Front and rear axle abrasive experimental device for bicycle

A wear-resistant testing machine and bicycle technology, which is applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of concentricity deviation, twisting force of hub shaft center, damage of hub wear test, etc., to avoid test damage, easy to operate, The effect of low overall product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

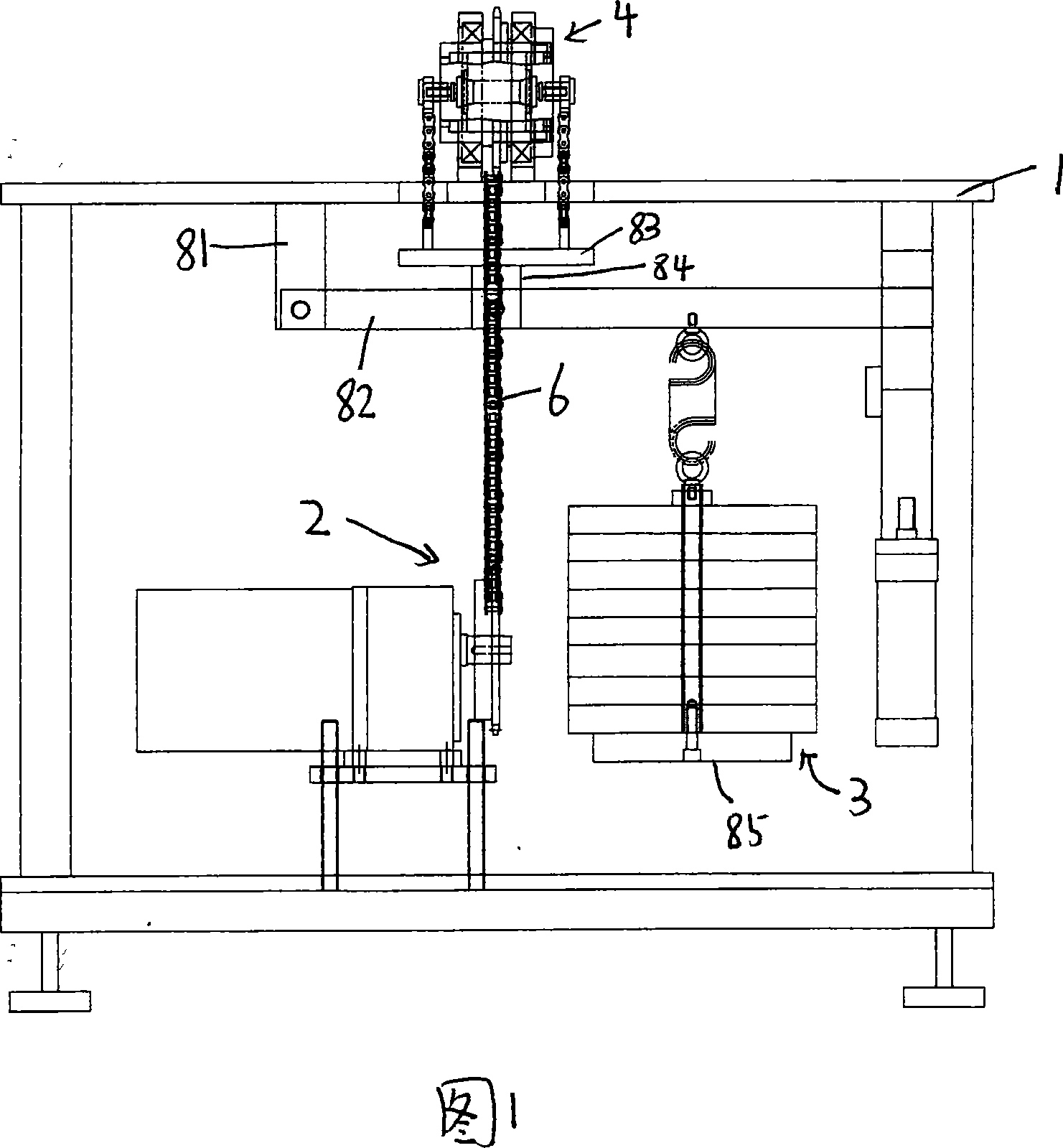

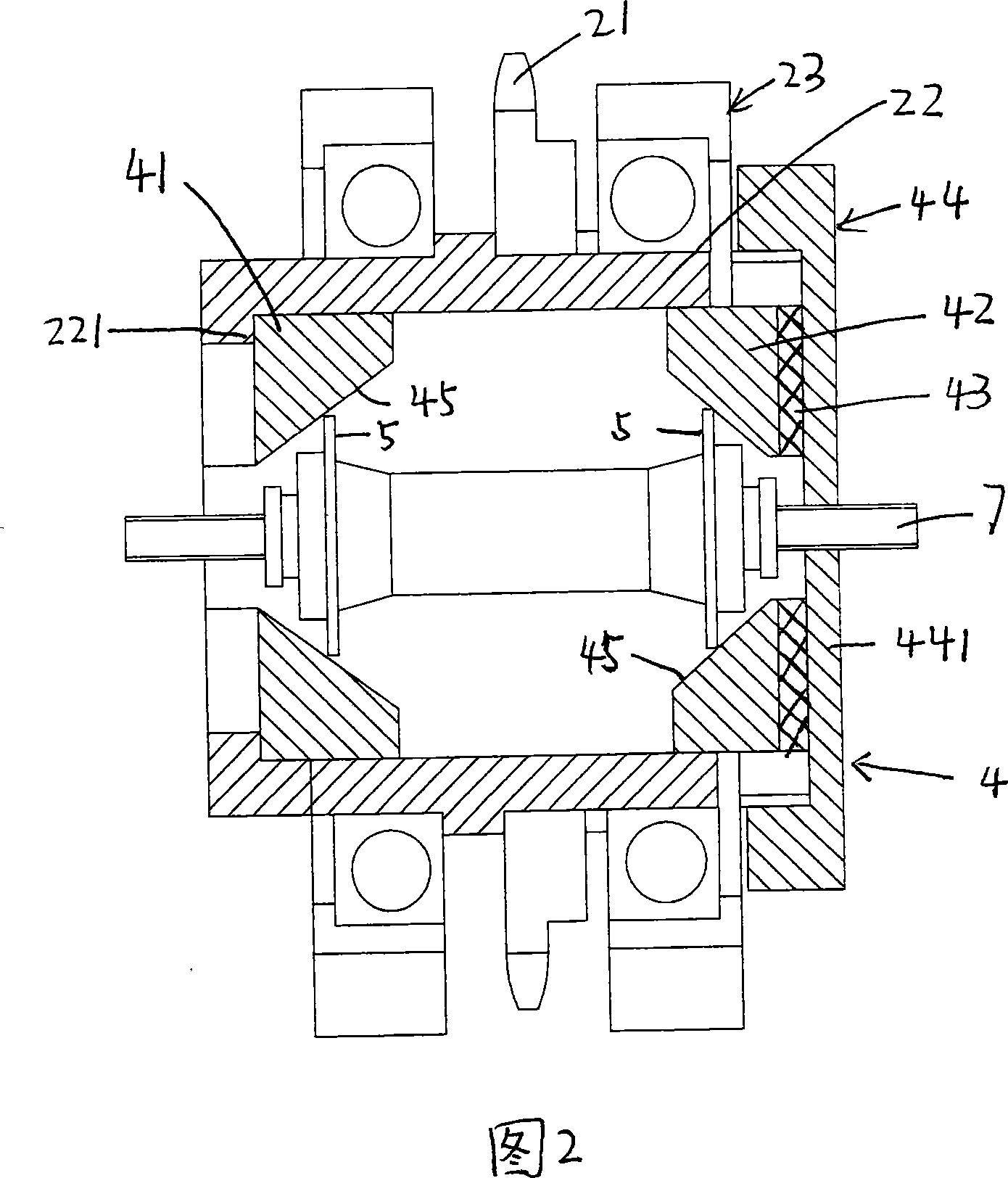

[0019] Embodiment: A bicycle front and rear axle wear-resistant testing machine, mainly composed of a support platform 1, a driving device 2, a loading device 3 and a clamping device 4, and the driving device is mainly composed of a bearing seat, a supporting bearing 23, a sprocket 21 and a mounting sleeve 22 components, the outer surfaces of both ends of the installation sleeve are respectively fixed in the inner rings of the two support bearings, the outer rings of the two support bearings are respectively fixed in the bearing housings, the bearing housings are fixed on the support platform, and the sprockets are fixed on the installation sleeves , the clamping device is made up of the first fixed sleeve 41, the second fixed sleeve 42, the adjustment washer 43 and the locking device 44, the first and second fixed sleeves and the adjustment washer in the clamping device are movable in the installation sleeve, the first 1. One side of the two fixing sleeves is respectively slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com