Bi-three-jaw shaped contrarotating planetary grinding head

A technology of planetary grinding and grinding head, which is applied in the direction of grinding head, etc., can solve the problems of easily affecting the lives of surrounding residents, grinding and refurbishing wool boards, and low product efficiency, and achieve the effects of improving grinding and polishing efficiency, no noise pollution, and convenient and flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

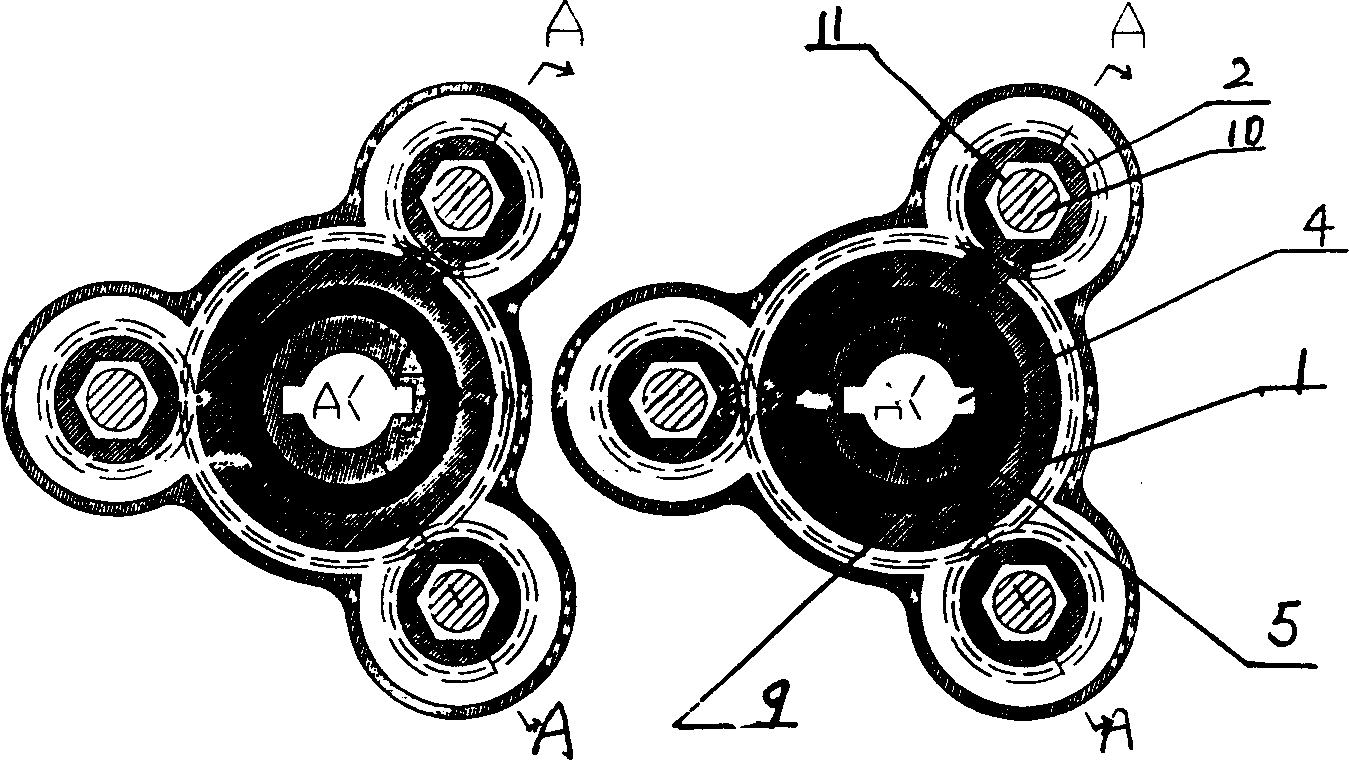

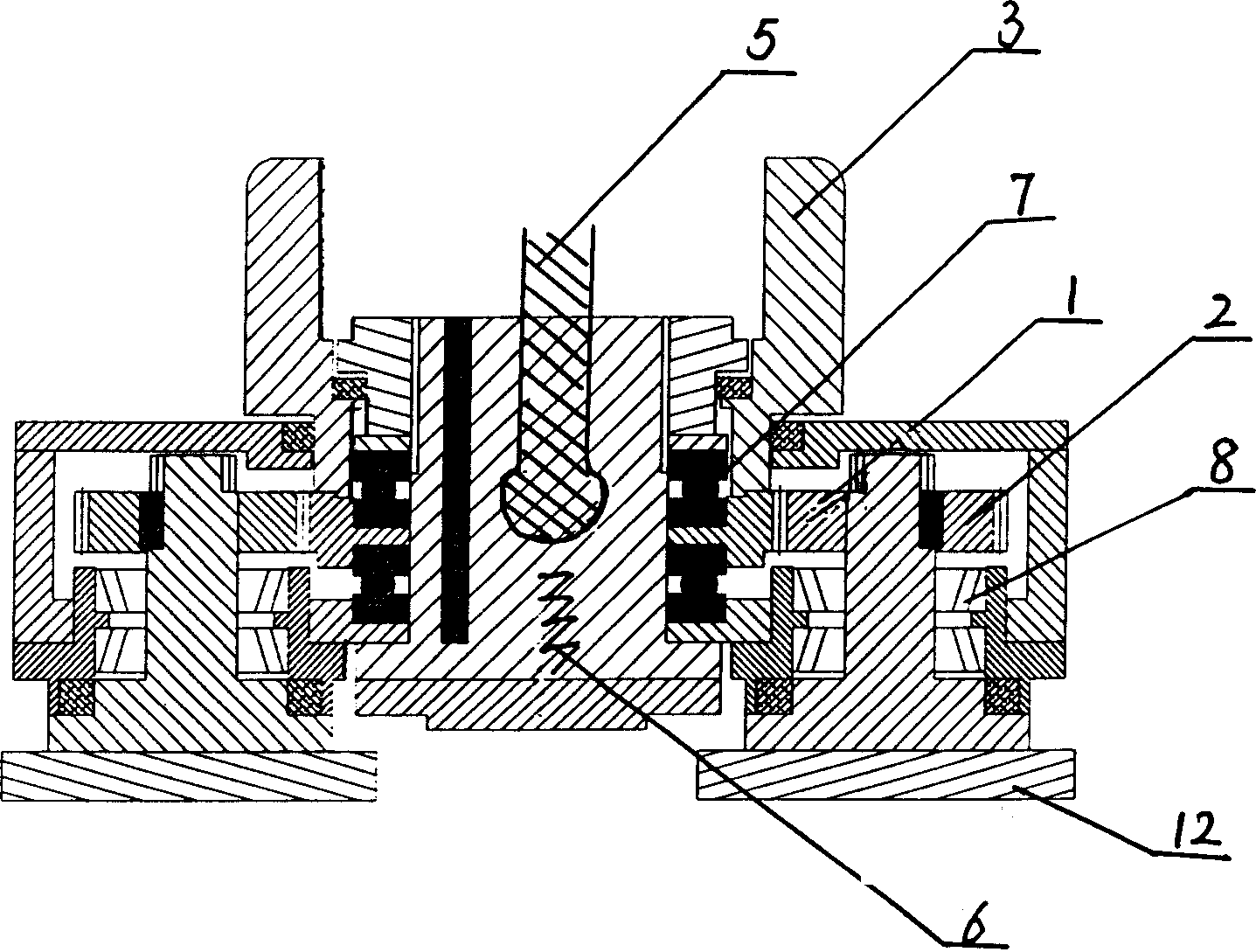

[0021] Attached below figure 1 and figure 2 Further explain how the present invention is realized:

[0022] Such as figure 1 and figure 2 As shown, the double three-jaw shape counter-rotating planetary grinding head is composed of two counter-rotating planetary grinding heads with three small grinding heads, each of which includes a large planetary gear 1 and three small planetary gears 2. Plane bearings 7 are installed on the upper and lower sides of the large planetary gear 1, and fastening nuts 9 are installed on the plane bearings. The upper and lower plane bearings 7 are used between the large planetary gear and the main shaft of the three-jaw planetary grinding head, and can independently surround the three-jaw planetary grinding head. The main shaft of the claw planetary grinding head rotates, and the fastening nut adjusts the concentricity adjustment and fixation of the large planetary gear and the main shaft of the three-jaw planetary grinding head. The planetary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com