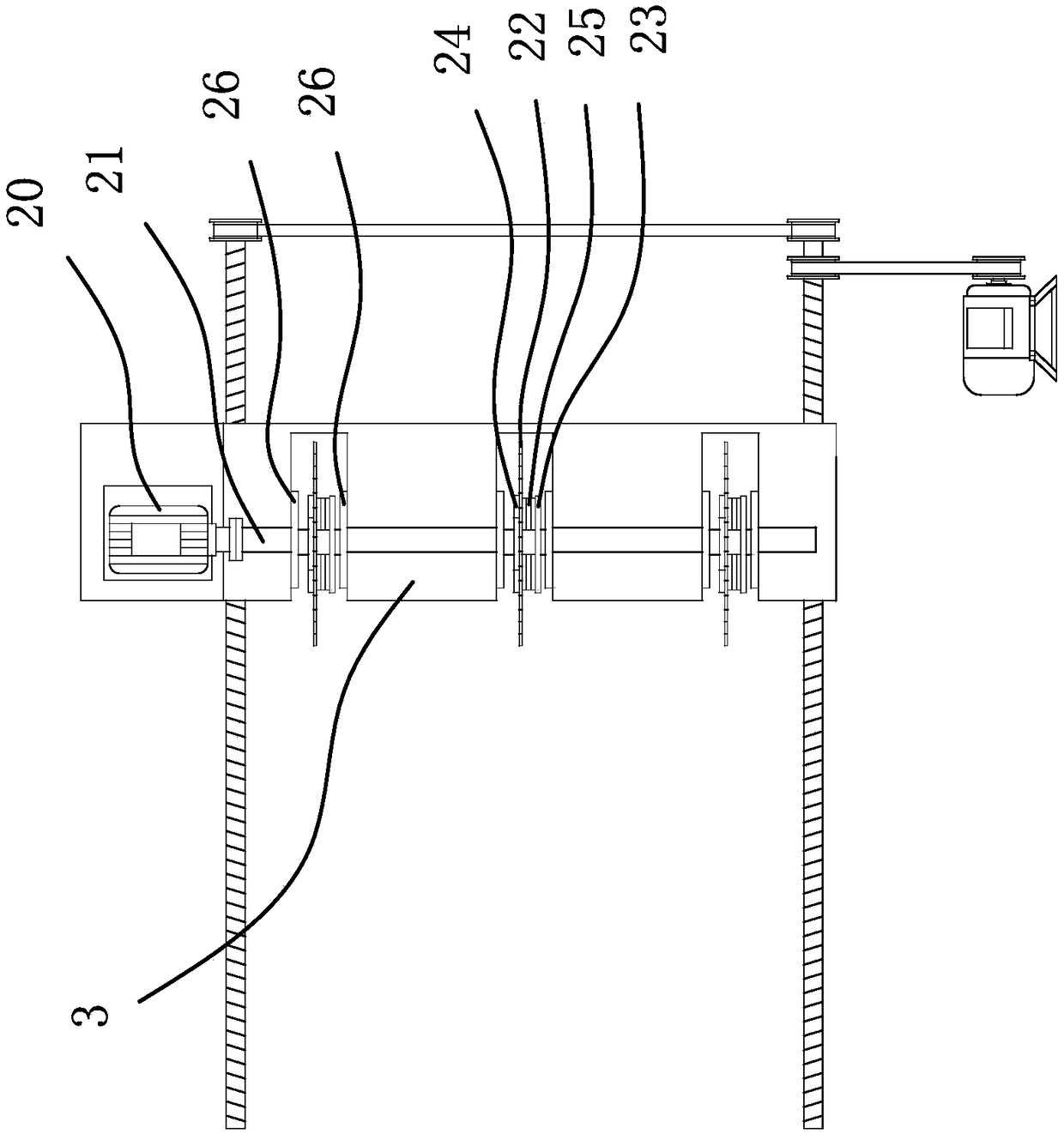

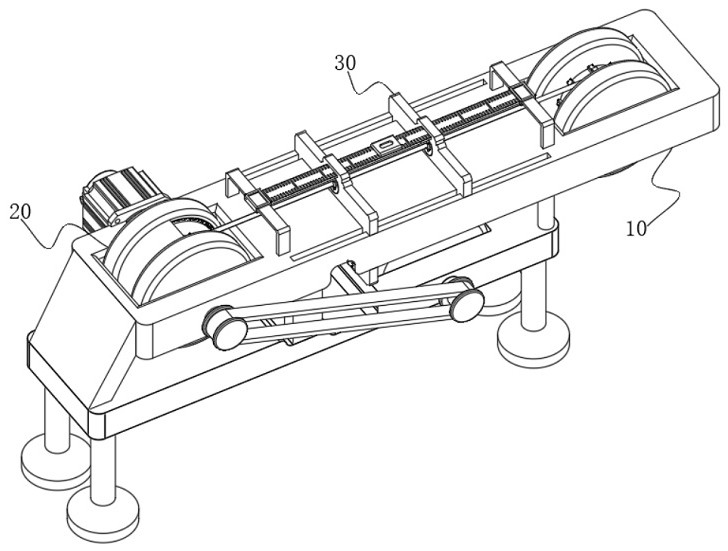

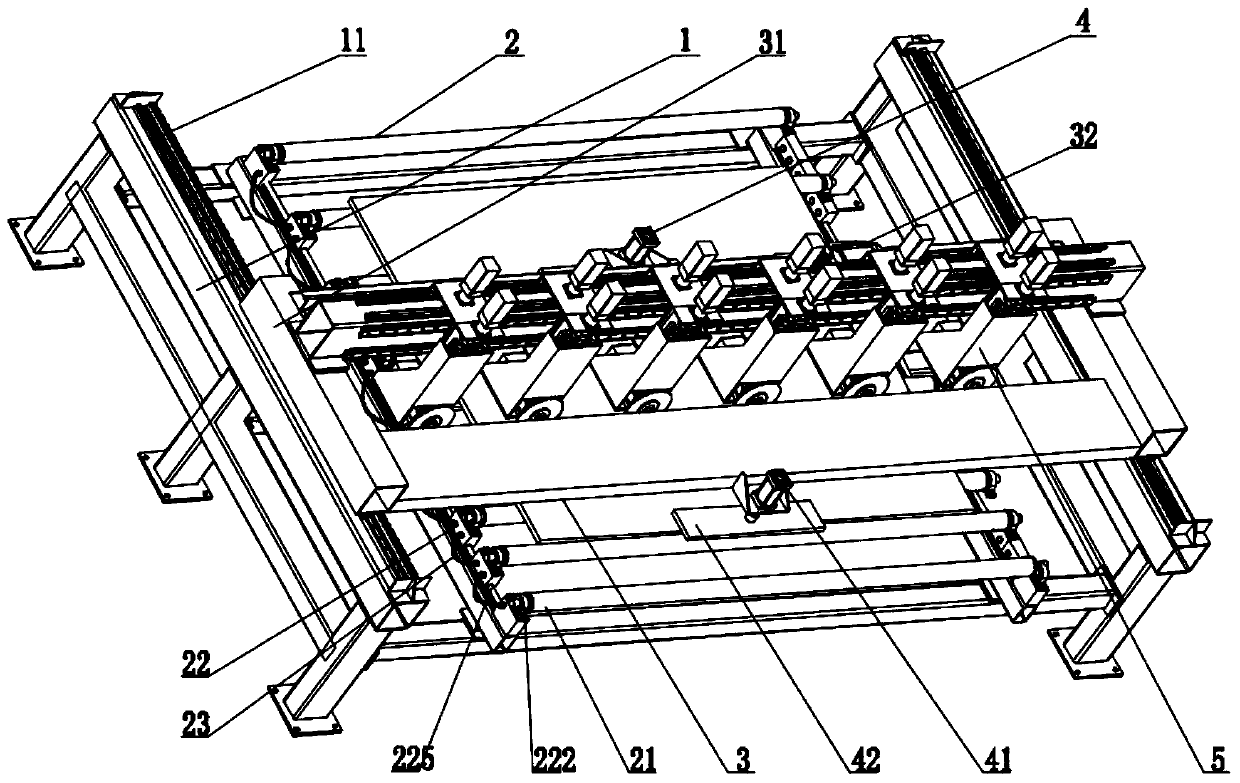

Steel pipe cutting machine

ActiveCN103752935AAvoid jumping upFixed and accurateMetal-working feeding devicesOther manufacturing equipments/toolsGrinding wheelMechanical engineering

The invention belongs to the technical field of cutting and provides a steel pipe cutting machine which can improve the cutting efficiency of steel pipe cutting machines. The steel pipe cutting machine comprises a bench, and a clamping device, a cutting device, a trimming device, a cutting length adjusting device and a discharging device are disposed on the bench. The clamping device is used for clamping steel pipes, the cutting device is used for cutting the steel pipes, the trimming device is used for trimming a cutter, the cutting length adjusting device is used for adjusting the cutting length of the steel pipes, and the discharging device is used for moving the steel pipes into a containing box. When the steel pipe cutting machine is in use, the steel pipes are placed on the bench, the cutting length of the steel pipes can be adjusted through a measurement rod and a footstock, then the steel pipes are fixed by a first clamping block, a second clamping block and a pressure bar, the steel pipes cut by the cutter can be conveyed to the containing box through the discharging device, and when the cutter is abraded, a disc abrasive can be used for trimming the cutter. Cutting efficiency of the steel pipe cutting machine can be effectively improved.

