Concave pit notching and cutting composite mould for integrated chip lead frame

A lead frame and integrated chip technology, applied in the directions of forming tools, manufacturing tools, feeding devices, etc., can solve the problems of single punching and individual positioning of precision transmission devices and precision cutting devices, and achieve the effect of eliminating transmission errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

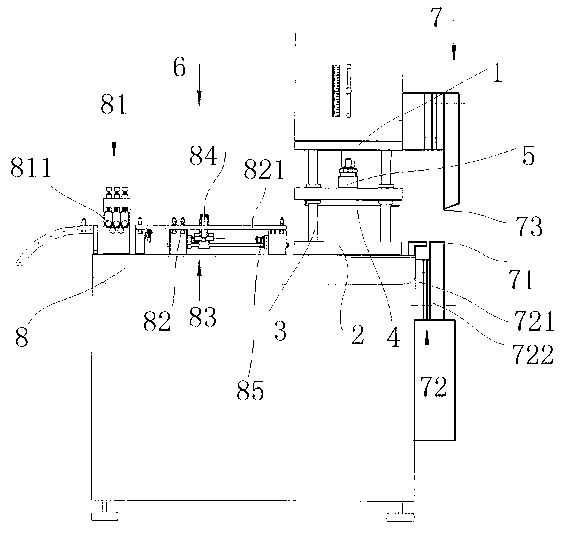

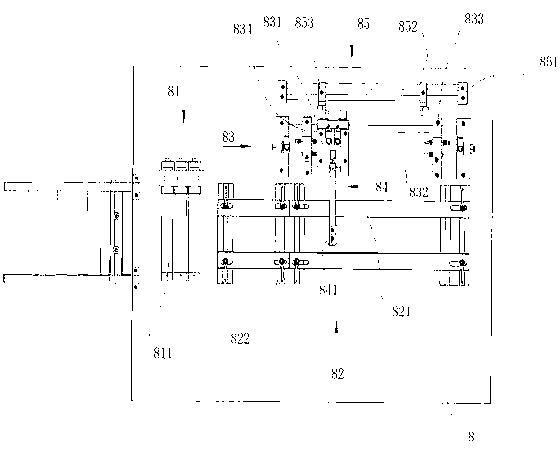

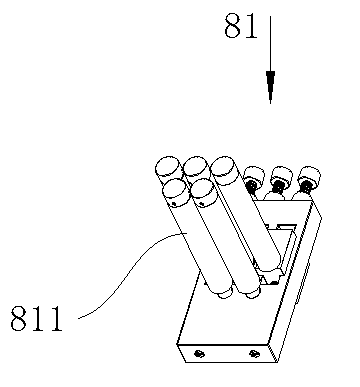

[0031] Embodiment 1: as figure 1 As shown, an integrated chip lead frame base island is punched and cut composite mold, including upper mold base 1, lower mold base 2 and a controller provided with a microprocessor; upper mold base 1 and lower mold base 2 pass through four The guide mechanism composed of guide sleeve and guide post is slidingly connected. The guide post 3 is provided with a movable slider 4; There are three positioning pins symmetrically arranged on the side according to a certain rule. The center distances of all adjacent positioning pins are different. The unequal distance setting mode of the positioning pins can prevent the mold from closing when the fixed-length transmission device occasionally loses synchronization. Specifically The most important thing is that the center distances of adjacent positioning pins are 4mm and 3mm respectively; the bottom of the upper mold is connected with the upper mold through four limit screws, and a movable slider is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com