Patents

Literature

36results about How to "Guaranteed sticking effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

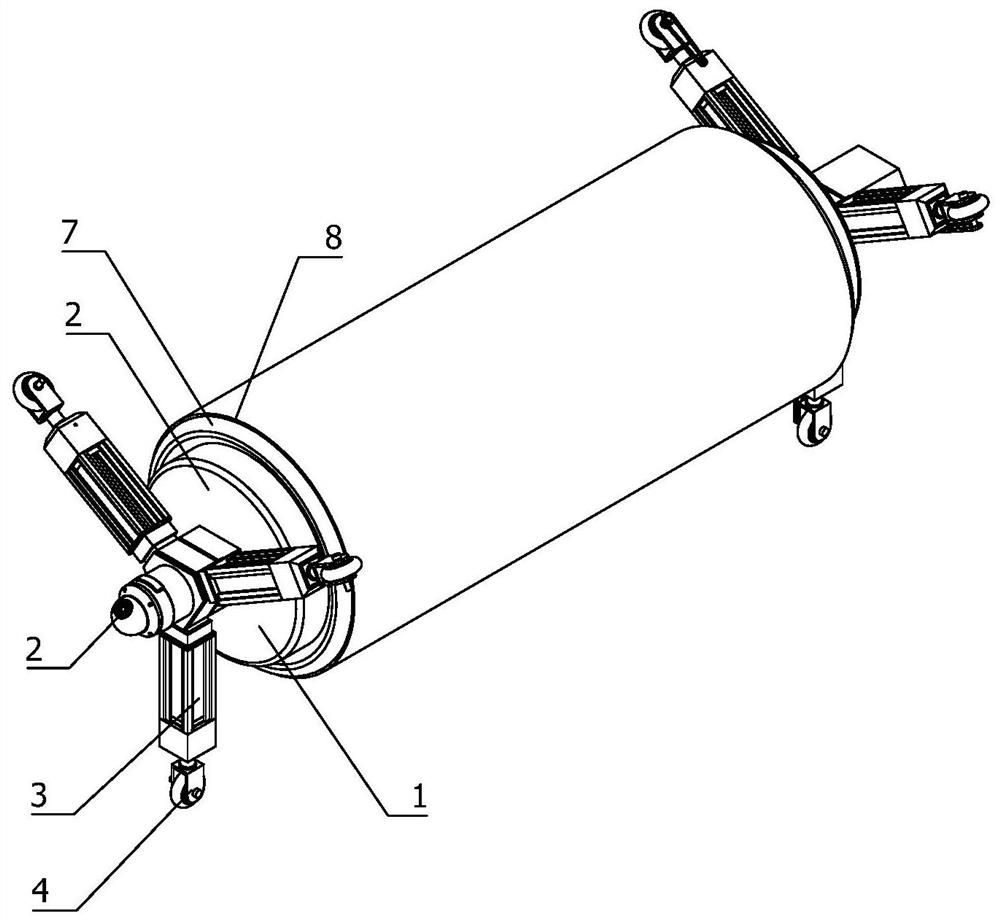

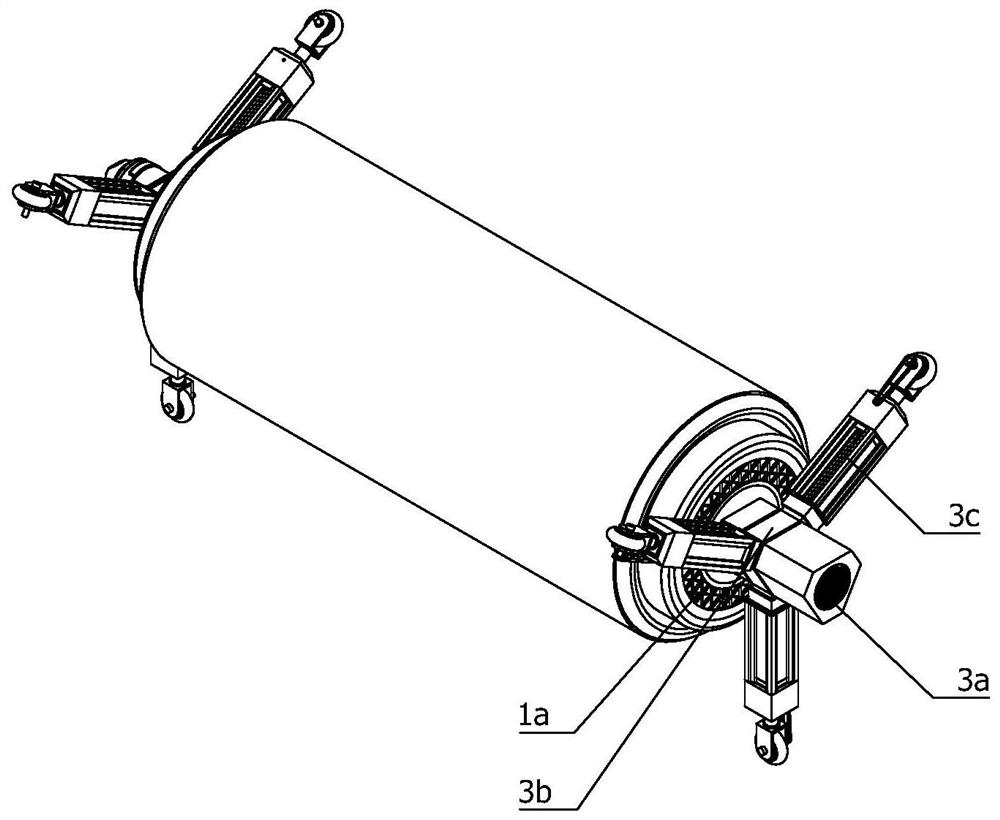

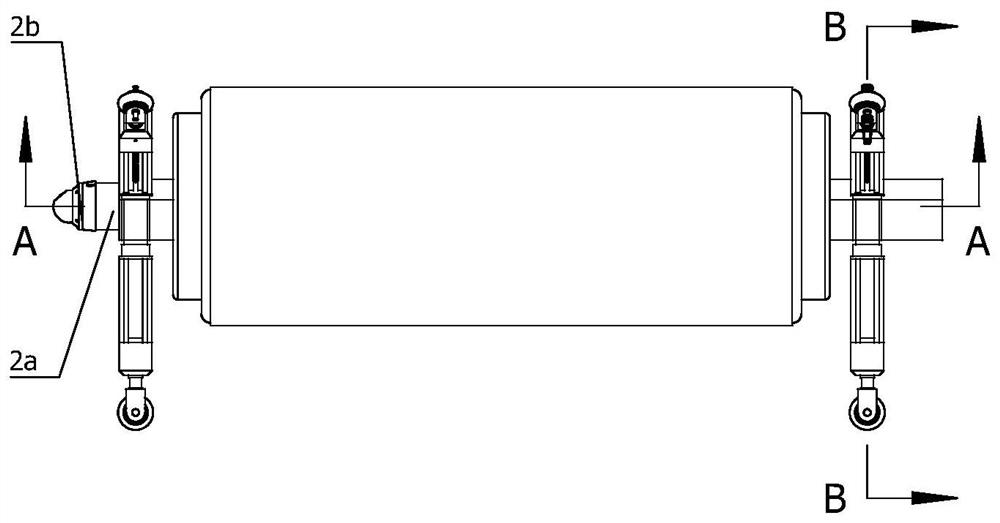

Automatic sealing mechanism of trenchless petroleum pipeline damage repairing device

InactiveCN111810763AAvoid troubleTo achieve the purpose of automatic repairPigs/molesGlass fiberAir pump

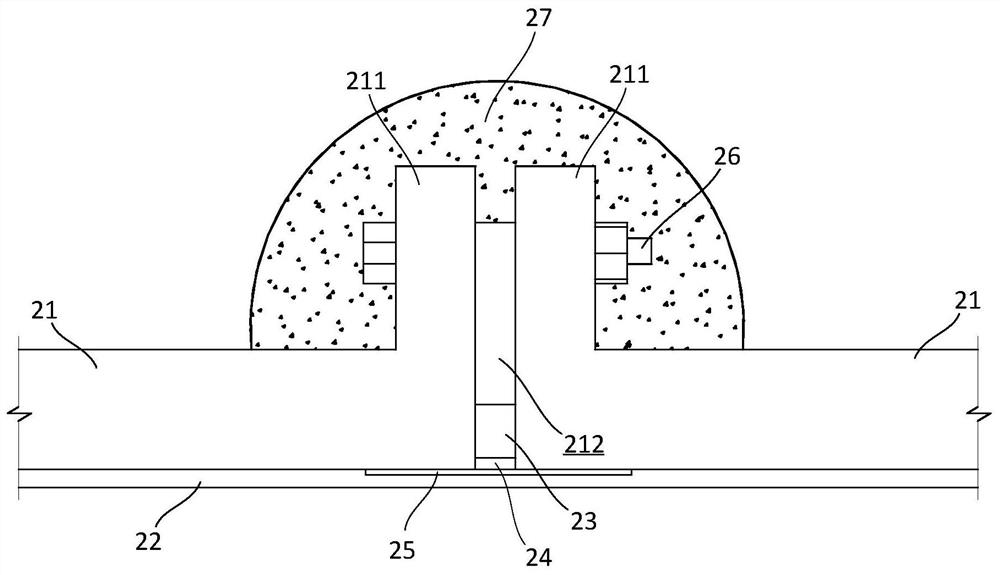

The invention discloses an automatic sealing mechanism of a trenchless petroleum pipeline damage repairing device. The automatic sealing mechanism comprises a telescopic adjusting mechanism, a repairing liquid spraying mechanism and a cleaning and gluing mechanism, wherein a repairing liquid spraying machine body comprises a main shaft shell, an air pump, a power supply, an air bag and glass fibermat cloth, the telescopic adjusting mechanism comprises a lead screw lifting assembly, and a rotating roller is arranged at the end part of the lead screw lifting assembly; the cleaning and gluing mechanism comprises a cleaning rotary disc and a gluing rotary disc, a rotating brush is arranged on the cleaning rotary disc, a glue opening is formed in the gluing mechanism, the glass fiber mat clothis wrapped on the outer wall of the air bag, and repairing liquid is arranged on the glass fiber mat cloth and is pasted to the damaged position of the pipeline through the glass fiber mat cloth. Therepairing effect on the inner wall of the pipeline can be greatly improved, and the inner wall of the pipeline can be cleaned through the cleaning and gluing mechanism; and meanwhile, sealant coatingcan be carried out, and the repairing effect on the inner wall of the pipeline can be greatly guaranteed.