Owner:QIDONG YONGXING RUBBER PROD

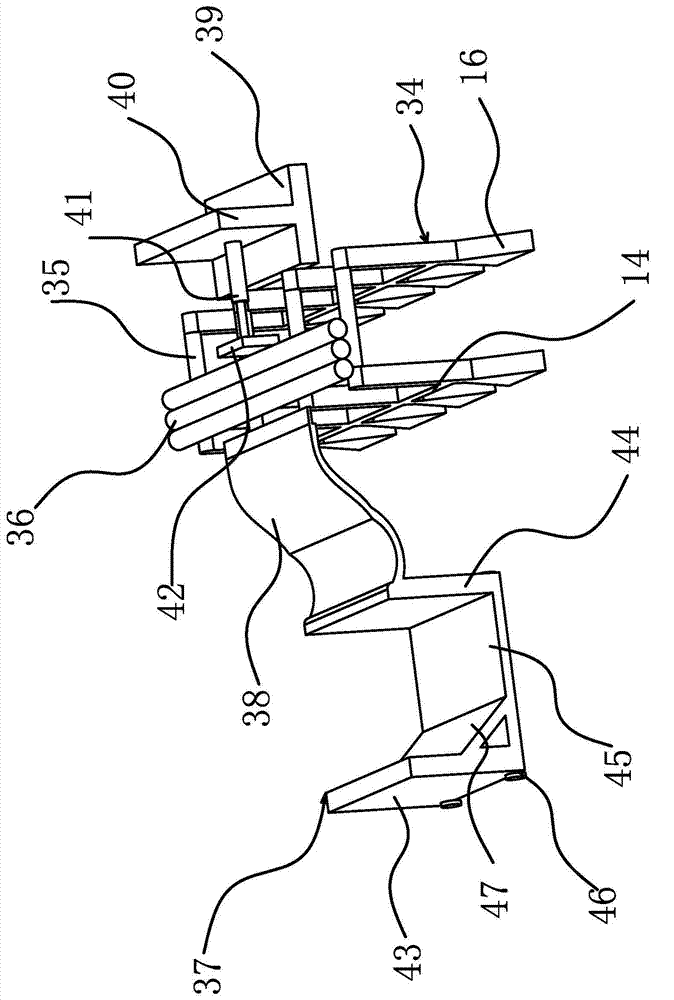

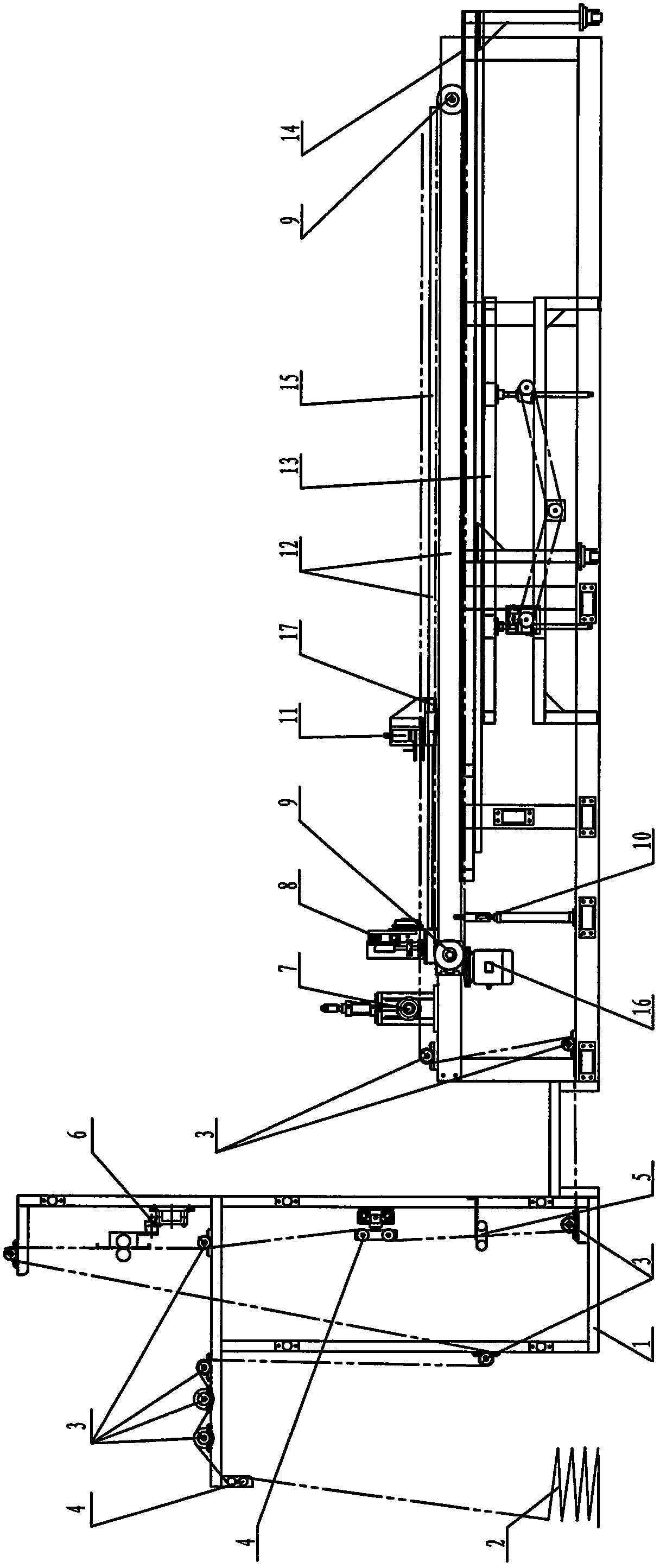

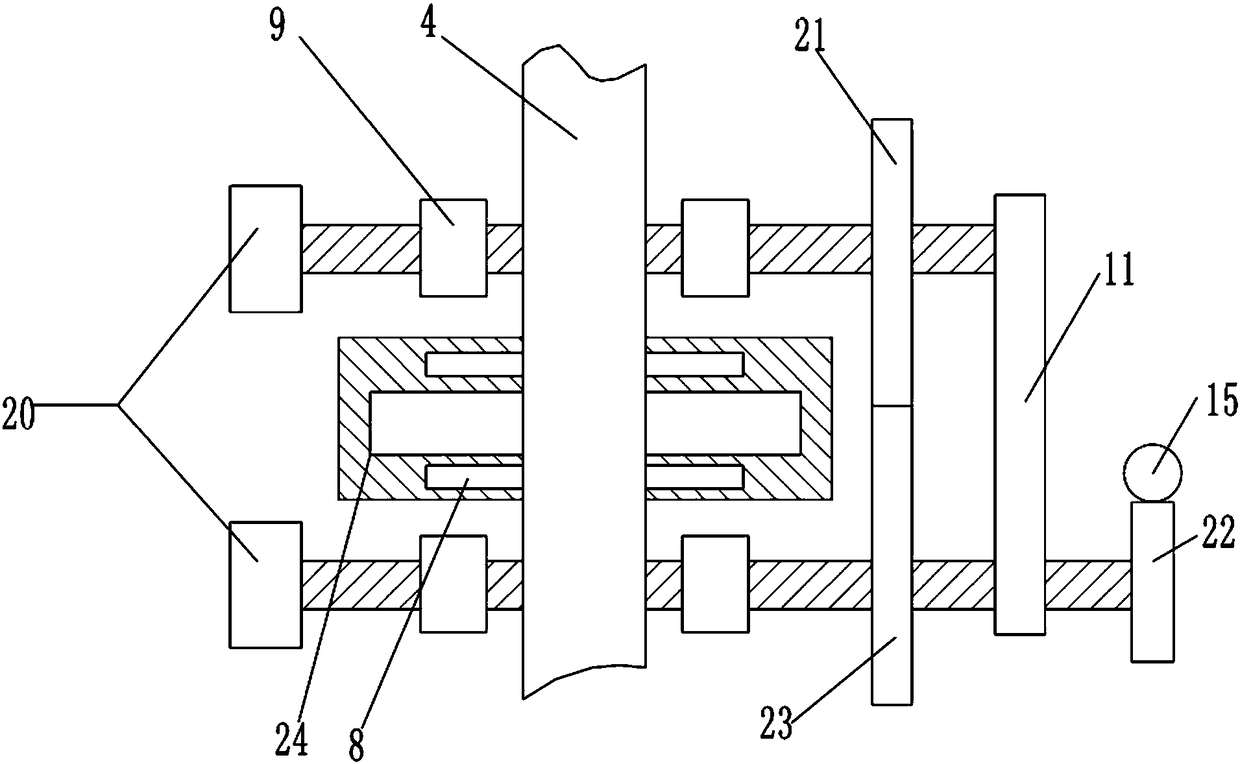

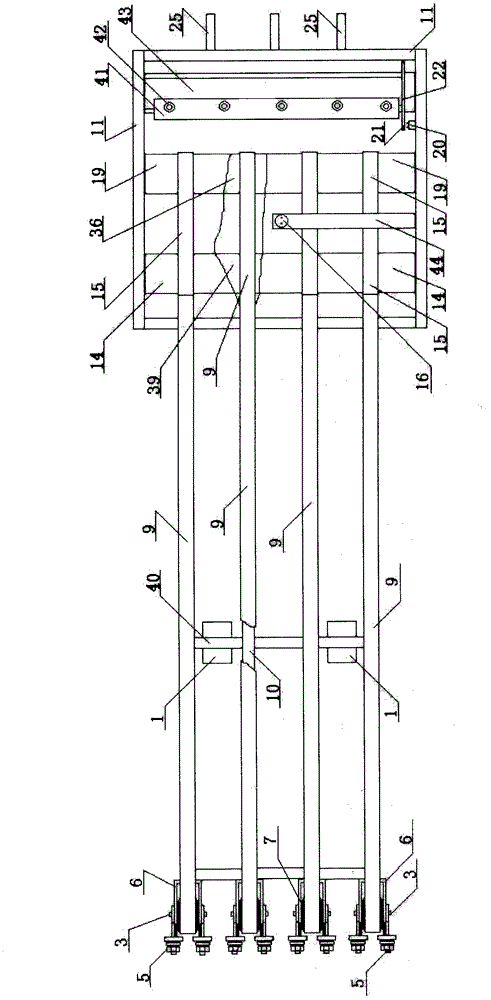

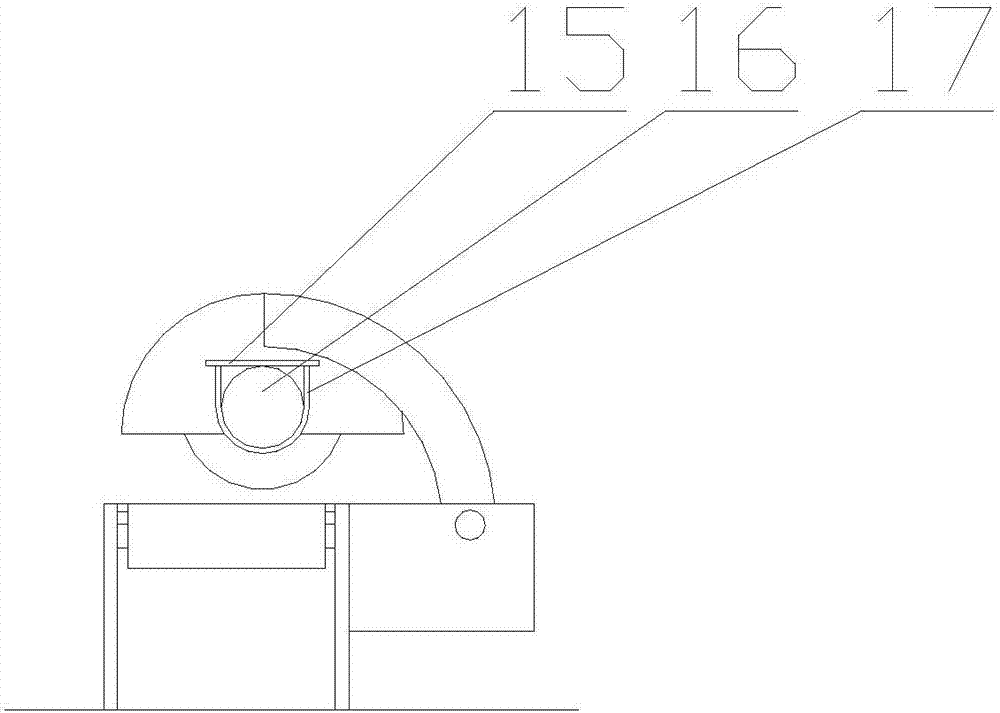

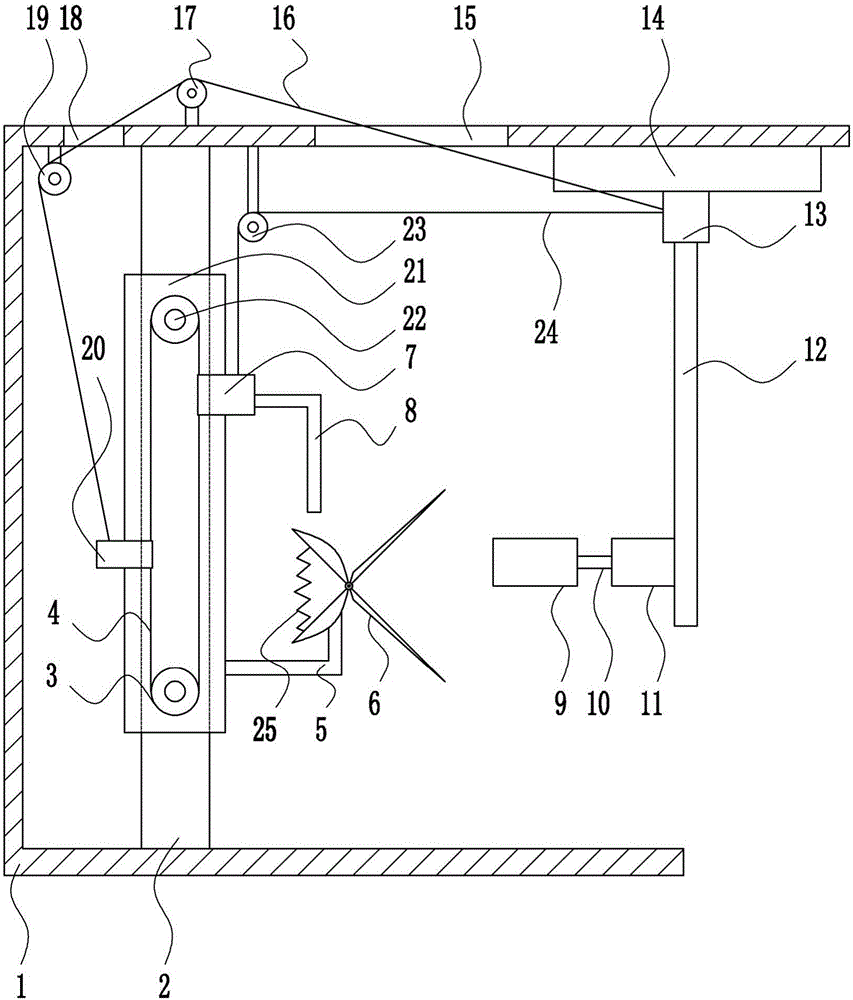

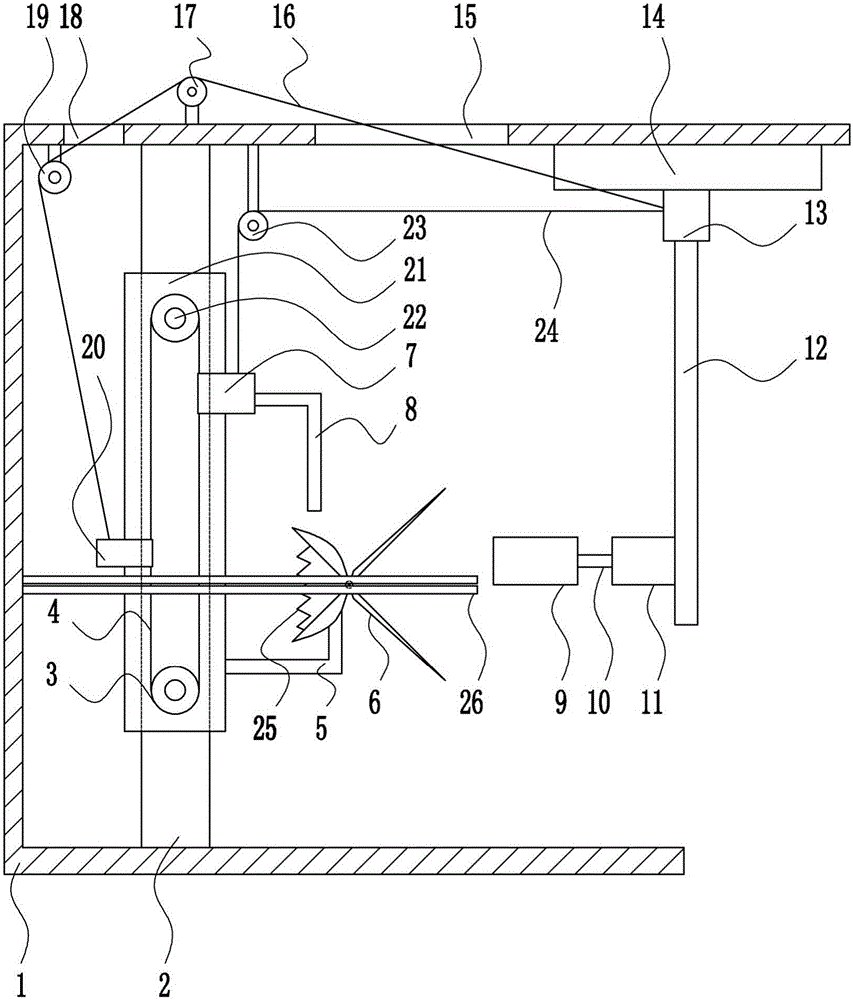

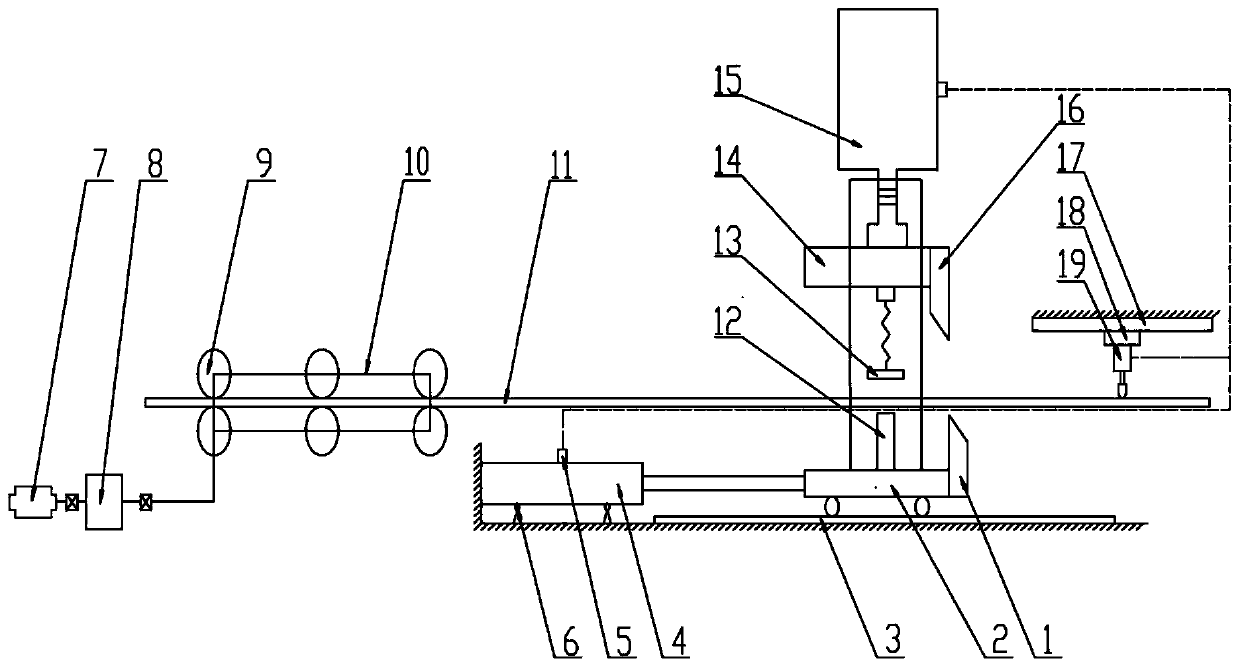

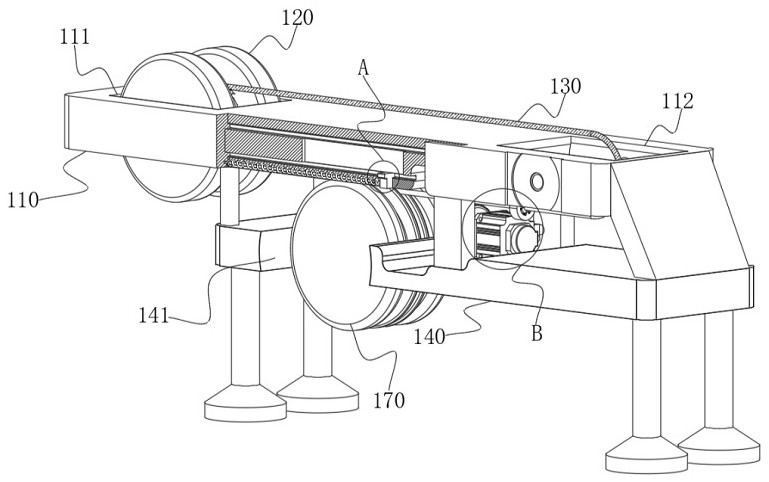

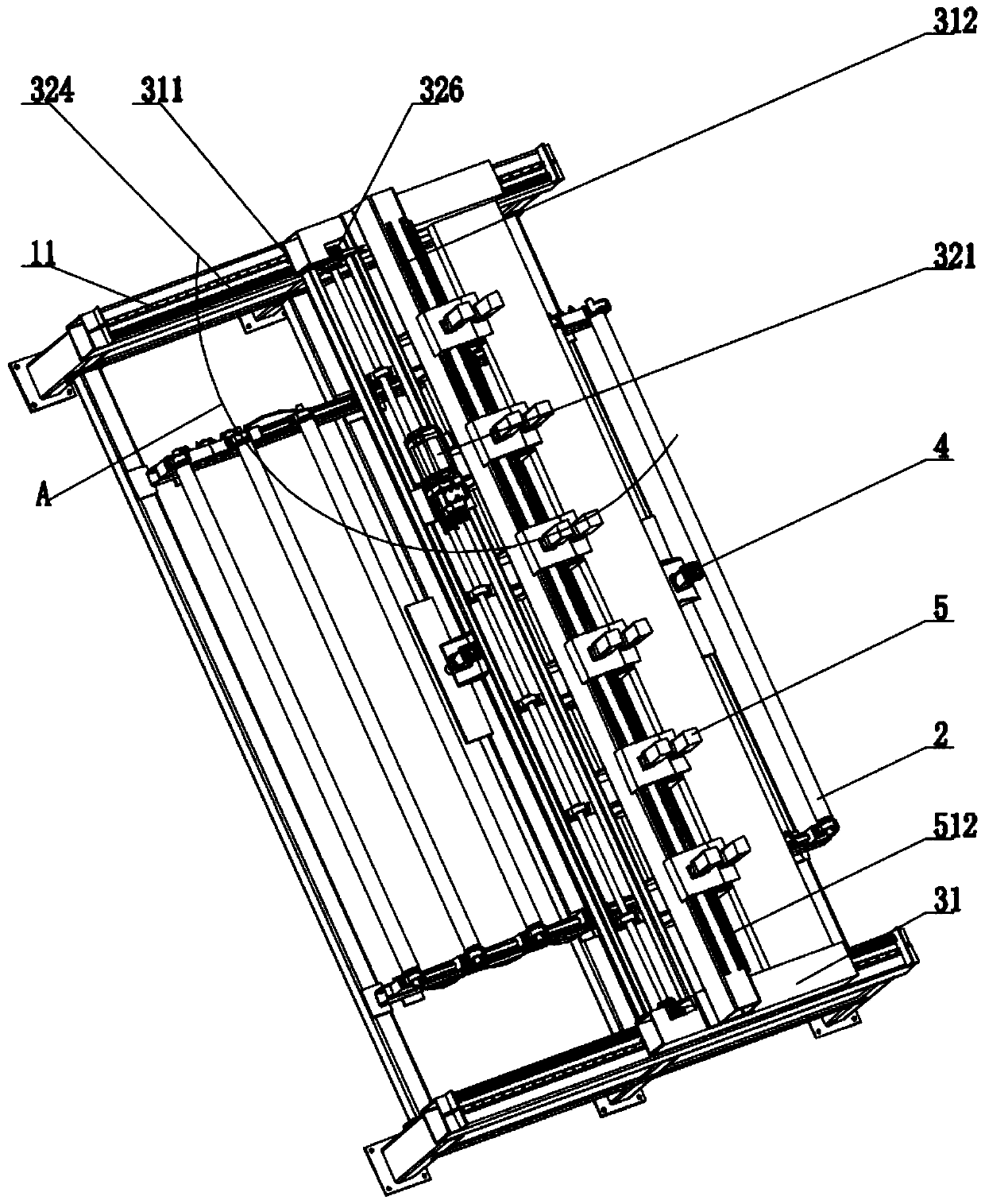

Pipe cutting equipment

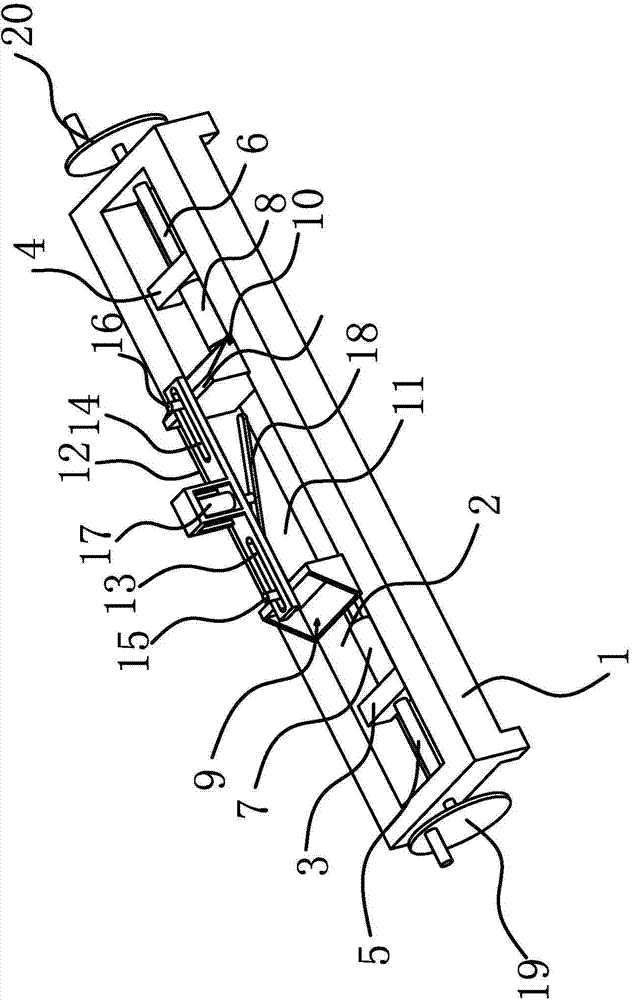

InactiveCN105522213ASave human effortImprove securityTube shearing machinesPositioning apparatusEngineeringMechanical engineering

The invention provides pipe cutting equipment. The pipe cutting equipment comprises a base, a positioning device, a clamping device, a supporting frame, a feeding device, a cutting device and a worktable installed on the base, wherein the clamping device is arranged in the position, close to the obverse surface of the worktable, of the upper surface of the worktable, and the supporting frame is fixed to the position, far away from the obverse surface of the worktable, of the upper surface of the worktable; the positioning device corresponds to the clamping device and is arranged on the lateral surface of the worktable; the middle of the cutting device is rotationally connected to the supporting frame, a cutter is installed at the end, above the clamping device, of the cutting device, and the other end of the cutting device is hinged to the upper portion of the feeding device; the feeding device is installed on the base vertically upwards. According to the pipe cutting equipment, a pipe is fixed reliably and does not shift when cut, and the situation that too many burrs and oblique sections are generated is avoided. The feeding device realizes the feeding motions for cutting, labor is saved, and safety is improved. In addition, the cutting length can be accurately measured by means of scale marks on the positioning device, thereby being accurate.

