Inner tube splicer with protection mechanism

A protection mechanism and jointing machine technology, applied in tires, household utensils, other household utensils, etc., can solve the problems that do not involve cutting or scalding of joint machine workers, so as to prevent manual burns, prevent uneven incisions, prevent The effect of product failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

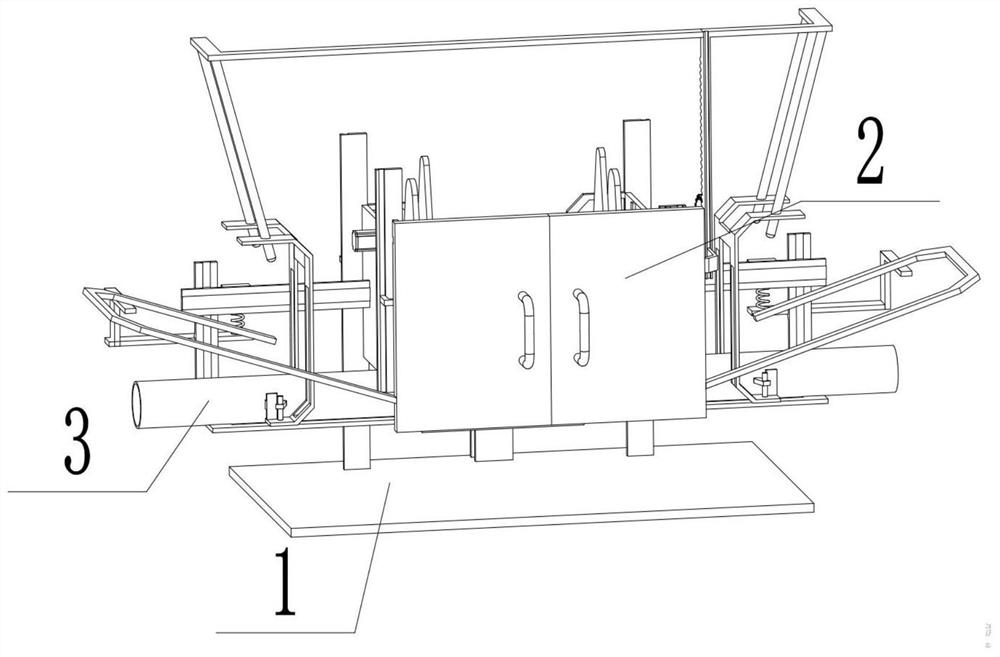

[0020] Example: such as Figure 1-Figure 8 The shown inner tube splicing machine with protection mechanism includes a base plate device 1, a protection device 2, and an inner tube 3. The protection device 2 is installed on the base plate device 1, and the inner tube 3 is arranged on the protection device 2.