Owner:郝芮一

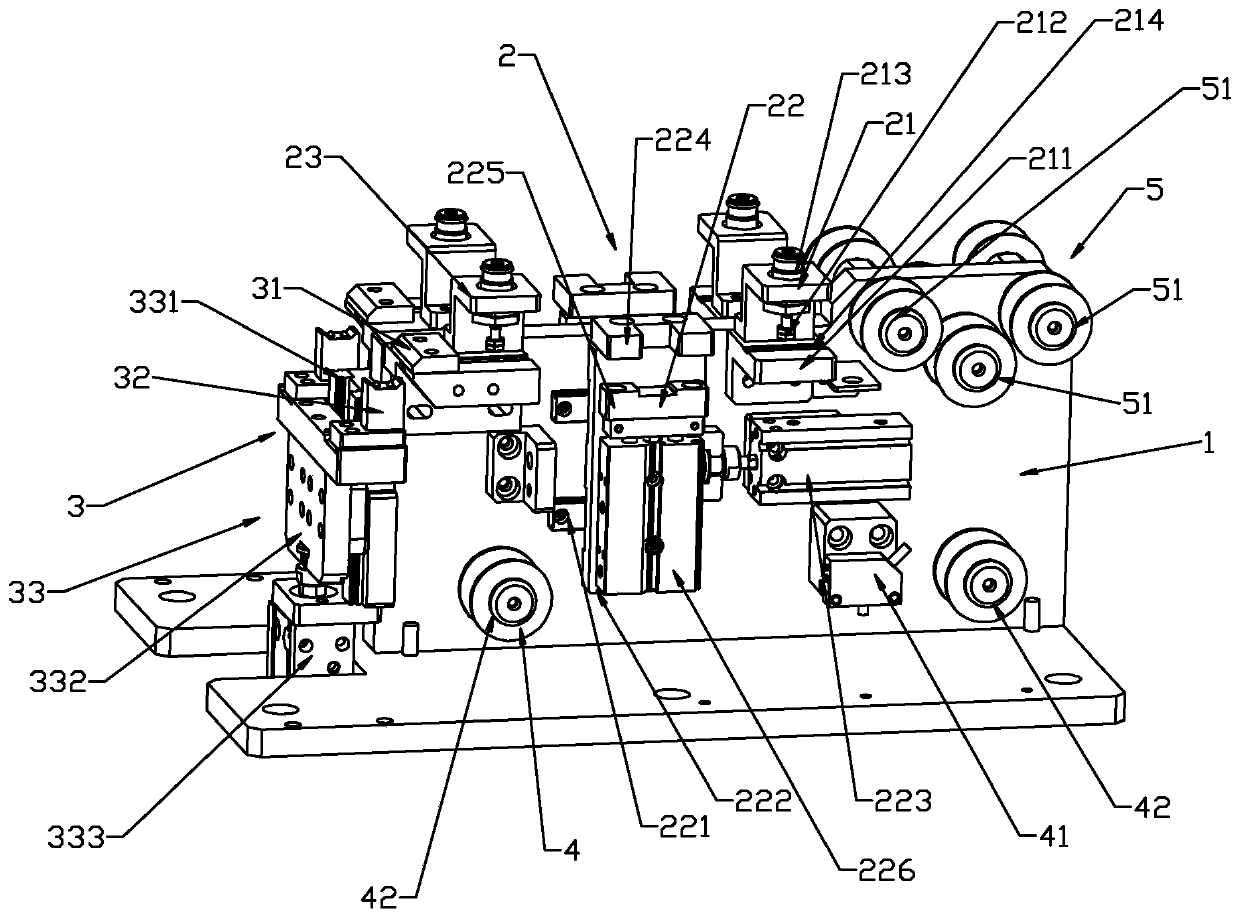

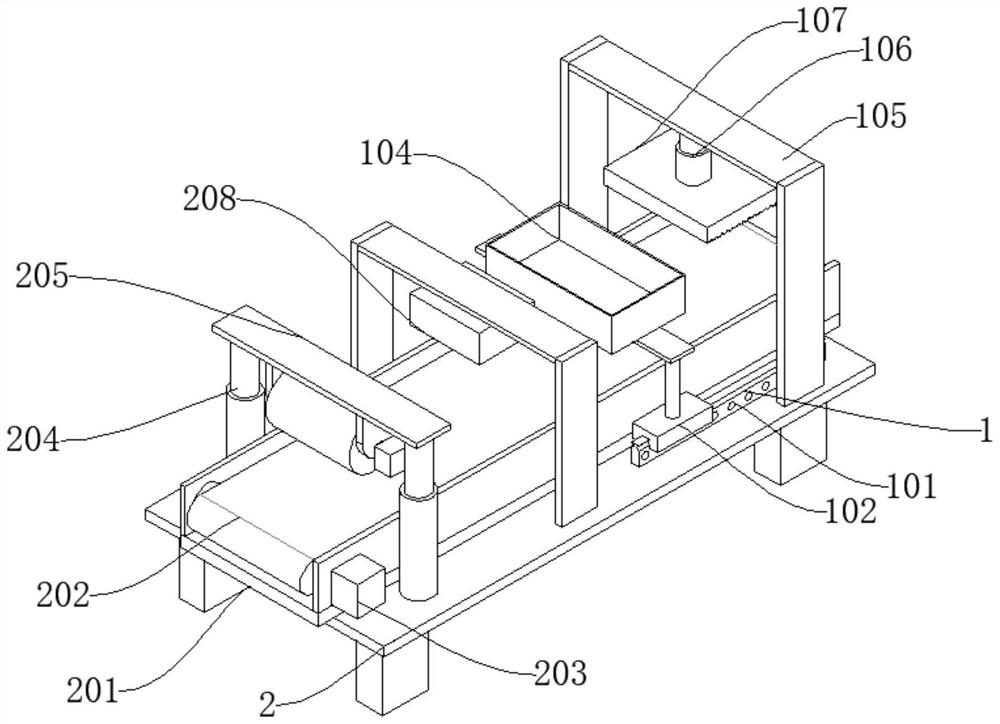

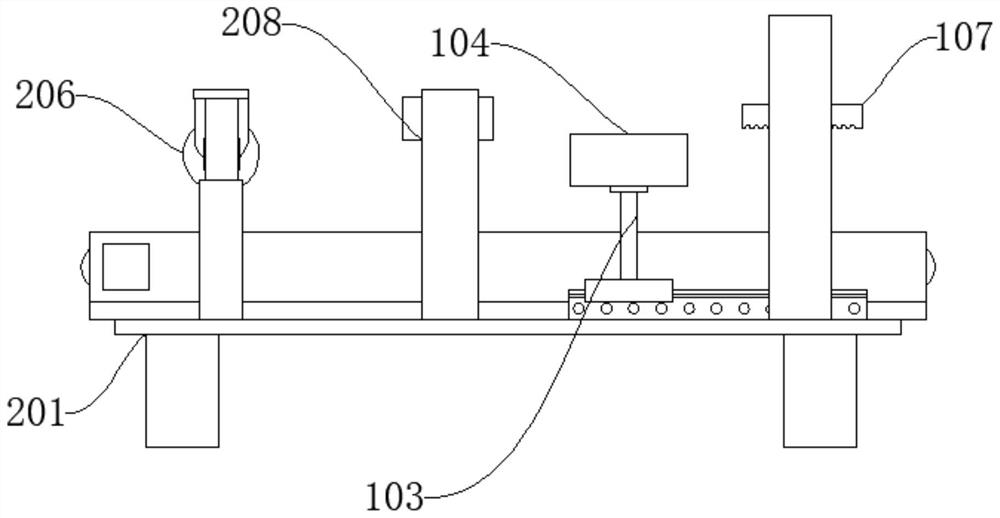

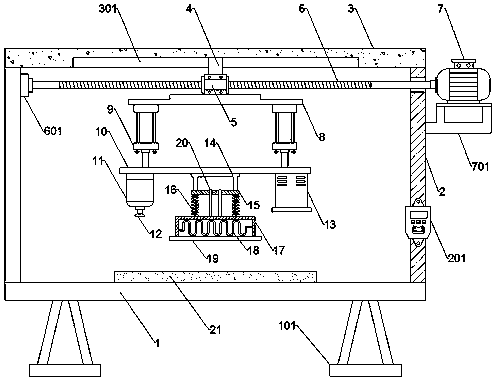

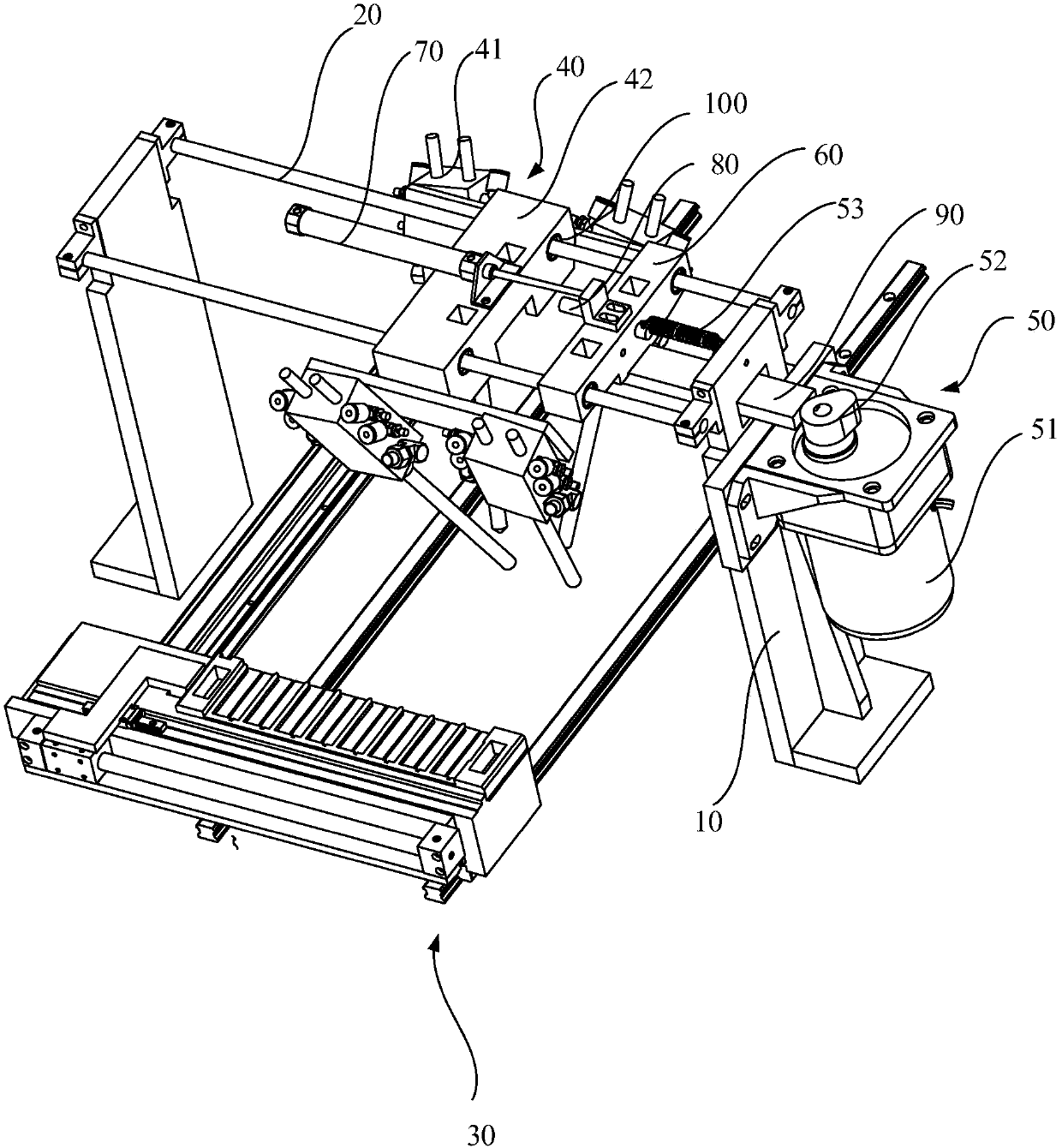

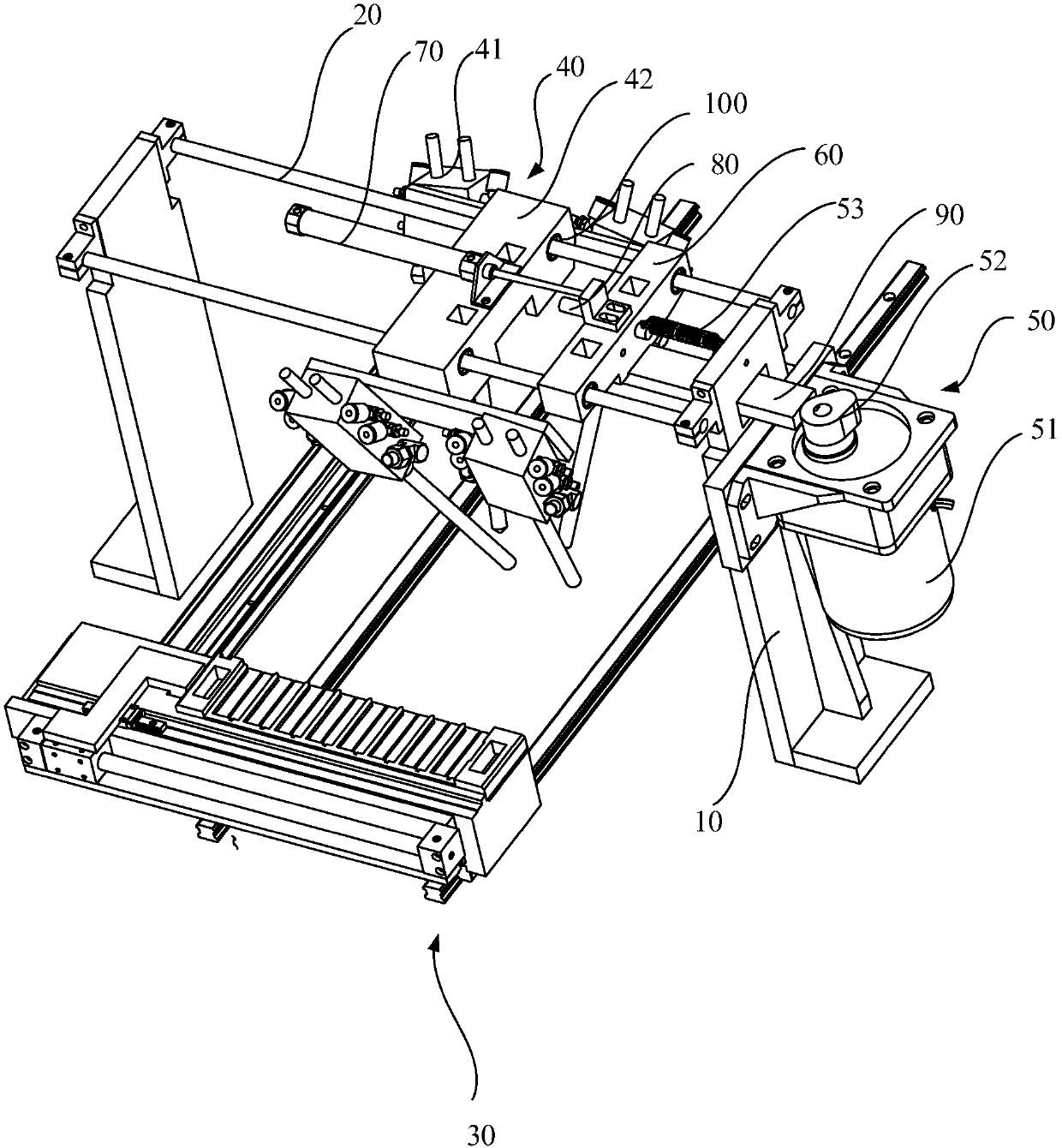

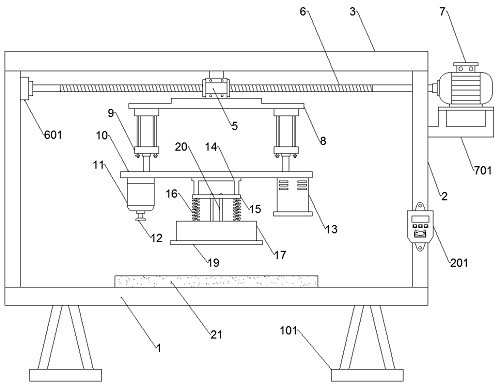

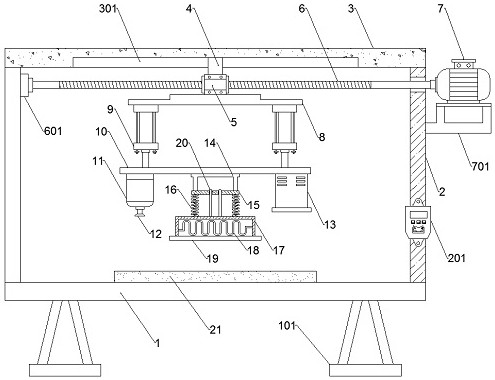

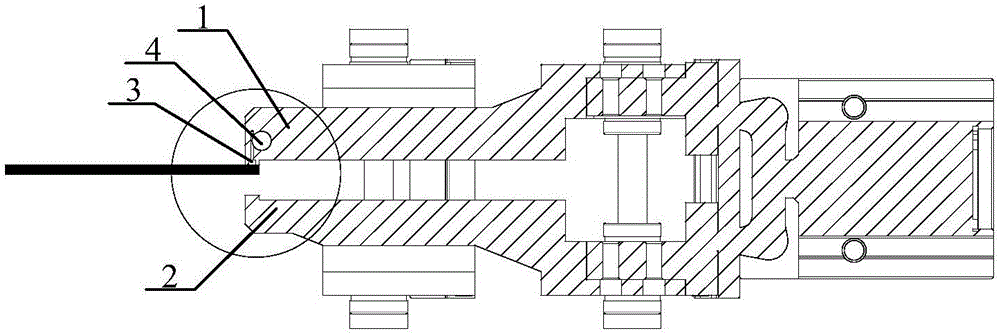

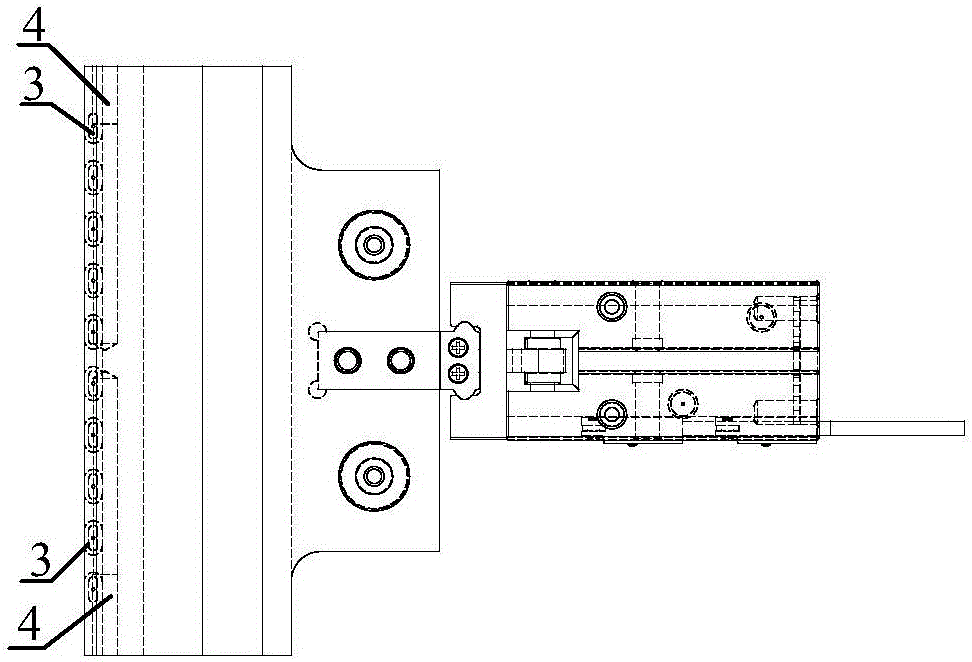

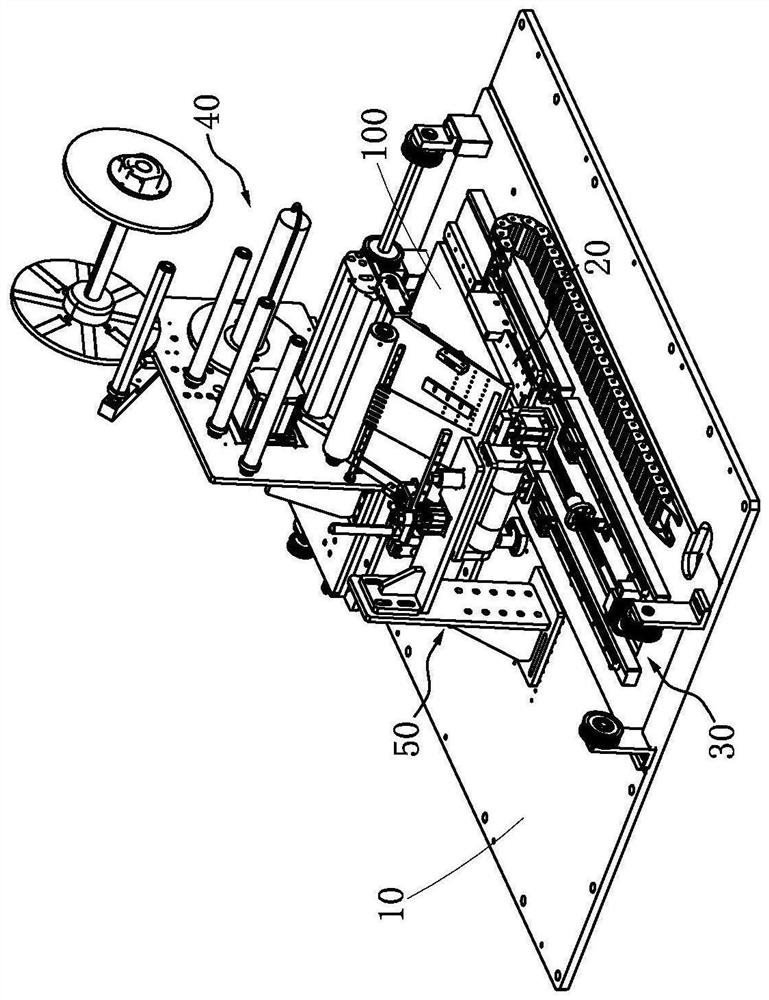

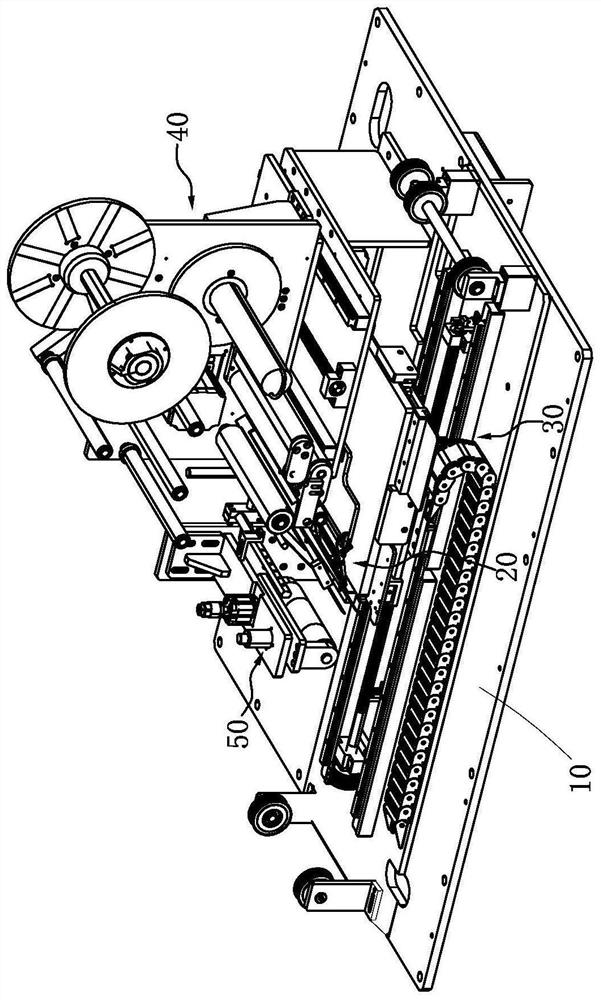

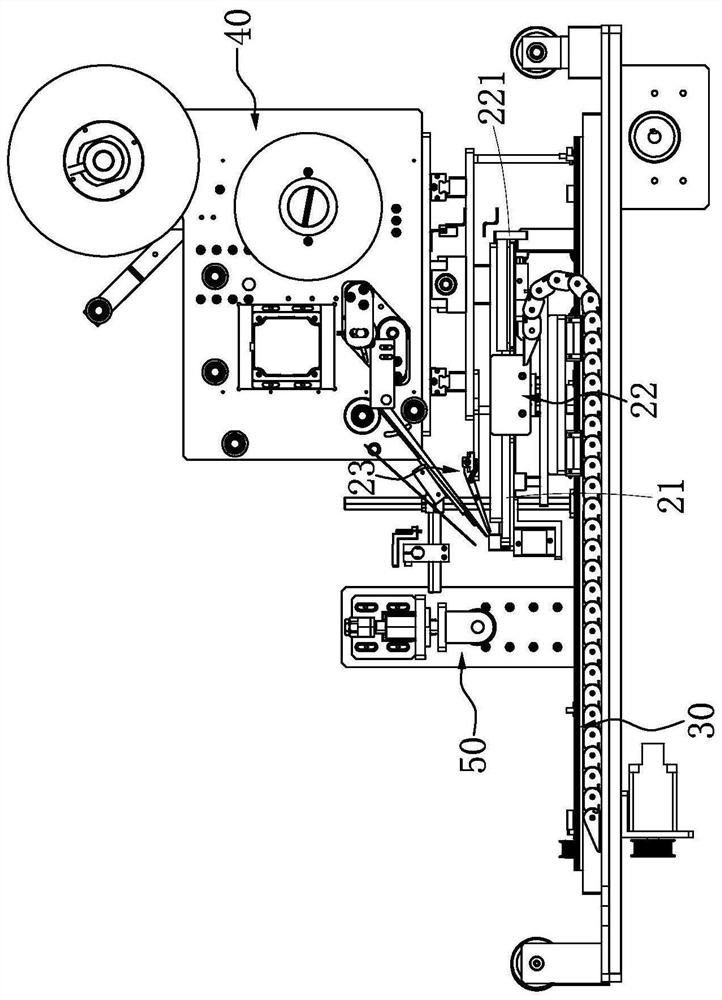

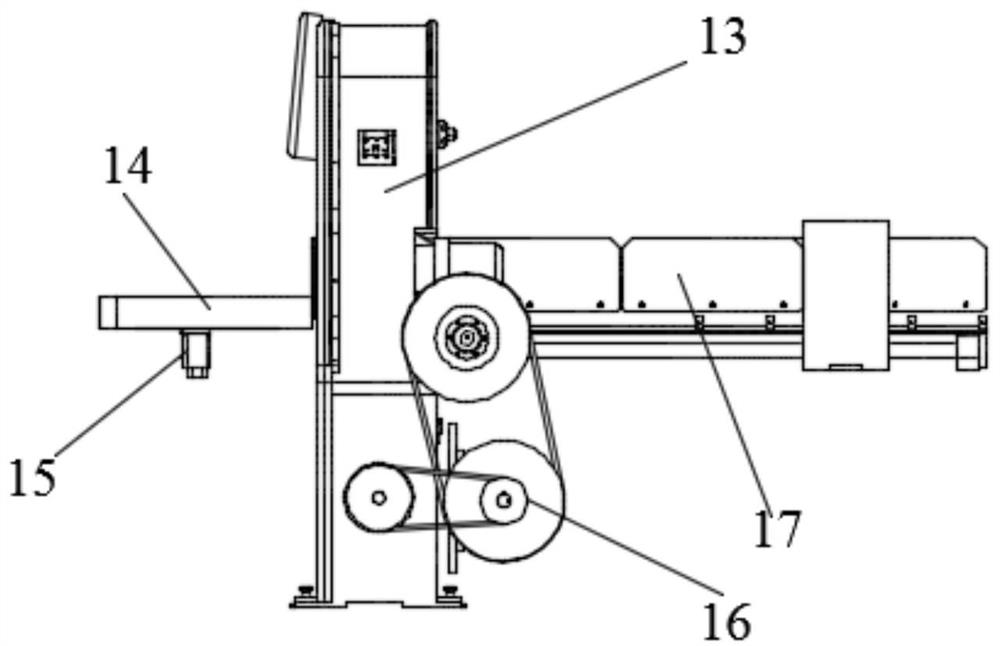