Owner:天津鑫旭成科技有限公司

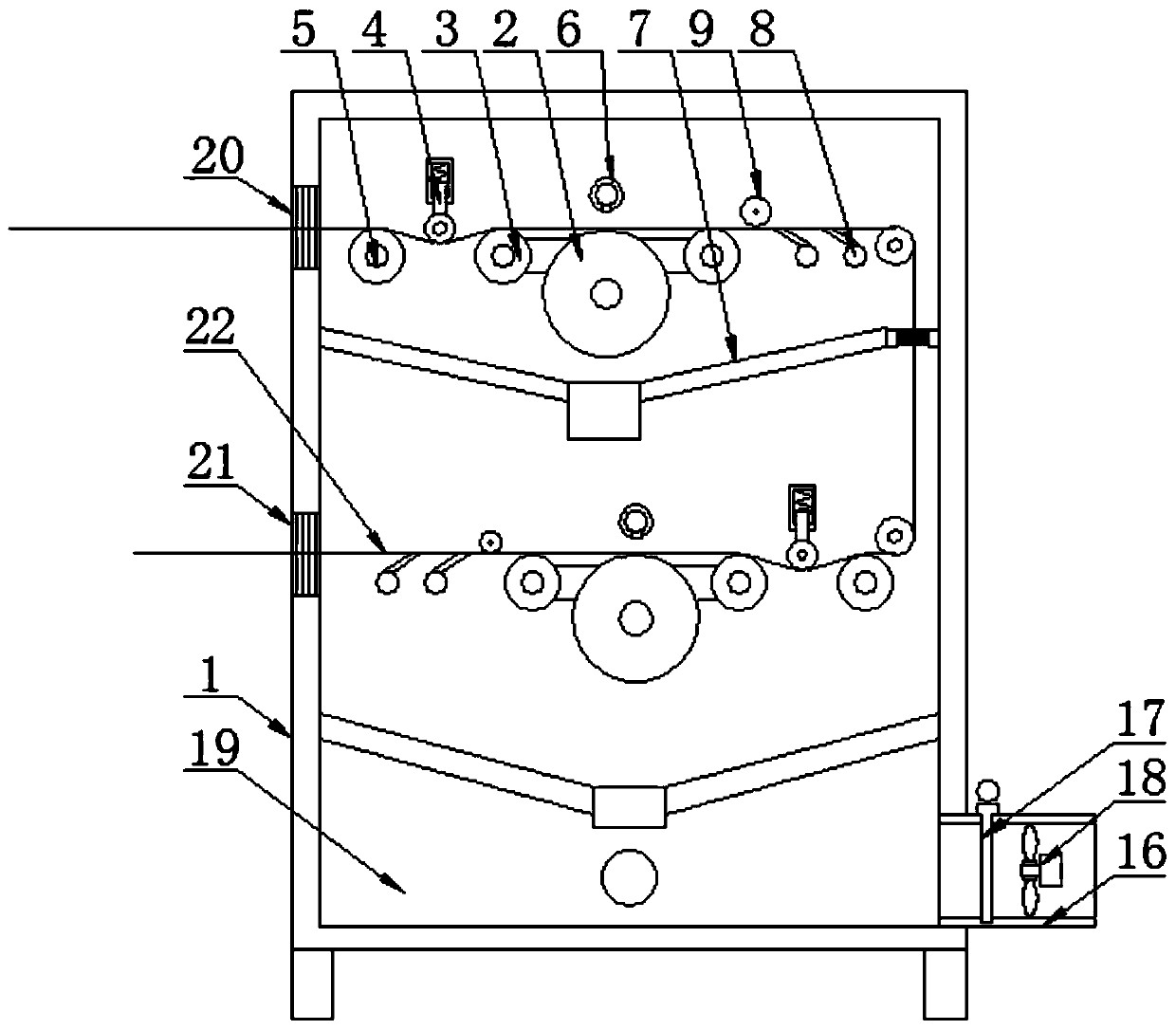

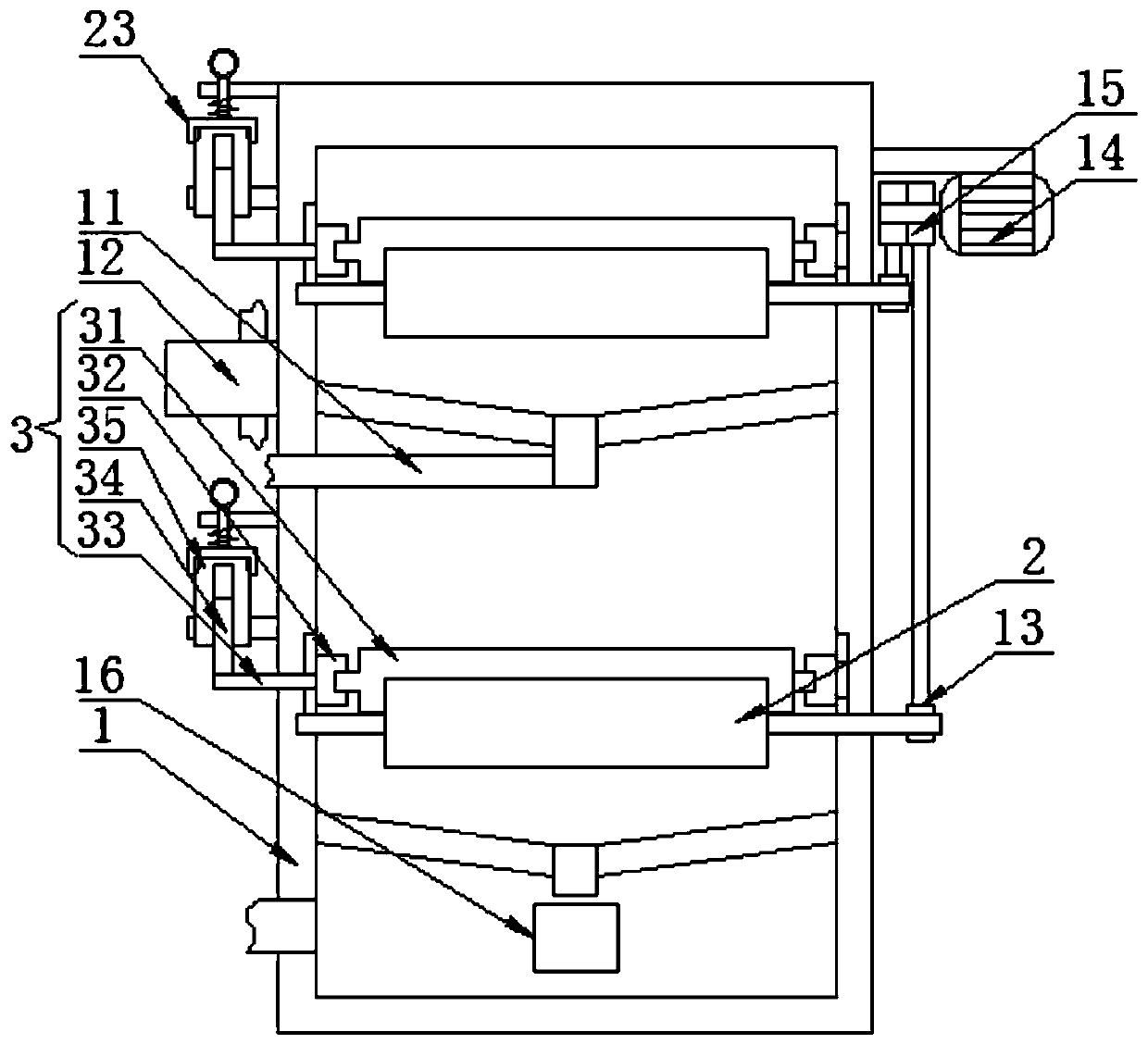

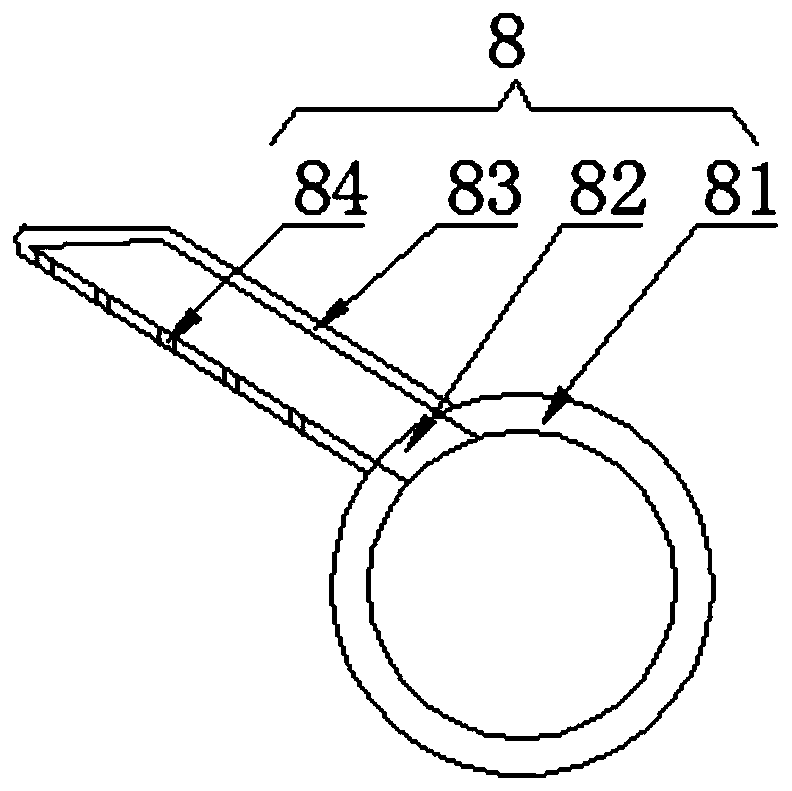

Length-changeable reinforcement equal-distance tailoring device

The invention discloses a length-changeable reinforcement equal-distance tailoring device. The device comprises a base plate; a driving roller is arranged on a rotating transverse shaft; two guide rollers are arranged on the other support side plate; a mounting frame is arranged between two support side plates; a rotary cutting tool is mounted on the lower side of the mounting frame; a fixed lifting rod penetrating through a top plate is arranged at the top end of the mounting frame; a magnet plate is arranged at the top end of the fixed lifting rod; the lower end surface of a magnet block isconnected with the top plate through a first spring; rotary push plates hinged with the side surfaces of the support side plates are arranged on the right side surfaces of the support side plates; thelower end of an upper push sealing plate is connected with fixed blocks arranged on the upper end surfaces of the rotary push plates; and the fixed blocks are slidingly connected with the upper end surfaces of the rotary push plates. The device is simple in structure, can continuously cut multiple reinforcement sections with the same length, and meanwhile, is invariable in reinforcement cutting length, accurate in cutting length, convenient to operate, higher in linkage, lower in labor capacity and higher in practicability.

Owner:日照市国丰远大住宅工业有限公司

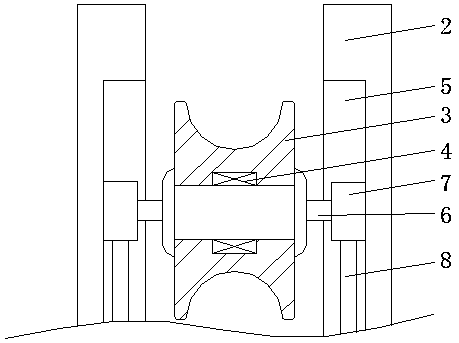

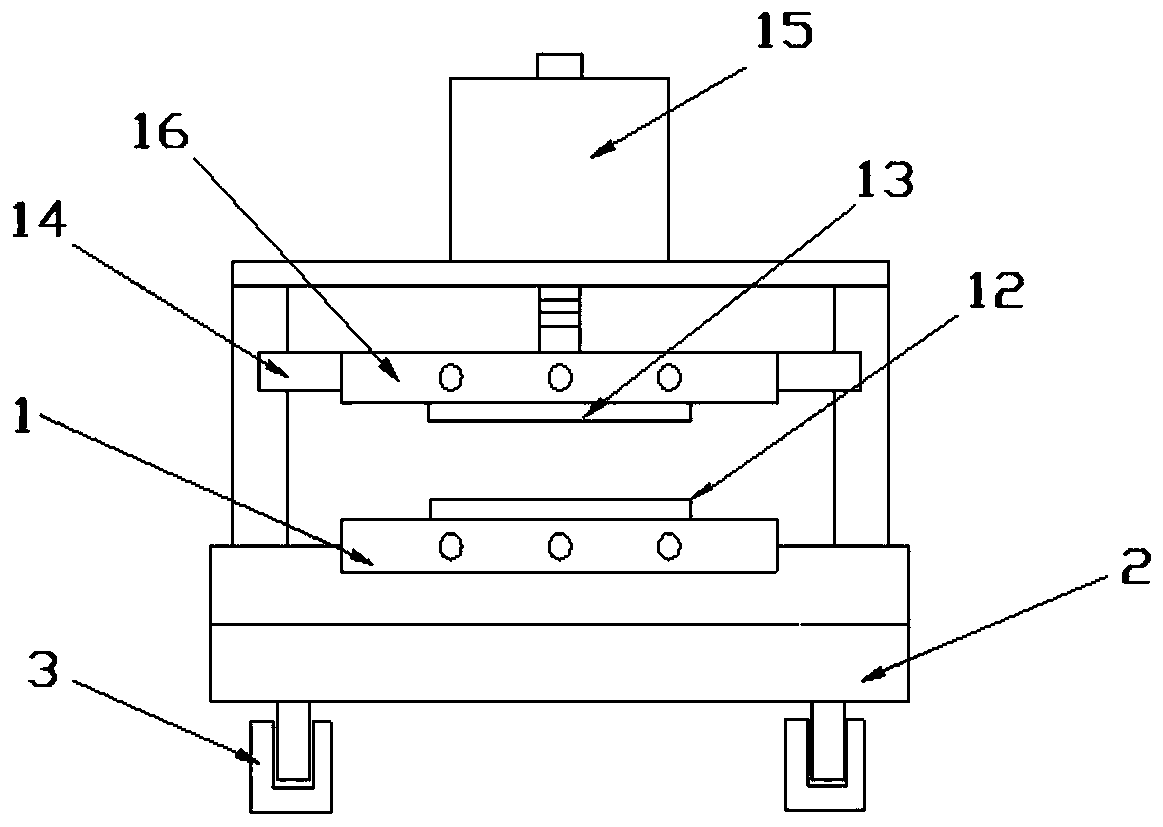

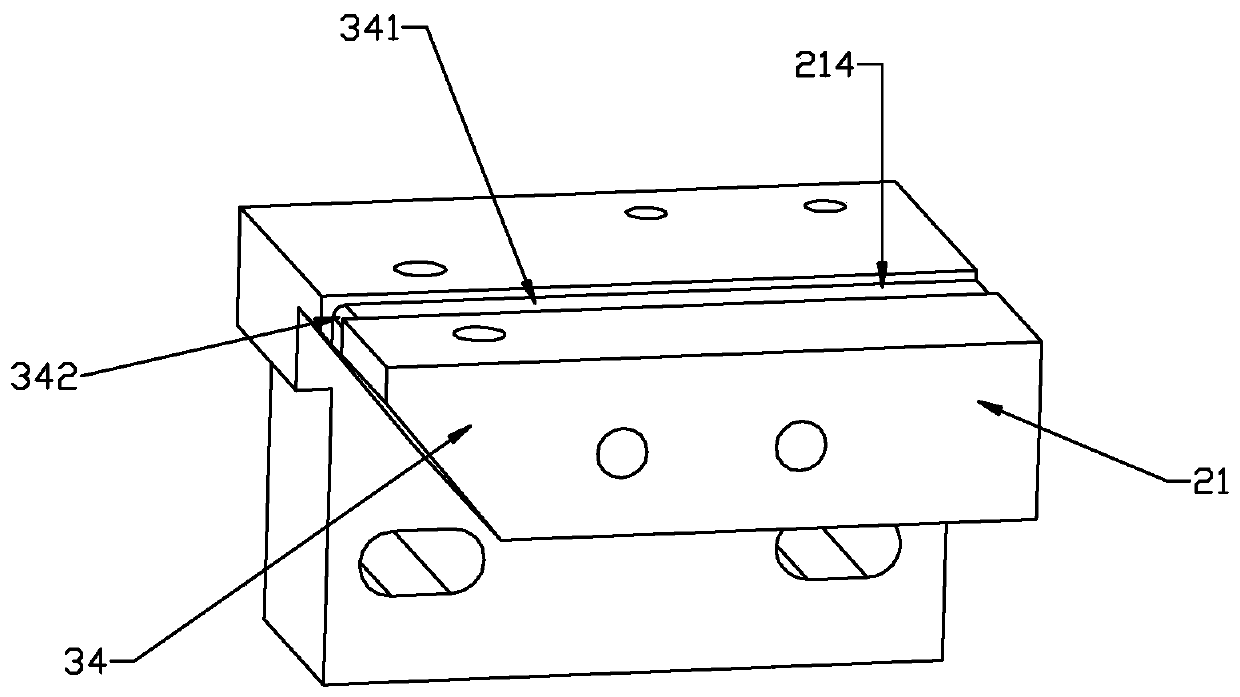

Concave pit notching and cutting composite mould for integrated chip lead frame

ActiveCN102909268AAvoid clampingHeight adjustableShaping toolsMetal-working feeding devicesPunchingStructural engineering

The invention discloses a concave pit notching and cutting composite mould for integrated chip lead frame, overcomes the defect of singular notching of the conventional notching mould, and provides the composite mould which is precise in notching, system positioning and cutting. The concave pit notching and cutting composite mould comprises an upper mould seat, a lower mould seat and a controller; the upper and lower moulds are slidingly connected through four guide mechanisms; movable sliders are arranged on guide columns; a concave mould is arranged on the lower mould seat; a square concave pit is formed in the middle of the concave mould; positioning pins are symmetrically arranged on front and back sides of the square concave pit; a square through hole is formed in the corresponding part of the movable sliders and the square concave pit; a positioning pin hole is formed in the corresponding part of the movable sliders and the square concave pit; a convex mould is arranged in the middle of the upper mould seat; the head of the convex mould slidably penetrates through the square through hole; a height adjusting device is arranged at the upper end of the convex mould; a fixed length transmission device of the integrated chip lead frame is arranged on the left side of the lower mould seat; and a cutting device of the integrated chip lead frame is arranged on the right side of the lower mould seat. By the concave pit notching and cutting composite mould, the concave part can be notched precisely; the system positioning is precise, and fixed length cutting is accurate; and guide rail error of a punching machine can be prevented.