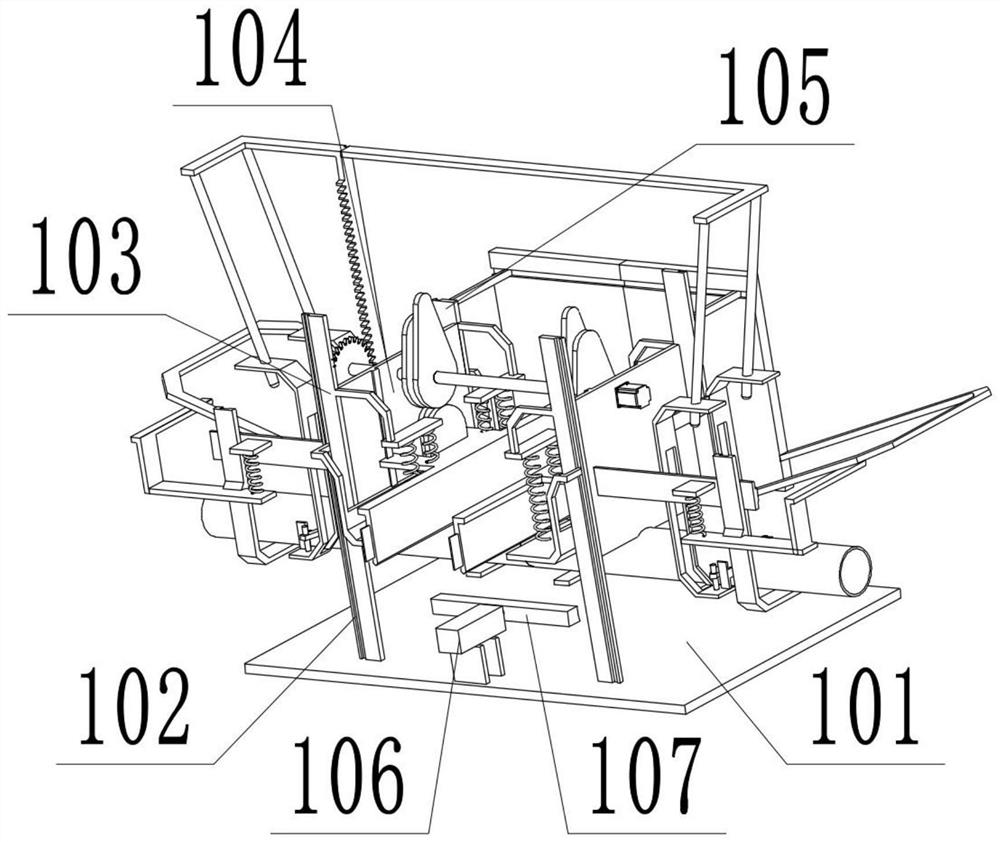

[0021] The long slideway 102 is arranged on the long side plate 103, the long side plate 103 is fixedly installed on the base 101, the middle plate 104 is fixedly installed on the long side plate 103, and the short side plate 105 is fixedly installed on the middle plate 104 , the air cylinder 106 is fixedly installed on the base 101 , and the auxiliary table 107 is fixedly installed at the output end of the air cylinder 106 .

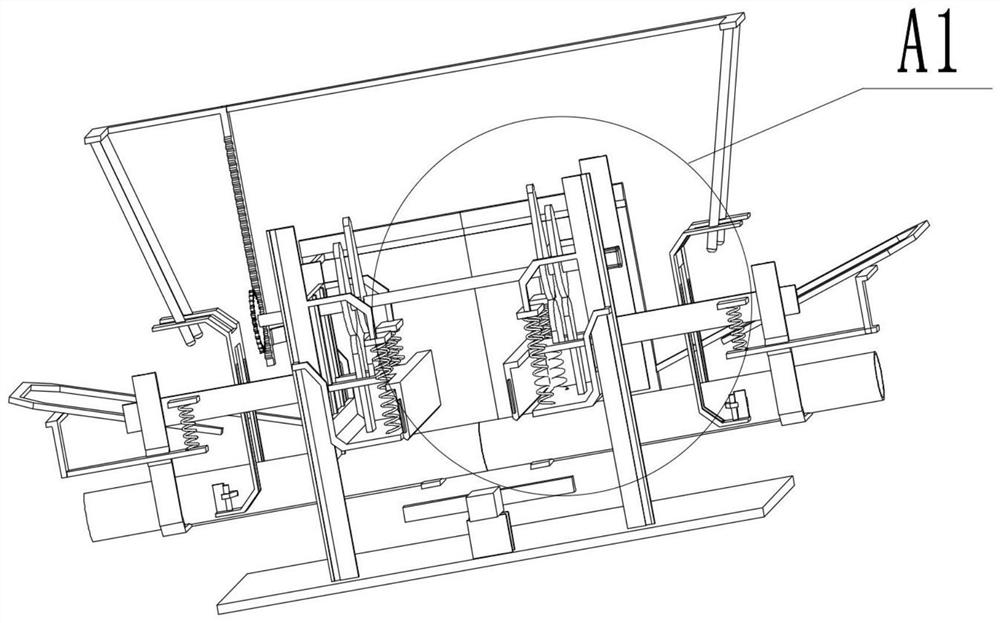

[0022] The motor 201 is fixedly mounted on the middle plate 104, the short cam 202 is fixedly mounted on the main shaft 204, the long cam 203 is fixedly mounted on the main shaft 204, the main shaft 204 is fixedly mounted on the output shaft of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com