Cutting mechanism of rod material automatic cutting machine

A cutting mechanism and cutting machine technology, applied in the field of automatic bar cutting machine and cutting mechanism of the automatic bar cutting machine, can solve the problems of low precision, inconsistent cutting length, easy tilting of the bar, and achieve reliable operation and structure. Simple and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

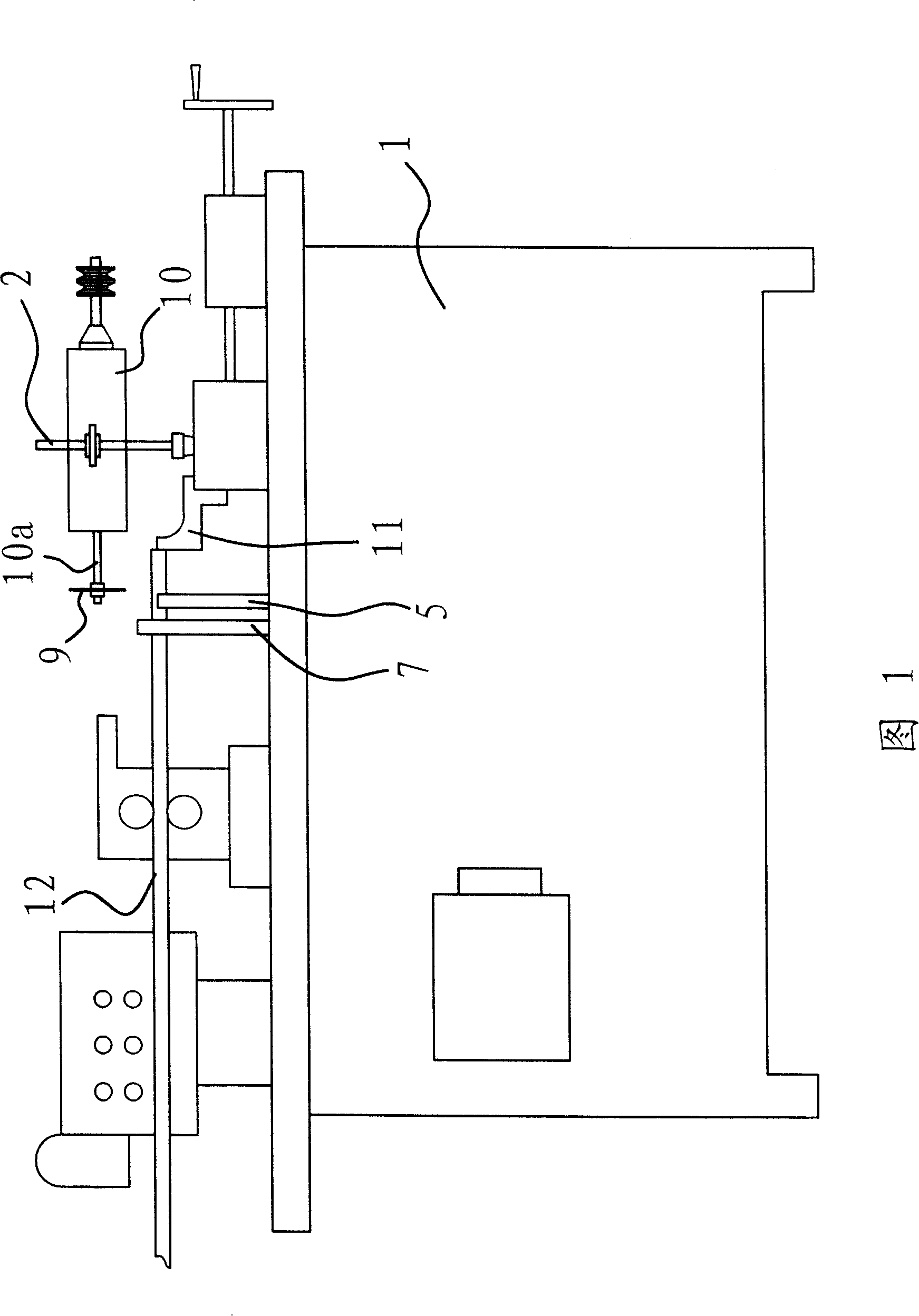

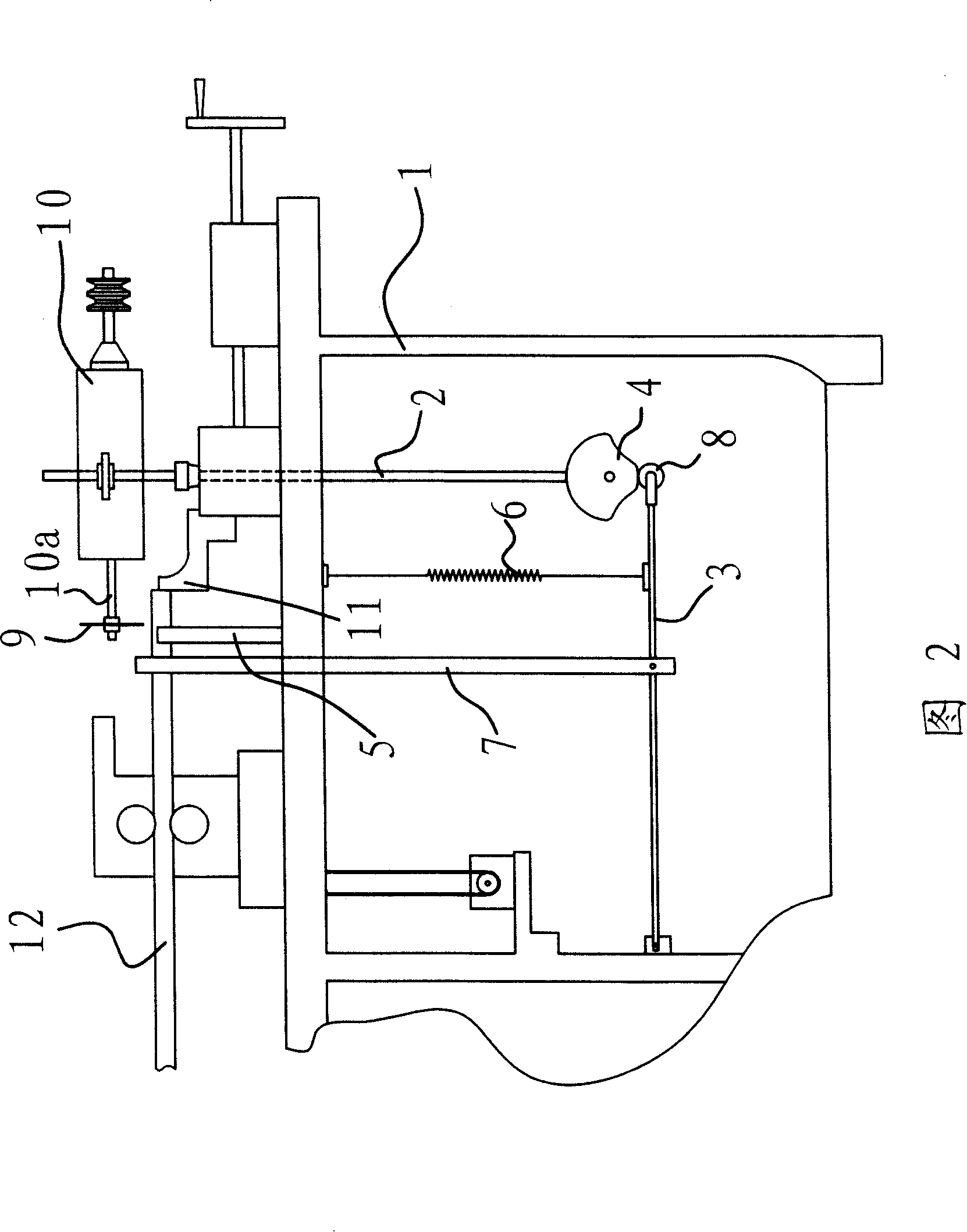

