Pipeline cutting device with rotary cutting function for constructional engineering

A technology for construction engineering and pipe cutting, which is applied in the direction of pipe shearing devices, shearing devices, and attachments of shearing machines. Potential safety hazard, life extension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

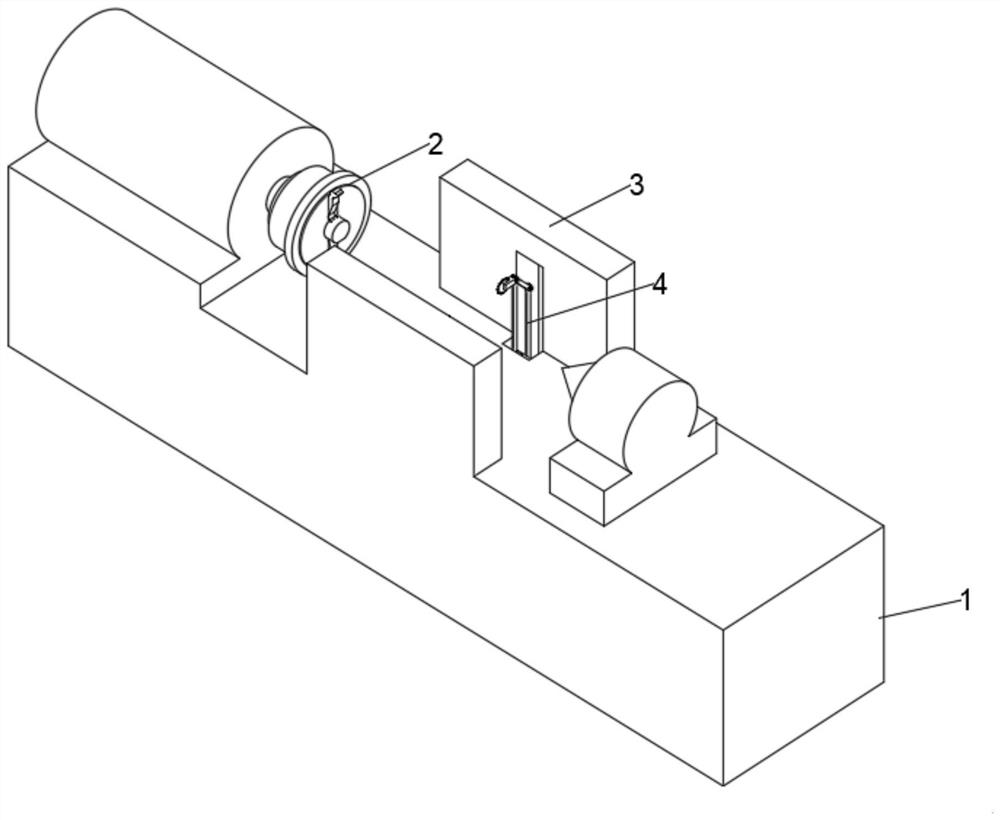

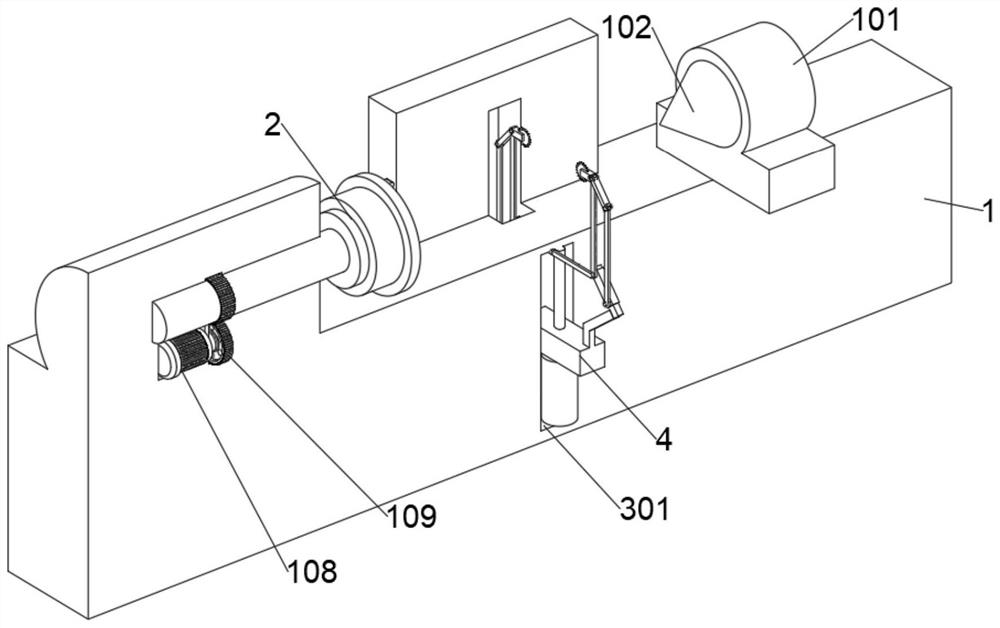

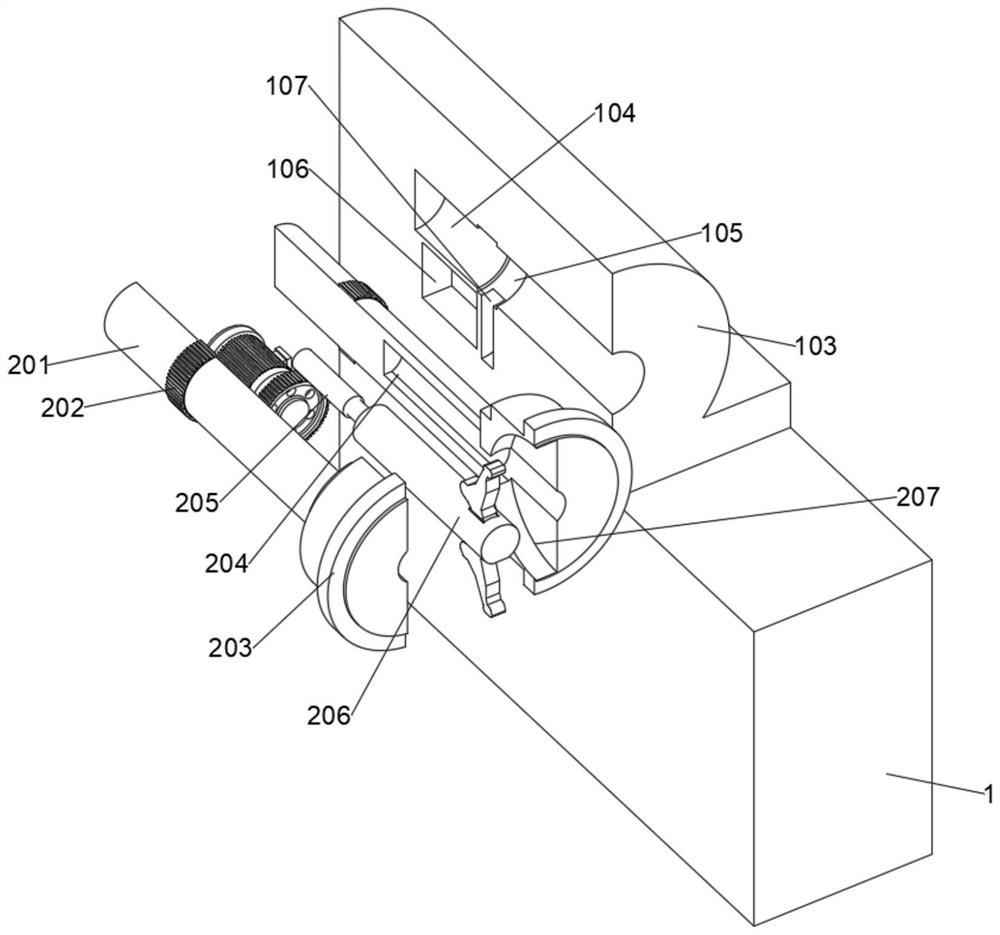

[0027] see Figure 1-5 , the present invention provides a specific embodiment:

[0028] A pipe cutting device for construction engineering with a rotary cutting function, comprising a workbench 1, such as figure 2 and image 3 As shown, a centering block 101 is slidingly arranged on the outside of the surface of the workbench 1, and a conical centering block 102 is provided on one side of the centering block 101; a cutting processing block 103 is provided on the inside of the surface of the workbench 1, and a Circular groove 104, the inner wall of circular groove 104 is provided with annular groove 105, and circular groove 104 interior is provided with limit rotation rotary cutting mechanism 2; One side of cutting processing block 103 interior offers organic chamber 106, and machine chamber 106 outside offers circular groove 106. Slot 107, motor 108 is provided inside the machine cavity 106, the output end of the motor 108 extends through the inner wall of the machine cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com