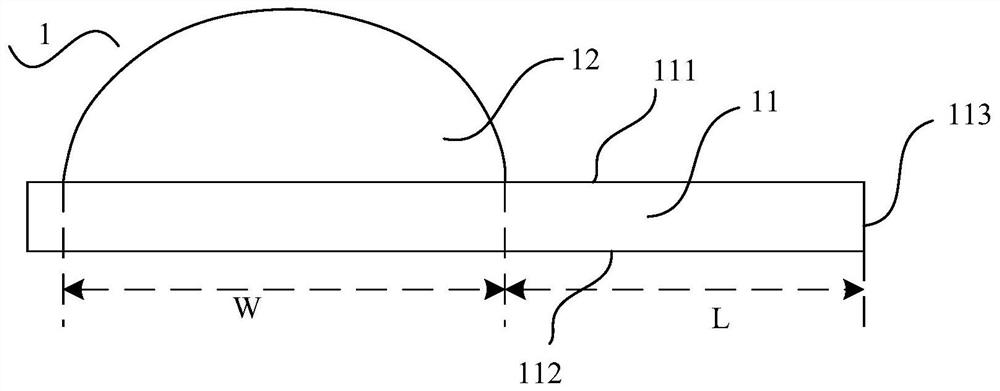

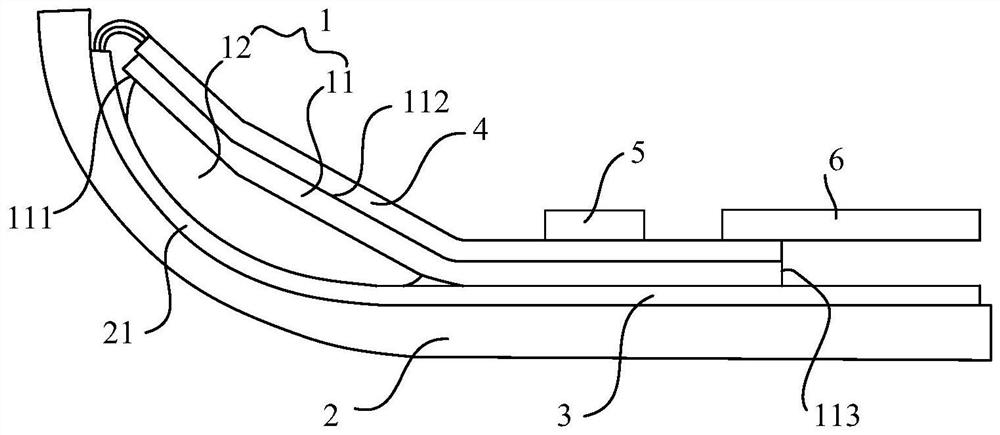

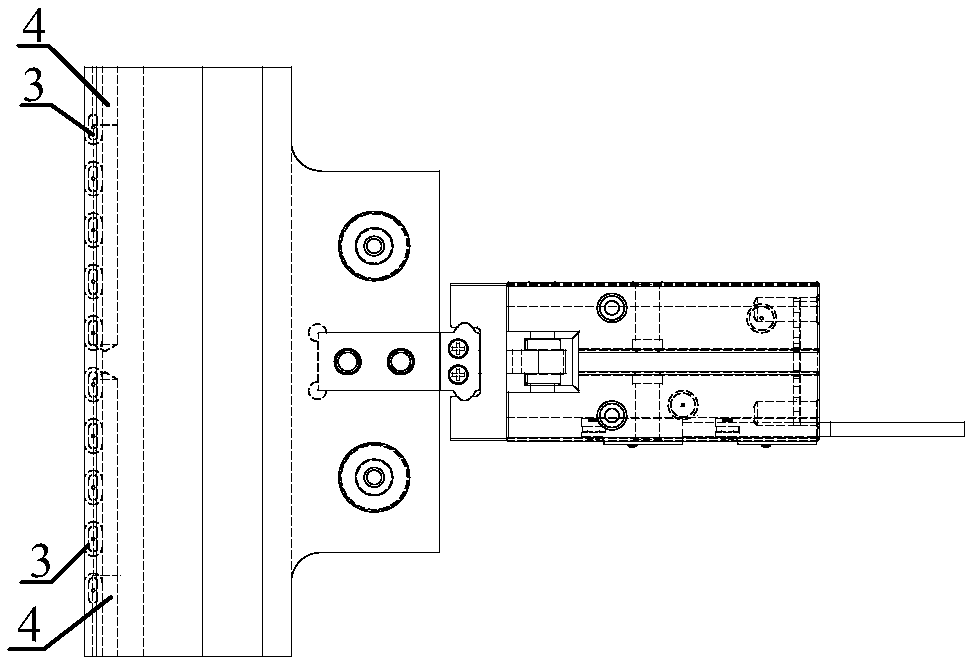

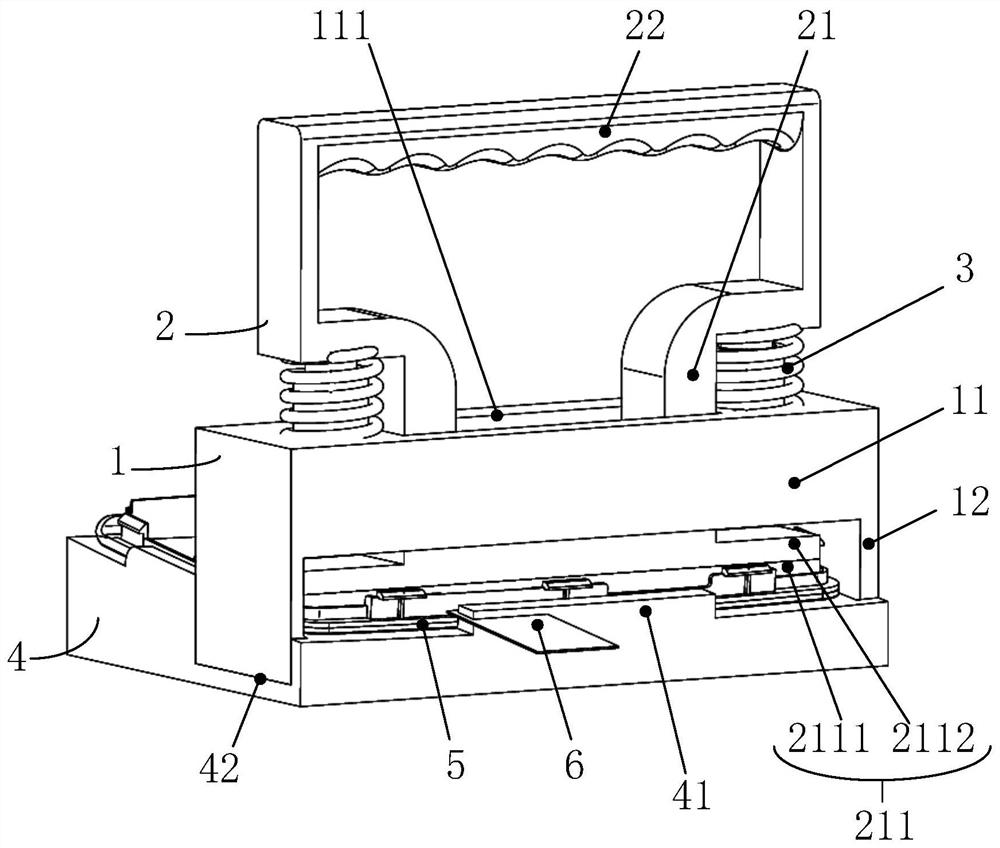

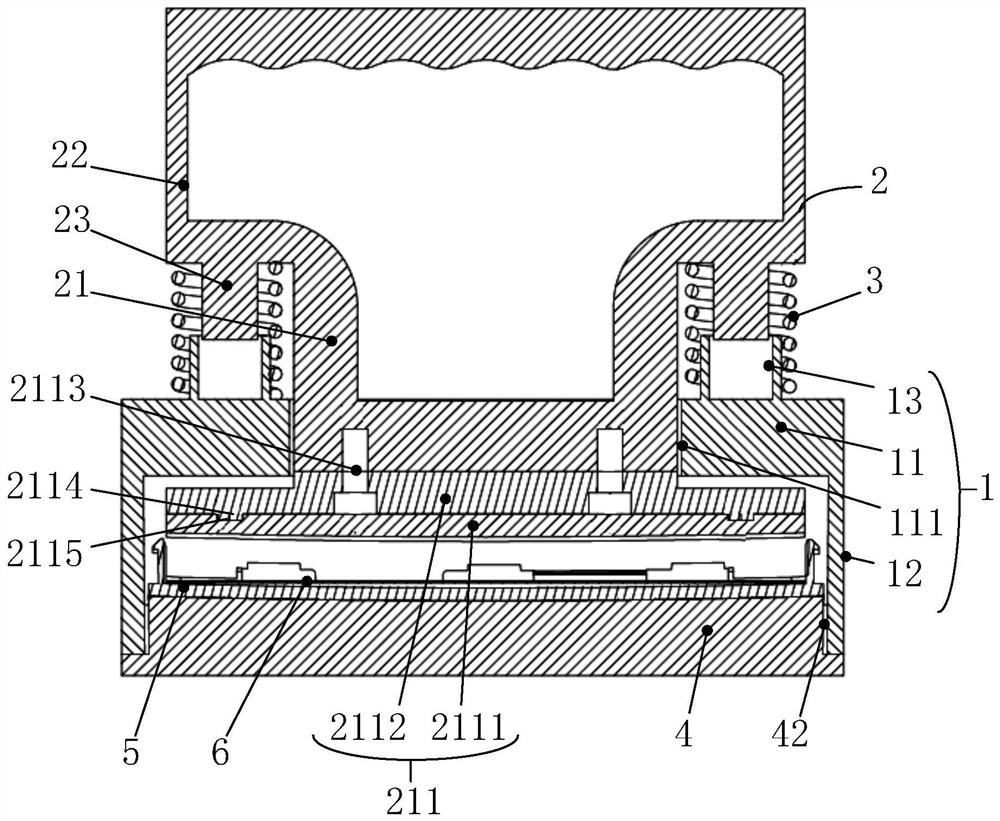

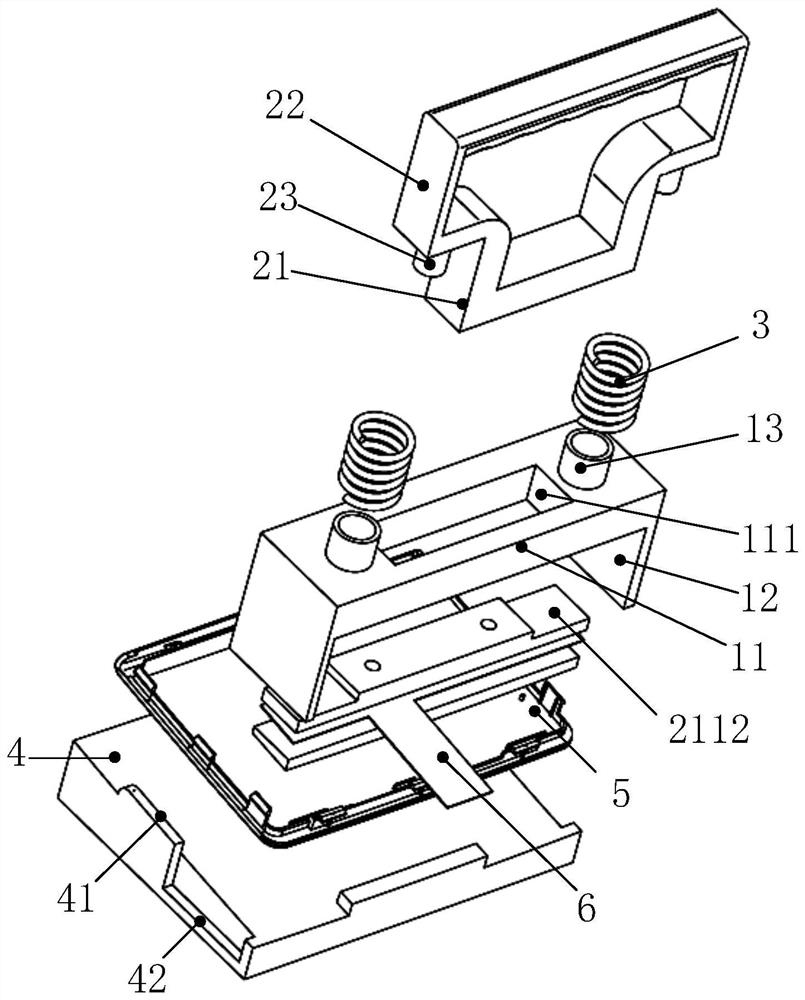

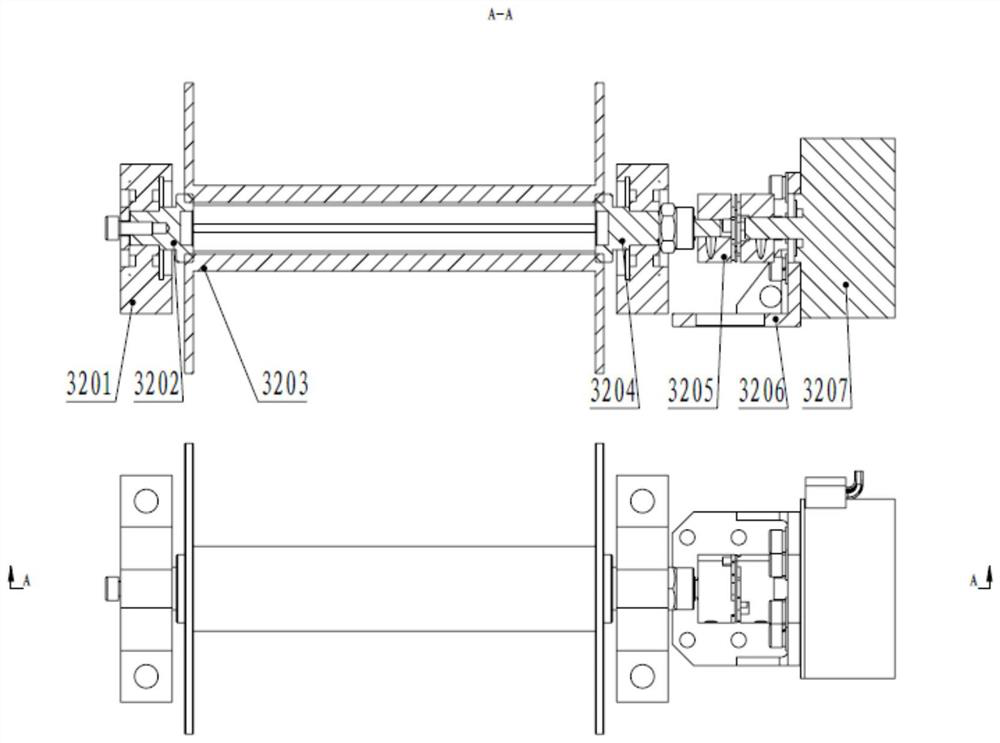

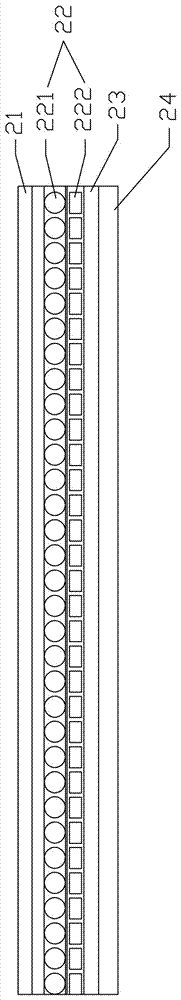

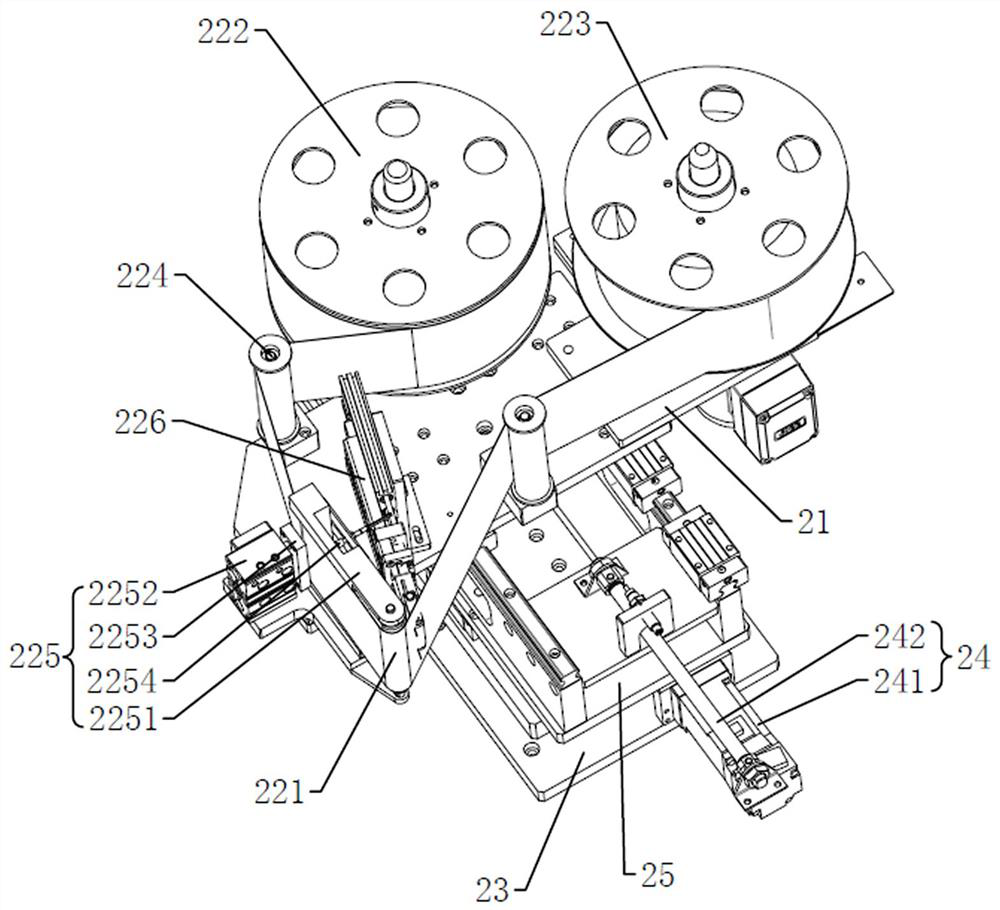

Feeding slicing device

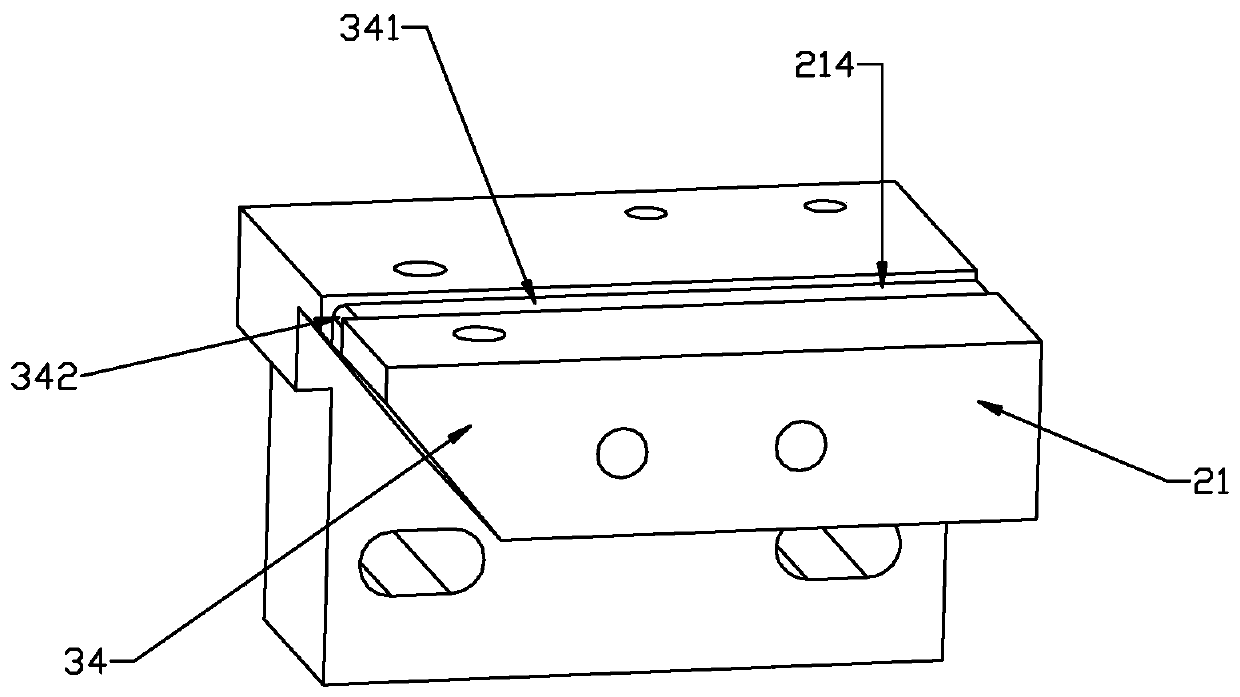

PendingCN109823892AGuaranteed sticking effectCut to exact lengthMetal working apparatusArticle deliveryEngineeringMechanical engineering