Owner:浙江捷华电子有限公司

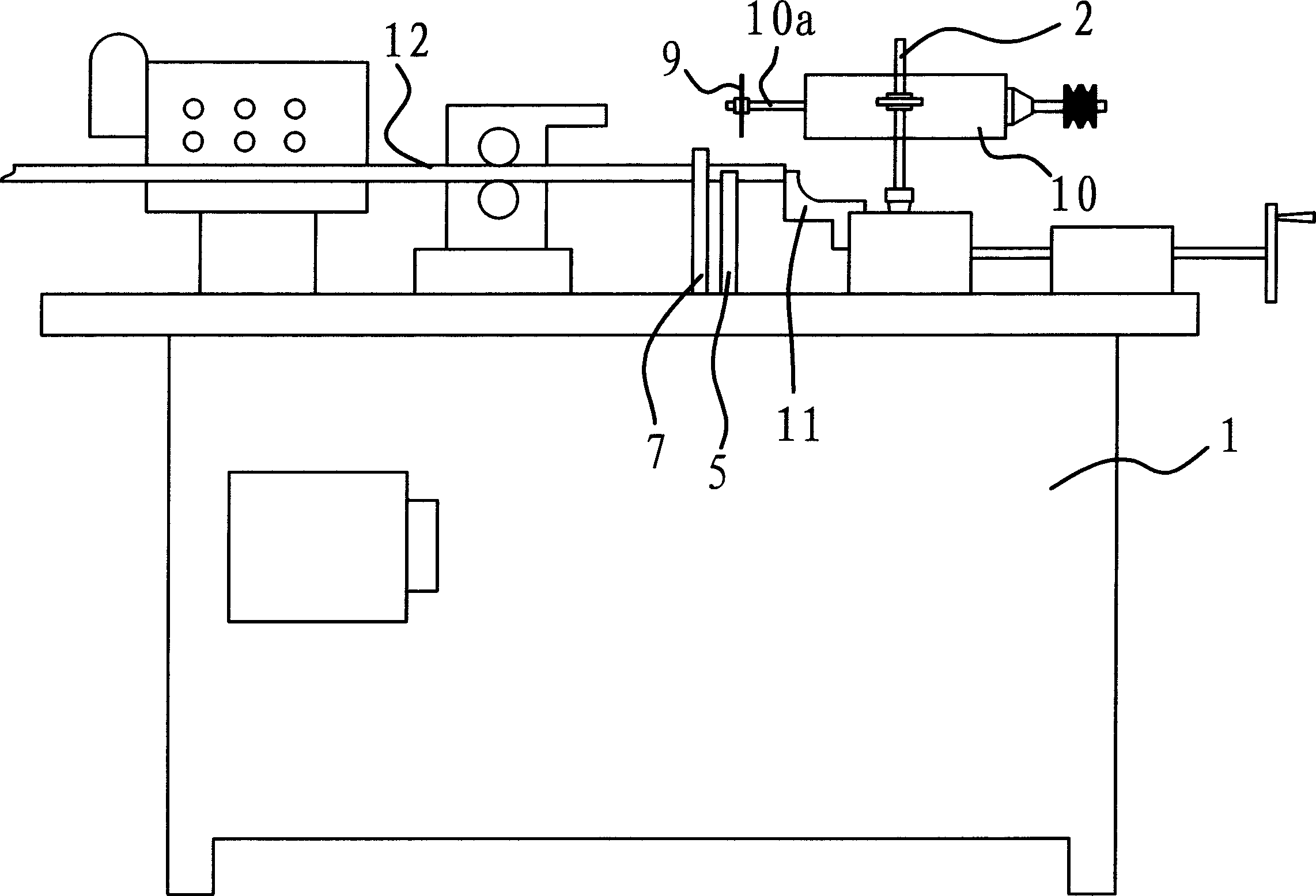

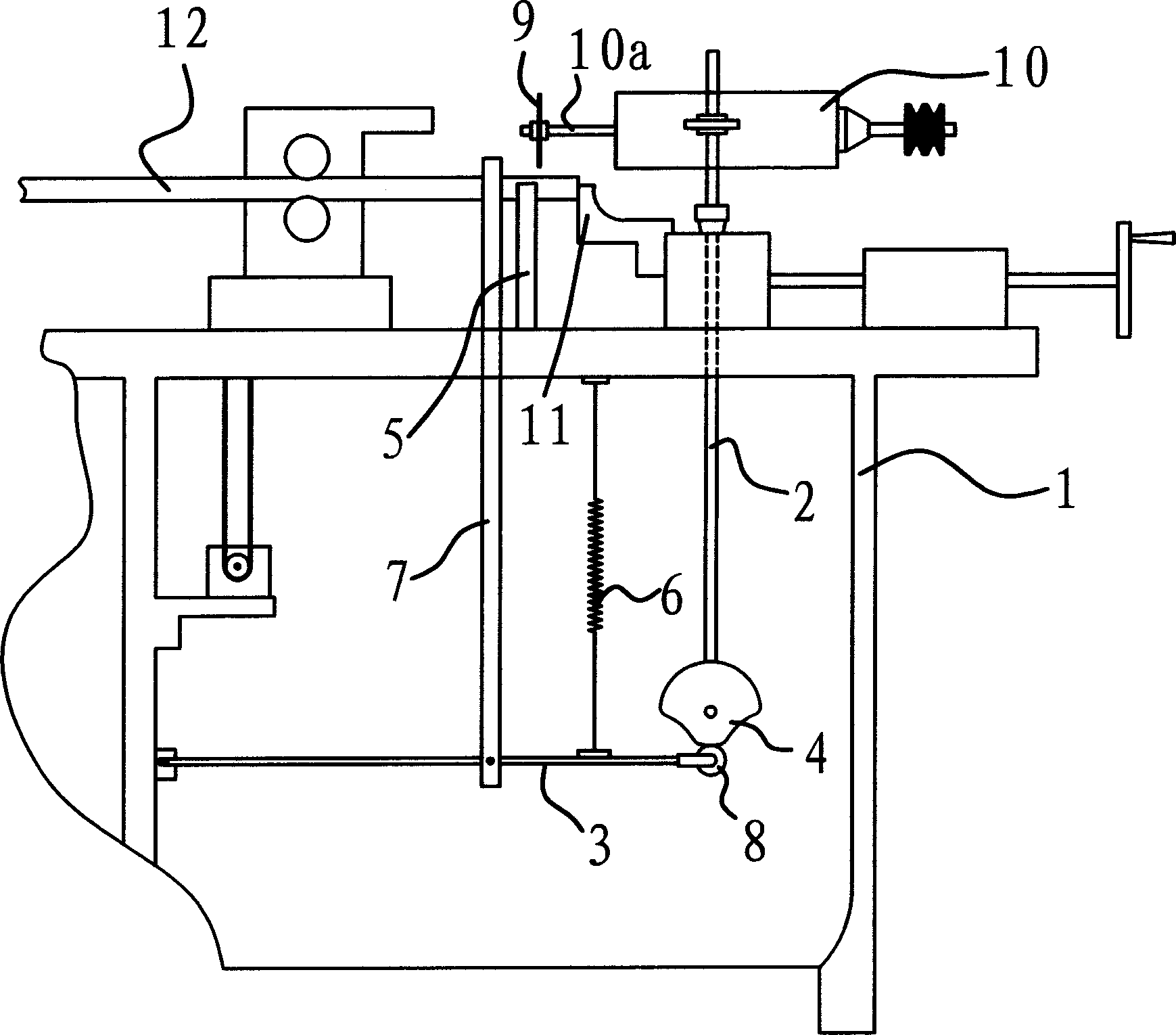

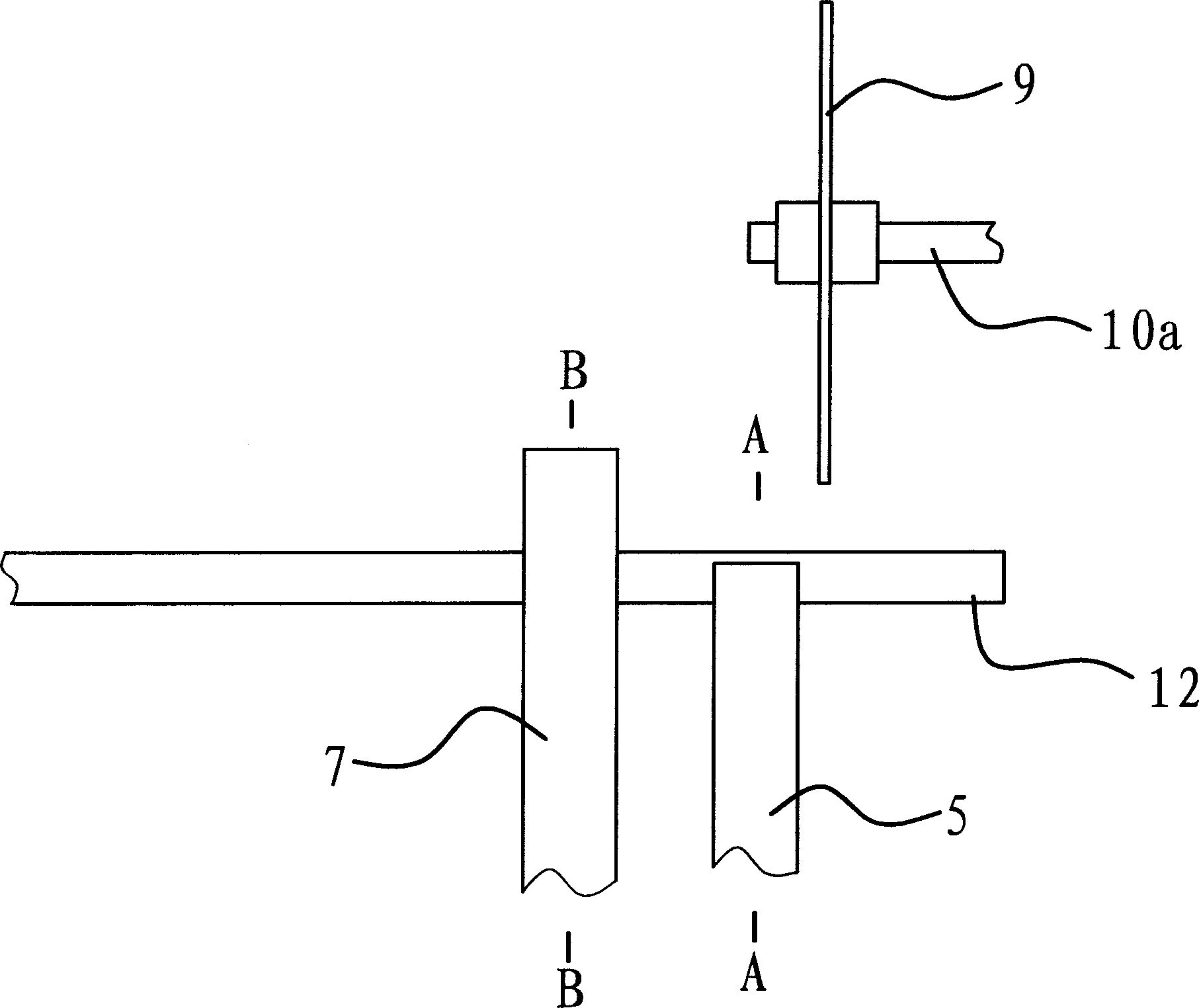

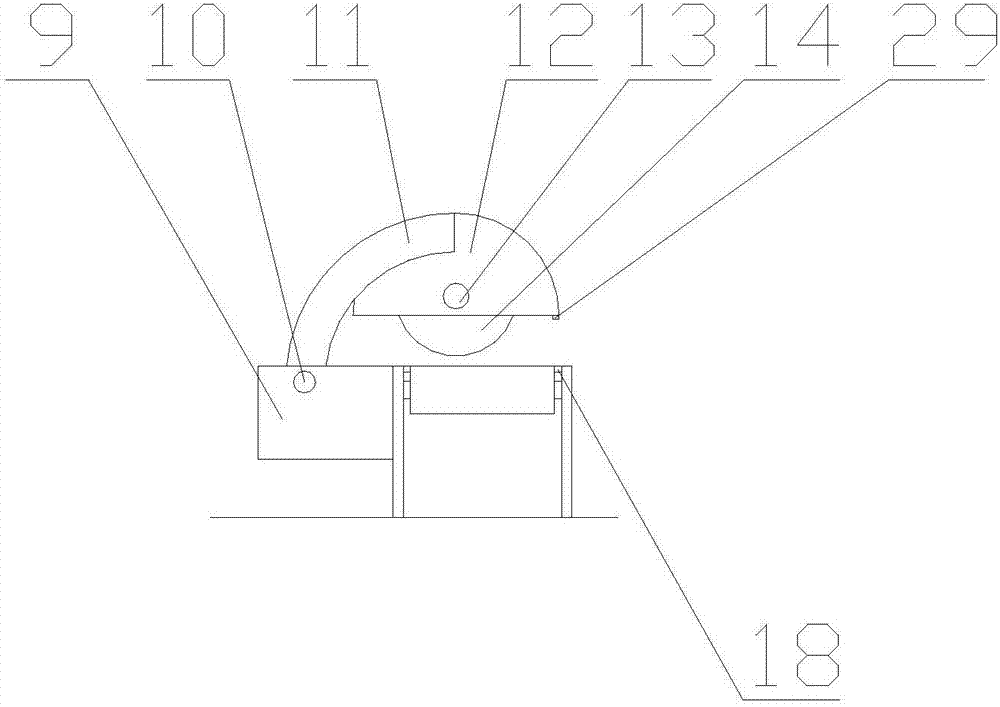

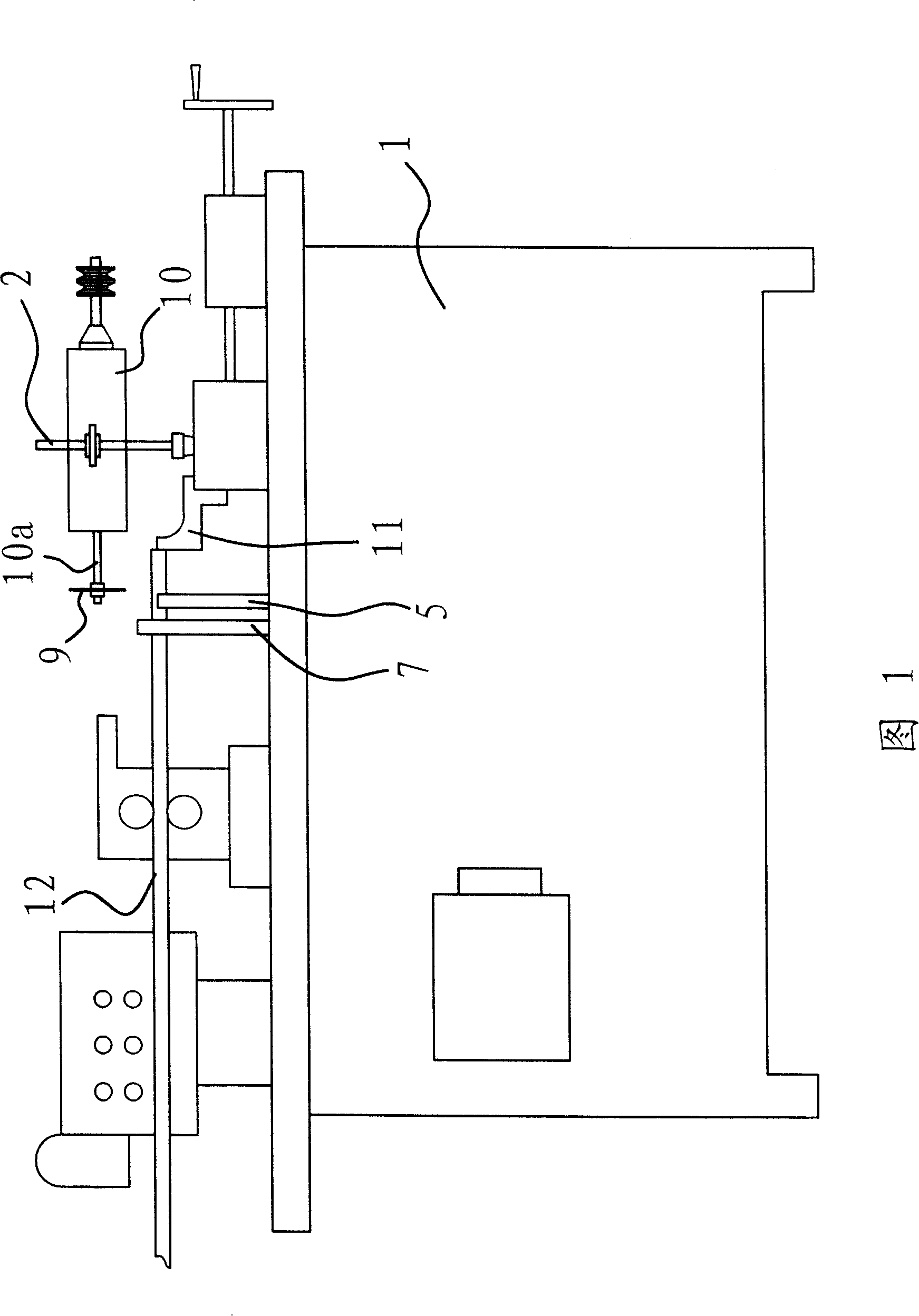

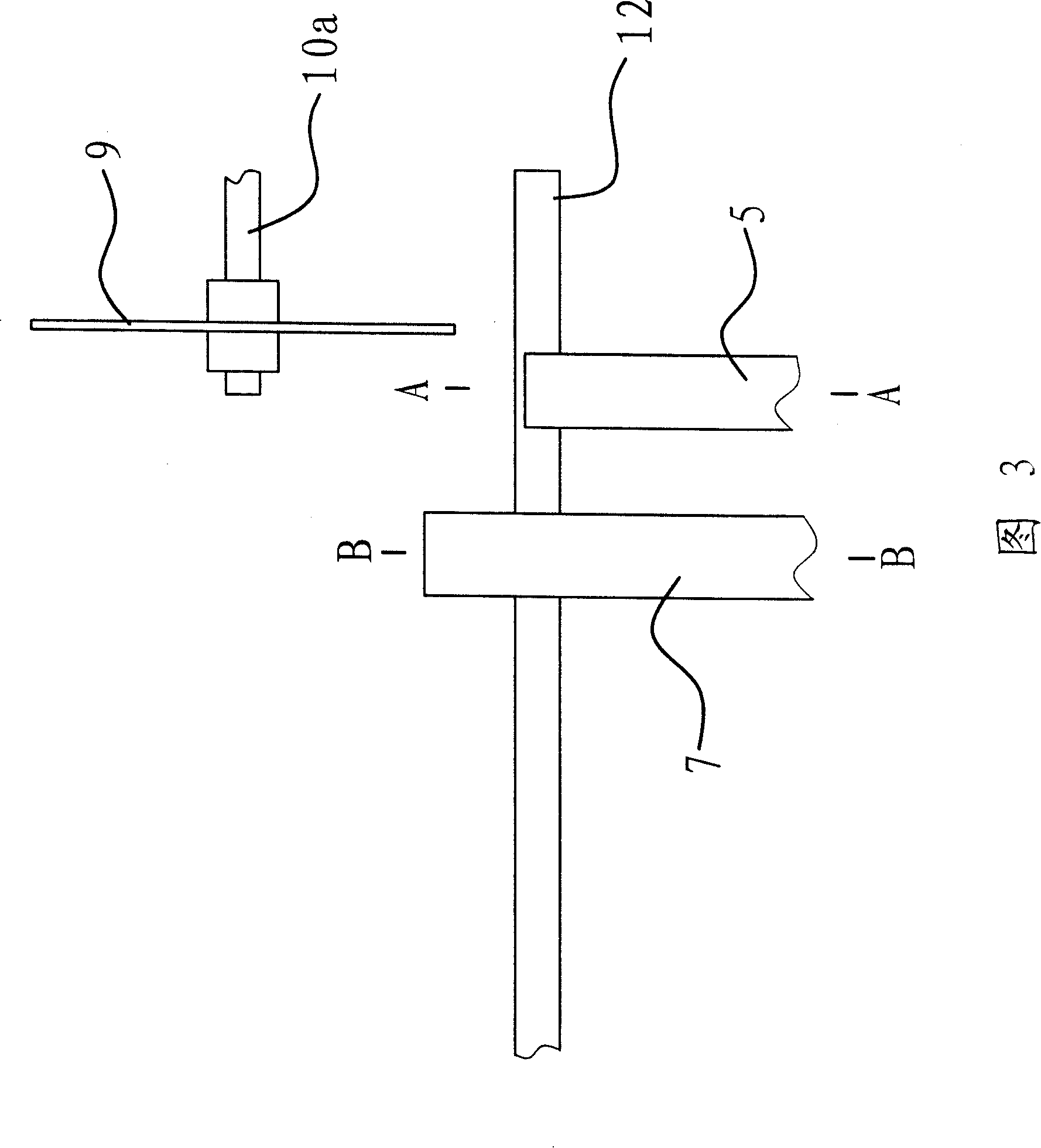

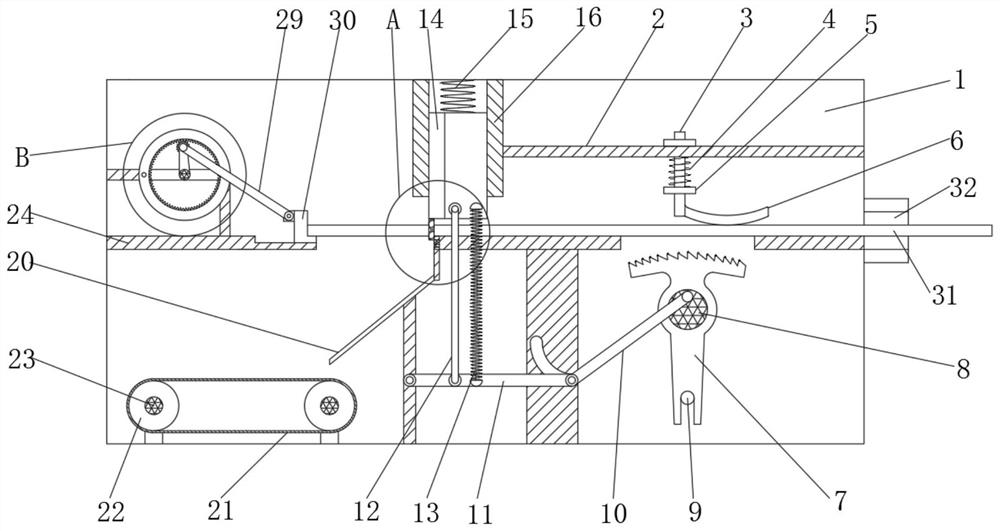

Cutting mechanism of rod material automatic cutting machine

InactiveCN1651172ASimple structureGuaranteed uptimeShearing machinesShearing machine accessoriesEngineeringCam

A cutting mechanism for automatic rod cutter is composed of an electric motor, cutting blades fixed to shaft of motor, a cam, a vertically moving connection rod with a top end linked to motor and a lower end in touch with said cam, a supporting block at discharge exit, a transverse bar, and a press rod with lower end connected to said transverse bar. Its advantage is correct cutting length.

Owner:玉环县三合机床厂(普通合伙)

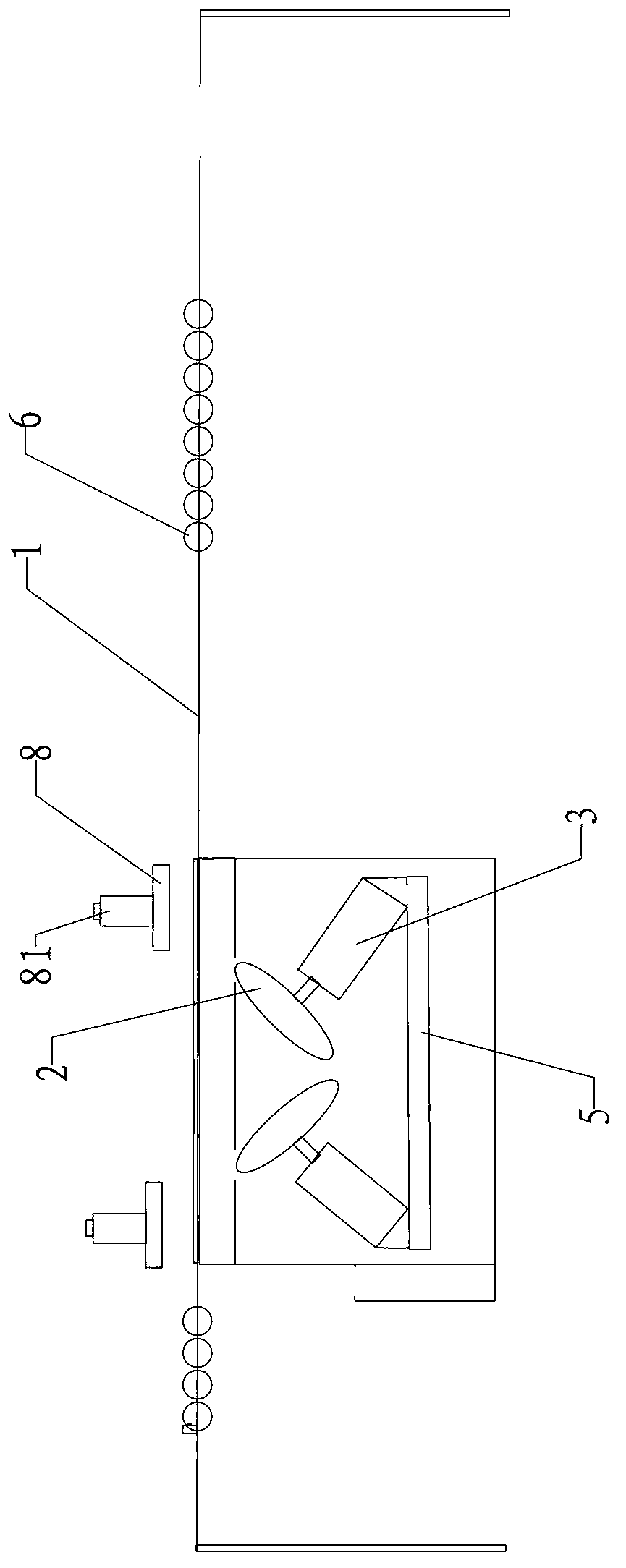

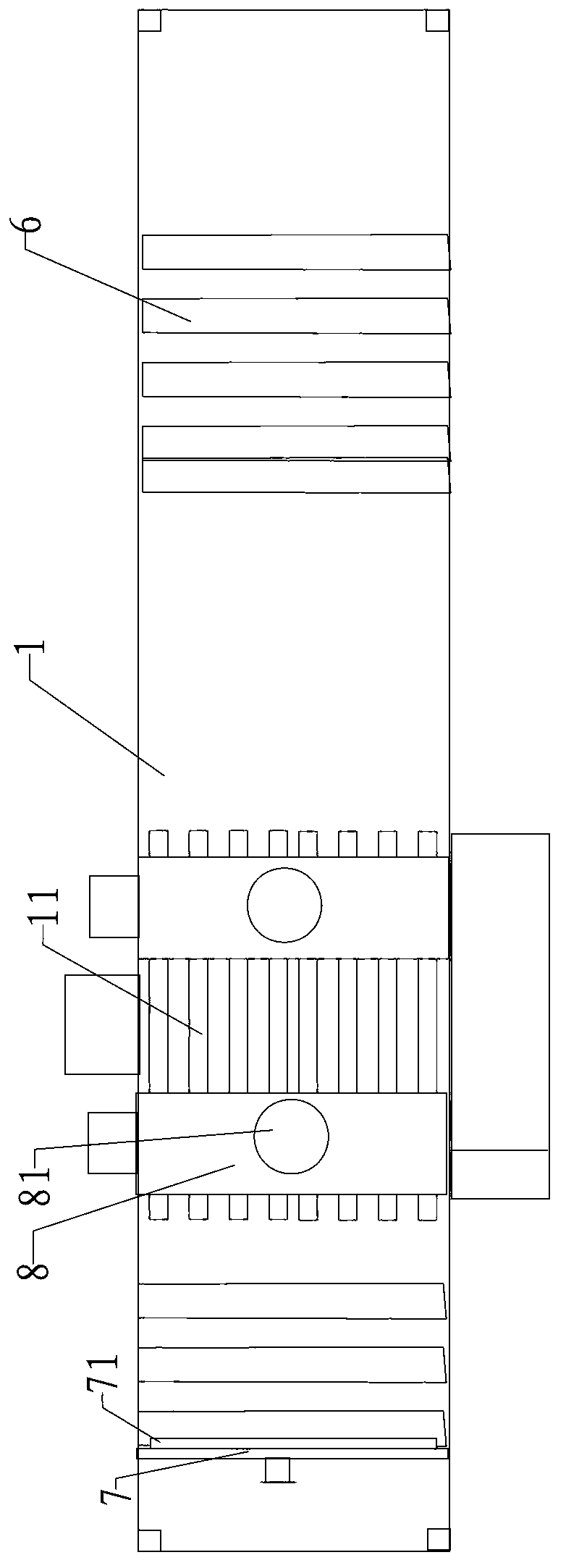

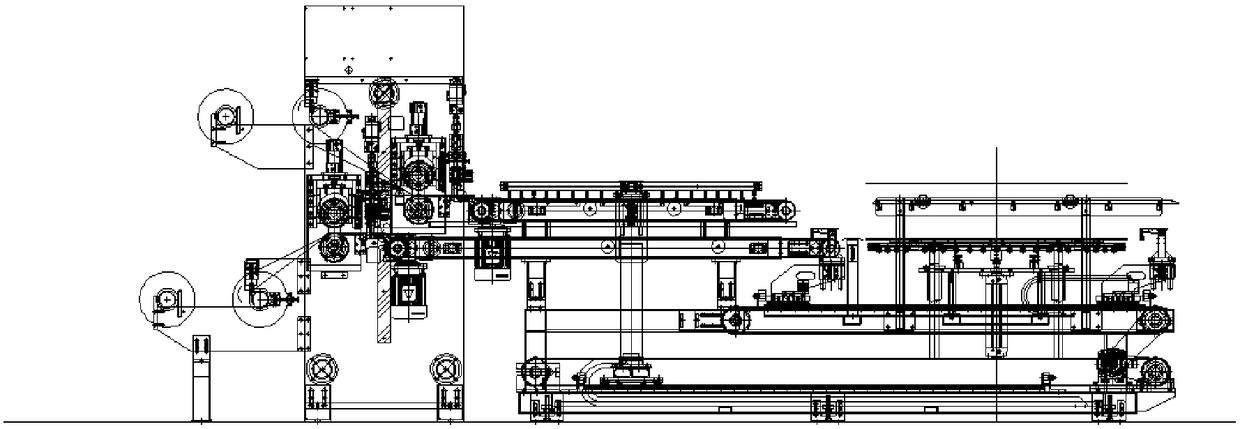

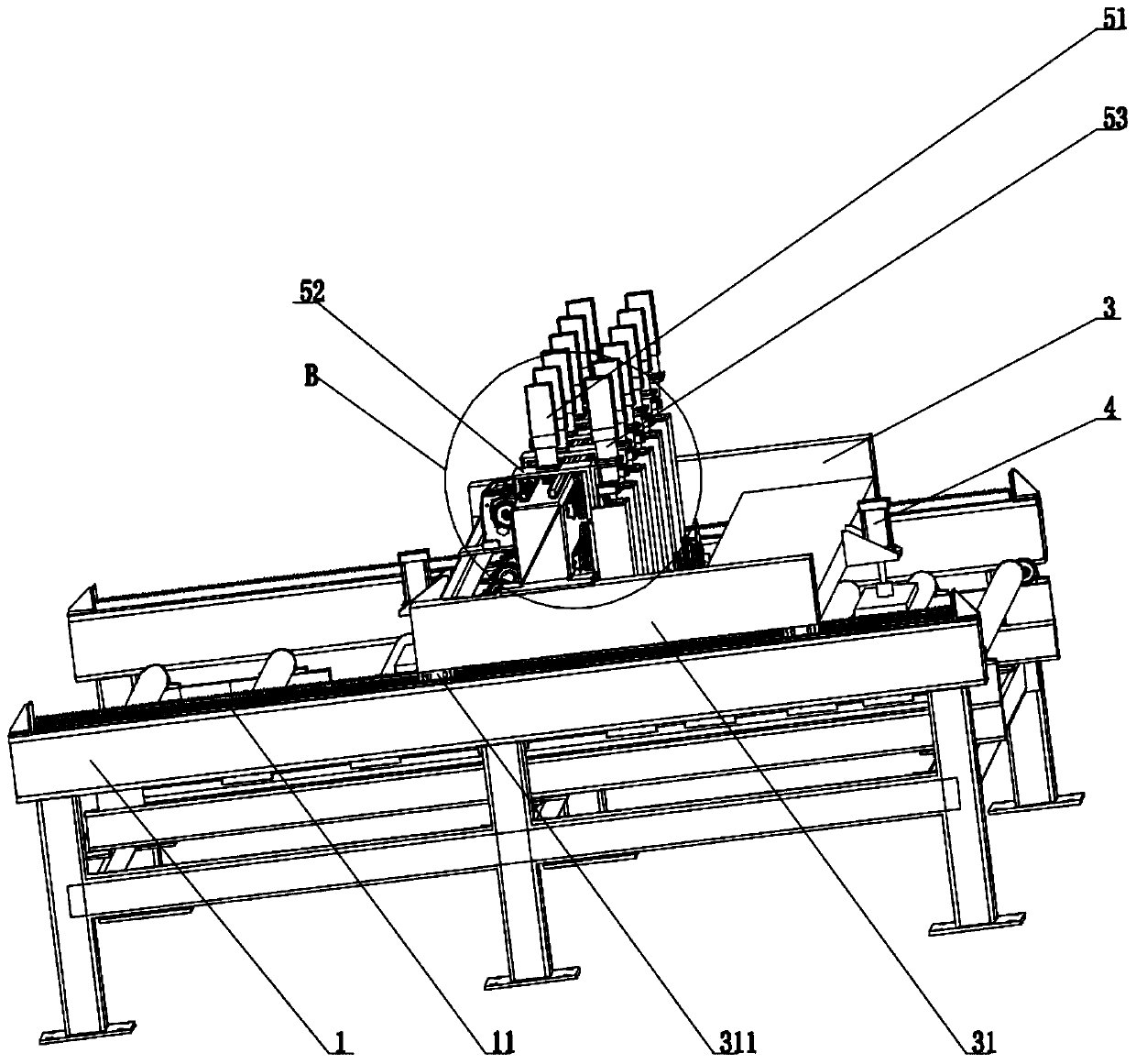

Intelligent full-automatic cloth pulling, splitting and cutting machine

PendingCN108238479ANo pollutionHigh degree of automationSevering textilesFolding thin materialsFiberLongitudinal splitting

The invention discloses an intelligent full-automatic cloth pulling, splitting and cutting machine. The intelligent full-automatic cloth pulling, splitting and cutting machine comprises a rack, cloth,cloth guiding rolls, cloth tensioners, a centralizer, an opposite-site flattening device, a longitudinal splitting device, a transverse cutting device, synchronizing wheels, a chemical fiber ironingand cutting device, a cloth pulling device, left and right side plates, a lifting platform, a movable cloth containing platform, a linear sliding support, a servo motor A, sliding blocks, cutter shaftsliding block brackets, a right-angle motor bracket, a right-angle motor, cutter shaft gears, cutter shaft bearings, air cylinders A, cutter shaft sliding blocks and the like. The machine adopts a mechanical-electrical integration intelligent control technology and is high in automation degree. When the machine is used, the machine flattens and straightens the cloth according to instructions andconducts transverse cutting and chemical fiber ironing and cutting according to the length dimension, the machine is widely applied to the industries of clothing, shoes and hats, home textiles and thelike, the automation degree is high, the cutting length is precise, the defects such as bevel edges and swing angles are not generated, time and labor are saved, the working efficiency is high, no noise is generated, the environment is not polluted, and the economic benefit is increased.

