Efficient cable shearing device for electric power

A cable device, high-efficiency technology, applied in the field of high-efficiency cable cutting device for electric power, can solve the problems of low work efficiency and low accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

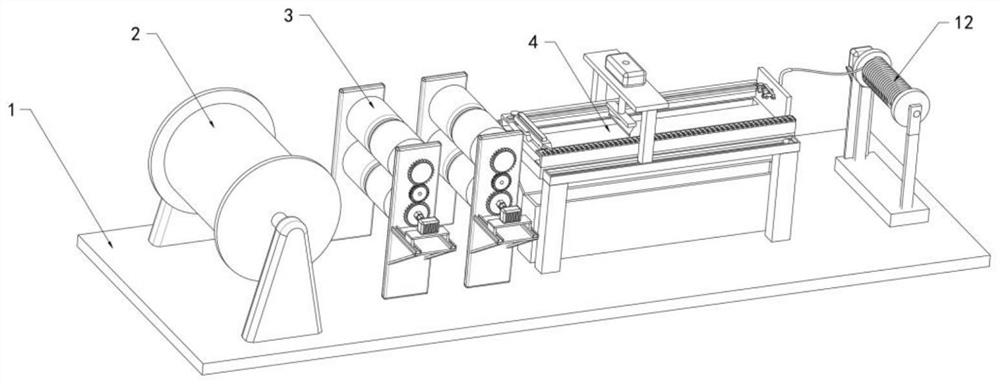

[0035] refer to Figure 1-4 , the loading plate 1 and the winding roller-2 on the top side of the loading plate 1, and the side of the winding roller-2 are parallelly provided with two pay-off auxiliary mechanisms 3, and the two pay-off auxiliary mechanisms 3 are far away from the winding roller-2 One side is provided with cutting device 4.

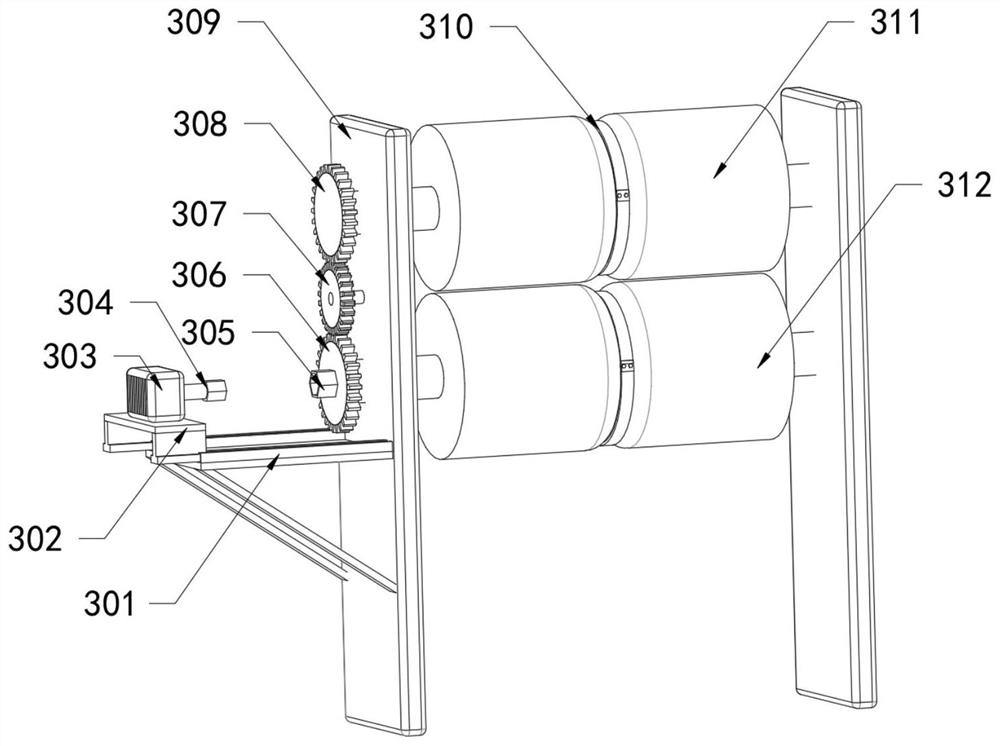

[0036] The two auxiliary wire release mechanisms 3 all include two vertical plates 309 fixedly connected to the top of the bearing plate 1 and two parallel rollers 311 and 312 arranged between the two vertical plates 309, the first roller 311 and the second roller 312. Roller shaft 2 312 is rotatably connected with two vertical plates 309 through a rotating shaft, and the middle of the outer ring of roller shaft 1 311 and roller shaft 2 312 is provided with a circular groove 310, and one side of one of the vertical plates 309 of the two vertical plates 309 Be provided with driven gear plate two 308 two, the bottom of driven gear plate tw...

