Equipment for cutting cable moving in horizontal direction

A horizontal direction, cable technology, applied in the field of cable processing, can solve the problems of uneven incision, poor appearance, difficult cable length measurement, etc., and achieve the effect of accurate cutting length and uniform incision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

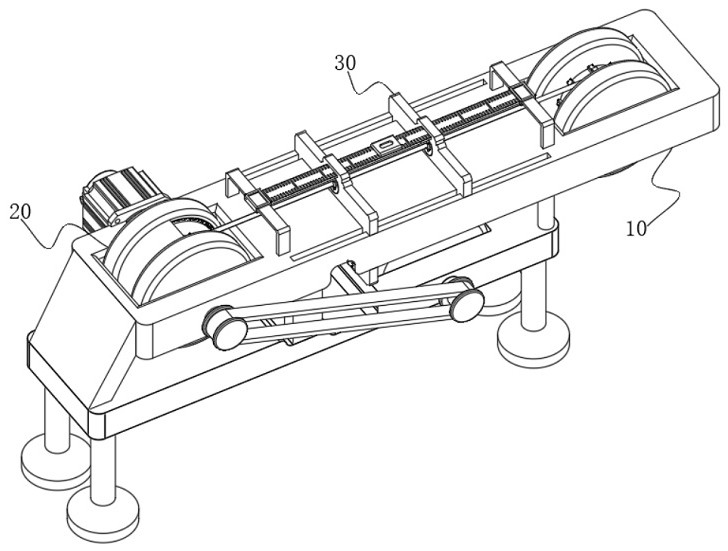

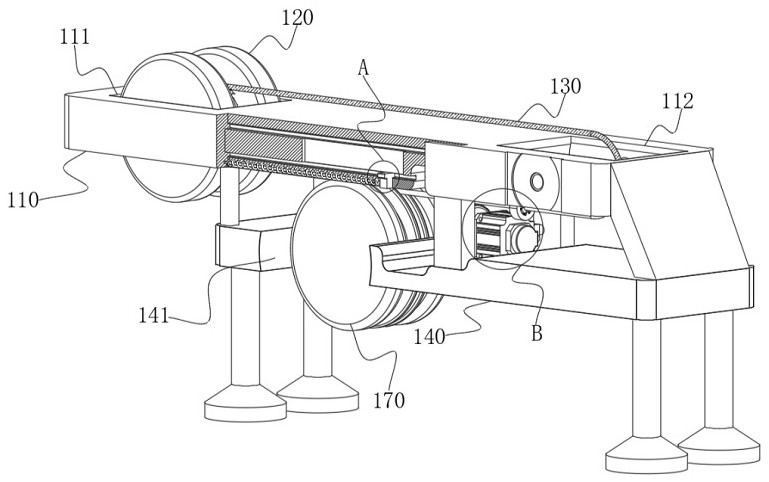

[0046] see Figure 1-Figure 11 As shown, the purpose of this embodiment is to provide a device for cutting cables moving in a horizontal direction, including an operation table 10 and a cable tightening mechanism 20 installed on the top side of the operation table 10. The operation table 10 Include at least:

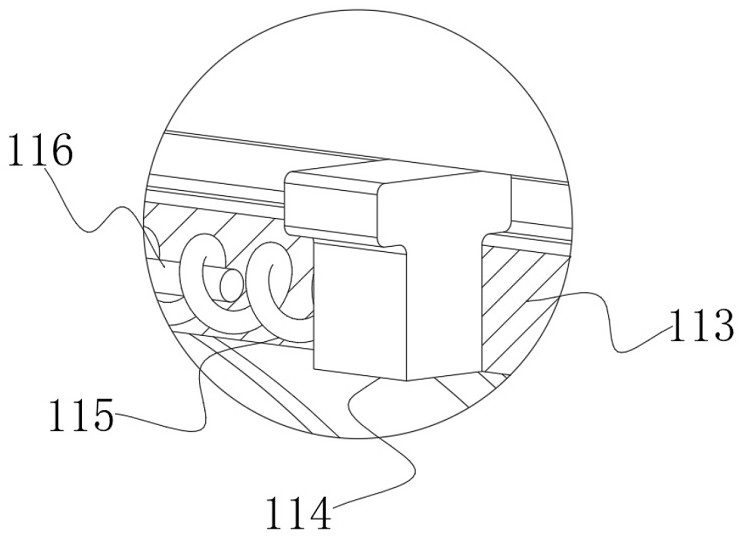

[0047] The upper plate 110, a front groove 111 is provided on one side of the top of the upper plate 110, and a rear groove 112 is provided on the other side of the top of the upper plate 110;

[0048] a cable pay-off reel 120, the cable pay-off reel 120 is arranged at the inner end of the front groove 111, and the cable pay-off reel 120 is rotatably connected with the front groove 111;

[0049] The cable body 130, one end of the cable body 130 is connected to the side of the cable pay-off tray 120 in a spiral manner;

[0050] the lower plate 140, the lower plate 140 is arranged at the bottom end of the upper plate 110, and the bottom groove 141 is arranged on one side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com