Owner:YANCHENG XIEHE MACHINERY

Guard bar cutting device

ActiveCN108127179ARealize automatic clampingImprove cut qualityMetal sawing devicesMetal sawing accessoriesEngineeringMachining

The invention belongs to the technical field of guard bar machining, and particularly discloses a guard bar cutting device. The device includes a worktable, and a conveying mechanism used for conveying pipe materials and a cutting mechanism used for cutting the pipe materials are arranged on the worktable. The conveying mechanism includes a conveyor belt, multiple V-shape locating blocks are movably connected to the conveyor belt, and each V-shaped locating block is provided with an approaching switch. The cutting mechanism includes a supporting frame and a second motor, an output shaft of thesecond motor is fixedly provided with an air expanding shaft, and a worm sleeves the air expanding shaft. A first lead screw is arranged on the air expanding shaft, and a first nut support is screwedwith the first lead screw. A connecting rod is hinged to the first nut support and the supporting frame and provided with the cutting mechanism. A worm gear is meshed with the worm, a bidirectional lead screw is connected to the center of the worm gear, second nut supports are screwed at both ends of the bidirectional lead screw, and clamping blocks are connected to both the two second nut supports. According to the scheme, cutting of the pipe materials can be achieved according to different length demands, and high cutting quality is ensured.

Owner:临沂经济开发有限公司

Full-automatic photovoltaic module aluminum product cutting machine

InactiveCN103231109AGuaranteed uptimeSmooth feedingMetal sawing devicesEngineeringMechanical engineering

A full-automatic photovoltaic module aluminum product cutting machine comprises a machine frame, a pressing device and a cutting device. The cutting device comprises two saw blades, two motors, a pushing cylinder and a placing plate. The two motors respectively drive the respective saw blades to rotate and are arranged on two sides of the placing plate. The two motors are relatively slantly arranged on the placing plate, inclination angles of the motors can be controlled through an adjusting positioning device, the pushing cylinder drives the placing plate to move longitudinally, the machine frame is further provided with an open groove matched with moving tracks of the saw blades, and the saw blades are used for cutting aluminum products in the placing plate moving process. The full-automatic photovoltaic module aluminum product cutting machine in a novel structure runs smoothly, the aluminum products are fed evenly, a cutting section is high in quality, a cutting length is accurate, and the aluminum product cutting machine is safe and reliable, can perform one-time cutting on a plurality of aluminum products and is simple in structure and high in using efficiency.

Owner:深圳市索阳新能源科技有限公司

Automatic cutting machine

The invention discloses an automatic cutting machine. The automatic cutting machine comprises a frame, a conveying belt, a conveying frame, a front conveying roller and a rear conveying roller, and is characterized by further comprising a front pressure roller, a rear pressure roller and a pressing and sending belt which are arranged on the frame and correspondingly parallel to the front and rear conveying rollers and the conveying belt at the upper part; a cutting roller which is arranged behind the rear conveying roller and parallel to the rear conveying roller; a knife roller which is arranged at the vertical upper part of the cutting roller; a plate measuring device which is arranged at the upper part between the front pressure roller and the rear pressure roller; and a positioning, cutting and measuring device which is arranged on one side of the cutter roller. The machine can be used for cutting thin plate blocks from crude wood thin plates which are continuously output by a rotary cutting machine according to the set length under the control of the plate measuring device, the positioning, cutting and measuring device and a controller. The conveying of the crude wood thin plates and the rotation cutting of the cutting roller and the knife roller are automatically performed without manual operation under the drive of an electric motor and the action of an electric controller. Furthermore, the speed is high, and the efficiency and the quality are high. The automatic cutting machine is suitable for cutting various thin plates.

Owner:刘达羡

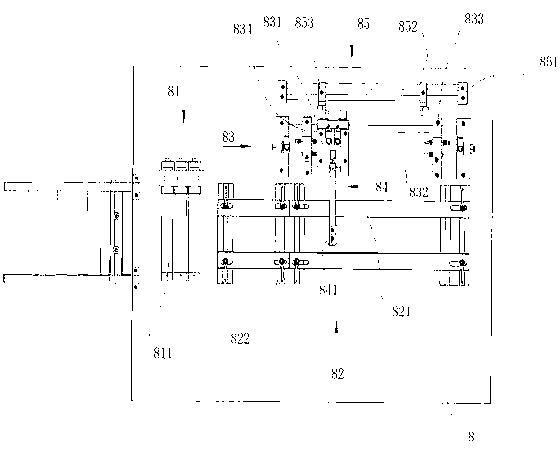

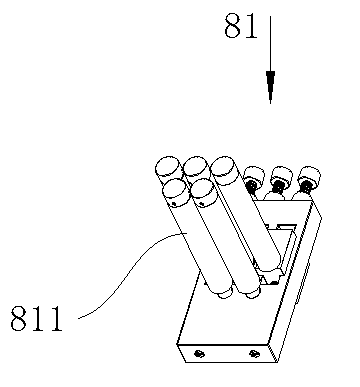

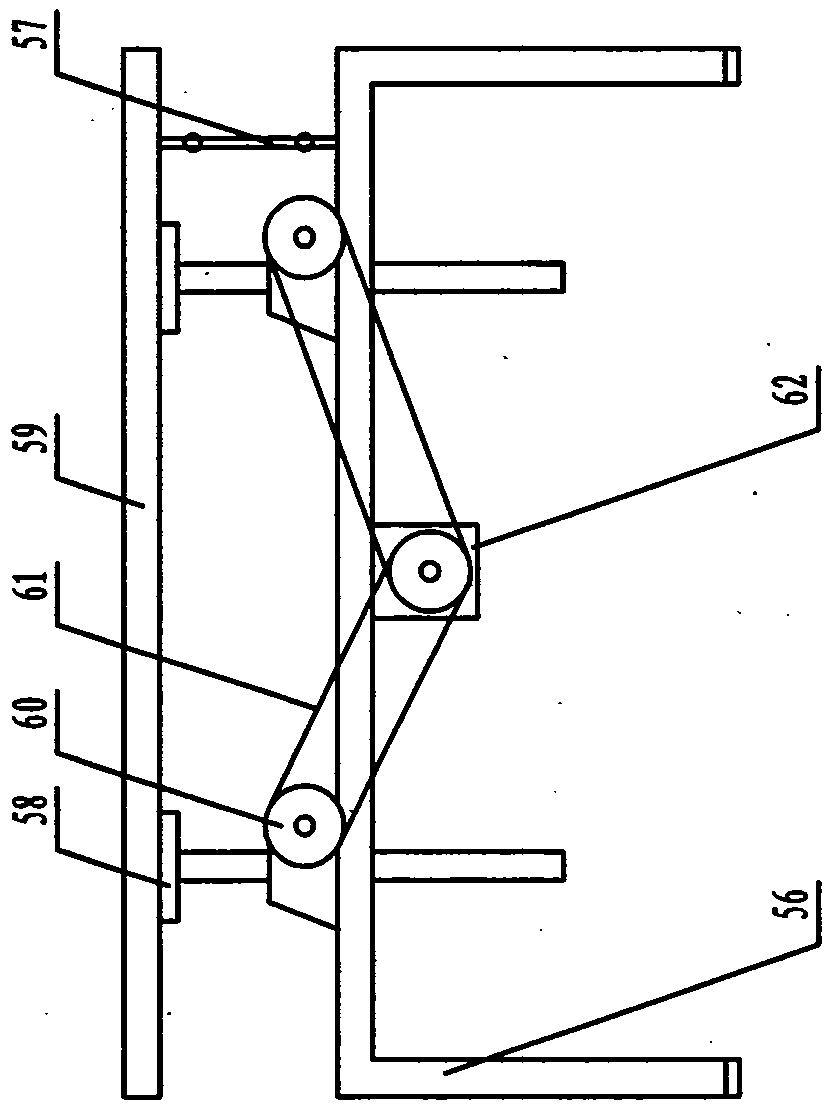

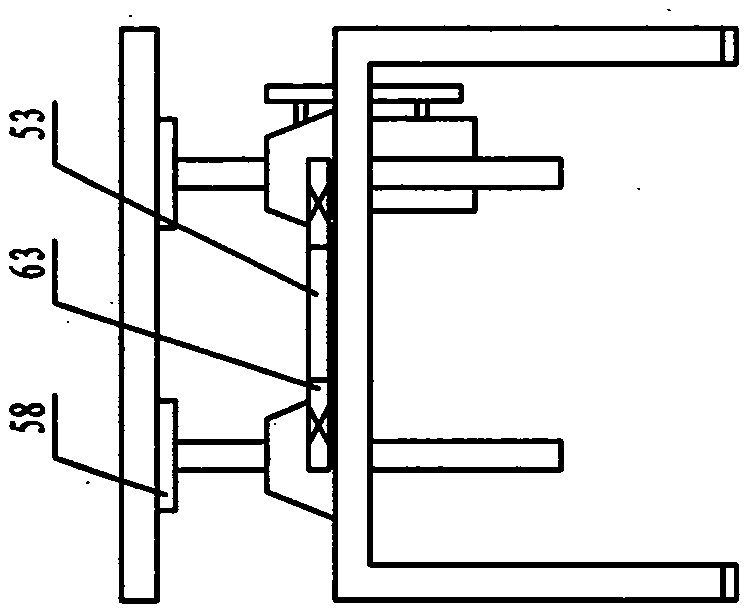

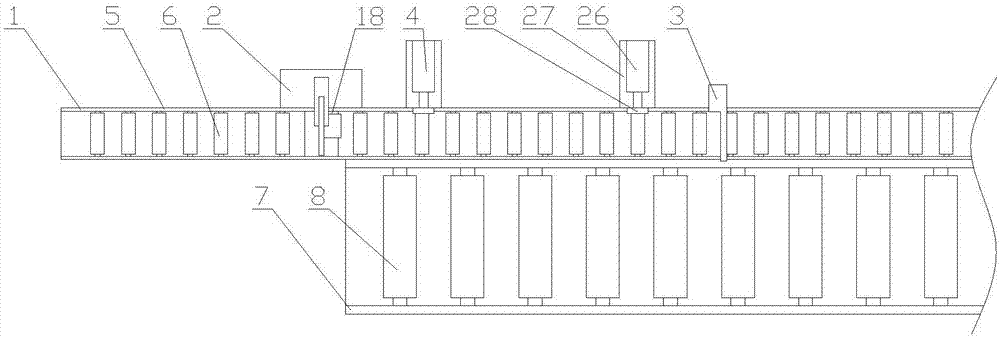

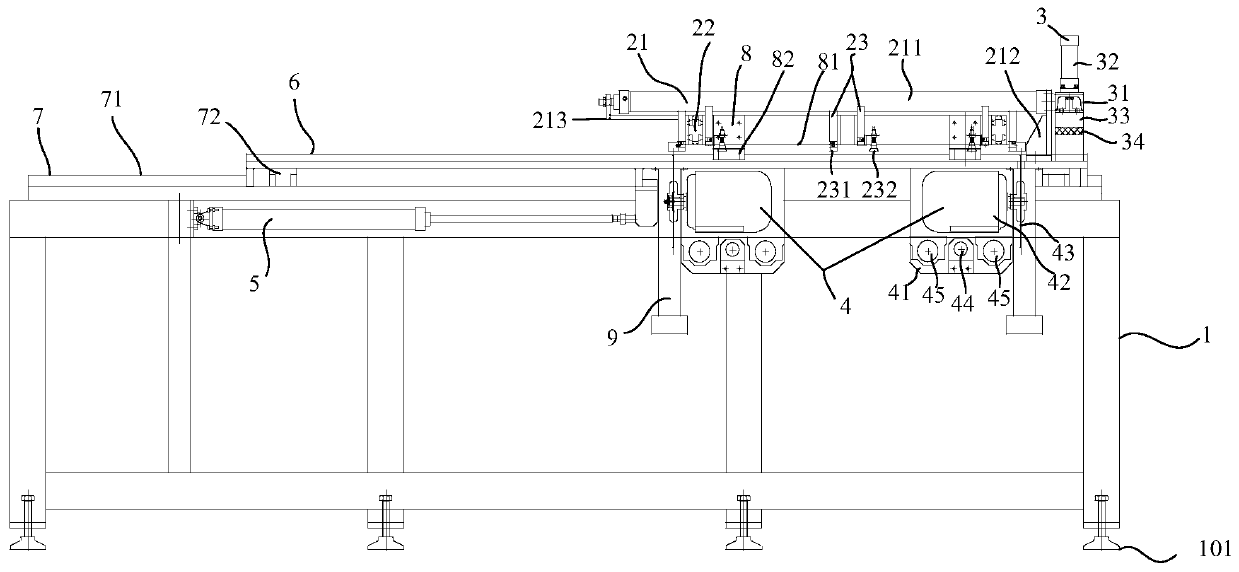

Automatic cutting equipment of aluminum profile

InactiveCN106903361ANo manual operation requiredCut to exact lengthShearing machinesShearing machine accessoriesAutomatic test equipmentAutomatic control

The invention provides an automatic cutting equipment for aluminum profiles, which includes a conveying track, a cutting machine, a spacer assembly and a blanking assembly; the conveying track is located at the front end of the discharge port of the hot extrusion molding machine and extends forward in the workshop; The cutting machine is located on one side of the conveying track, and is fixedly connected with the edge of the conveying track; the spacer assembly is located in front of the cutting machine and at the edge of the conveying track. , is located on the same side as the cutting machine, and slides freely along the conveying track; the blanking assembly is located on one side of the conveying track, and is located on the same side as the cutting machine and the spacing assembly , fixed on the bottom of the workshop. The invention provides an automatic cutting equipment for aluminum profiles, which determines the length of the aluminum profiles through a distance-fixing component, controls the start and stop of the equipment, automatically cuts after the distance is determined, and pushes the profiles to the unloading area after the cutting is completed. Automatic control, no manual operation is required, and the production efficiency is improved while ensuring the accurate cutting length.

Owner:苏州银得铝业有限公司

Efficient shearing device for textile fabric production and working method thereof

ActiveCN109868601ACut to exact lengthImprove cutting efficiencyMechanical cleaningPressure cleaningEngineeringTextile

The invention discloses an efficient shearing device for textile fabric production in the technical field of textile fabric production. The efficient shearing device comprises a box body and a fabric.Circular knives are movably arranged on the top and in the middle of an inner cavity of the box body. A spraying pipe is arranged on the top of each circular knife. A supporting device is arranged onthe outer side of each circular knife. The right side of the supporting device on the upper side and the left side of the supporting device on the lower side are each provided with a cleaning device.The left side of the supporting device on the upper side and the right side of the supporting device on the lower side are each provided with a tensioning device. The fabric is pushed downwards to betensioned through the tensioning devices, the cutting length precision is ensured, the fluff on the lower side of the fabric is in a vertical state under the influences of the wind blowing and gravity, the hair cutting is facilitated, the fluff on the two sides of the fabric is cut by the circular knives on the upper side and the lower side, the effect of improving the fluff cutting efficiency isrealized, the wind in a pipe body enters an inner cavity of a combing rod and is vertically downwards sprayed out of a spraying hole to blow off the adhered fluff, and the cleanliness of the fabric is ensured.

Owner:义乌市航英科技有限公司

Automatic photovoltaic module aluminum cutting machine

A full-automatic photovoltaic module aluminum product cutting machine comprises a machine frame, a pressing device and a cutting device. The cutting device comprises two saw blades, two motors, a pushing cylinder and a placing plate. The two motors respectively drive the respective saw blades to rotate and are arranged on two sides of the placing plate. The two motors are relatively slantly arranged on the placing plate, inclination angles of the motors can be controlled through an adjusting positioning device, the pushing cylinder drives the placing plate to move longitudinally, the machine frame is further provided with an open groove matched with moving tracks of the saw blades, and the saw blades are used for cutting aluminum products in the placing plate moving process. The full-automatic photovoltaic module aluminum product cutting machine in a novel structure runs smoothly, the aluminum products are fed evenly, a cutting section is high in quality, a cutting length is accurate, and the aluminum product cutting machine is safe and reliable, can perform one-time cutting on a plurality of aluminum products and is simple in structure and high in using efficiency.

Owner:深圳市索阳新能源科技有限公司

Efficient tailoring device for clothing factory

ActiveCN106087378AHigh precisionImprove collection efficiencySevering textilesIndustrial engineeringPulley

The invention relates to a tailoring device, in particular to an efficient tailoring device for a clothing factory. The technical problem to be solved is how to provide an efficient tailoring device high in tailoring efficiency for a clothing factory. In order to solve the technical problem, the efficient tailoring device for the clothing factory comprises a box, a base plate, a second electric wheel, a first pull rope, a first supporting rod, a pair of scissors, a third sliding block, a push rod, a roller, a rotating shaft, a servo motor, a second supporting rod, a first sliding block, a second sliding rail, a second pull rope, a first fixed pulley, a second fixed pulley, a second sliding block, a first sliding rail and a first electric wheel and the like. The base plate is arranged between the front wall and the rear wall in the box. The efficient tailoring device for the clothing factory has the advantages of high tailoring efficiency, tailoring length accuracy, simplicity in operation, convenience in the operation process and long service life. Besides, since a limiting plate and a limiting block are arranged, the tailoring accuracy can be further improved.

Owner:平湖凯隆新材料科技有限公司

Efficient cable shearing device for electric power

The invention relates to the technical field of cable equipment, in particular to an efficient cable shearing device for electric power. The device solves the problems that in the prior art, manual cutting is carried out through a shearing device, the working efficiency is low and tiredness is caused, a large amount of cutting cannot be completed and then loaded in a material receiving direction for unified collection and use, the length of a cable is also manually estimated and sheared, the accuracy is low, and the working efficiency is relatively low. The efficient cable shearing device for the electric power comprises a bearing plate and a first winding roller on one side of the top of the bearing plate, two pay-off auxiliary mechanisms are arranged on one side of the first winding roller in parallel, and a cutting device is arranged on one sides, away from the first winding roller, of the two pay-off auxiliary mechanisms. According to the efficient cable shearing device, automatic shearing of cables can be conveniently achieved, the working efficiency is improved, the labor amount of workers is reduced, the shearing length accuracy is improved, the shearing quality is improved, the collecting efficiency is improved, and the time occupied by later classification is shortened.

