Coil steel surface treatment equipment and surface treatment process

A surface treatment and equipment technology, which is applied in the field of coil steel surface treatment equipment and surface treatment technology, can solve the problems of high labor intensity, uneven polishing, large volume of coil steel, etc., and achieve the effect of improving automation and uniform grinding and polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

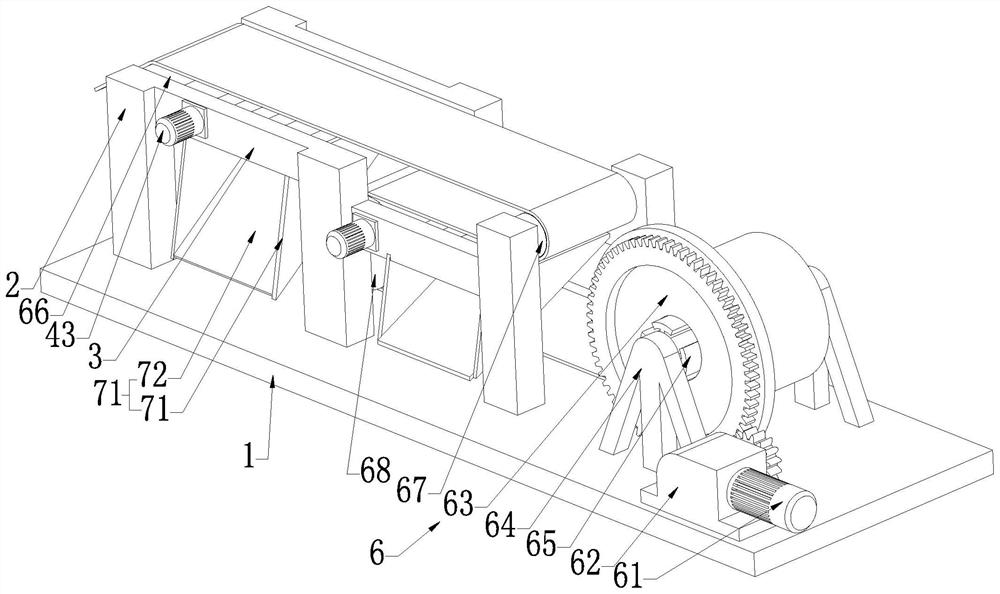

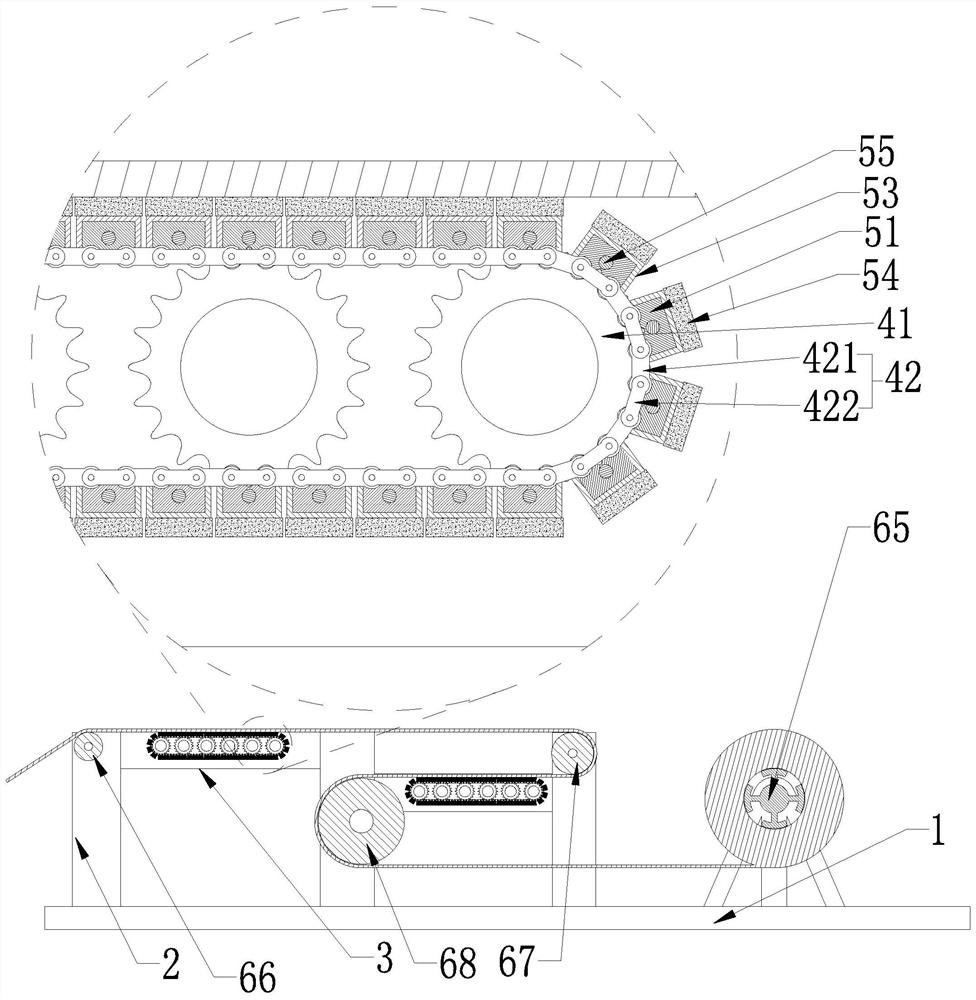

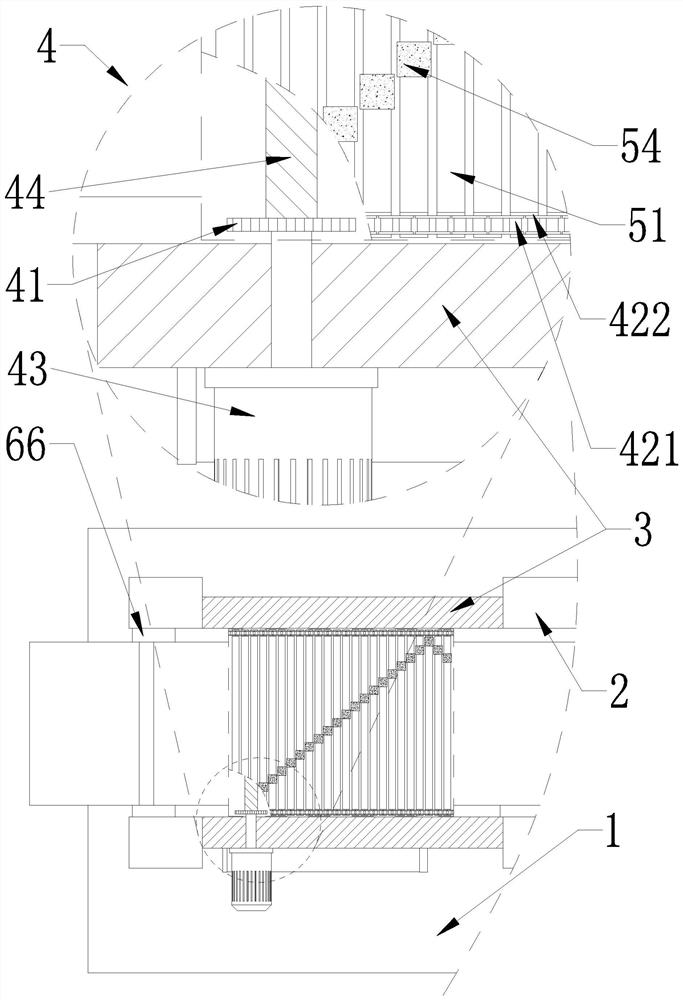

[0022] Contraction below Figure 1-6 The present invention will be described in further detail.

[0023] A roller steel surface treatment apparatus of the present invention, comprises a table 1, the support block 2 and connection block 3, further comprising a drive mechanism 4, the grinding mechanism 5, 6 selected support block 2 into two groups symmetrically disposed on the table 1 on each group of three adjacent support block 2 is provided with two connecting block 3 between the support block 2 and connection block 3 from top to bottom at a certain height difference sequentially provided to facilitate rolled steel polishing both surfaces, the grinding mechanism 5, the drive mechanism 34 are located between the opposite side of the connection block.

[0024] The drive mechanism 4 comprises a sprocket 41, chain 42, motor 43 and the drive shaft 44, a plurality of uniformly disposed on the transmission shaft 44 is connected between the opposite side of the block 3, and both ends conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com