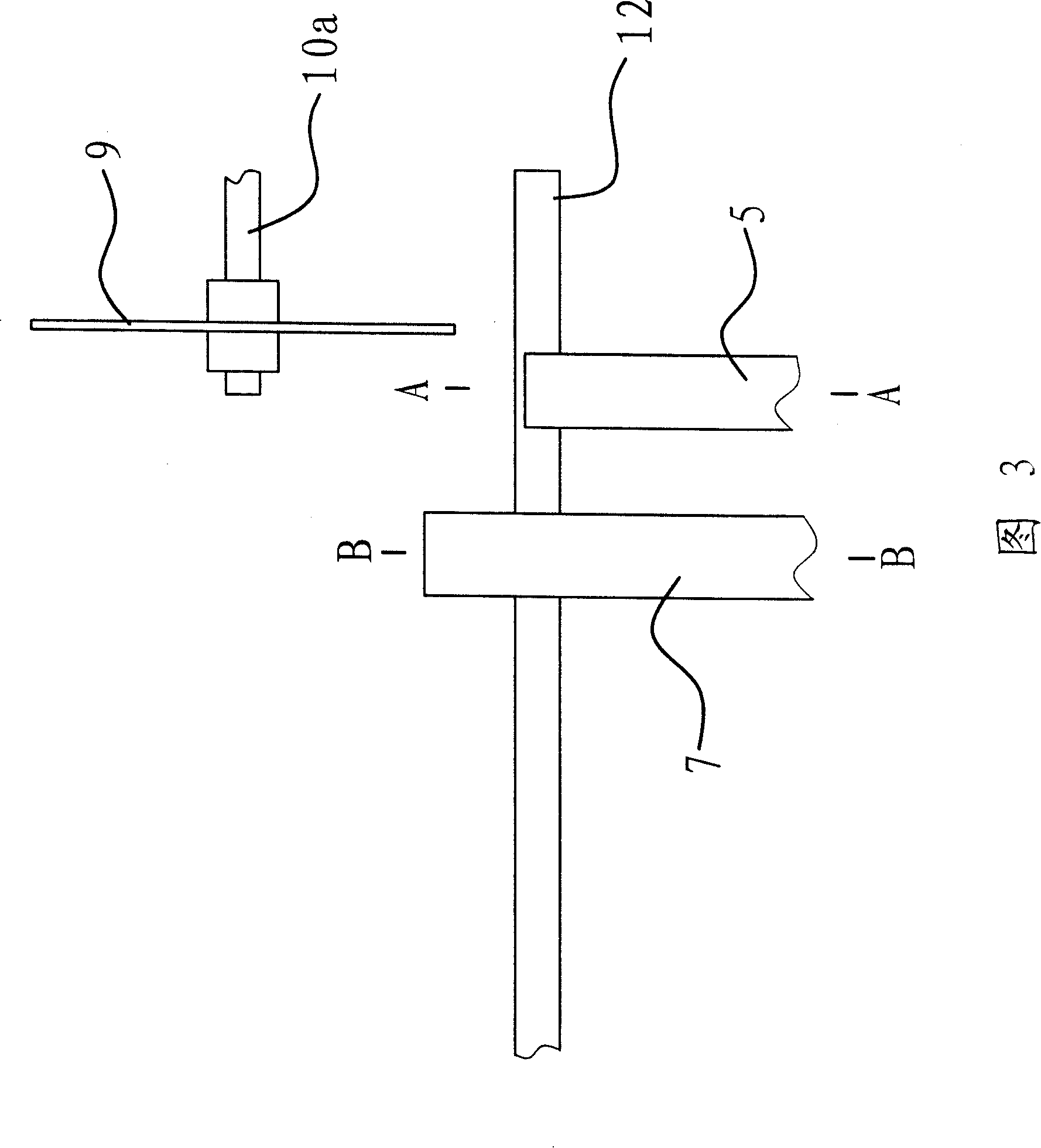

[0021] As shown in Figures 1 and 2, the cutting mechanism of the automatic bar cutting machine is installed in the body 1 of the cutting machine. It includes parts such as connecting rod 2, cross bar 3, cam 4, support block 5, spring 6, pressing bar 7 and pulley 8.

[0022] As shown in FIG. 2 , the cam 4 is fixedly connected in the fuselage 1 , and the cam 4 is driven to rotate by a motor. The connecting rod 2 is vertically arranged, and the upper end of the connecting rod 2 protrudes from the fuselage 1 and is fixedly connected with the motor 10 . The lower end of the connecting rod 2 is in the fuselage 1, and its end is pressed against the edge of the cam 4.

[0023] The blade 9 is at the discharge of the cutting machine. The blade 9 is fixed on the rotating shaft 10 a of the motor 10 . The rotation of blade 9 is driven by motor 10 . Simultaneously, by the rotation of cam 4, blade 9 has been moved up and down.

[0024] There is a cross bar 3 in the fuselage 1, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com