Owner:纵凯旋

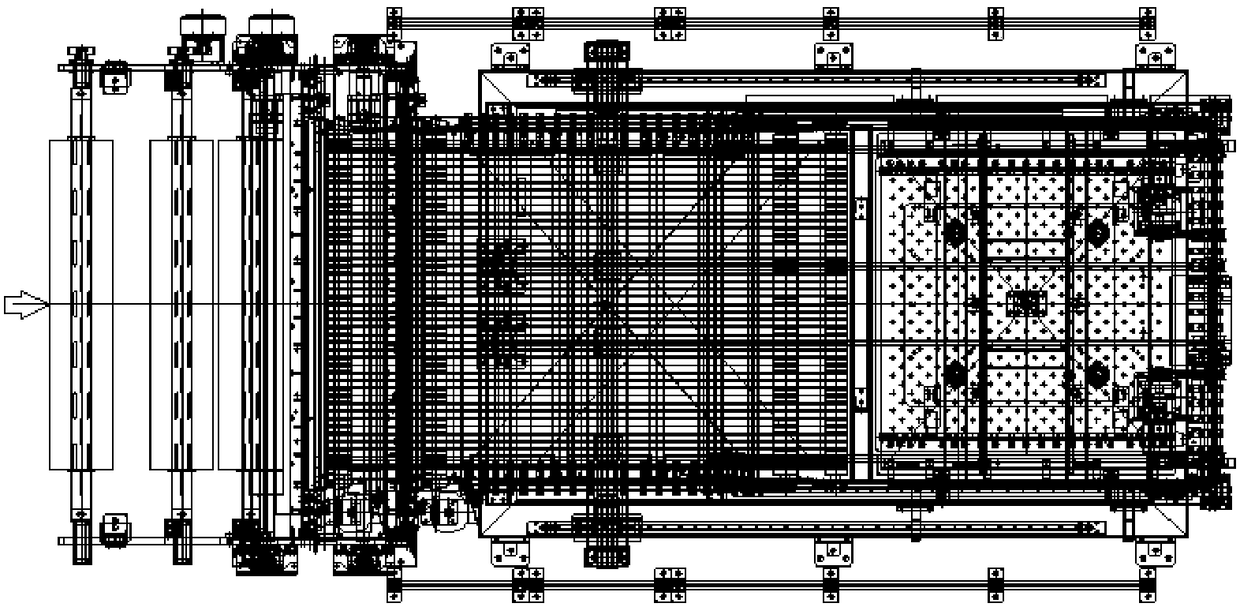

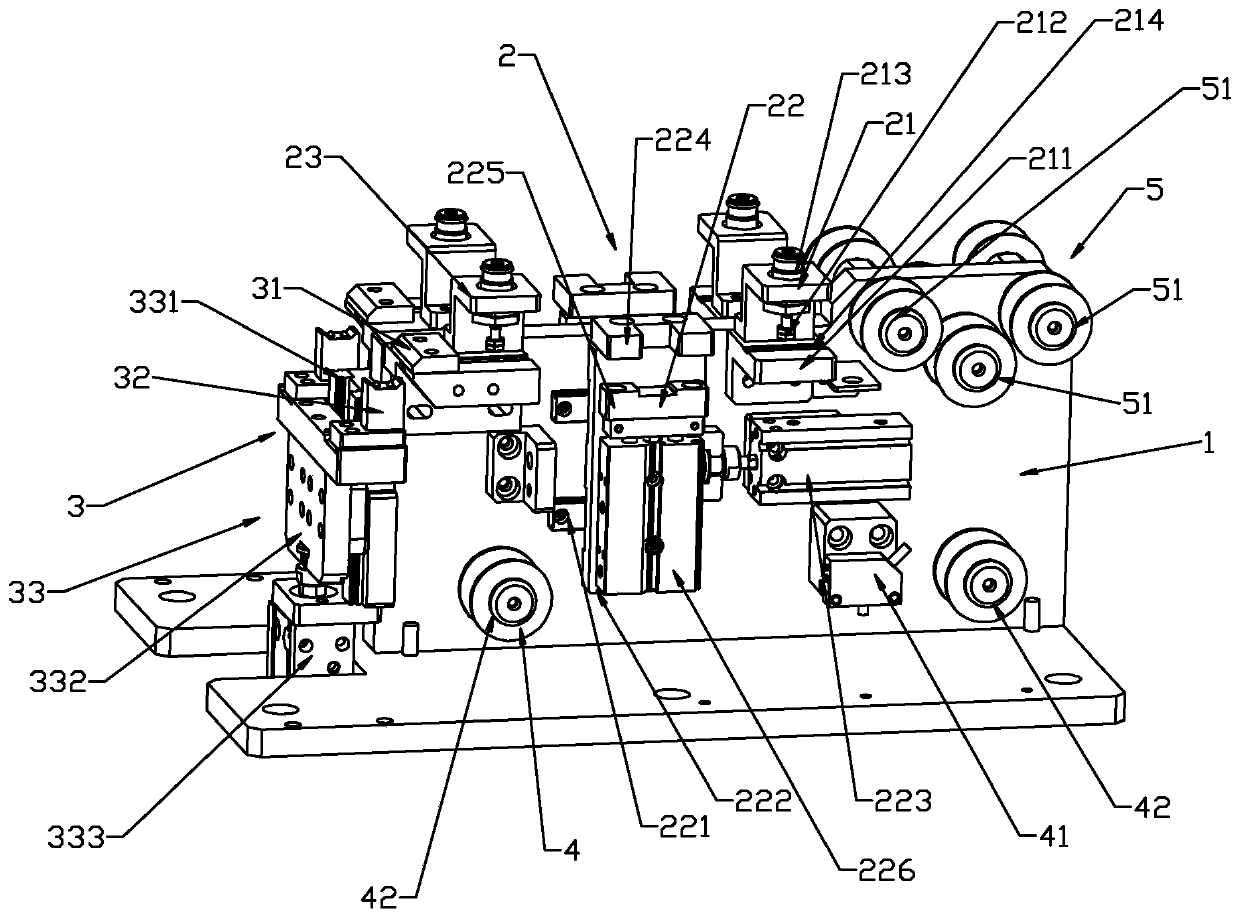

Pressure-free guide type double-copper-foil cutting forming system

PendingCN108455330AAvoid wrinklesPrevent slippingMetal working apparatusArticle deliveryCopper foilEngineering

The invention discloses a pressure-free guide type double-copper-foil cutting forming system. At least one copper foil cutting and conveying mechanism is arranged on a rack at intervals in the longitudinal direction. Each copper foil cutting and conveying mechanism comprises a chuck, a first plane conveying device, a cutting mechanism and a second plane conveying device are sequentially arranged in the conveying direction of copper foil. Conveying driving devices drive the chucks for mounting copper foil coils on the rack. The copper foil on the copper foil coils is led out to the surfaces ofthe corresponding first plane conveying devices. The first plane conveying devices and the second plane conveying devices can conduct conveying in the conveying direction of the copper foil correspondingly. First air pressure supply devices and second air pressure supply devices are used for providing air pressure making close contact with the surfaces of the first plane conveying devices and thesecond plane conveying devices for the copper foil on the surfaces of the first plane conveying devices and the second plane conveying devices. The first plane conveying devices, the cutting mechanisms and the second plane conveying devices are aligned and connected in pairs. The copper foil getting into the cutting areas of the cutting mechanisms can be cut off through the cutting mechanisms. Thepressure-free guide type double-copper-foil cutting forming system can convey the copper foil without being pressed by guide wheels, and the phenomenon that the copper foil slips and gets wrinkled inthe conveying process is avoided.

Owner:KUNSHAN JUHONG MACHINERY TECH

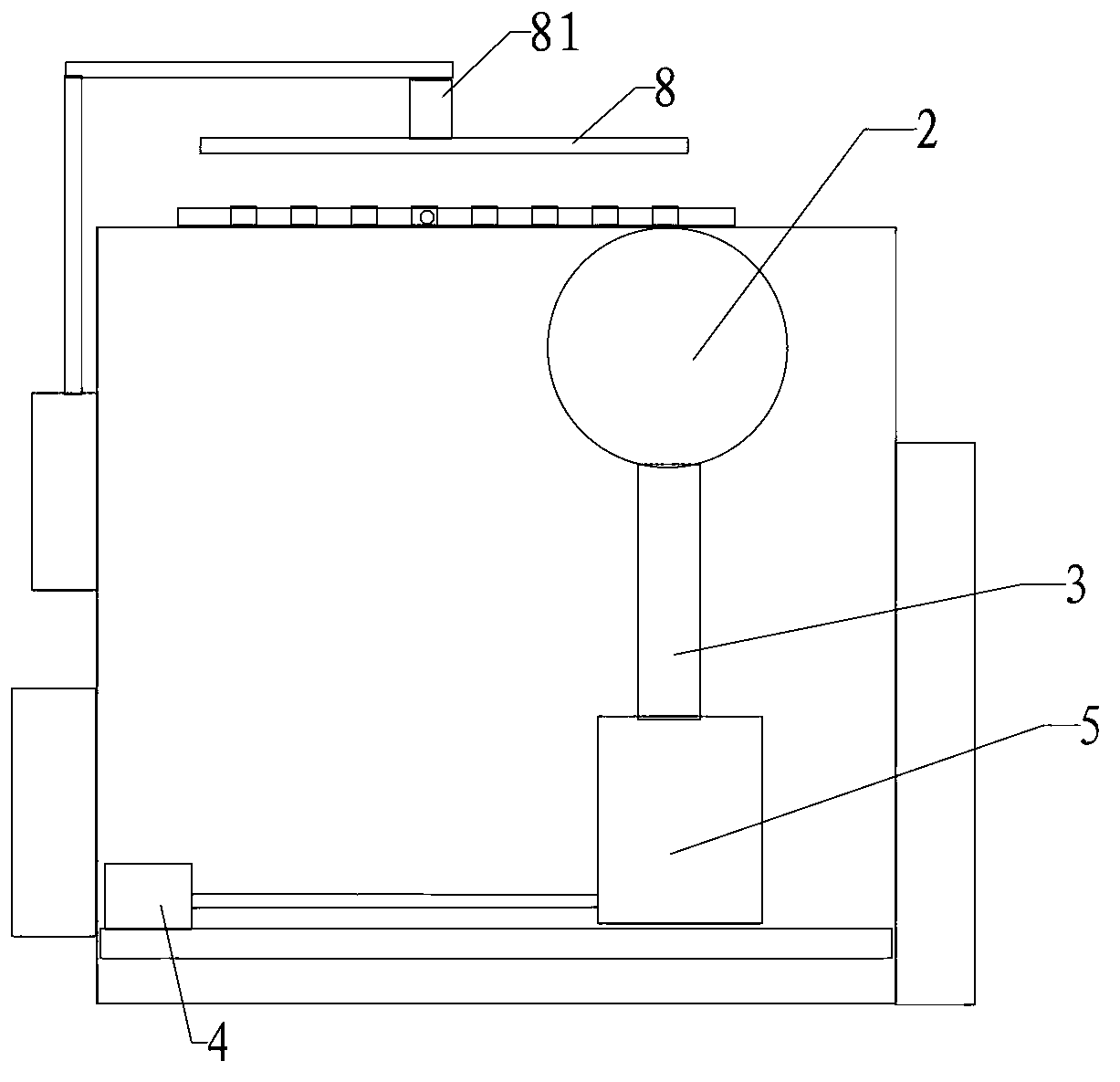

Anti-deformation aluminum profile cutting equipment

The invention provides anti-deformation aluminum profile cutting equipment and belongs to the technical field of aluminum material machining. The anti-deformation aluminum profile cutting equipment comprises a box internally provided with a cavity and is characterized in that a driving table and a cutting table are arranged in the box; the cutting table is provided with a clamping assembly capableof locating an aluminum profile on the cutting table; the clamping assembly comprises a fixing plate, an adjusting plate and a locating plate; a conveying mechanism is arranged between the cutting table and the box and can enable the aluminum profile to horizontally move in the box; the driving table is provided with a cutting assembly; the cutting assembly comprises a cutting motor and a rotaryshaft which are fixed to the driving table; a plurality of cutting saw blades are fixed to the rotary shaft; and a driving mechanism is arranged between the driving table and the box and can enable the aluminum profile to horizontally move in the box. The anti-deformation aluminum profile cutting equipment has the advantage that the aluminum profile can be cut precisely and stably.

Owner:平湖市法埃斯铝制品有限公司

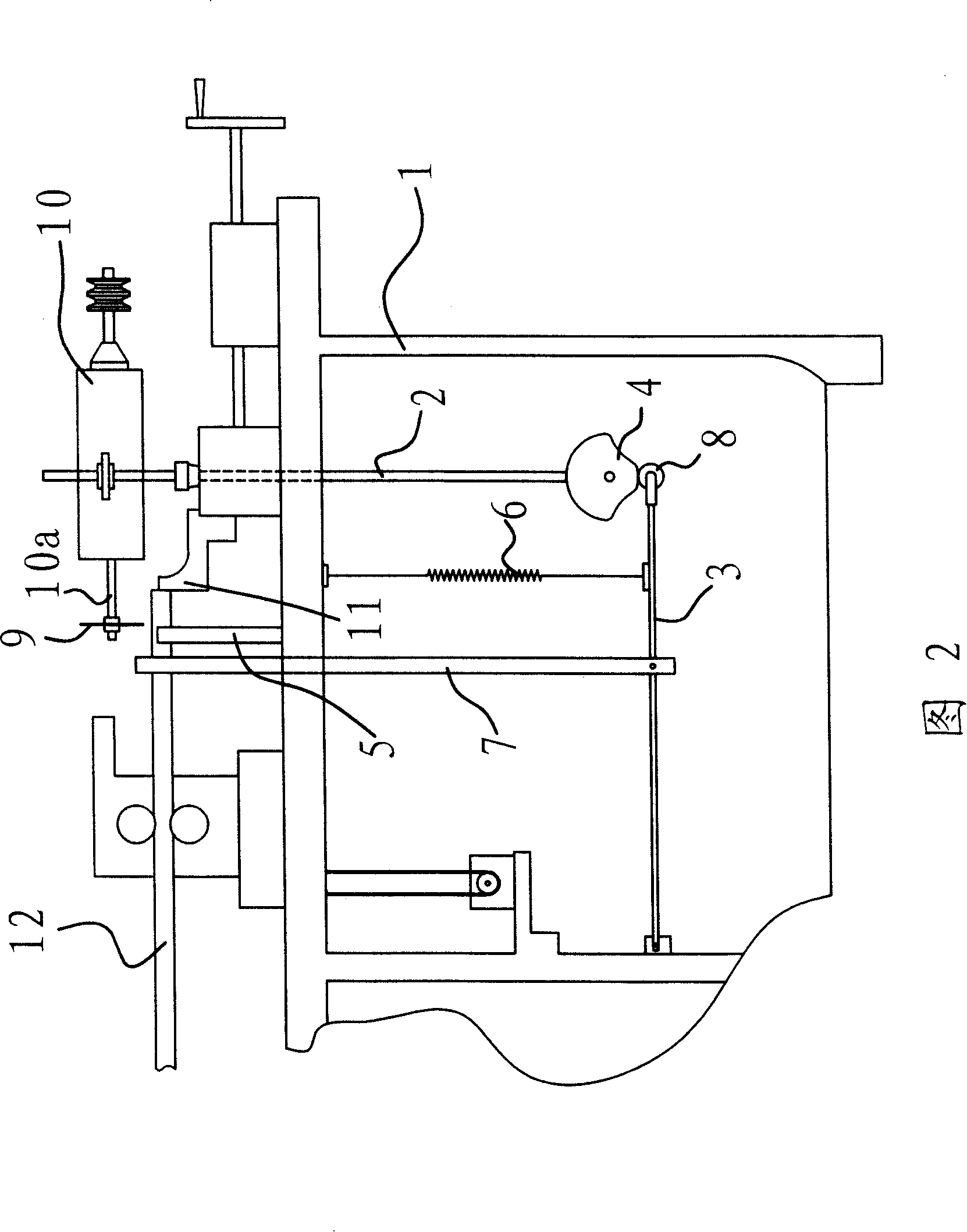

Cutting mechanism of rod material automatic cutting machine

InactiveCN100393461CSmooth rotationReduce frictionShearing machinesShearing machine accessoriesCamFuselage

A cutting mechanism for automatic rod cutter is composed of an electric motor, cutting blades fixed to shaft of motor, a cam, a vertically moving connection rod with a top end linked to motor and a lower end in touch with said cam, a supporting block at discharge exit, a transverse bar, and a press rod with lower end connected to said transverse bar. Its advantage is correct cutting length.

Owner:玉环县三合机床厂(普通合伙)

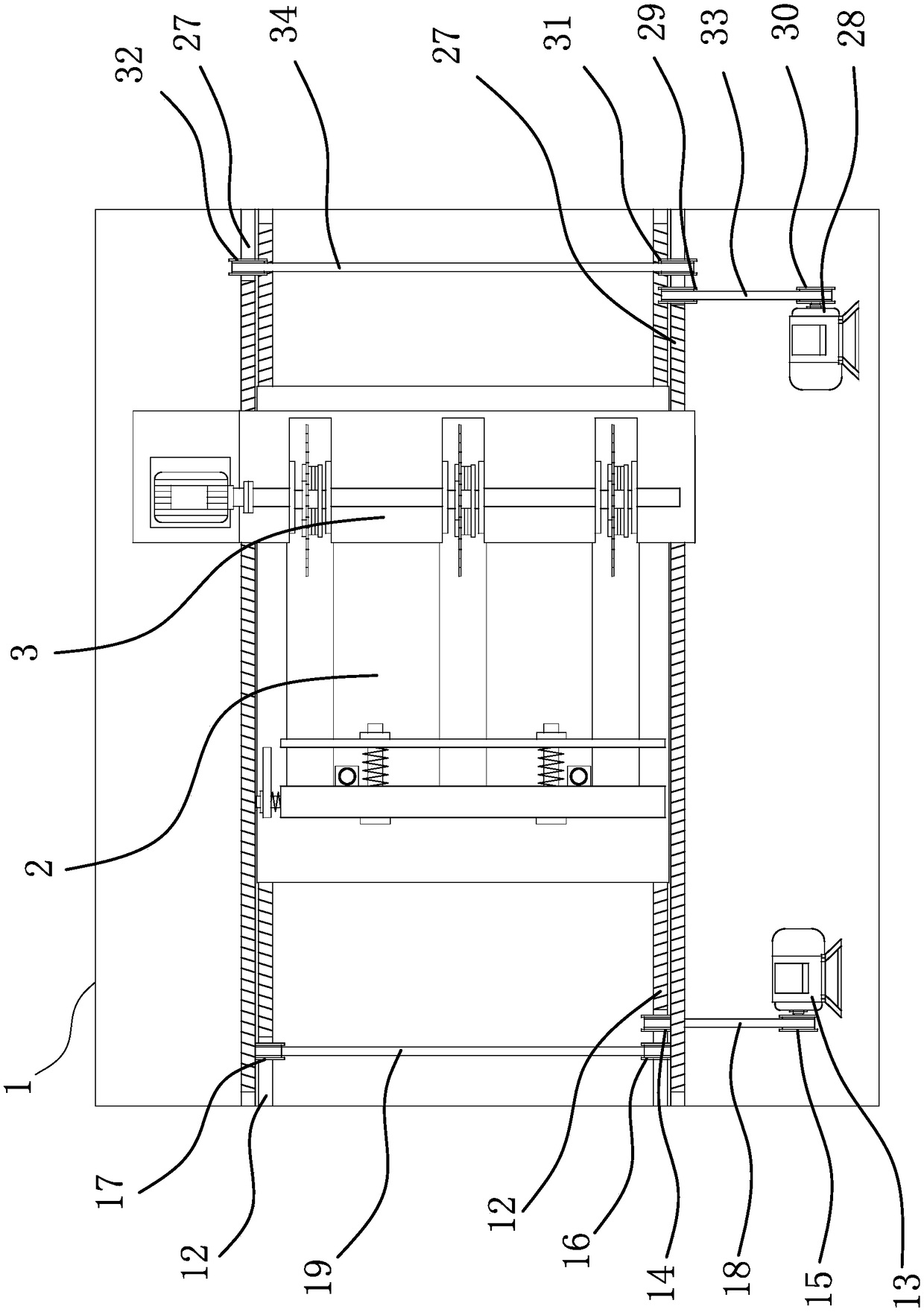

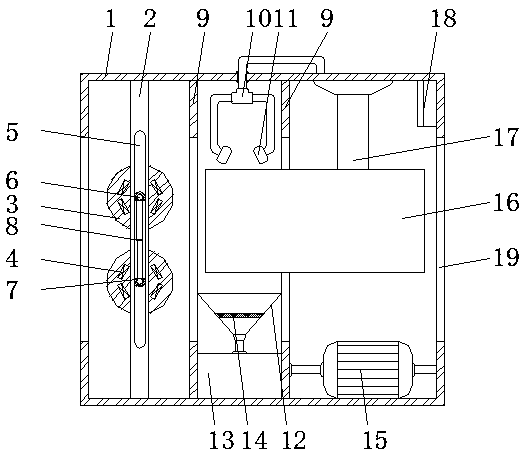

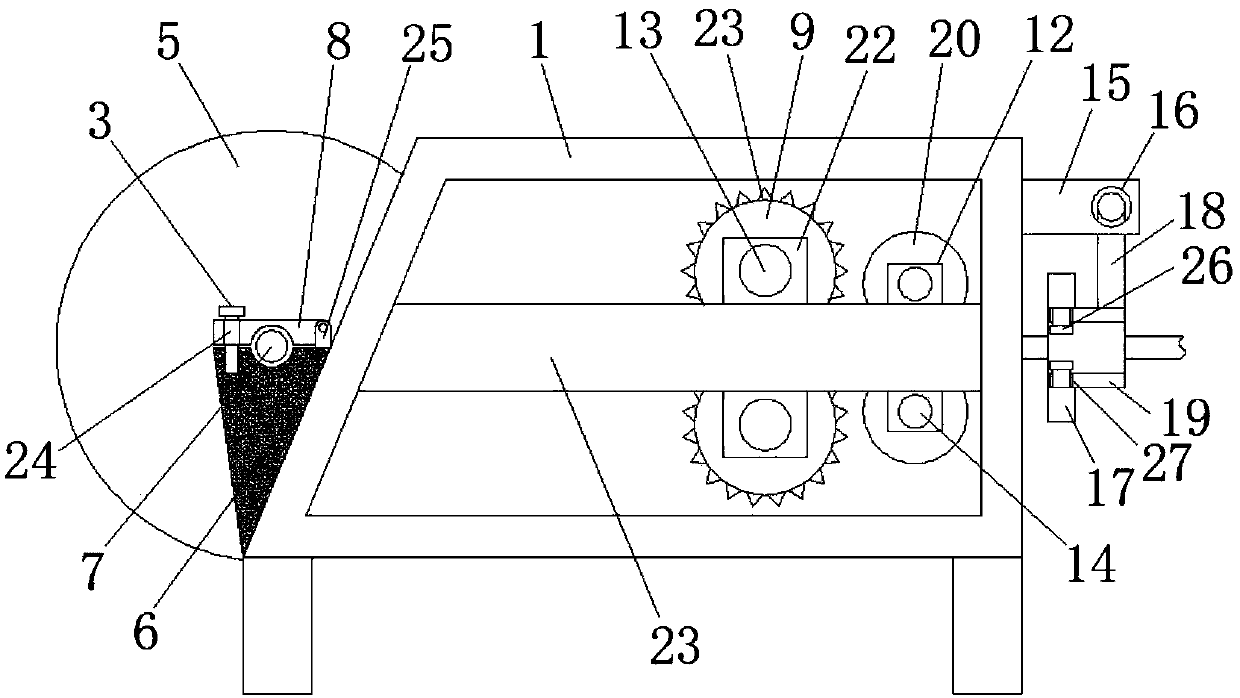

Cutting device for high-strength large-diameter nodular cast iron pipe production

InactiveCN108015359ACut to exact lengthPrecise cutting length controlMetal working apparatusMaintainance and safety accessoriesEngineeringHigh intensity

The invention discloses a cutting device for high-strength large-diameter nodular cast iron pipe production. The cutting device comprises a box body, transmission rollers, pressure sensors, an electric telescopic rod, spraying heads, a collecting device and a PLC. A mounting frame is arranged in the box body, the transmission rollers are arranged on the mounting frame, evenly-distributed pressuresensors are arranged in the transmission rollers, a sliding groove is formed in the mounting frame, sliding blocks are arranged in the sliding groove, the two sliding blocks in the sliding groove areconnected through the electric telescopic rod, the transmission rollers are arranged on the sliding blocks in the sliding groove through rotating shafts, and a partition board is arranged on the rightside of each transmission roller. According to the cutting device for high-strength large-diameter nodular cast iron pipe production, the box body, the transmission rollers, the pressure sensors, theelectric telescopic rod, the spraying heads, the collecting device and the PLC are arranged, and the problems that the cast iron pipe cutting length error is large, and generated chippings and dust danger body health of a worker are solved.