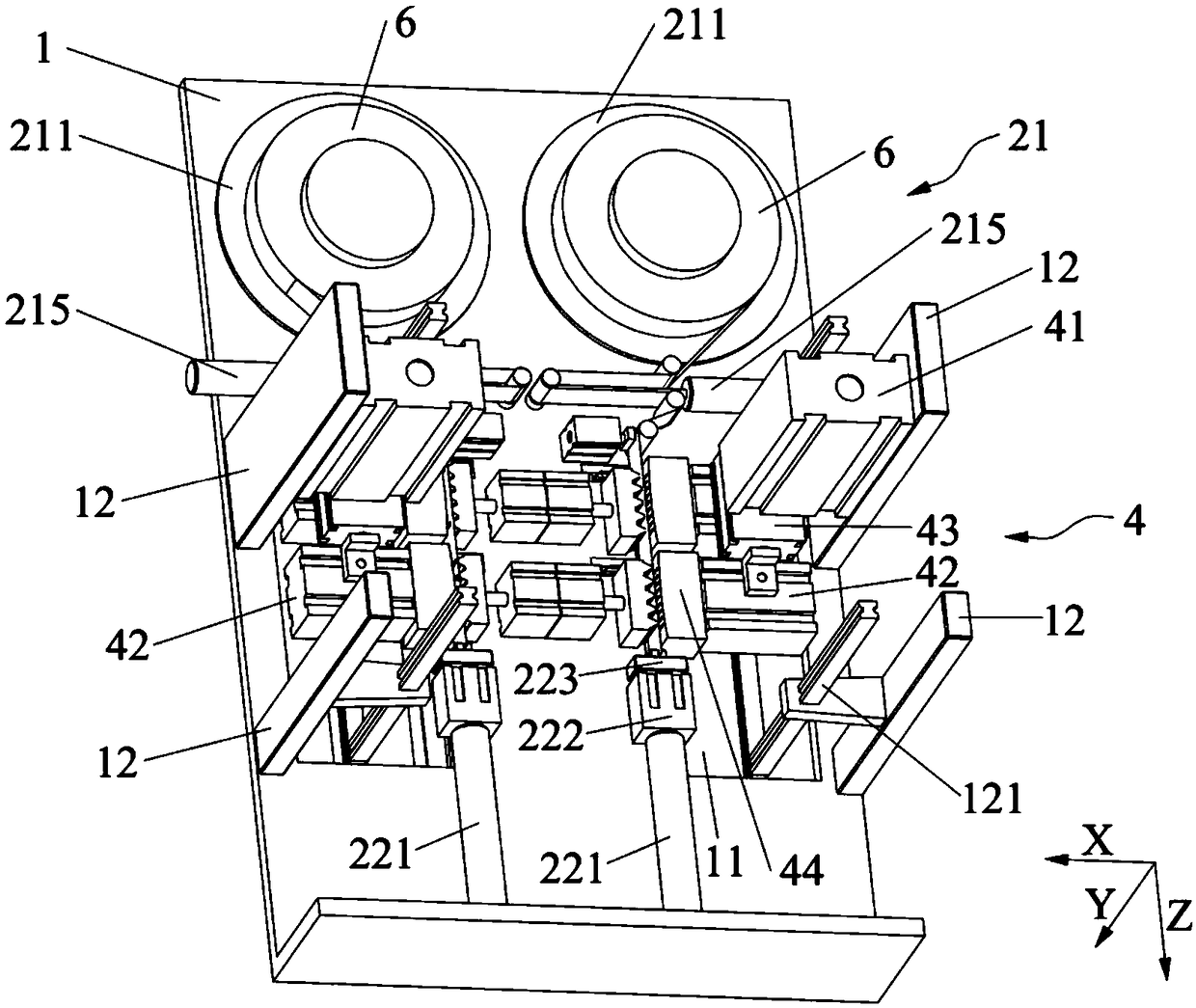

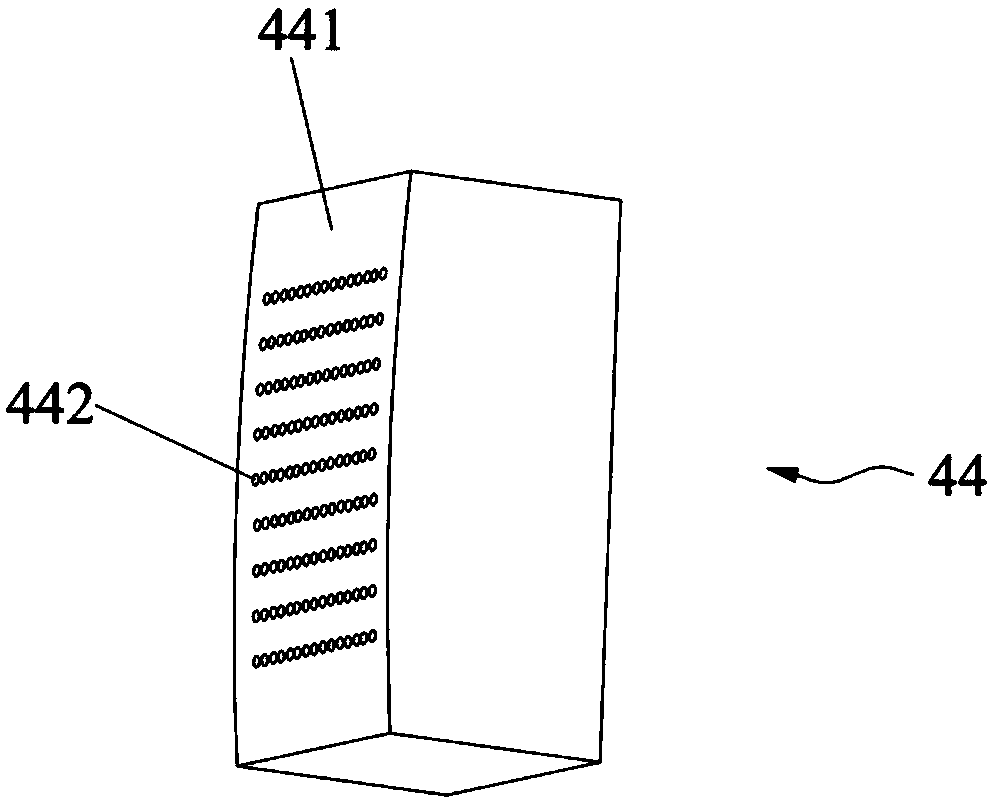

The invention relates to a feeding slicing device. The feeding slicing device comprises a machine frame; the machine frame is sequentially provided with an equal-length material feeding mechanism, a cutting mechanism and a guiding mechanism in the material belt conveying direction; the equal-length material feeding mechanism conveys equal-length material belts to the cutting mechanism at a time, slice bodies are separated from the material belts at the position of the cutting mechanism, equal-length slice bodies are cut from a continuous slice body through the cutting mechanism, and the guiding mechanism guides the material belts separated from the slice bodies to the recycling position. The scheme is adopted, according to the feeding slicing device provided by the invention, the cutting precision and the machining efficiency are improved, and material belt recycling is facilitated.

Owner:浙江华亿电气有限公司

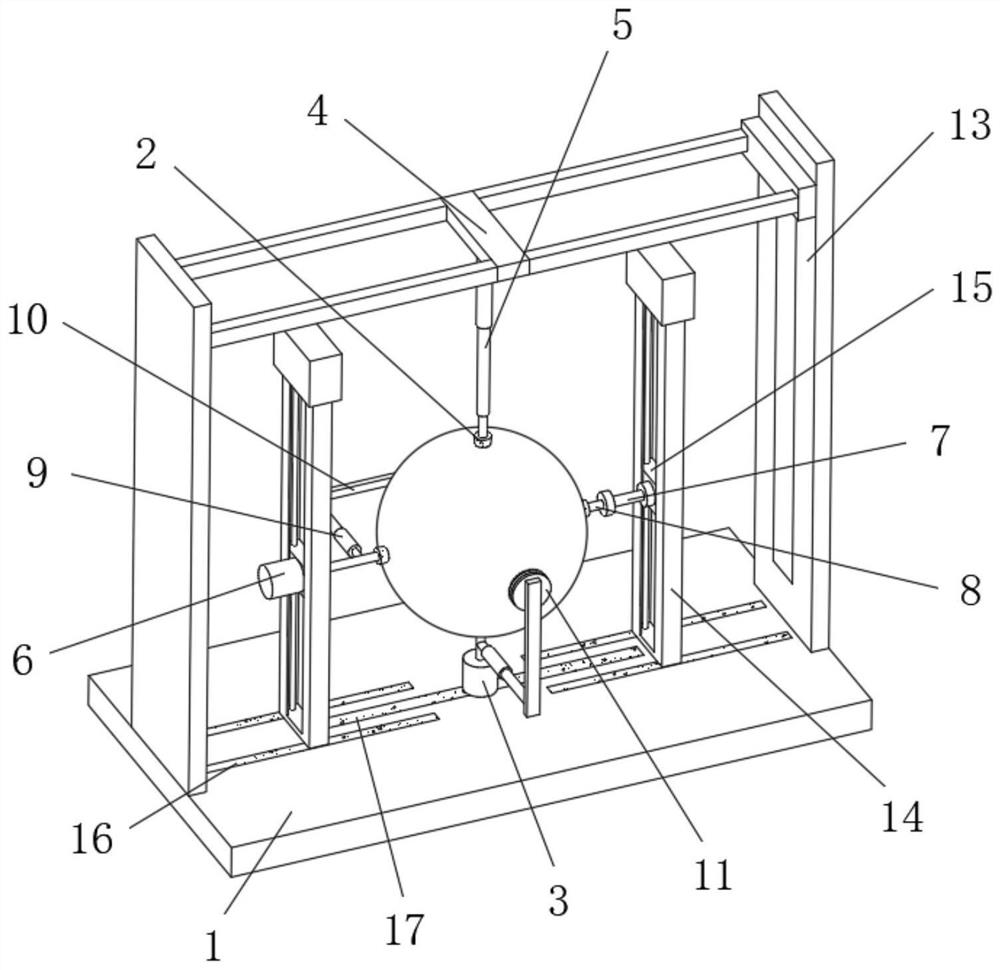

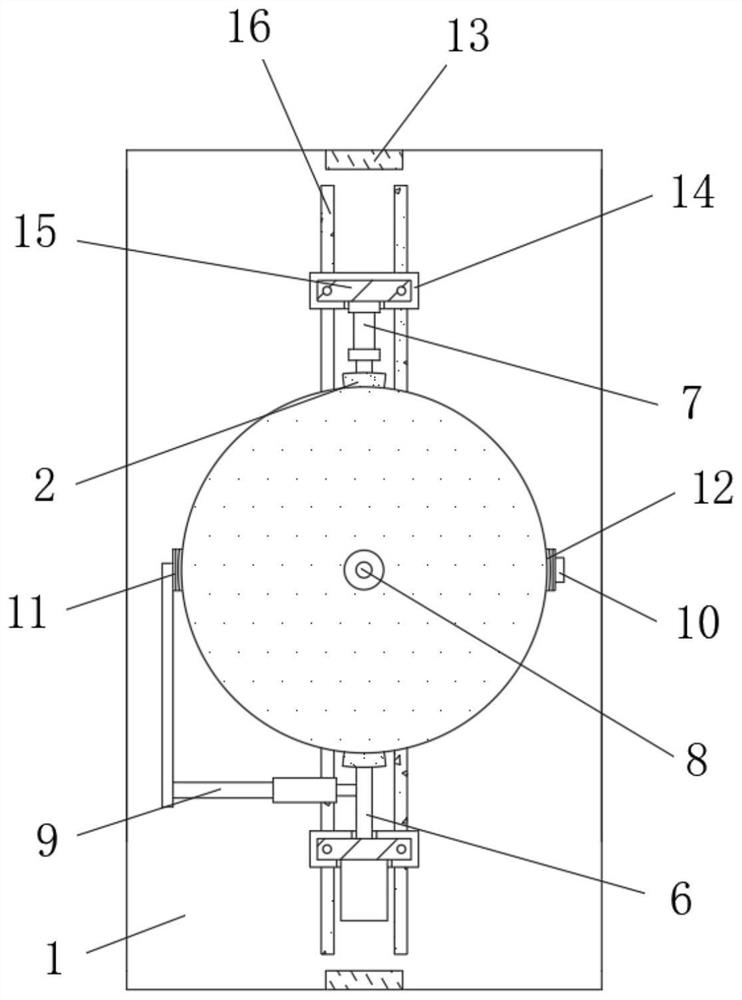

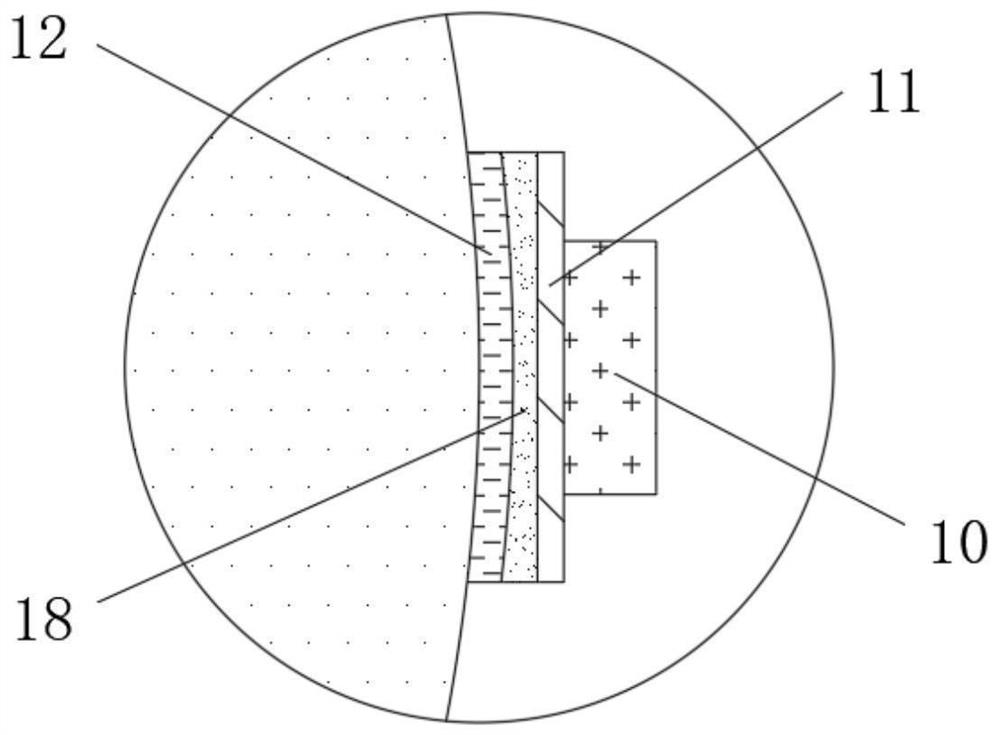

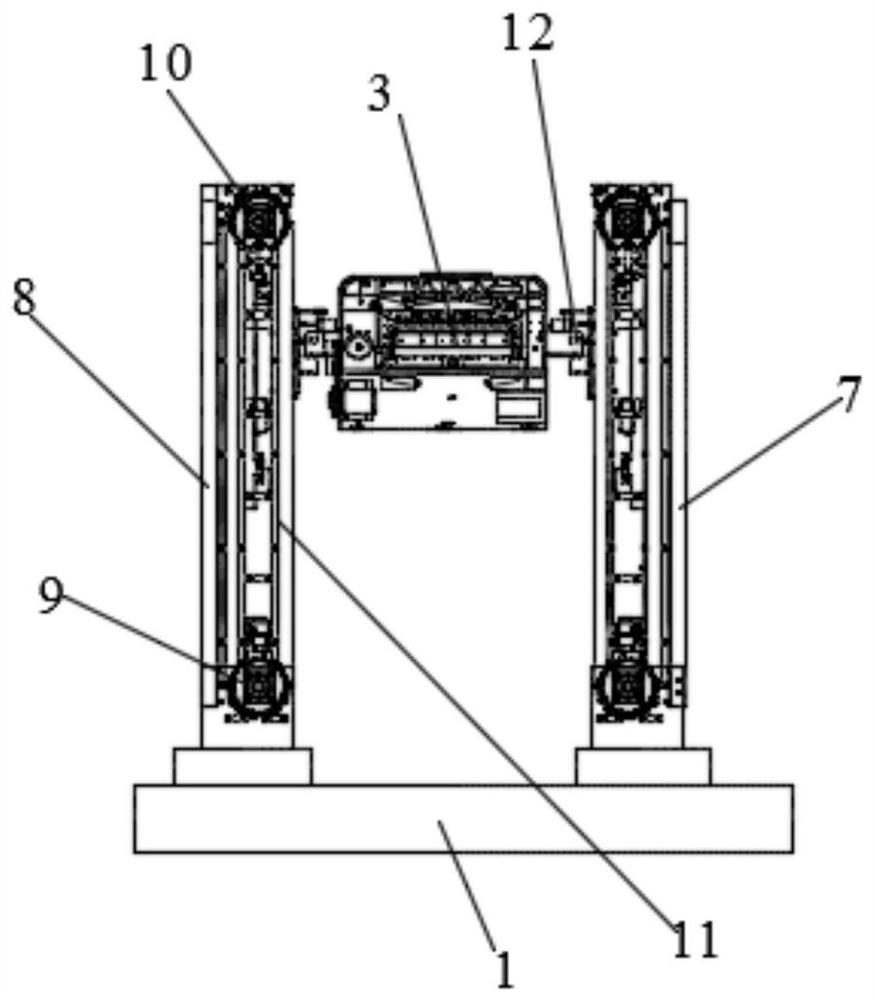

A spherical industrial product grinding device for industrial product design

ActiveCN111347319BAvoid manual replacementReduce labor intensityGrinding carriagesGrinding drivesElectric machineryProcess engineering

Owner:南通鑫拓封头制造有限公司

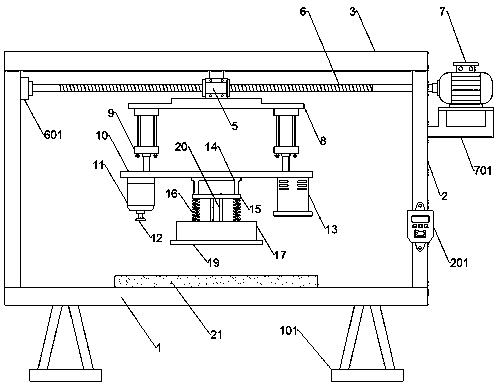

SMT chip mounter for circuit board production

PendingCN112399726AGuaranteed sticking effectAvoid it happening againPrinted circuit assemblingElectrical componentsElectric machineDust control

The invention discloses an SMT chip mounter for circuit board production. The SMT chip mounter comprises a dust removal mechanism and a working mechanism. The dust removal mechanism comprises a sliding rail, an electric sliding block and a supporting frame. The electric sliding block is installed on the sliding rail, the supporting frame is arranged on the upper end surface of the electric slidingblock, and a collection box is arranged on the supporting frame. The dust removal mechanism is mounted on one side of the collecting box; and the working mechanism comprises a conveying frame, a conveying belt and a first motor, the conveying belt is installed on the inner side of the conveying frame, a first motor is installed on the front portion of the conveying frame, and a second electric telescopic column is installed on one side of the first motor. The SMT chip mounter is simple in structure, reasonable in design and low in production cost, dust on the circuit board can be removed, attached patches are rolled at the same time, gaps and bubbles are prevented from being generated, and the attaching effect of the patches is greatly guaranteed.

