Automobile die grinding and polishing assembly

A technology for automotive molds and components, applied in grinding/polishing equipment, grinding/polishing safety devices, grinding workpiece supports, etc., can solve problems affecting the production of accessories, inconvenient removal of burrs, economic losses, etc., to ensure processing Production, avoiding economic loss, ensuring the effect of grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

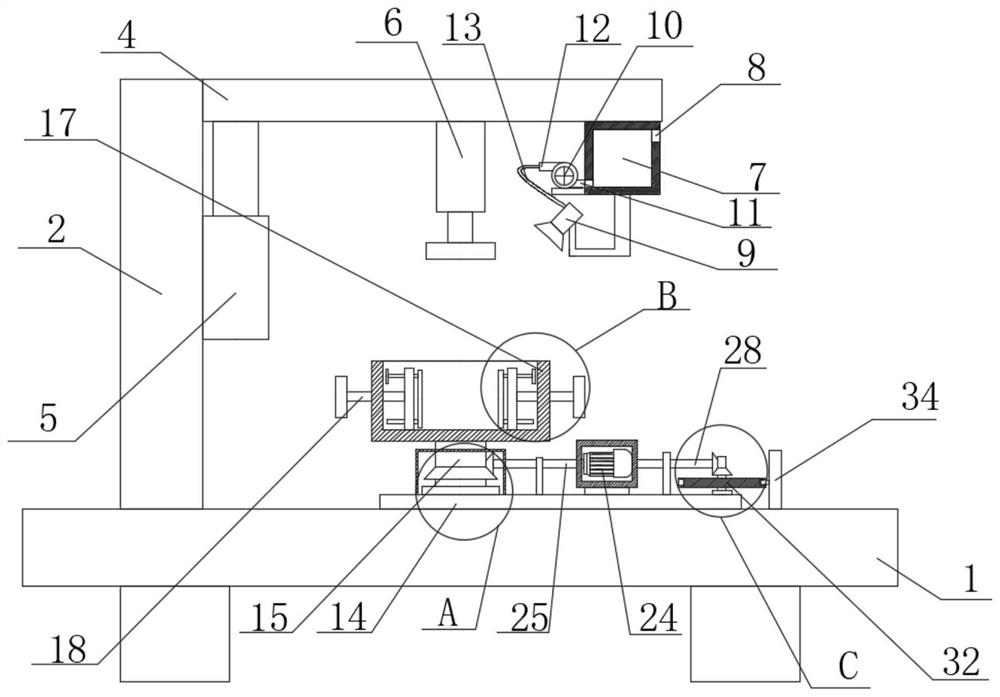

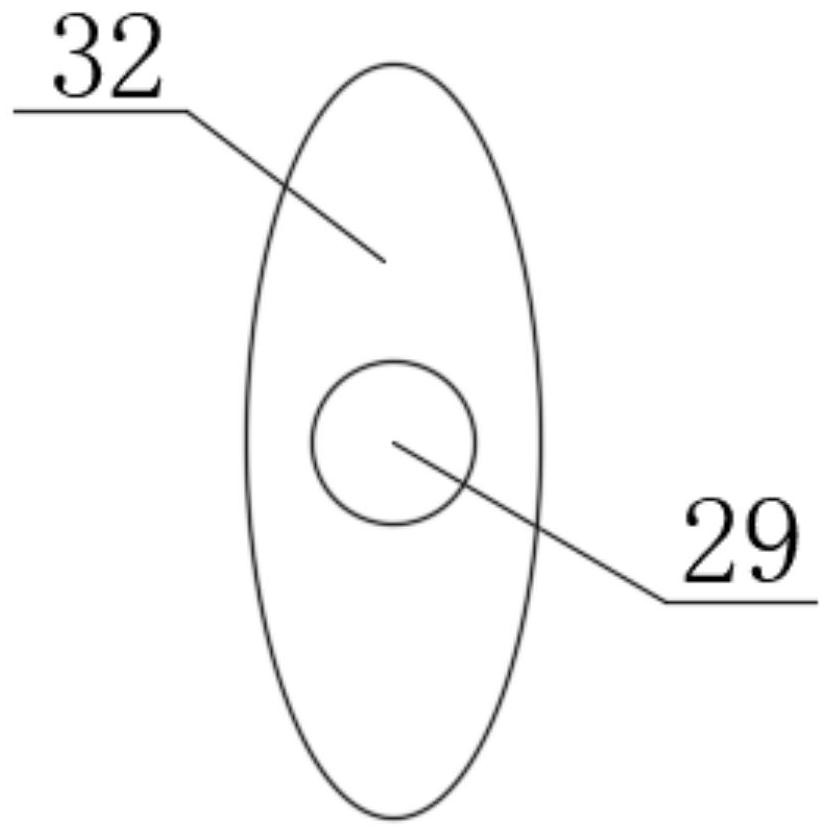

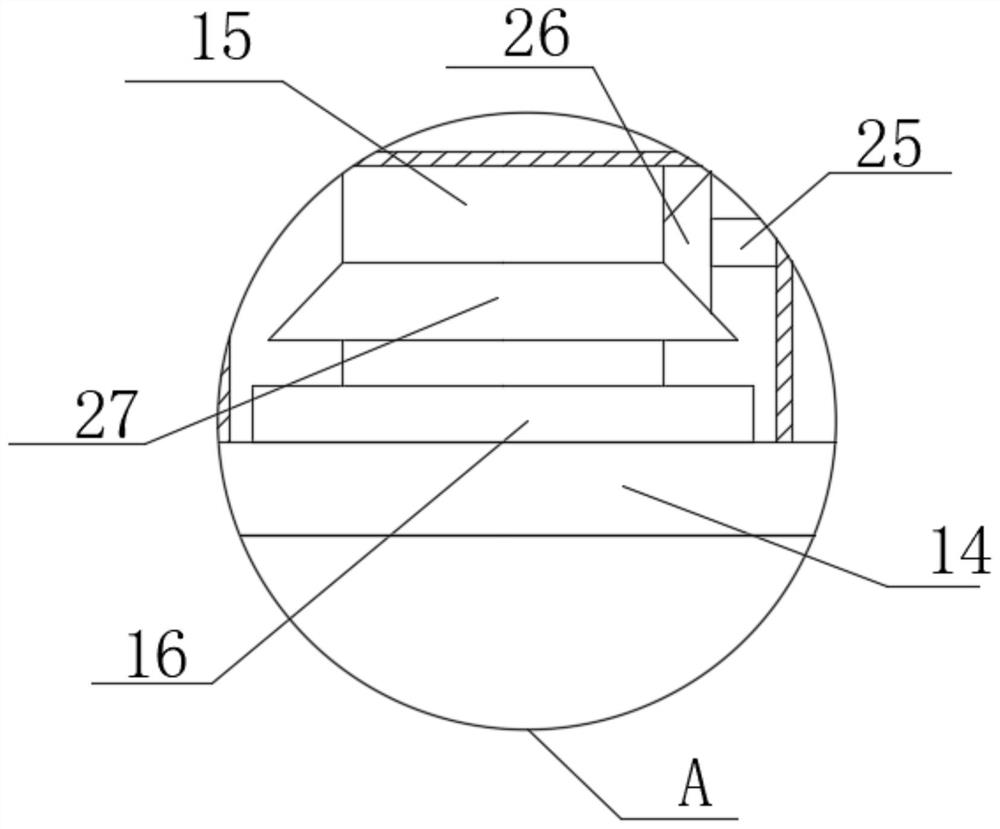

[0026] refer to Figure 1-5 , an automobile mold grinding and polishing assembly, comprising a base 1, a first mounting plate 2 is fixedly mounted on the top of the base 1, a second mounting plate 4 is slidably mounted on one side of the first mounting plate 2, and the bottom of the second mounting plate 4 A grinding and polishing machine 6 is fixedly installed, an electric push rod 5 is fixedly installed on one side of the first mounting plate 2, the output shaft of the electric push rod 5 is fixedly connected with the second mounting plate 4, and the bottom of the second mounting plate 4 is fixedly installed with The material receiving box 7 is provided with a discharge port 8 on the material receiving box 7, and a pump machine 10 is fixedly installed on one side of the material receiving box 7, and the pump machine 10 is fixedly installed due to the suction pipe 11 and the discharge pipe 12. The bottom of the box 7 is fixed with a powder suction head 9, and one end of the h...

Embodiment 2

[0035] refer to Figure 1-5, an automobile mold grinding and polishing assembly, comprising a base 1, the top of the base 1 is fixedly installed with a first mounting plate 2 by welding, one side of the first mounting plate 2 is slidably mounted with a second mounting plate 4, and the second mounting plate 4 Grinding and polishing machine 6 is fixedly installed on the bottom by welding, and an electric push rod 5 is fixedly installed on one side of the first mounting plate 2 by screws. The output shaft of the electric push rod 5 is fixedly connected with the second mounting plate 4, and the second mounting plate The bottom of 4 is fixedly installed with receiving box 7 by welding, and is provided with discharge opening 8 on the receiving box 7, and the pump machine 10 is fixedly installed on one side of receiving box 7 by screw, is fixedly installed by welding on the pump machine 10 because The suction pipe 11 and the discharge pipe 12, the bottom of the material receiving box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com