Owner:江苏日升电力机械有限公司

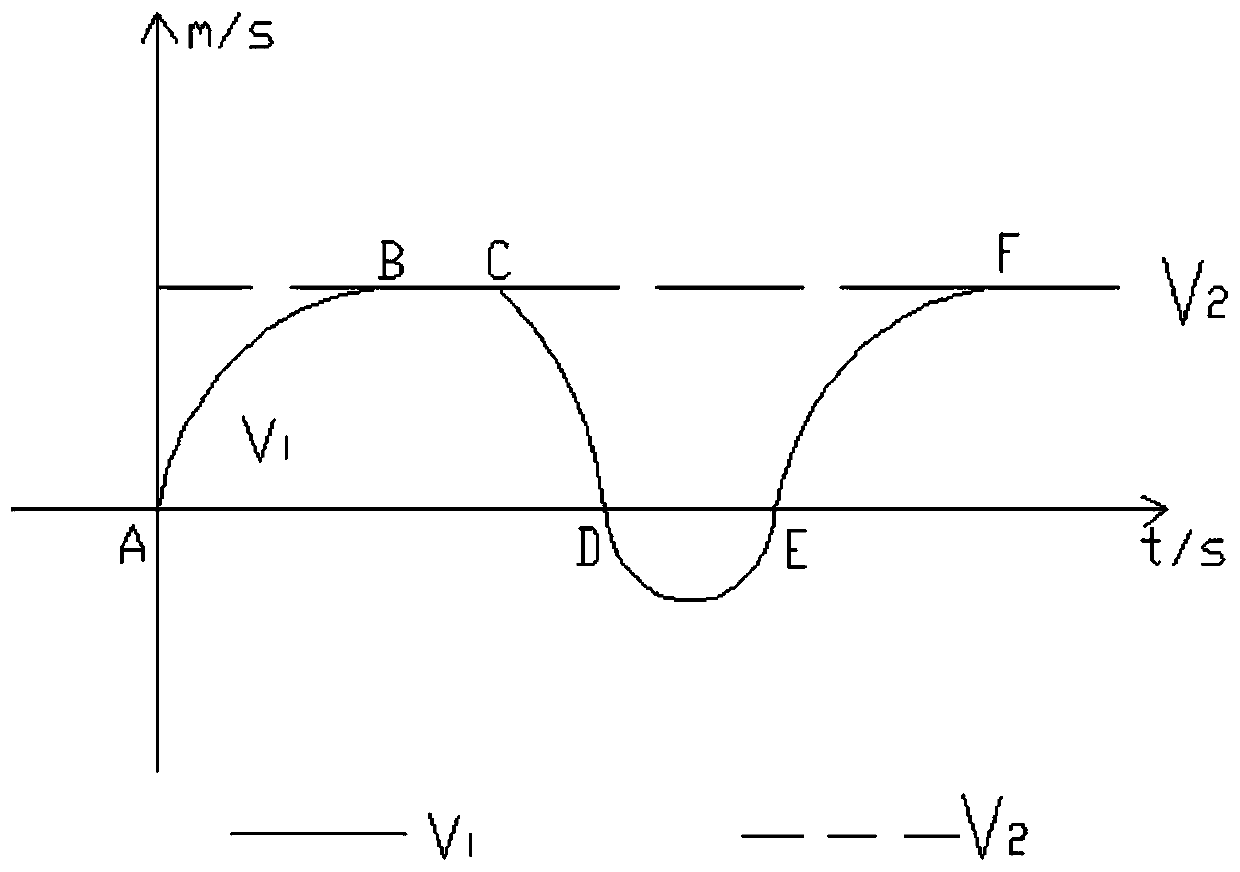

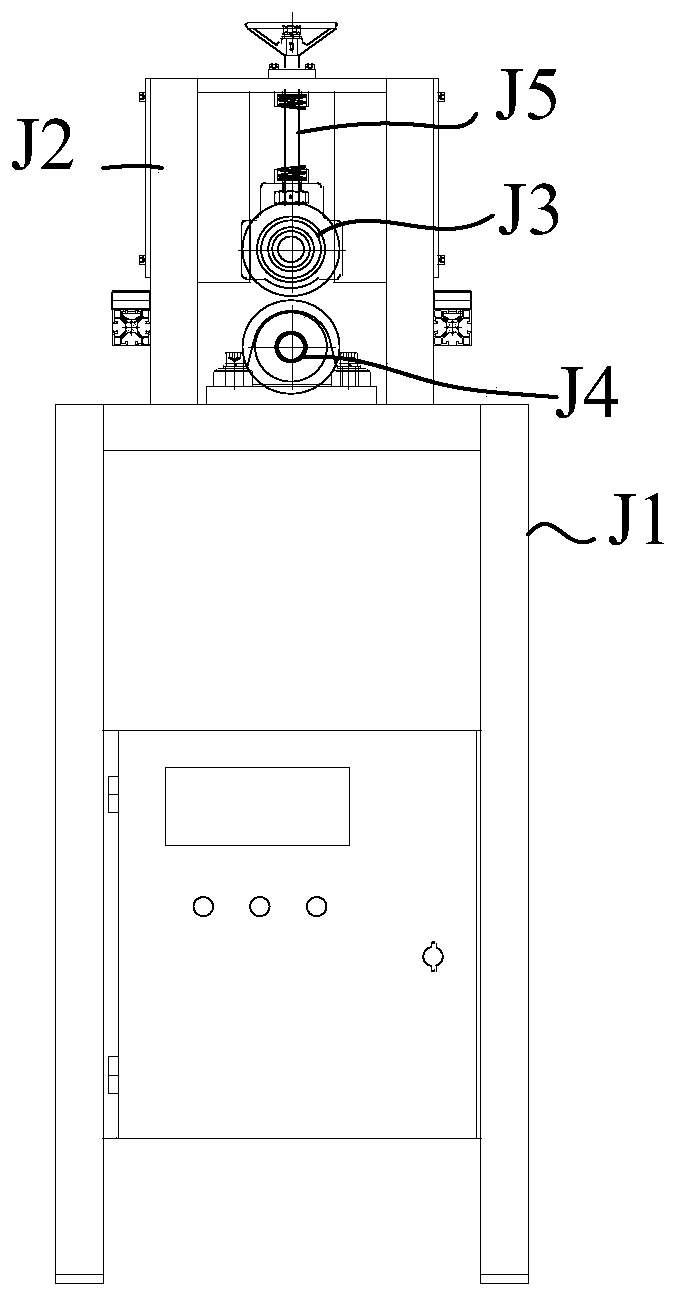

Flying shearing machine

InactiveCN110497018ASmooth motionRealize automatic controlStock shearing machinesShearing machine accessoriesProduction rateActuator

The invention discloses a flying shearing machine. The flying shearing machine comprises a tool-carrying trolley, a lower tool block, a carrier, a first actuator which is used for controlling the tool-carrying trolley to move in a first direction and making the speed of the tool-carrying trolley be consistent with the workpiece feeding speed, a mobile tool holder, a second actuator which is arranged on the carrier and used for controlling the mobile tool holder to move in the vertical direction, an upper tool block which is arranged on the mobile tool holder and located above the lower tool block, and a stroke monitoring mechanism for generating a shearing monitoring signal when detecting a workpiece, wherein the lower knife block and the carrier are arranged on the knife-carrying trolley;and the first direction is parallel to the length direction of workpieces. The flying shearing machine is stable in movement and can be automatically control, the position of the workpieces during the cutting process can be stabilized, the accurate cutting length of the workpieces is ensured, the productivity is high, and the product cutting quality is improved.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

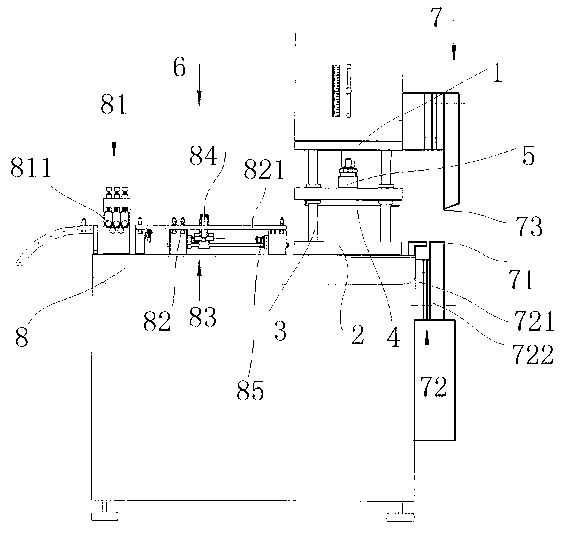

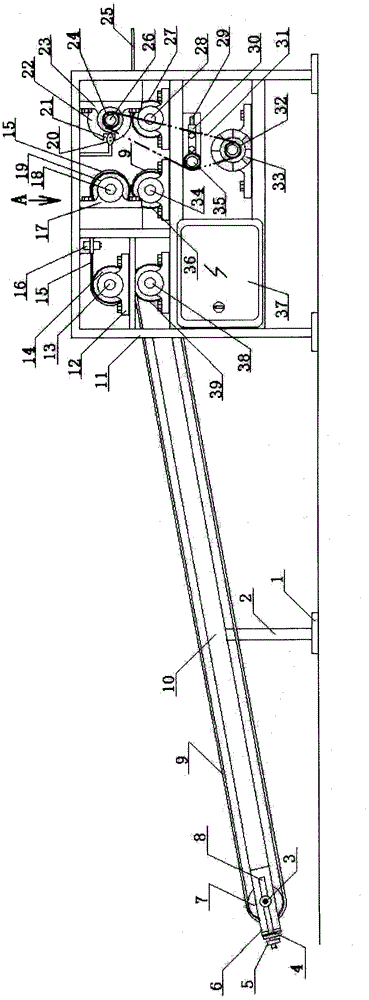

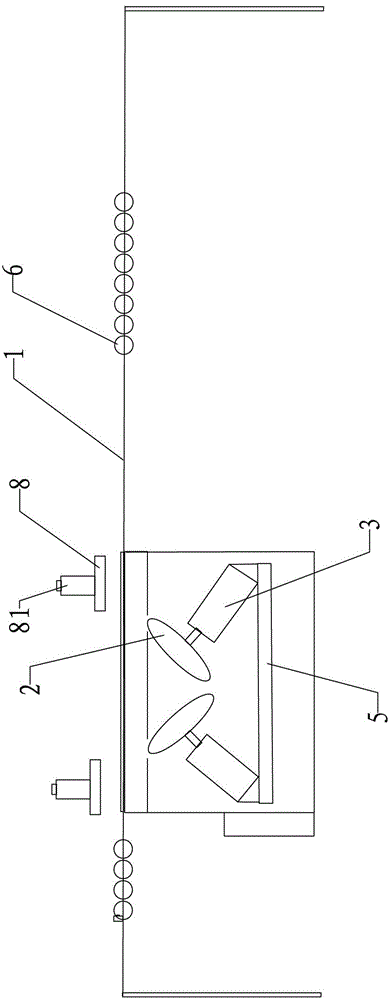

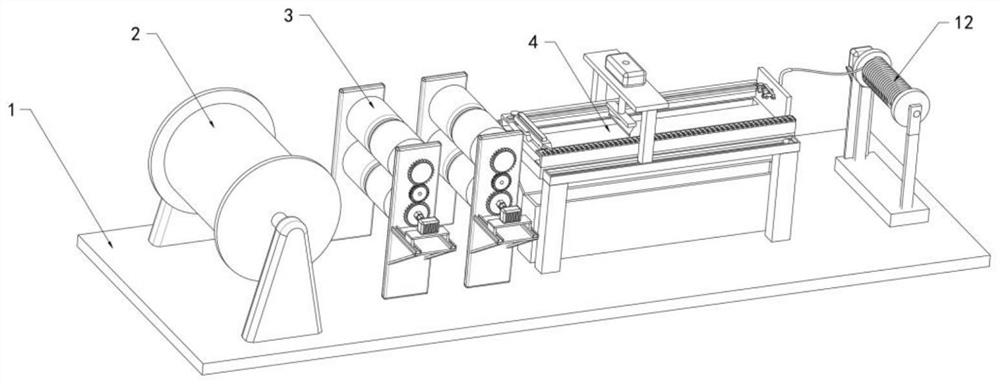

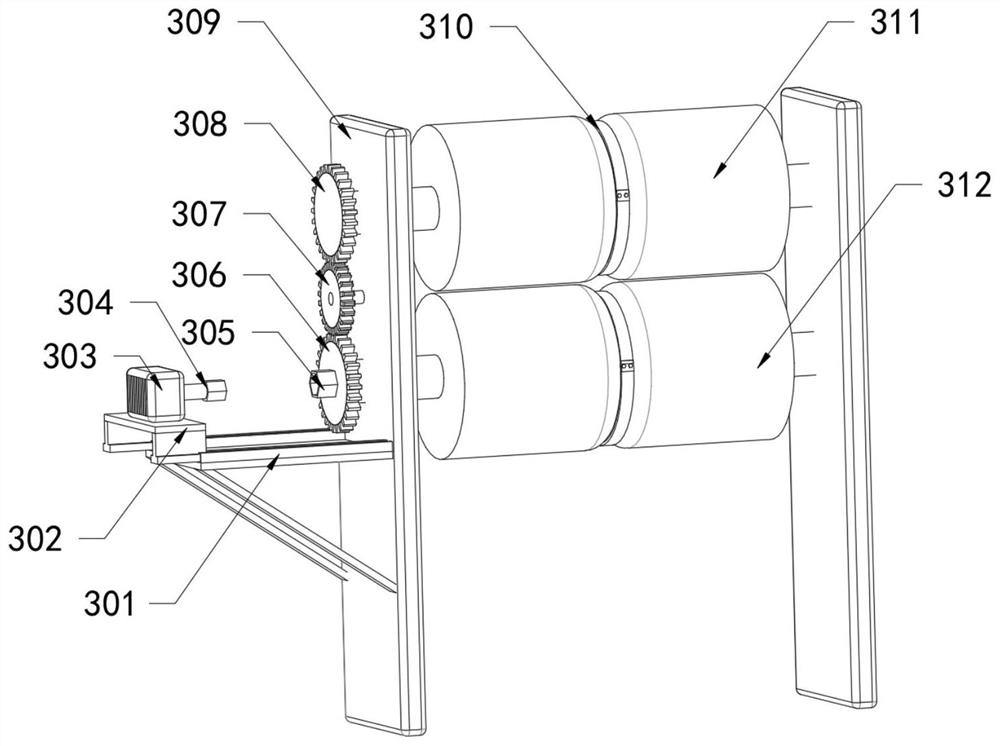

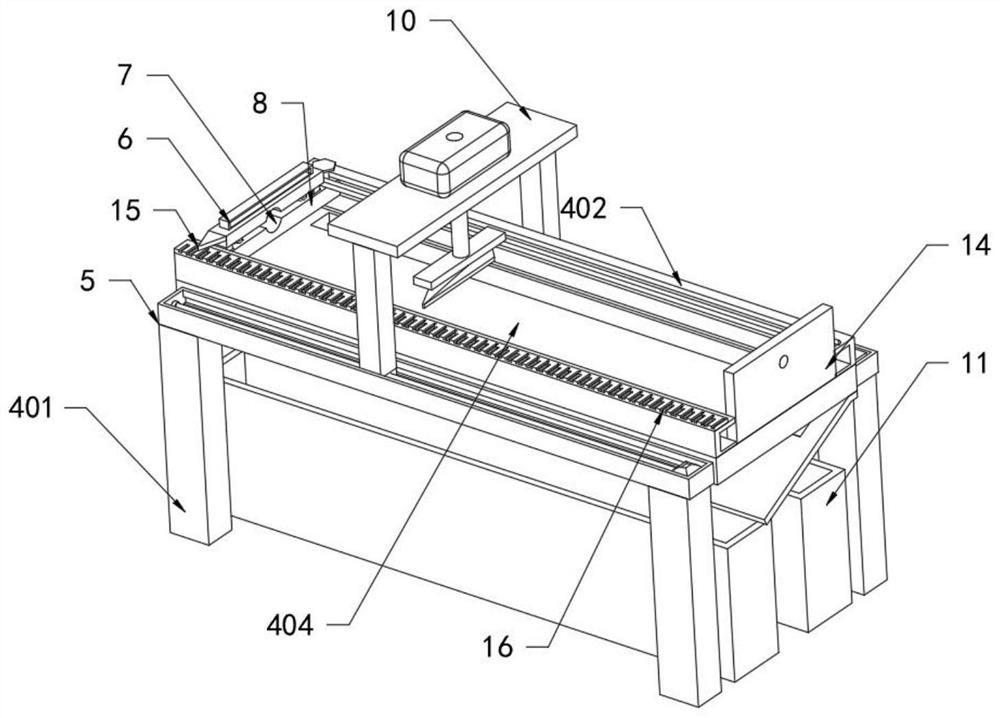

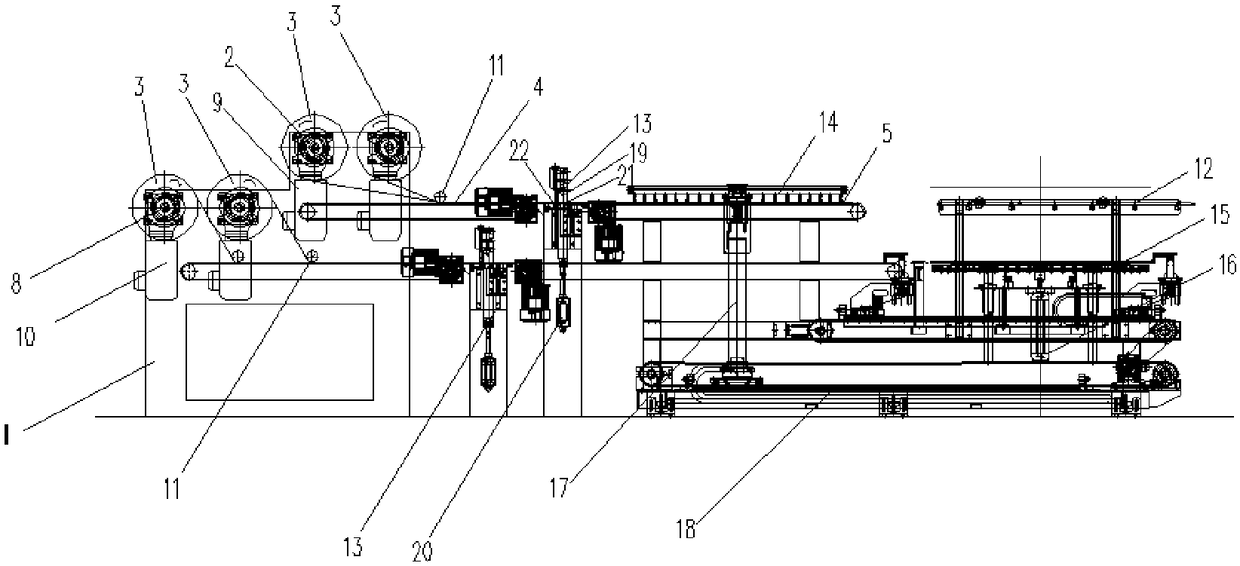

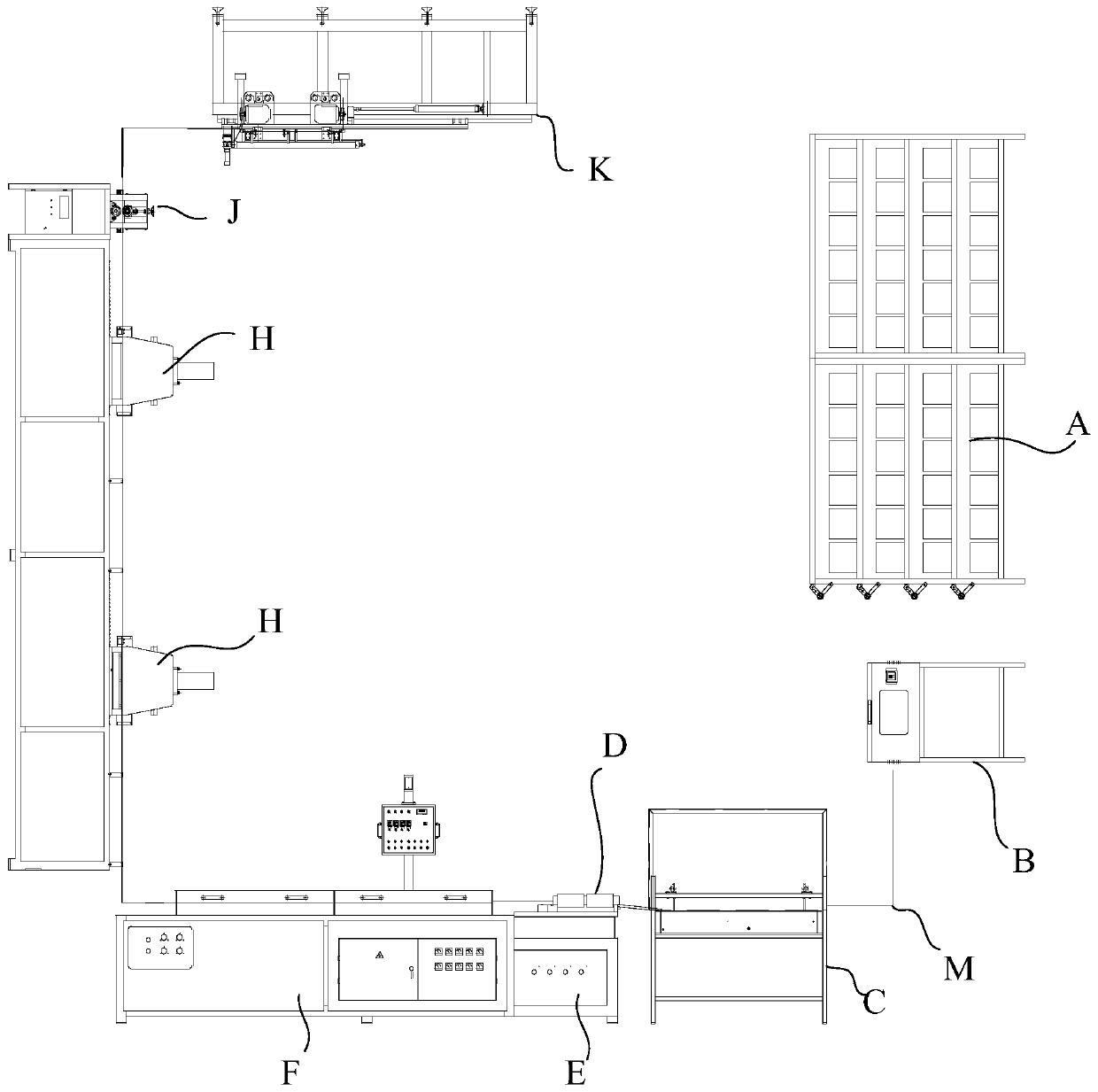

Production method and matched production line of fiber reinforced composite ribbon

PendingCN111016222AIncrease productivityImprove cutting accuracyMetal working apparatusGlass fiberFiber-reinforced composite

The invention belongs to the field of ribbon production, and relates to an industrial production technology of ribbons, in particular to a production method and a matched production line of a fiber reinforced composite ribbon. The production method comprises that glass fibers are sequentially dehumidified, impregnated, shaped, straightened, cured, dried and cut, the matched production line sequentially comprises a creel, a dehumidifier, a resin tank, a mold table, a post-curing oven, traction equipment and a ribbon cutting device in the glass fiber flowing direction. The overall design is simple and reasonable, and a pressing mechanism, a feeding mechanism, a cutting mechanism and two sliding assemblies of the ribbon cutting device greatly improve the cutting precision of the ribbon. Due to the arrangement of a photoelectric switch and a product collecting box, the cutting length of the ribbon is more accurate, the ribbon is more convenient to collect, the manpower is correspondingly saved, and the efficiency is improved.