Owner:苏州昶恒电子科技有限公司

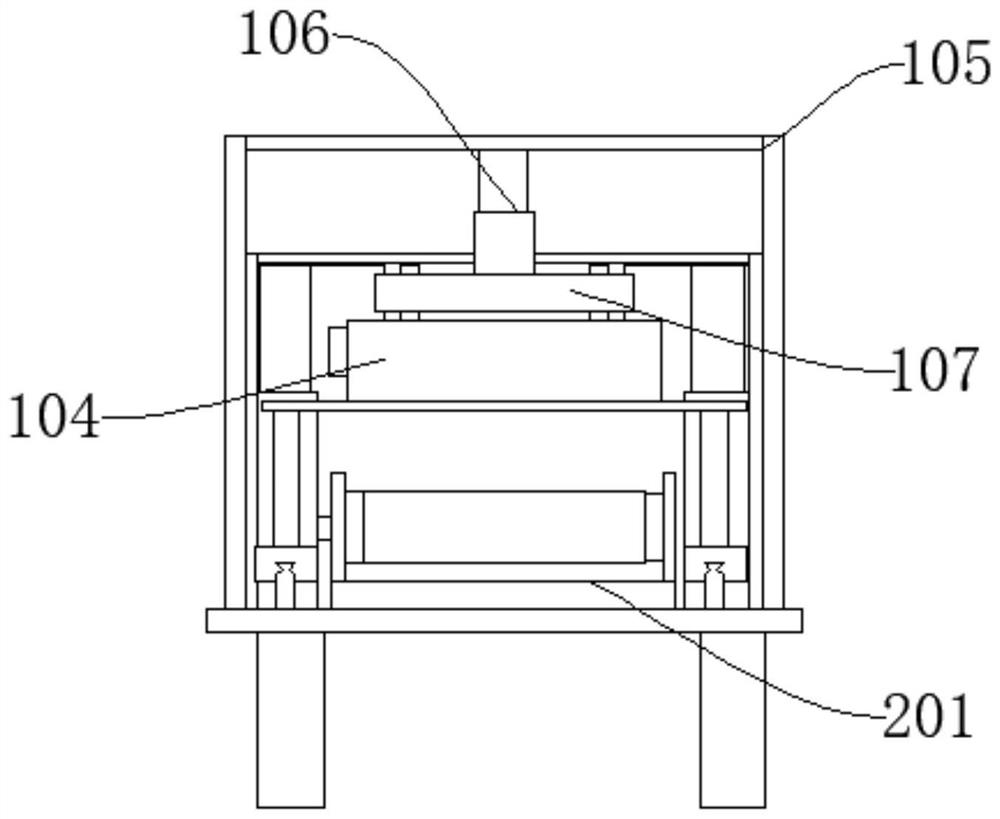

Wrinkle-proof furniture veneer pressing machine

ActiveCN109203631AGood wrinkle resistanceGood effectLaminationLamination apparatusWrinkleEngineering

The invention relates to the technical field of furniture, and particularly relates to a wrinkle-proof furniture veneer pressing machine, which comprises a working platform, wherein the left and rightends of the top surface of the working platform are fixedly provided with two groups of frame plates; the tops of the two groups of frame plates are fixedly provided with a top plate; the bottom of the top plate is provided with a sliding groove; a sliding block is connected into the sliding groove in a sliding manner; the bottom of the sliding block is fixedly provided with a lead screw nut; thelead screw nut is in threaded connection with a lead screw; the left end of the lead screw is rotationally connected to the upper end of the inner side of the frame plate on the left side; and the right end of the lead screw penetrates through a through hole formed in the upper end of the frame plate on the right side and is fixedly mounted together with an output end of a motor. The invention provides the wrinkle-proof furniture veneer pressing machine; the motor is used for driving the lead screw, mounted at the output end, to rotate; the lead screw nut is enabled to drive a component, arranged at the lower end of a mounting rack, to move on the working platform to and fro in a left-right manner; a hot pressing component, a glue spraying component and a heat dissipation fan are enabledto be capable of carrying out treatment on a wooden plate to and fro; and realized veneer pressing and wrinkle-proof effects are better.

Owner:杭州荣正家具有限公司

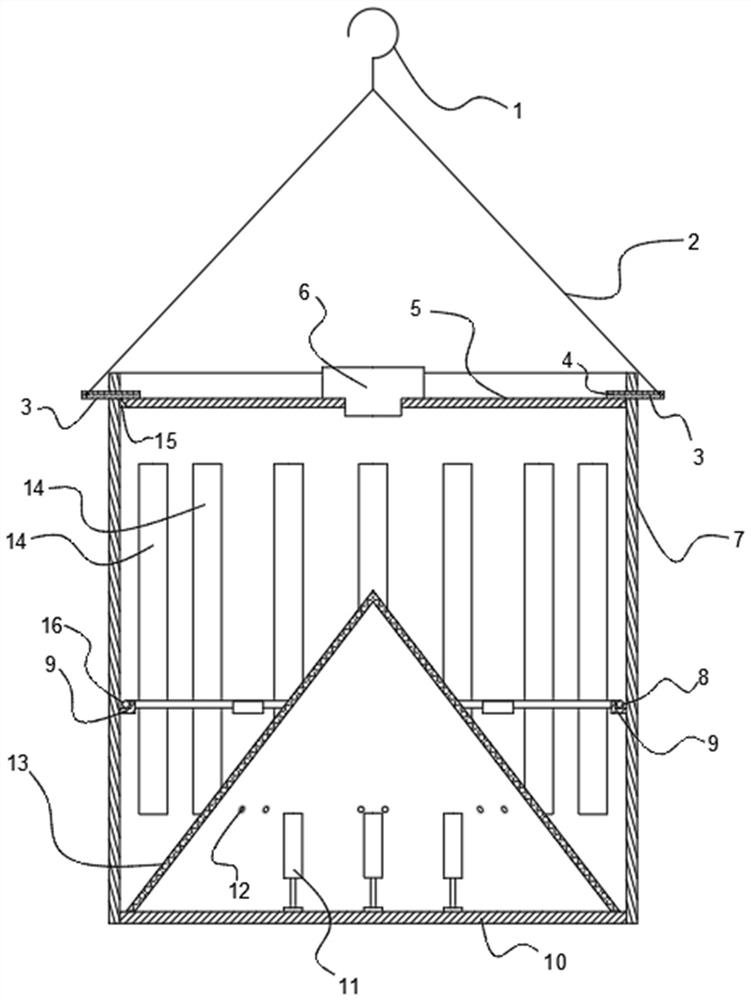

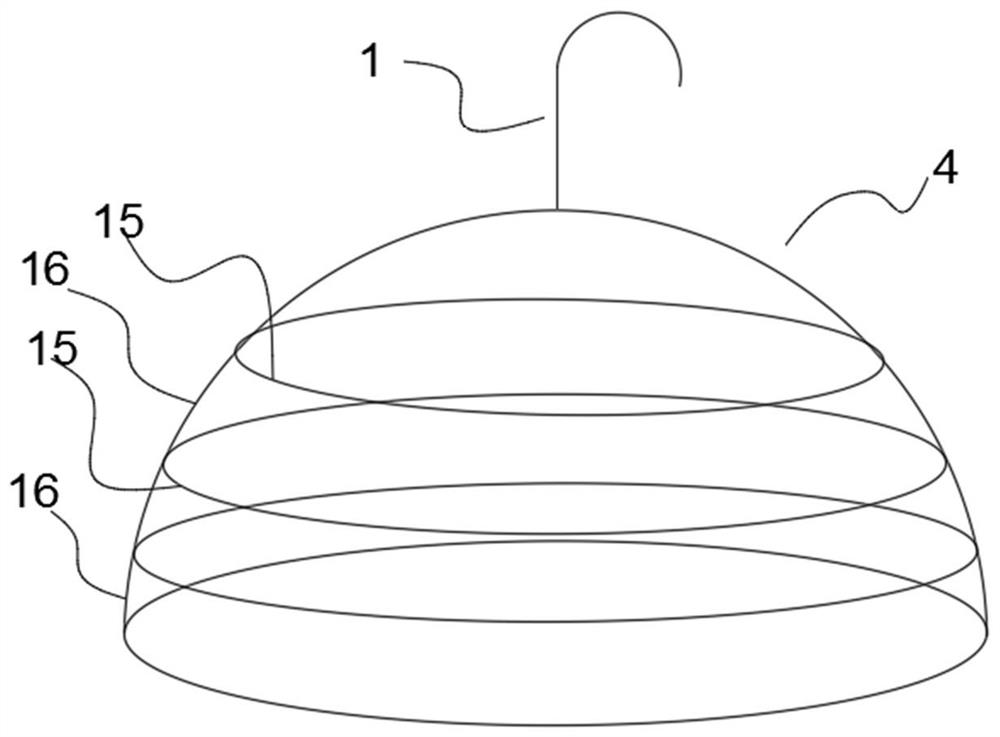

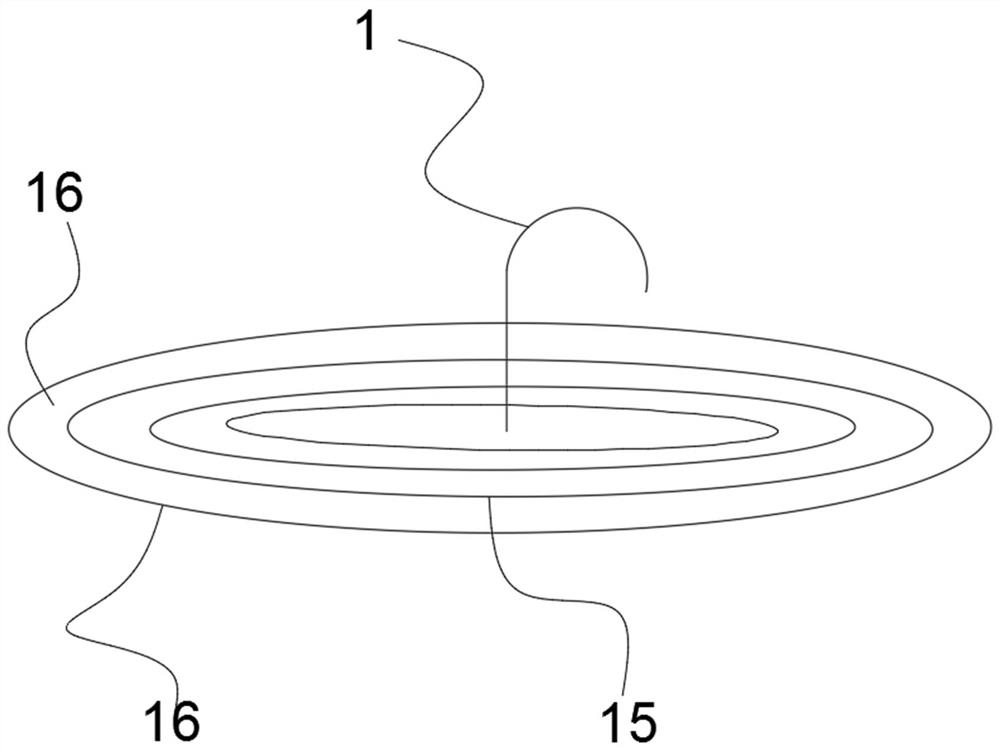

Flying insect online monitoring device

PendingCN111903641AGuaranteed sticking effectNarrow camera angle requirementsTelevision system detailsCharacter and pattern recognitionTrappingEngineering

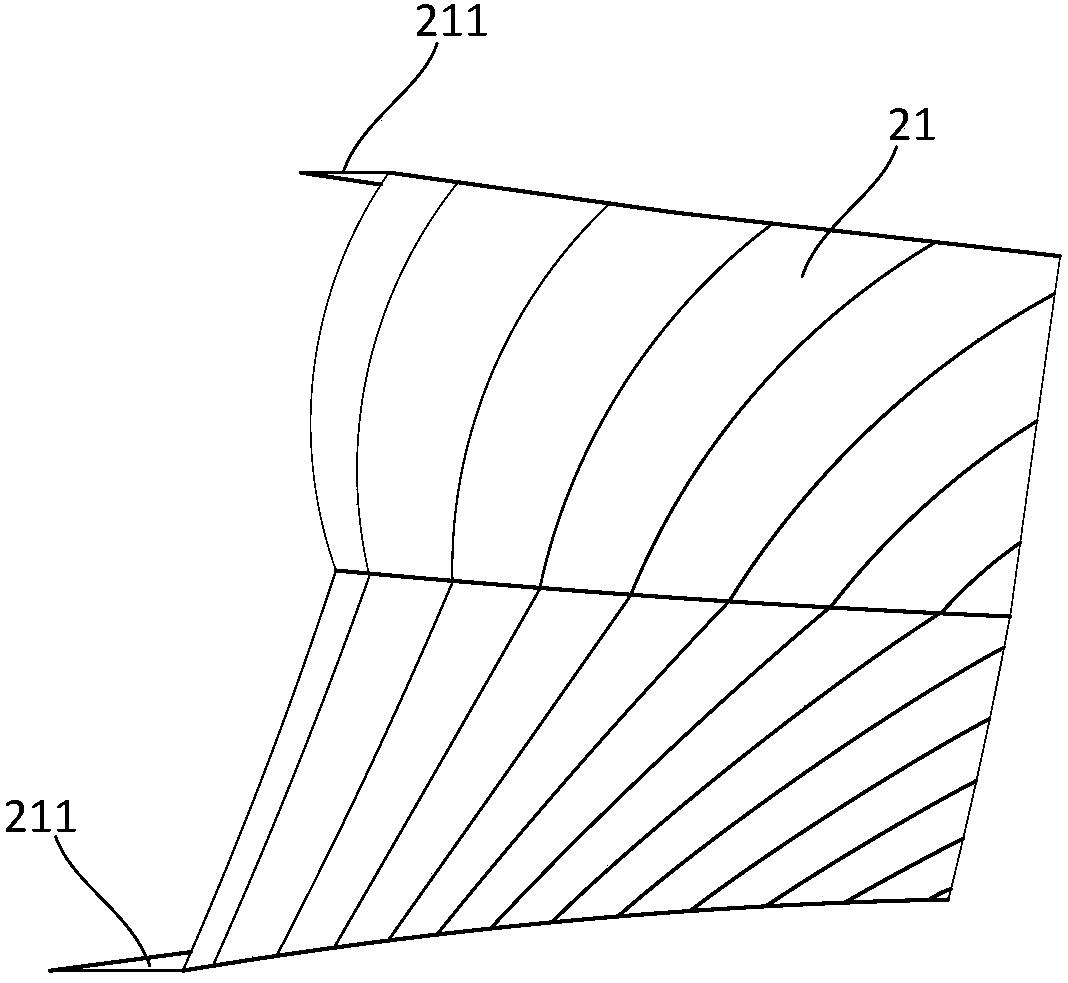

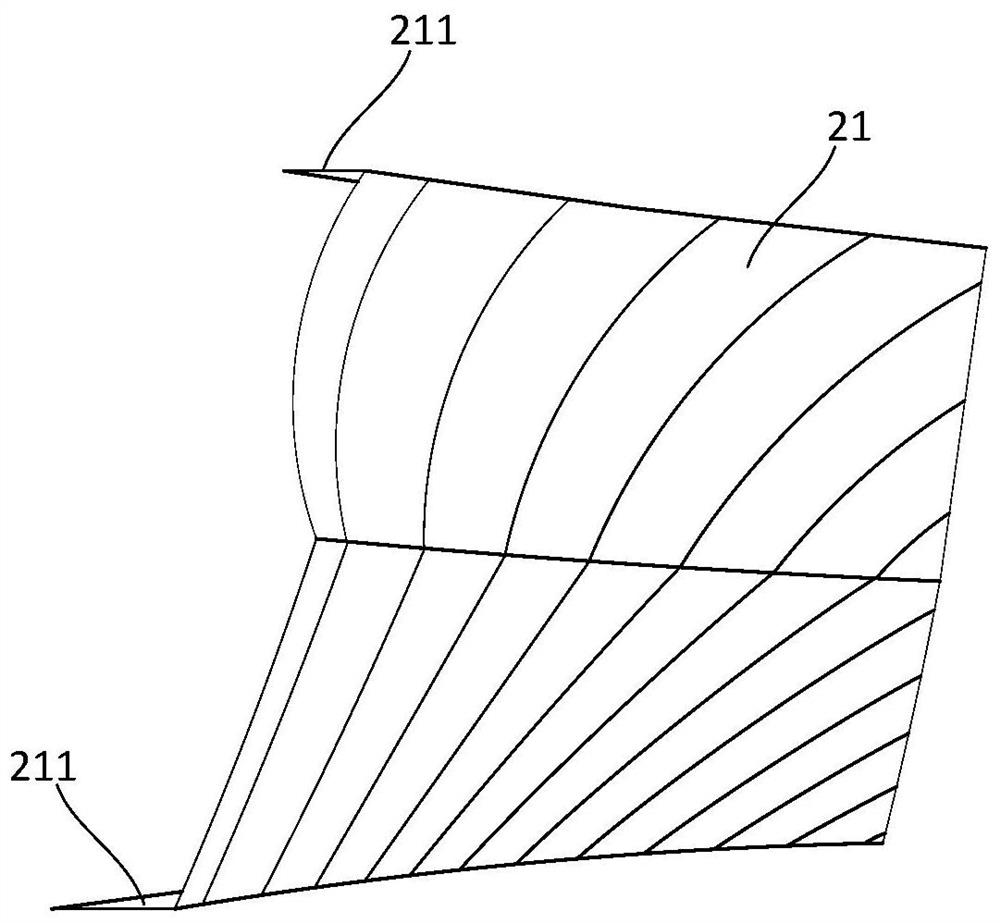

The invention relates to a flying insect online monitoring device which comprises a trapping device and a trapper outer cylinder. The trapping device comprises a big-end-down conical viscose plate arranged in the trapper outer cylinder, the outer conical surface of the conical viscose plate is used for trapping insects, and an insect inlet allowing the insects to fly in from outside to inside is formed in the cylinder wall of the trapper outer cylinder. A top cover is arranged at the upper end of the trapper outer cylinder, and a camera used for shooting and recording the outer conical surfaceof the conical viscose plate downwards is arranged at the position, over the conical viscose plate, of the top cover. Due to the big-end-down structure of the conical viscose plate, it is guaranteedthat the adhesive trapping area is large enough, the adhesive trapping effect on flying insects can be guaranteed, meanwhile, the requirement for the photographing angle of the camera is reduced, thecamera can photograph the whole outer conical surface of the conical viscose plate, the flying insects cannot move after being trapped on the conical viscose plate, the camera can record the number ofinsects on the conical viscose plate, and data and a working basis are provided for realization of an insect online counting and monitoring technology.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