Embodiment 2

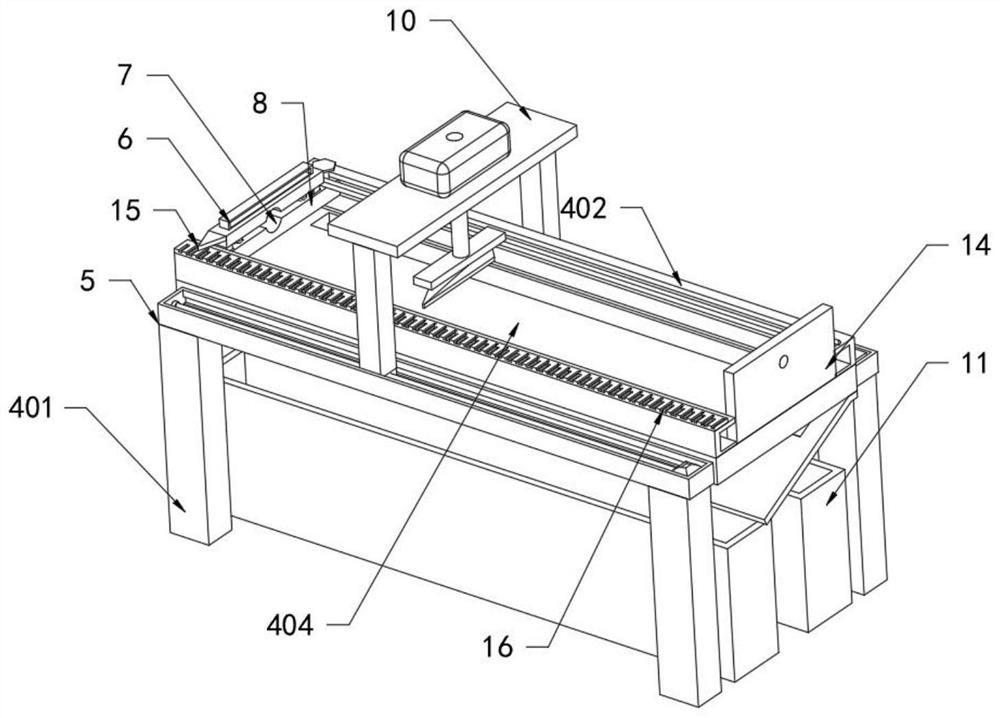

[0044] refer to figure 1 with Figure 6-7 , both sides of the top of the platen 404 are fixedly connected with a cross bar 402, a slide plate 8 is arranged between the two cross bars 402, the top of the slide plate 8 is elastically connected with a top plate 6 through two extrusion springs, and the top plate 6 and the slide plate 8 The corresponding side is provided with a semi-circular groove 7, the corresponding side of the two cross bars 402 is provided with a chute compatible with the slide plate 8, and the corresponding sides of the top plate 6 and the slide plate 8 are provided with a semi-circular groove 7 plays the role of guiding the cables, so that the cables can be placed on the platen 404 horizontally and without bending, which is convenient for cutting and improves operation efficiency.

[0045] A scale plate 16 is fixedly connected to the top of one of the two cross bars 402 , an arrow 15 is arranged on one side of the top of the scale plate 16 , and one side of...

Embodiment 3

[0050] refer to figure 1 with Figure 5 , the bottom of the platen 404 is provided with a collection mechanism 11, the collection mechanism 11 includes a collection bin one 1101 and a second collection bin 1102 fixedly connected to the top of the carrier plate 1 and a sorting plate 1103 fixedly connected to the bottom of the deck 404, the sorting plate 1103 and The angle of the platen 404 is 30°-50°, the corresponding side of the platen 404 and the sorting plate 1103 is provided with a notch 1104, and the notch 1104 of the sorting plate 1103 is equipped with an electric valve 1105, and the second collection bin 1102 It is arranged at the bottom of one side of the sorting plate 1103 , and the collection bin one 1101 is set at the bottom of the notch 1104 of the sorting plate 1103 .

[0051] Through the setting of the first collection bin 1101 and the second collection bin 1102, the sorting plate 1103, the notch 1104 and the electric valve 1105, the cut cable can fall on the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com