Owner:JINAN GOLD LEAD MACHINERY

Feeding slicing device

PendingCN109823892AGuaranteed sticking effectCut to exact lengthMetal working apparatusArticle deliveryEngineeringMechanical engineering

The invention relates to a feeding slicing device. The feeding slicing device comprises a machine frame; the machine frame is sequentially provided with an equal-length material feeding mechanism, a cutting mechanism and a guiding mechanism in the material belt conveying direction; the equal-length material feeding mechanism conveys equal-length material belts to the cutting mechanism at a time, slice bodies are separated from the material belts at the position of the cutting mechanism, equal-length slice bodies are cut from a continuous slice body through the cutting mechanism, and the guiding mechanism guides the material belts separated from the slice bodies to the recycling position. The scheme is adopted, according to the feeding slicing device provided by the invention, the cutting precision and the machining efficiency are improved, and material belt recycling is facilitated.

Owner:浙江华亿电气有限公司

Arc-shaped dome plate machining device

ActiveCN112276200AReduce labor costsImprove work efficiencyMetal-working feeding devicesShearing machinesGear driveDrive shaft

The invention relates to the technical field of industrial automation, and discloses an arc-shaped dome plate machining device. The arc-shaped dome plate machining device comprises a machine body; a carrying plate is fixedly connected to the upper side of the right side in the machine body; an internal tooth gear is arranged above a bearing plate; a third driving shaft is arranged in the internaltooth gear; a rotating rod is fixedly connected to the surface of the third driving shaft; the other end of the rotating rod is rotationally connected with a driven gear; the surface of the driven gear is rotationally connected with a push rod; the other end of the push rod is rotationally connected with an adjusting block; and a plate is arranged on the right side of the adjusting block. According to the arc-shaped dome plate machining device, the third driving shaft drives the rotating rod to rotate, the rotating rod drives the driven gear to rotate in the internal tooth gear, the driven gear drives the push rod to enable the adjusting block to slide on the bearing plate, and then through the cooperative use that the first driving shaft drives a tooth line plate and the tooth line plateis used for transporting the plate, the effect that the cutting length of the plate can be accurate is achieved.

Owner:湖南乔伟生态科技新材料股份有限公司

Equipment for cutting cable moving in horizontal direction

InactiveCN114833278AUniform incisionCut to exact lengthApparatus for cutting/splicing cablesStructural engineeringMechanical engineering

The invention relates to the technical field of cable processing, in particular to equipment for cutting a cable moving in the horizontal direction. The cable tightening device comprises an operation table and a cable tightening mechanism installed on one side of the top end of the operation table, the operation table comprises an upper plate, a cable pay-off reel is arranged on one side of the top end of the upper plate, a rear groove is formed in the other side of the top end of the upper plate, the cable tightening mechanism comprises a cable pulling disc, a plurality of inner grooves are formed in the inner side of the cable pulling disc, and T-shaped blocks are arranged at the inner ends of the inner grooves; the bottom end of the T-shaped block is connected with a pair of extrusion springs, contraction blocks are arranged on the two sides of the top end of the T-shaped block and matched with the T-shaped block in an inserted mode, and the side faces of the contraction blocks are connected with a plurality of reset springs. According to the cable cutting device, the tensioning function of a cable body is achieved through the arranged cable tightening mechanism, so that it is guaranteed that the cable body moves horizontally in the conveying process, meanwhile, during cutting, the cable body is in a straightened state, a notch is more uniform, it is guaranteed that the cutting length is more accurate, and errors are avoided, and the later use effect is not affected.

Owner:南通佳恒线缆材料有限公司

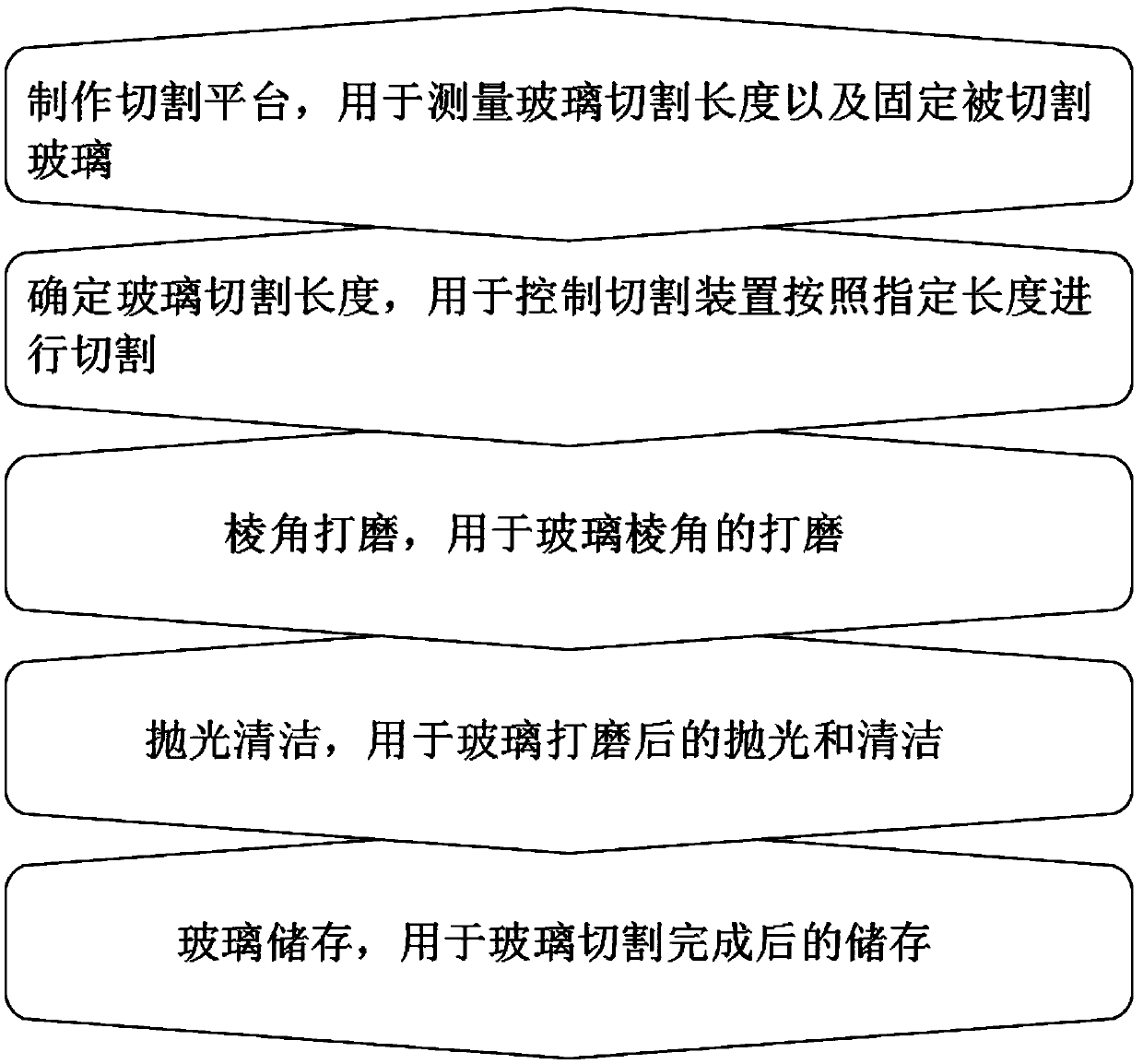

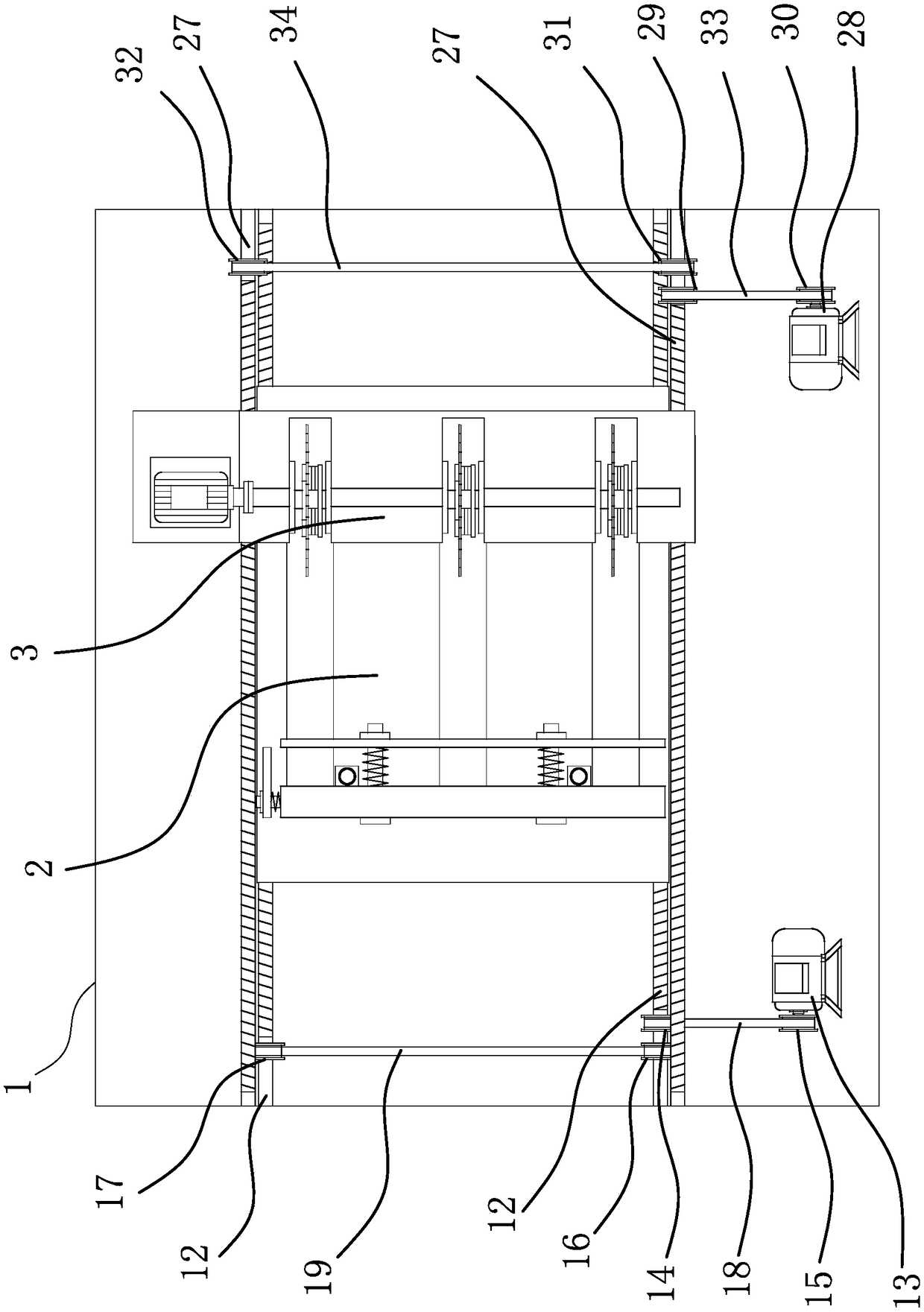

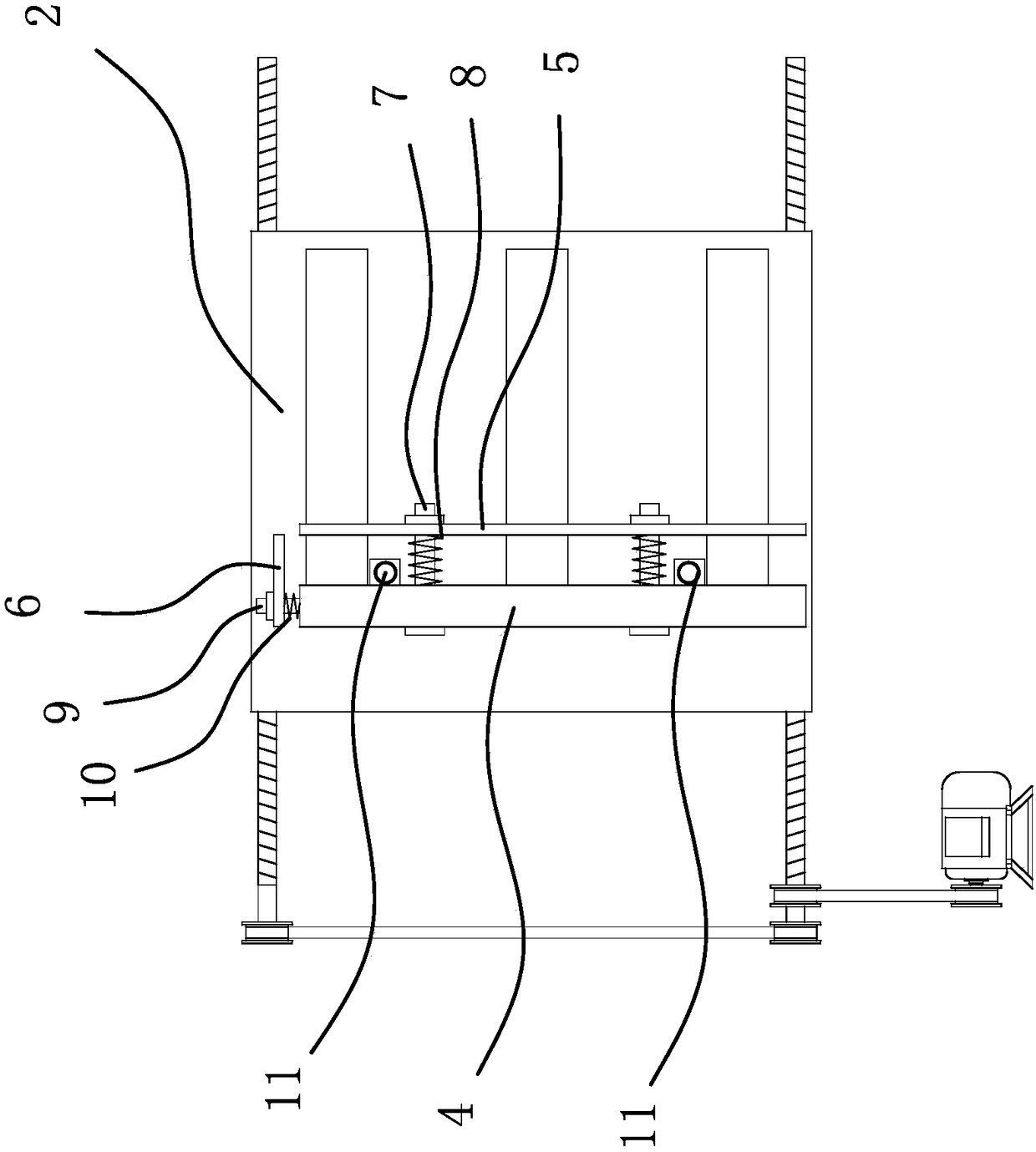

Glass cutting method

InactiveCN109605581ACut to exact lengthImprove efficiencyEdge grinding machinesPolishing machinesNumerical controlCutting glass

The invention discloses a glass cutting method. The glass cutting method comprises the following steps of making a cutting platform for measuring the glass cutting length and fixing glass to be cut; determining a glass cutting length so as to control the cutting device to cut according to assigned length; burnishing edges and corners so as to burnish the glass edges and corners; performing polishing and cleaning so as to polish and clean burnished glass; storing the glass so as to complete storage of the glass after being cut. A distance sensor and a computer numerical control automatic cutting machine are arranged for mutual assistance, the cutting length is input into a computer, and the distance sensor and a measuring ruler are used for precisely measuring the glass cutting length, so that the precise effect is strengthened by an automatic tool setting gauge, the glass cutting efficiency and accuracy are improved effectively, the glass cutting automation degree is effectively increased, and the working efficiency is improved.

Owner:安徽思睿门窗有限公司

Environment-friendly high-precision aluminum profile cutting assembly

PendingCN109317745AAchieve reductionCut to exact lengthMetal sawing devicesEnvironmental resistanceMotor shaft

The invention provides an environment-friendly high-precision aluminum profile cutting assembly and belongs to the technical field of aluminum material machining. The environment-friendly high-precision aluminum profile cutting assembly comprises a driving table and is characterized in that a cutting motor and a rotary shaft are fixed to the driving table; the rotary shaft is fixedly connected with a motor shaft of the cutting motor; a plurality of cutting saw blades are fixed to the rotary shaft; locating blocks are fixed to one sides of the cutting saw blades; limiting nuts are fixed to theother sides of the cutting saw blades, and a plurality of adjusting blocks are fixed between the cutting saw blades and the locating blocks; the adjusting blocks are gaskets with round sections; one sides of the gaskets are provided with openings; and the thickness of the gaskets is 3-10 mm. The environment-friendly high-precision aluminum profile cutting assembly has the advantages that an aluminum profile can be cut efficiently and accurately.

Owner:平湖市法埃斯铝制品有限公司

Sectioned transverse cutting method for plates and multi-blade sectioned transverse cutting machine

PendingCN110026599ACut to exact lengthFast cutting speedShearing machinesShearing machine accessoriesEngineeringMechanical engineering

The invention discloses a sectioned transverse cutting method for plates and a multi-blade sectioned transverse cutting machine. In the plate cutting process, at least two cutting devices simultaneously cut the plates, the plates move while being cut, each cutting device keeps a relatively static state with the plates in the moving direction of the plates, and meanwhile, each cutting device simultaneously moves in the width direction of the plates. The plurality of cutting devices separately cut the plates by one section so that the plates can be cut in the whole width direction. Compared withthe prior art, alignment of the cutting devices with the cutting position of the plates can be ensured, so that the cutting length of the plates is accurate; and meanwhile, the plates are cut by themultiple cutting devices in sections, so that the cutting speed is increased; in addition, the number of cutting devices participating in the cutting of the plates can be determined according to the width and the thickness of the plates, and neither the cutting speed nor the cutting effect is influenced by the width and the thickness of the plates.

Owner:惠州市兴广宇智能科技有限公司

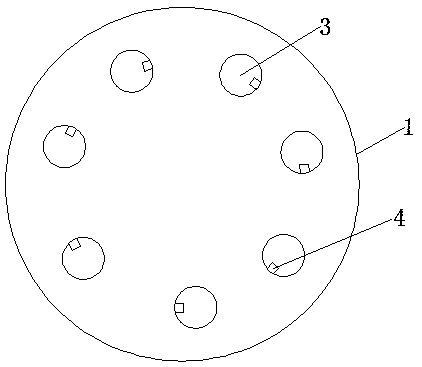

Quick cutting device for cemented carbide round rod

InactiveCN111390396ACut to exact lengthPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryEngineering

The invention provides a quick cutting device for a cemented carbide round rod. The quick cutting device for the cemented carbide round rod comprises a tooling platform, a bearing platform and a conveying device; a plurality of working holes are formed in the tooling platform, the multiple working holes are surrounded into a circle at equal intervals, and telescopic die blocks are correspondinglyarranged in the working holes; a rotary motor is arranged at the upper end of the tooling platform, a laser cutting machine is installed on the output shaft of the rotary motor in a sleeving mode, andwedge-shaped blocks used for pulling telescopic dies are arranged on the upper part of the output shaft; a plurality of leakage holes corresponding to the working holes one by one are circumferentially formed in the bearing platform, baffle plates are correspondingly and rotatably connected to one sides of the bottom ends of the leakage holes, and telescopic baffle blocks used for pulling the baffle plates are arranged at the lower end of the output shaft; and the quick cutting device further comprises a measuring column for supporting two sides of the tooling platform, a scale is arranged onthe measuring column, and the bearing platform is slidably installed on the measuring column in a sleeving mode. Through the rotation of the laser cutting machine, an alloy round rod with a set length exposed below the multiple working holes is cut, and accurate and quick cutting is achieved.

Owner:ZHUZHOU JINGGONG CEMENTED CARBIDE

Air conditioner copper pipe discharging device

ActiveCN108031911AEasy to cutThe center of the cutting tube is set on the same straight line, which can be operated convenientlyMeasurement/indication equipmentsTube shearing machinesFixed frameMaterial resources

The invention relates to the technical field of copper pipe machining, in particular to an air conditioner copper pipe discharging device. The discharging device comprises a support, wherein supporting legs with rolling wheels are installed at the bottom of the support, and the support is sequentially provided with a fixing device, a straightening device, a length meter device and a cutting devicefrom left to right, wherein the fixing device comprises fixing frames arranged at the lower parts of the two ends of the left side of the fixing device, and limiting devices are arranged on the upperportion of the fixing frames; fixing grooves are formed between the limiting devices and the fixing frames; the two fixing grooves are connected through a first rotating shaft; and the first rotatingshaft is inserted into a winding stick with a copper pipe; electric stretchable rods are installed on the outer side, close to cutting holes, of cutting pipes; and the bottom of the electric stretchable rods are fixedly connected with cutters. The air conditioner copper pipe discharging device is simple in structure, convenient to operate and various in function, and the copper pipe can be straightened at one time, so that manpower and material resources are saved, and meanwhile, size precision, bending degree and the like of the copper pipe are not affected.

Owner:重庆赛格尔汽车配件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com