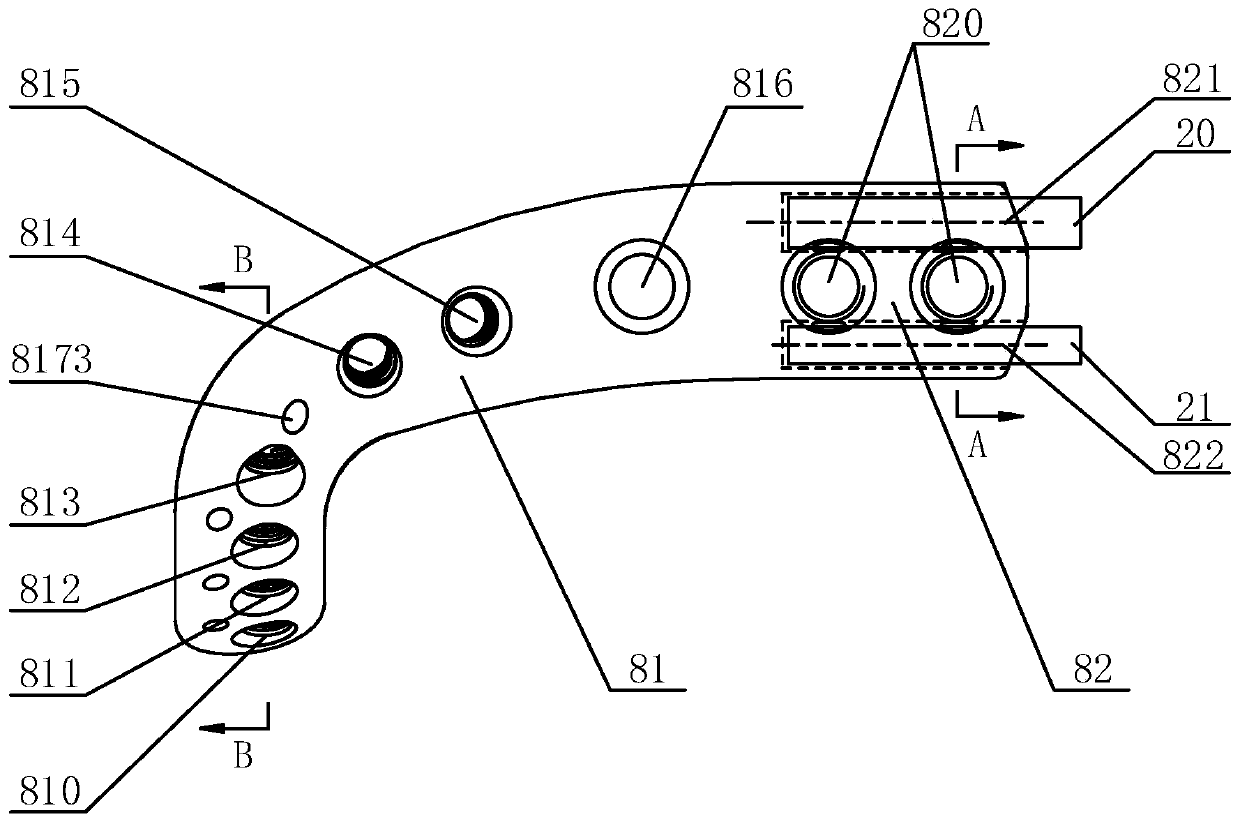

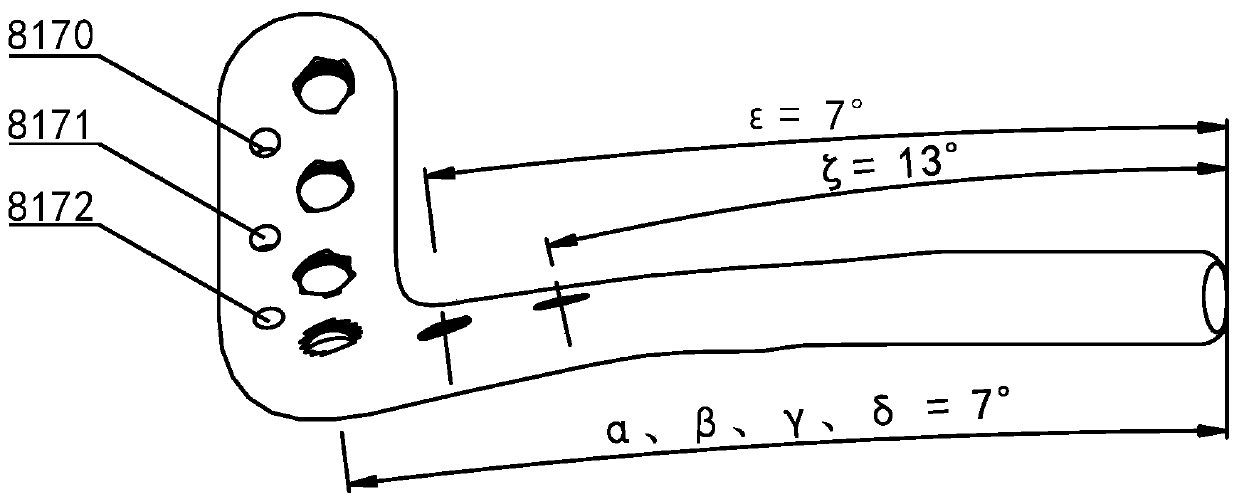

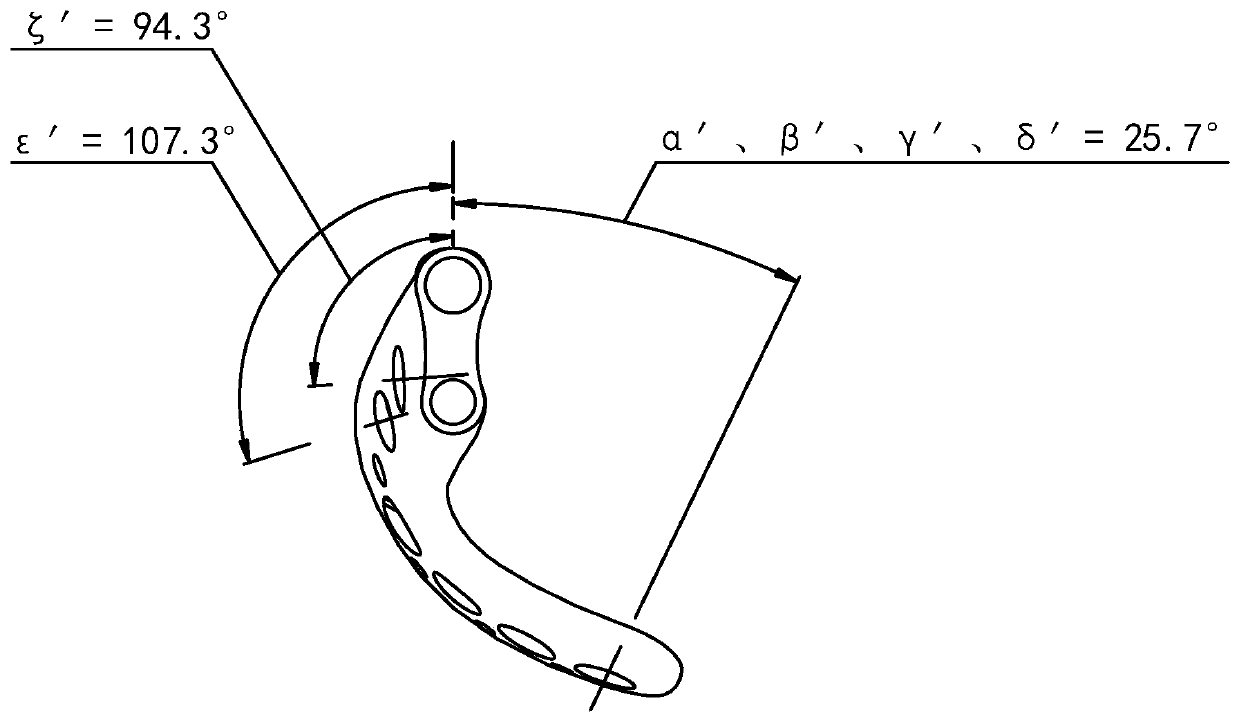

Distal tibial special-shaped block

Owner:TIANJIN WALKMAN BIOMATERIAL CO LTD

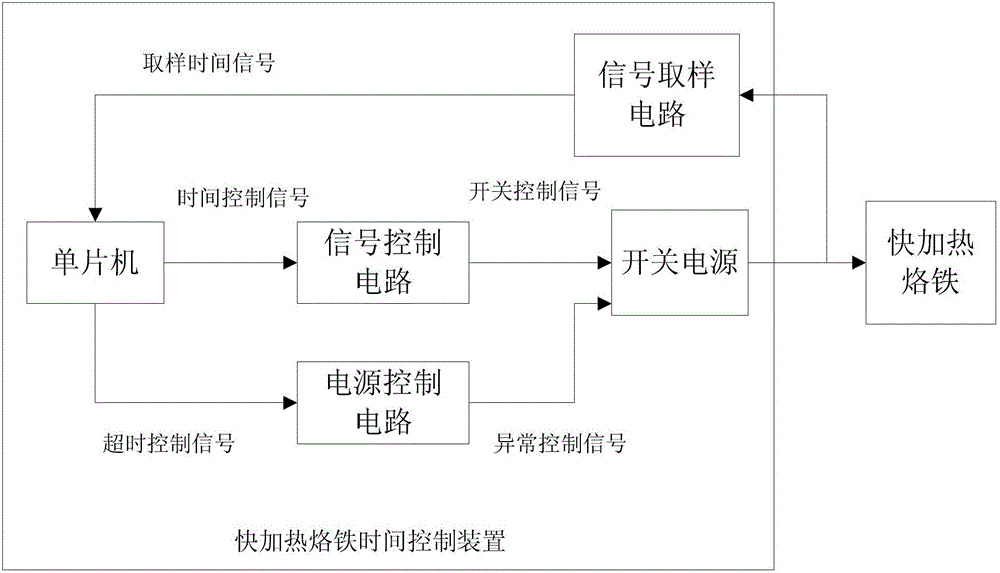

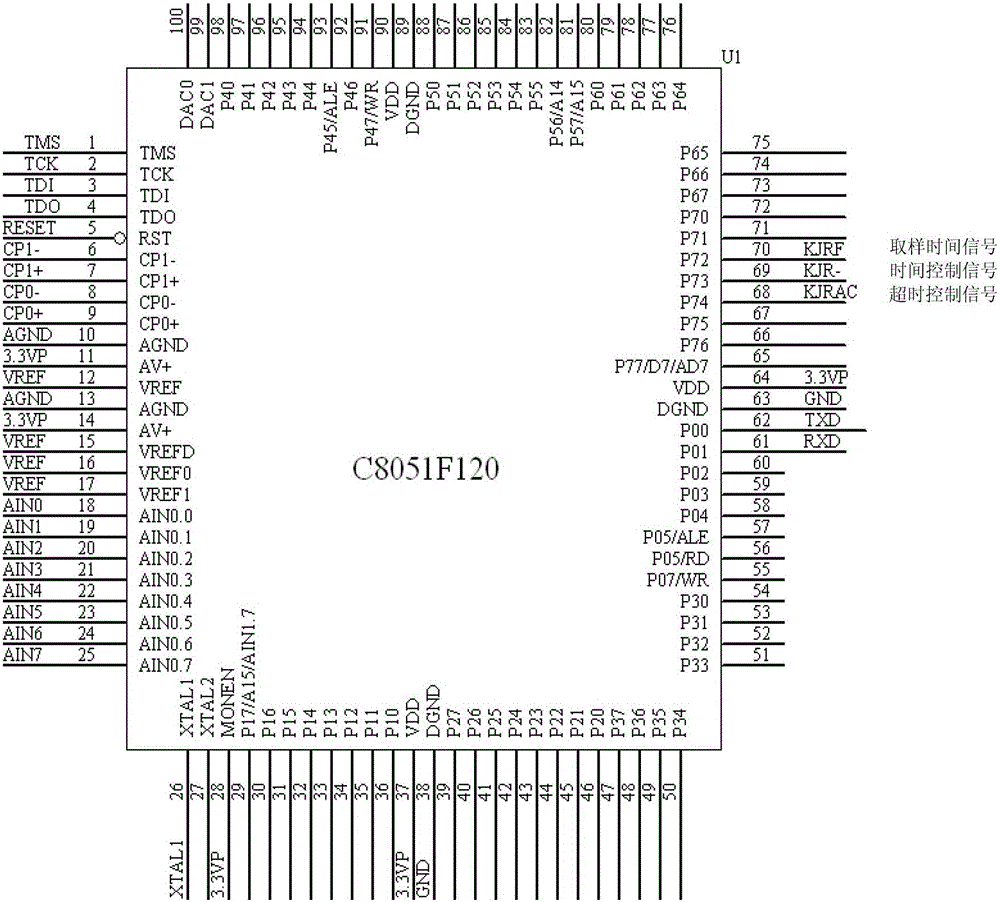

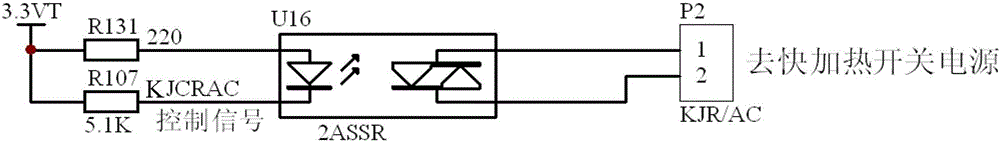

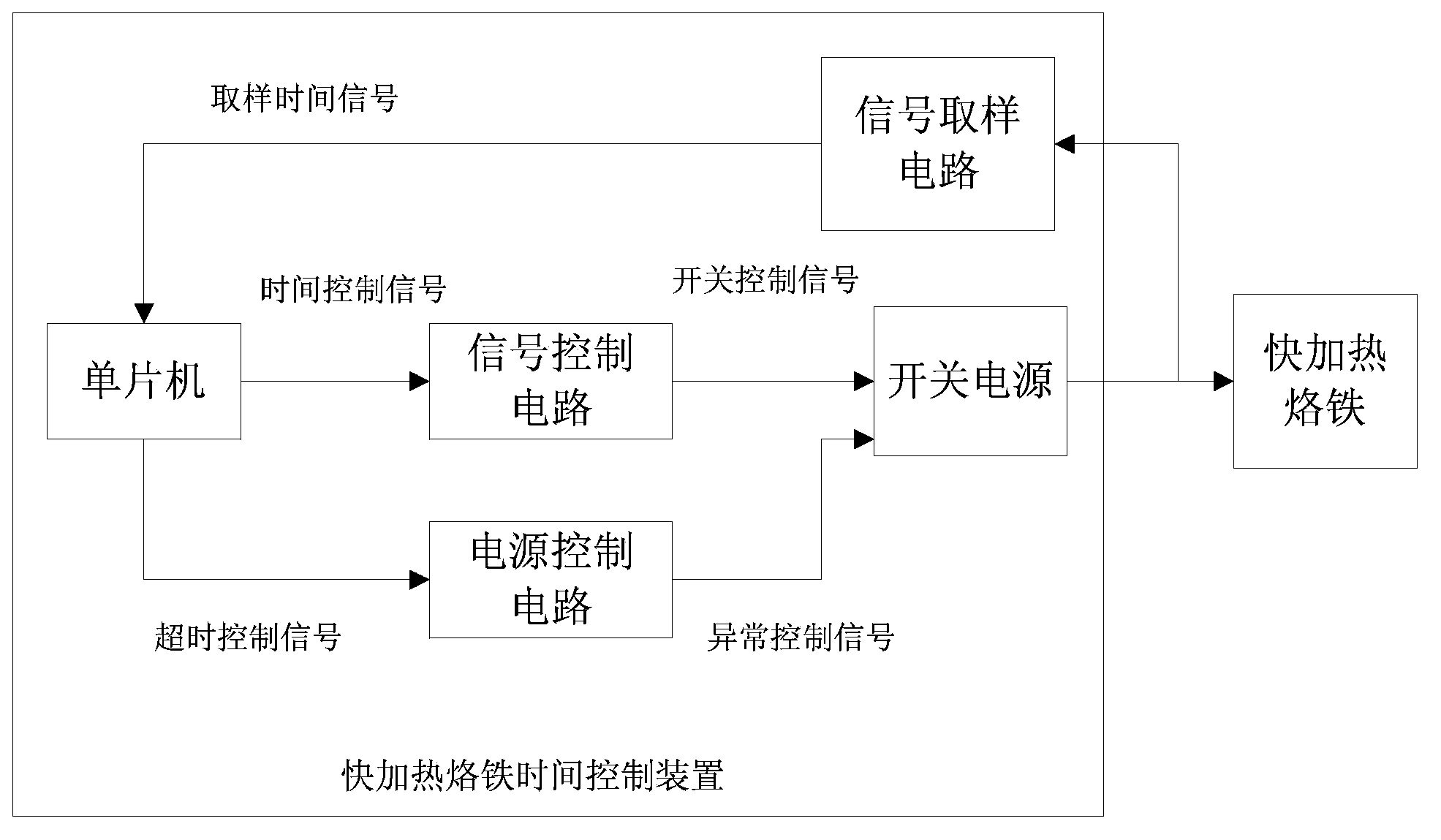

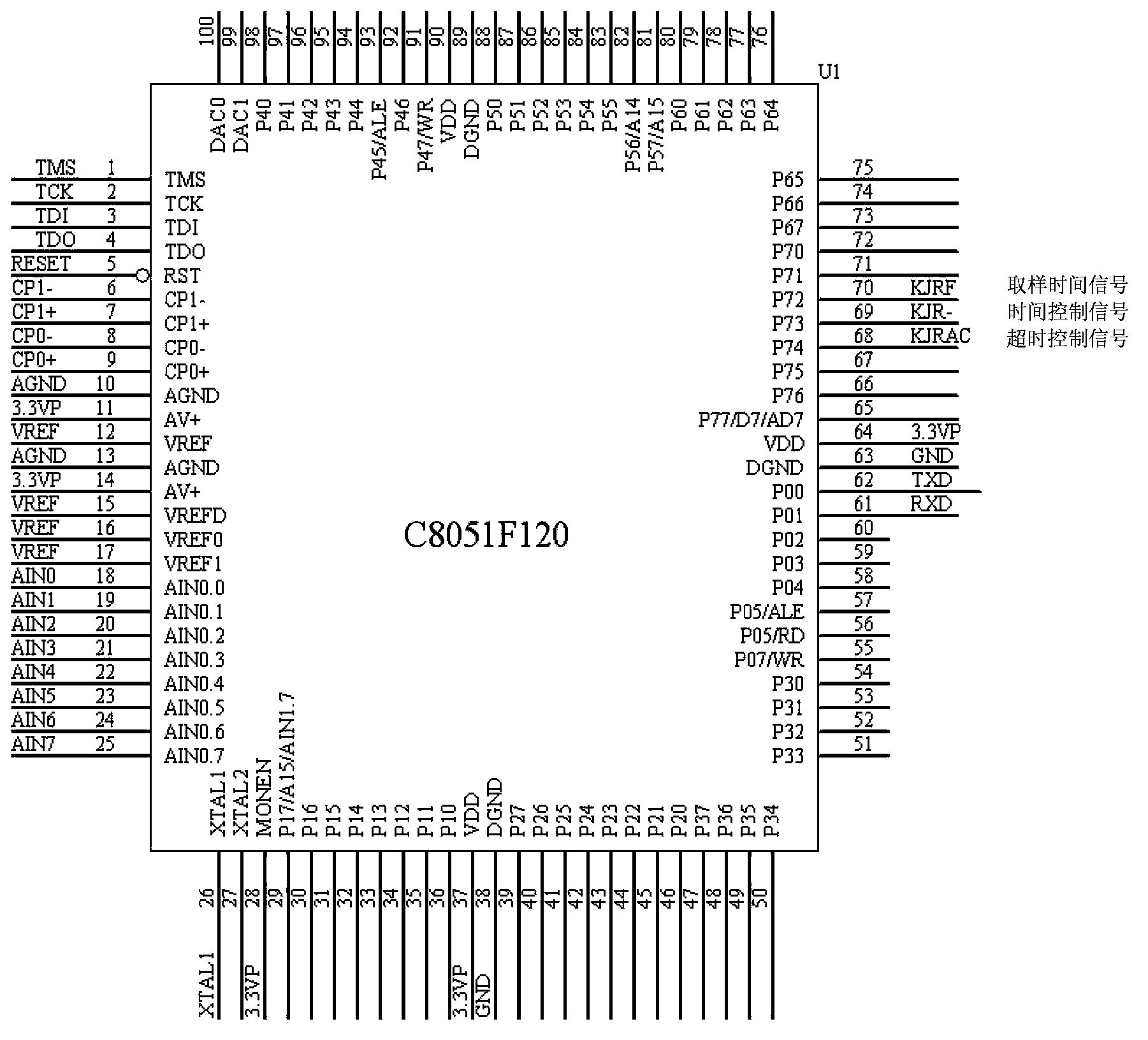

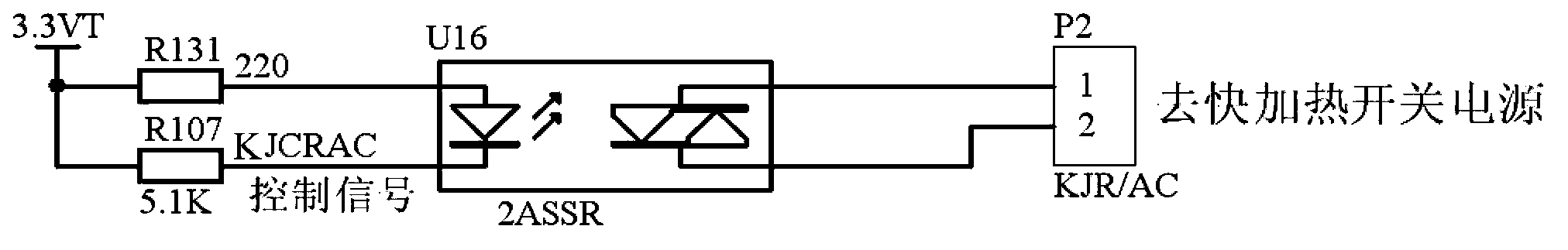

A fast heating soldering iron time control device

ActiveCN103576581BSolve the problem that affects the sticking and cutting effectWide range of voltage adaptationProgramme controlComputer controlMicrocomputerMicrocontroller

The invention relates to a time controlling device for fast heating soldering iron. The time controlling device comprises a single-chip microcomputer, a power supply control circuit, a signal control circuit and a signal sampling circuit, wherein the single-chip microcomputer is used for carrying out closed-loop control over the sampling time and time-out control over the feedback time on the fast heating soldering iron. The power supply control circuit is used for controlling the on-off state of a switching power supply, the signal control circuit is used for preventing the single-chip microcomputer from outputting an abnormal signal, and the signal sampling circuit is used for sampling the voltage of a working signal sent by the switching power supply to the fast heating soldering iron and converting the working signal into a sampling time signal to be fed back to the single-chip microcomputer. By means of the time controlling device, the stable work of the fast heating soldering iron can be effectively guaranteed, closed-loop control is adopted, error compensation control is precise, working efficiency is high, the waste of strapping belts is reduced, and meanwhile dangers caused by the abnormity of the single-chip microcomputer or the loss of control of a fast heating load in the process of working are avoided.

Owner:JULONG

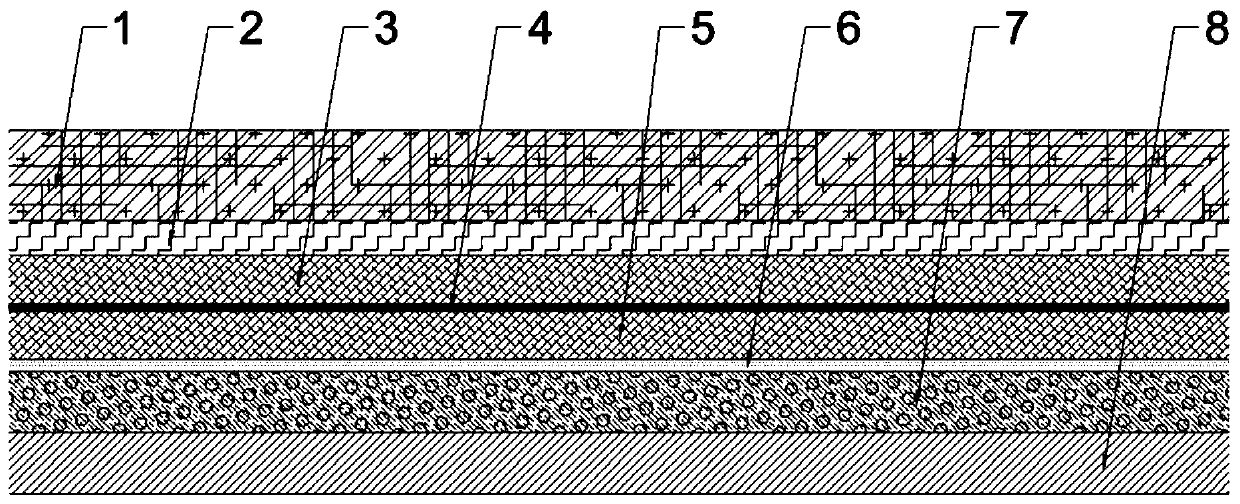

High-wear-resistance mica paper adhesive tape and preparation method thereof

InactiveCN111471407AHigh strengthLow self-strengthFilm/foil adhesive release linersPaper adhesive tapePaper tape

The invention discloses a high-wear-resistance mica paper adhesive tape and a preparation method thereof. A mica paper base tape of the mica paper adhesive tape prepared by the preparation method is adouble-layer mica paper tape; wherein a nickel-plated graphene layer is formed between the two layers of mica paper tapes; the inner side surface of the mica paper base band is a sticking surface; aninsulating rubber layer doped with inorganic phase-change material particles is formed on the surface; a release film is formed through the insulating rubber layer, a plurality of reinforcing bands are formed on the outer side face of the mica paper base tape, and surface sealing and reinforcing are conducted on the outer surfaces of the reinforcing bands and the mica paper base tape through resin reinforcing layers with aramid fibers, silica powder and conductive filler. The mica paper adhesive tape prepared by the preparation method disclosed by the invention is relatively good in fitting degree and adhesion property, has excellent characteristics of insulation, high temperature resistance and the like of mica paper, and has relatively high mechanical strength, toughness and surface wear resistance.

Owner:北京倚天凌云科技股份有限公司

Method for sticking solid wood skin on hyperboloid GRC plate

ActiveCN107756911AImprove ductilityAvoid crackingLamination ancillary operationsLaminationSolid woodHyperboloid

The invention relates to a method for sticking a solid wood skin on a hyperboloid GRC plate. The method comprises the following steps: providing multiple GRC plates, and splicing the multiple GRC plates to form a base layer structure; constructing the surface of the base layer structure to form a leveling layer; brushing the surface of the leveling layer with nitrocellulose varnish to form a closed layer; providing the solid wood skin with an adhesive layer, and sprinkling water to the surface of the solid wood skin to soften the solid wood skin; sticking the softened solid wood skin on the surface of the closed layer, wherein in the sticking process, air between the solid wood skin and the leveling layer is completely exhausted, thereby completing sticking of the solid wood skin. By the use of the nitrocellulose varnish to form the closed layer, the damp characteristic of the leveling layer can be controlled, and the problems of sticking falling and hollowing of the solid wood skin due to dampness are solved. During the sticking of the solid wood skin, the water is sprinkled on the surface for softening, so that changes of the stuck solid wood skin which is in contact with air canbe reduced; the stability of the solid wood skin is improved, and the sticking effect of the solid wood skin is guaranteed.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

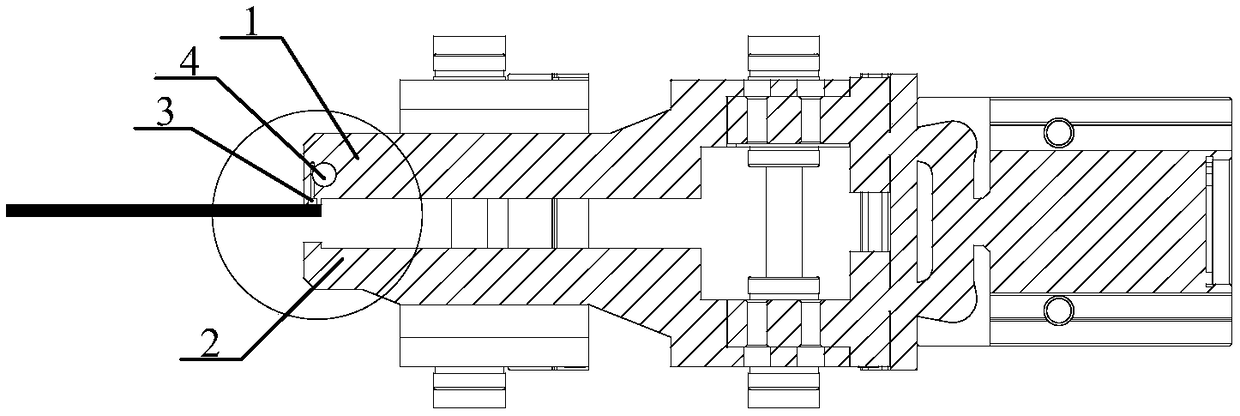

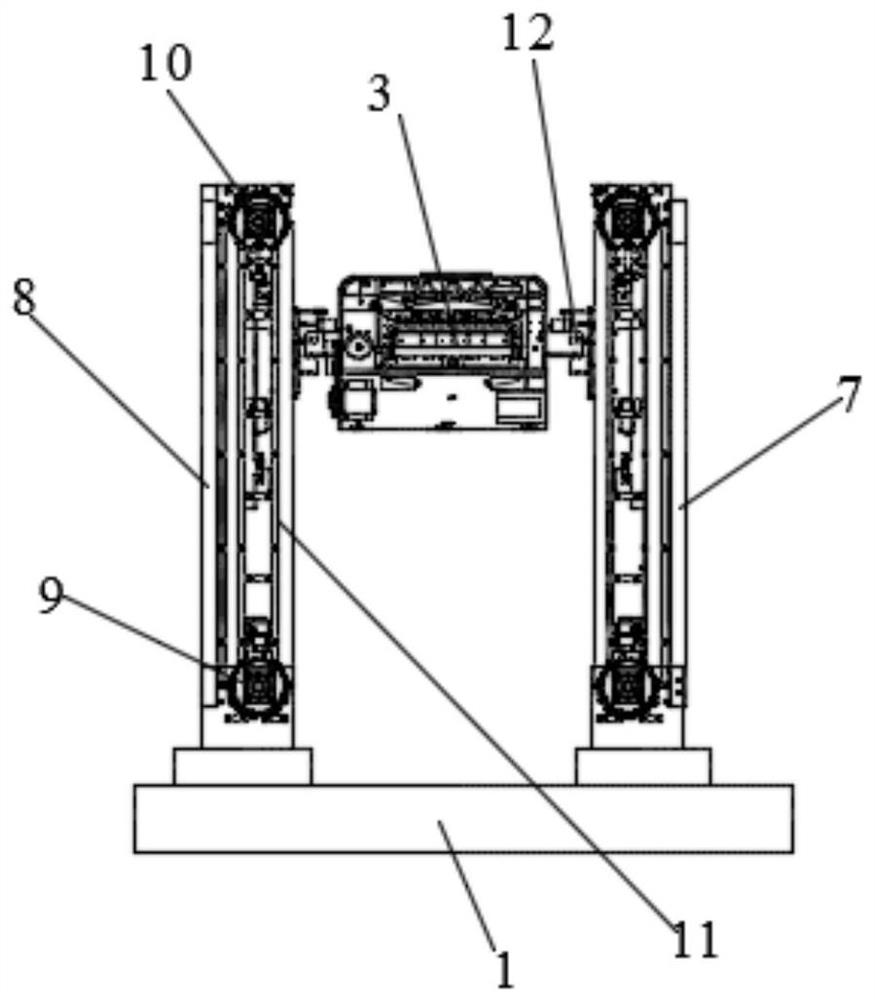

Gluing device

InactiveCN109985768AGuaranteed sticking effectImprove gluing efficiencyLiquid surface applicatorsCoatingsReciprocating motionElectrical and Electronics engineering

The invention discloses a gluing device which is used for coating magnetic steel with glue. The gluing device comprises a fixing frame, a cross beam, a conveying assembly, a gluing assembly, a driver,a pushing block and a distance adjusting assembly. The cross beam is fixed to the fixing frame. The conveying assembly is used for conveying the magnetic steel in a reciprocating mode, and the conveying direction of the conveying assembly is perpendicular to the extending direction of the cross beam. The gluing assembly can be slidably connected to the cross beam in the extending direction of thecross beam, and a glue outlet of the gluing assembly faces the conveying assembly. The driver is fixed on the fixing frame, the pushing block can be slidably connected to the cross beam in the extending direction of the cross beam, and the pushing block is driven by the driver to do reciprocating motion in the extending direction of the cross beam. The distance adjusting assembly is fixed to thegluing assembly and the pushing block, and the distance of the gluing assembly and the pushing block in the extending direction of the cross beam can be adjusted and fixed through the distance adjusting assembly. By means of the gluing device, S-shaped gluing can be carried out on the surface of the magnetic steel, continuous gluing can be carried out on multiple sets of magnetic steel, the working efficiency is high, and the gluing effect is good.

Owner:SHANGHAI LYNAC NUMERICAL CONTROL TECH CO LTD

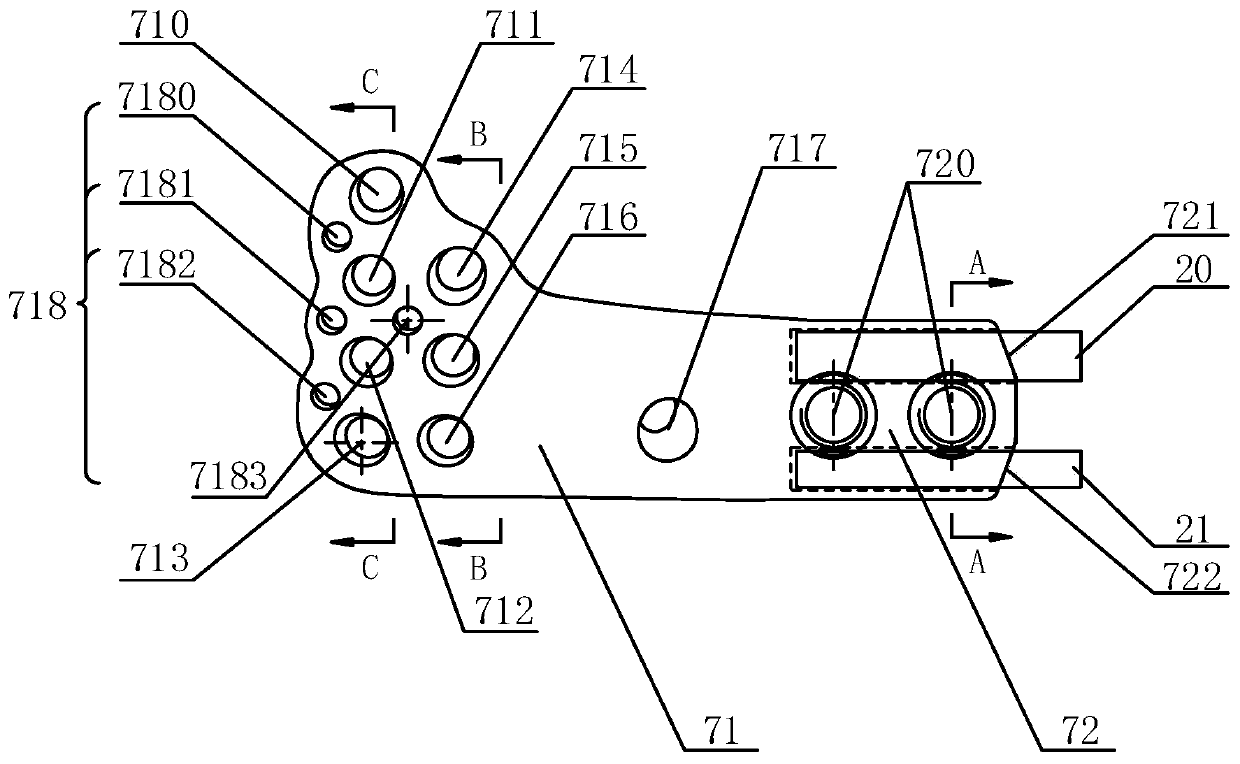

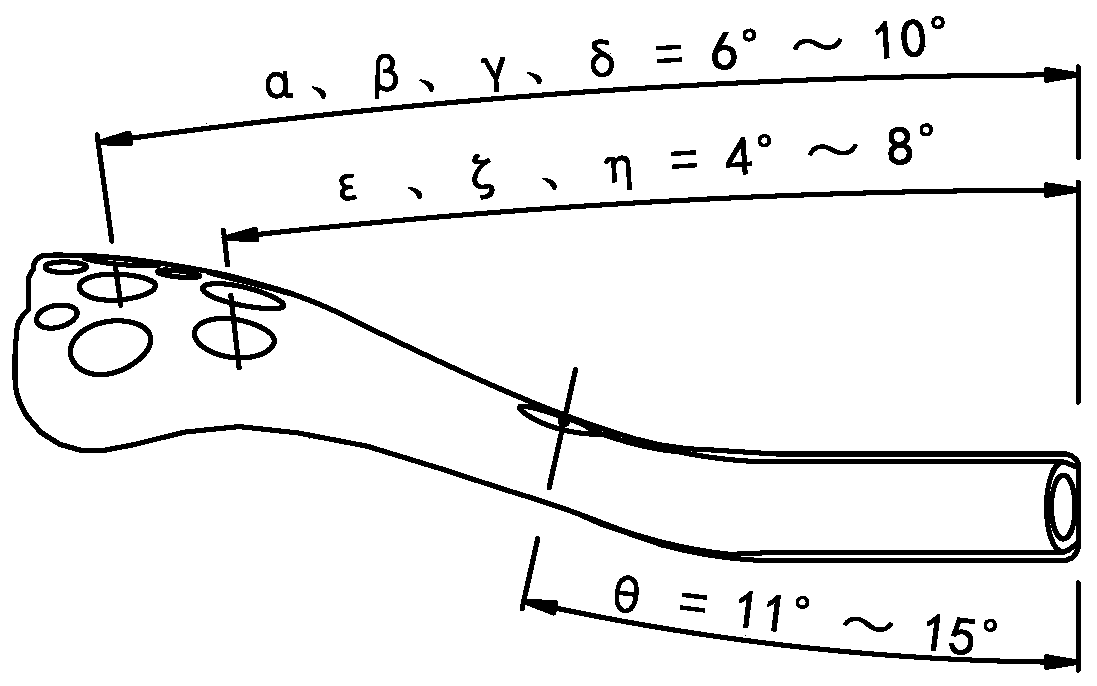

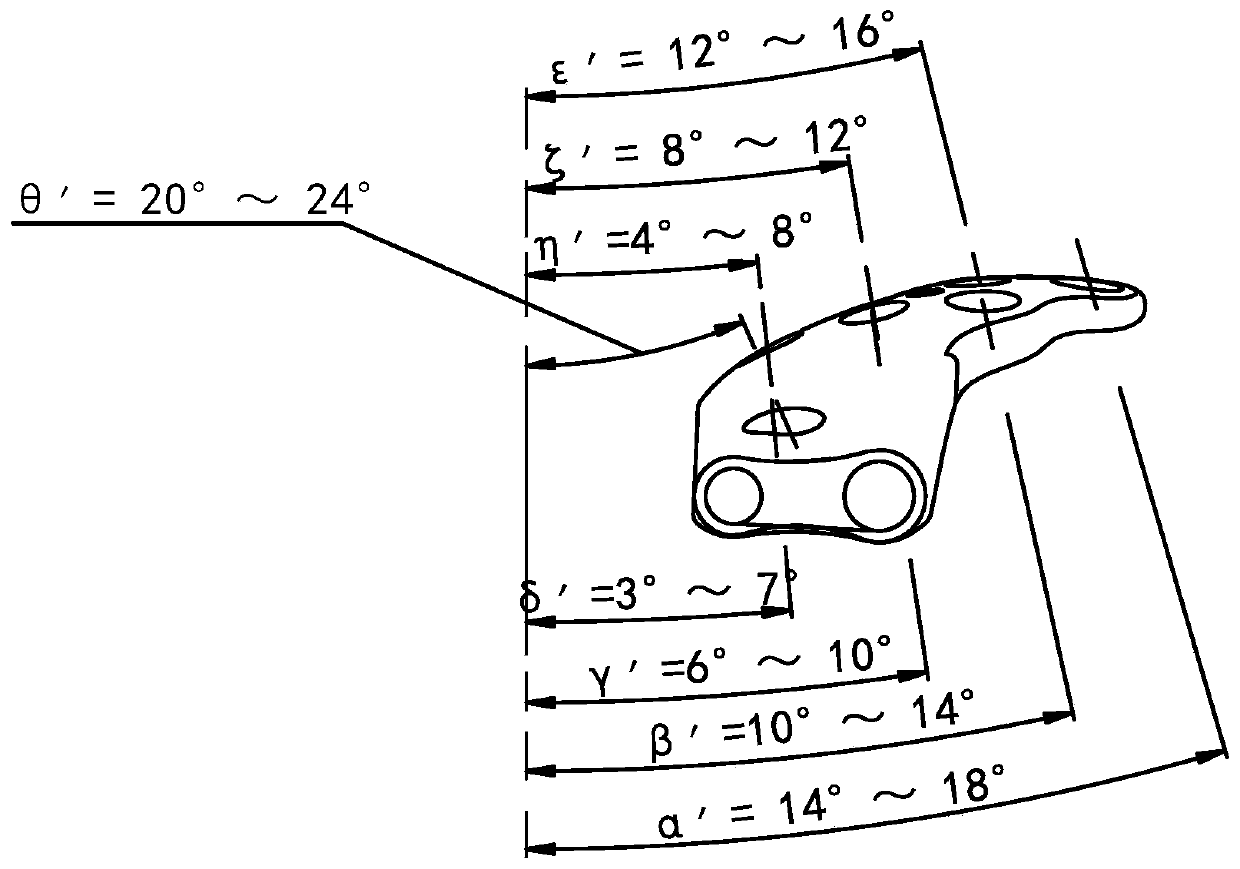

Special-shaped block at outer side of proximal tibia

Embodiments of the invention relates to a proximal tibia outer side special-shaped block. The special-shaped block at the outer side of proximal tibia specifically comprises a first fixing part and asecond fixing part, wherein the first fixing part is connected with the second fixing part; the inner surface of the first fixing part is an arc-shaped surface; a first top locking screw hole, a second top locking screw hole, a third top locking screw hole and a fourth top locking screw hole are sequentially formed in the top of the first fixing part from the inner side to the outer side; a firstmiddle locking screw hole, a second middle locking screw hole and a third middle locking screw hole are sequentially formed in the middle part of the first fixing part from the inner side to the outerside; a first oblique-insertion locking screw hole is formed in the lower part of the first fixing part; and the second fixing part comprises fixing screw holes located in the surface of the second fixing part, a front side connecting screw hole formed in the front side position of the side surface of the second fixing part, and a rear side connecting screw hole formed in the rear side position of the side surface of the second fixing part.

Owner:TIANJIN WALKMAN BIOMATERIAL CO LTD

Time controlling device for fast heating soldering iron

ActiveCN103576581ASolve the problem that affects the sticking and cutting effectWide range of voltage adaptationProgramme controlComputer controlMicrocontrollerMicrocomputer

The invention relates to a time controlling device for fast heating soldering iron. The time controlling device comprises a single-chip microcomputer, a power supply control circuit, a signal control circuit and a signal sampling circuit, wherein the single-chip microcomputer is used for carrying out closed-loop control over the sampling time and time-out control over the feedback time on the fast heating soldering iron. The power supply control circuit is used for controlling the on-off state of a switching power supply, the signal control circuit is used for preventing the single-chip microcomputer from outputting an abnormal signal, and the signal sampling circuit is used for sampling the voltage of a working signal sent by the switching power supply to the fast heating soldering iron and converting the working signal into a sampling time signal to be fed back to the single-chip microcomputer. By means of the time controlling device, the stable work of the fast heating soldering iron can be effectively guaranteed, closed-loop control is adopted, error compensation control is precise, working efficiency is high, the waste of strapping belts is reduced, and meanwhile dangers caused by the abnormity of the single-chip microcomputer or the loss of control of a fast heating load in the process of working are avoided.

Owner:JULONG

An anti-wrinkle furniture pressing machine

ActiveCN109203631BImprove anti-wrinkle effectGuaranteed sticking effectLaminationLamination apparatusElectric machineryStructural engineering

The invention relates to the technical field of furniture, in particular to an anti-wrinkle furniture pressing machine. There is a sliding groove, a slider is slidably connected in the sliding groove, a screw nut is fixedly installed at the bottom of the slider, a screw is threaded in the screw nut, the left end of the screw is connected to the inner upper end of the left frame plate, and the right end of the screw is Go through the through hole provided on the top of the frame plate on the right side and fix it with the output end of the motor. The invention provides an anti-wrinkle furniture pressing machine. The motor drives the lead screw installed at the output end to rotate, so that the lead screw nut Drive the parts provided at the lower end of the installation frame to reciprocate left and right on the workbench, so that the hot pressing parts, glue spraying parts and cooling fans can reciprocate to process the wooden boards, and the effect of pressing the skin and preventing wrinkles is better.

Owner:杭州荣正家具有限公司

Lined adhesive device

InactiveCN106252705AWon't hurtNo shape changeAssembling battery machinesFinal product manufactureSolenoid valveEngineering

The invention discloses a lined adhesive device. A cavity and an air inlet passage are arranged at one end, in contact with an adhesive film, of an upper air claw of an air claw, one end of the cavity is matched with the adhesive film, the other end of the cavity communicates with the air inlet passage, the air inlet passage is connected with an air inlet device through a pipeline, and a solenoid valve on the pipeline controls the air inlet device to supply air to the air inlet passage; when the solenoid valve is closed and the air claw is closed, the air inlet device does not supply air to the air inlet passage, a first clamping claw and a second clamping claw are matched to clamp the adhesive film, the adhesive film is matched with the cavity in the first clamping claw to form a sealed cavity so as to achieve effective clamping of the clamping claws on the adhesive film; and the air claw moves to an adhesive film releasing position, the air claw opens, the solenoid valve is opened, the air inlet device supplies air to the air inlet passage, a gas enters the cavity through the air inlet passages, and the adhesive film attached onto the first clamping claw is blown away from the clamping claws. With the lined adhesive device provided by the invention, the disconnection of the adhesive film is achieved by air blowing, the adhesive film cannot be damaged, the shape of the adhesive film cannot be changed, and the lamination effect of a battery core and the adhesive film is ensured.

Owner:DONGGUAN ALI AUTOMATION CO LTD

The method of sticking solid veneer to hyperboloid grc board

ActiveCN107756911BImprove ductilityAvoid crackingLamination ancillary operationsLaminationSolid woodPolymer science

The invention relates to a method for sticking a solid wood skin on a hyperboloid GRC plate. The method comprises the following steps: providing multiple GRC plates, and splicing the multiple GRC plates to form a base layer structure; constructing the surface of the base layer structure to form a leveling layer; brushing the surface of the leveling layer with nitrocellulose varnish to form a closed layer; providing the solid wood skin with an adhesive layer, and sprinkling water to the surface of the solid wood skin to soften the solid wood skin; sticking the softened solid wood skin on the surface of the closed layer, wherein in the sticking process, air between the solid wood skin and the leveling layer is completely exhausted, thereby completing sticking of the solid wood skin. By the use of the nitrocellulose varnish to form the closed layer, the damp characteristic of the leveling layer can be controlled, and the problems of sticking falling and hollowing of the solid wood skin due to dampness are solved. During the sticking of the solid wood skin, the water is sprinkled on the surface for softening, so that changes of the stuck solid wood skin which is in contact with air canbe reduced; the stability of the solid wood skin is improved, and the sticking effect of the solid wood skin is guaranteed.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Adhesive pasting device

PendingCN109378528AAvoid problemsGuaranteed sticking effectFinal product manufactureElectrolyte accumulators manufactureEngineeringMechanical engineering

The invention discloses an adhesive pasting device, and belongs to the technical field of battery producing equipment. The adhesive pasting device comprises an adhesive preparing mechanism, an adhesive ejecting mechanism and an adhesive pasting mechanism, wherein the adhesive preparing mechanism is configured to drive adhesive tape to move to the position between the adhesive pasting mechanism andthe adhesive ejecting mechanism, the adhesive ejecting mechanism comprises an adhesive ejecting ends which isare each provided with an arc-shaped concave surface and an air blowing assembly, the adhesive pasting mechanism comprises an elastic adhesive pasting ends which isare each provided with an arc-shaped convex surface matched with the corresponding arc-shaped concave surface, an adsorption assembliesy is are further arranged, and the adhesive ejecting mechanism can drive the adhesive tape to be adsorbed to the arc-shaped convex surfaces. According to the adhesive pasting device, the airblowing assembliesy and the adsorption assembliesy are matched to enable the adhesive tape to be adsorbed to the arc-shaped convex surfaces, and the adhesive tape can be prevented from being shifted or wrinkled; the elastic adhesive pasting ends enables the middle position of the adhesive tape to make contact with a welded part firstly, then the two ends of the adhesive tape make contact with thewelding part, and thus the pasting effect is guaranteed.

Owner:JIANGSU ZENIO NEW ENERGY BATTERY TECH CO LTD

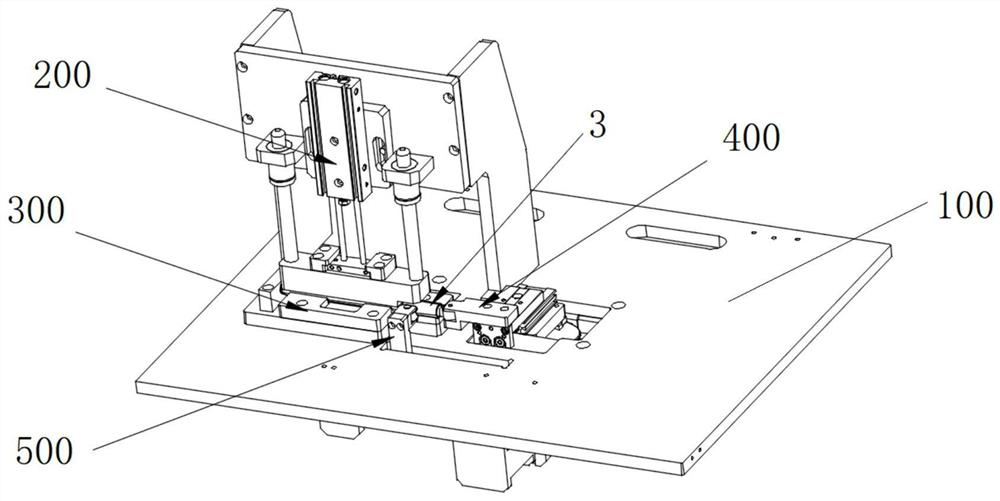

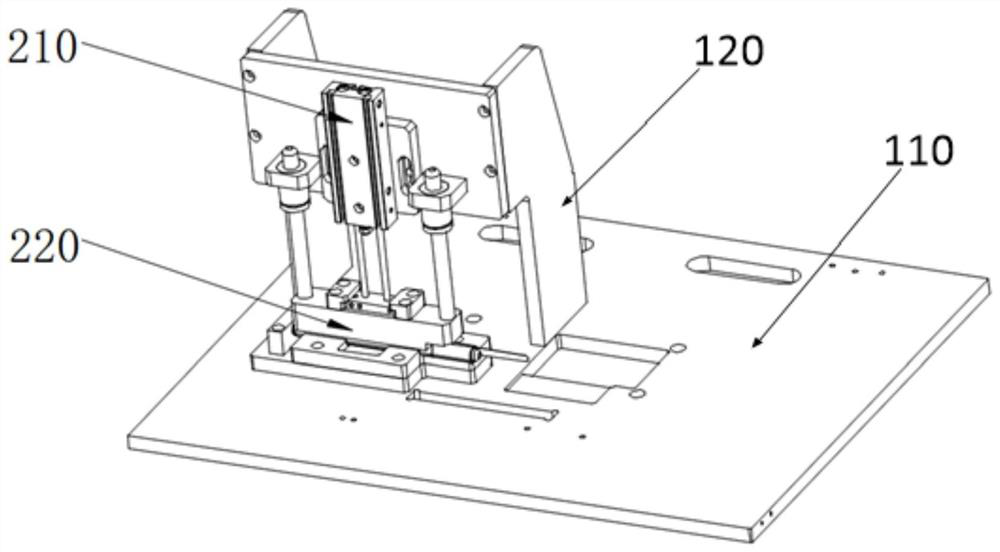

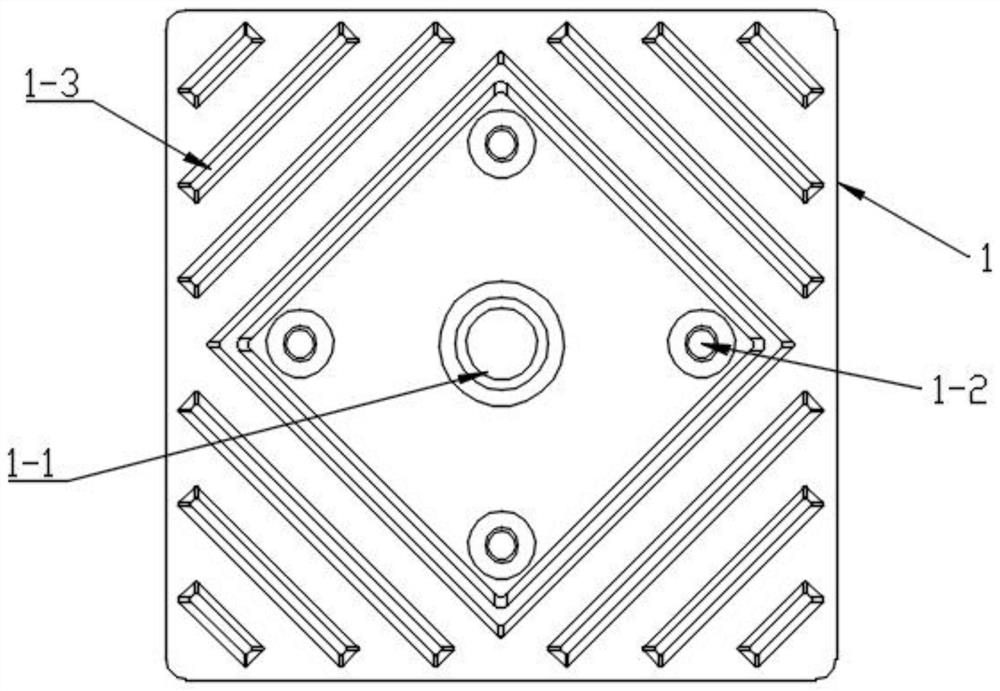

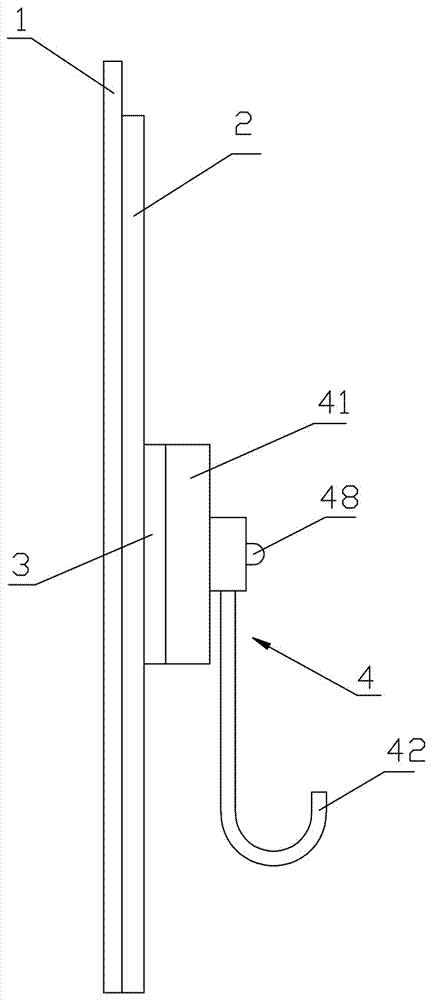

Fixing device for product label attaching and automatic labeling device

PendingCN112777072AGuaranteed attachment accuracy and attachment effectGuaranteed to attach securelyLabelling machinesProcess engineeringManufacturing engineering

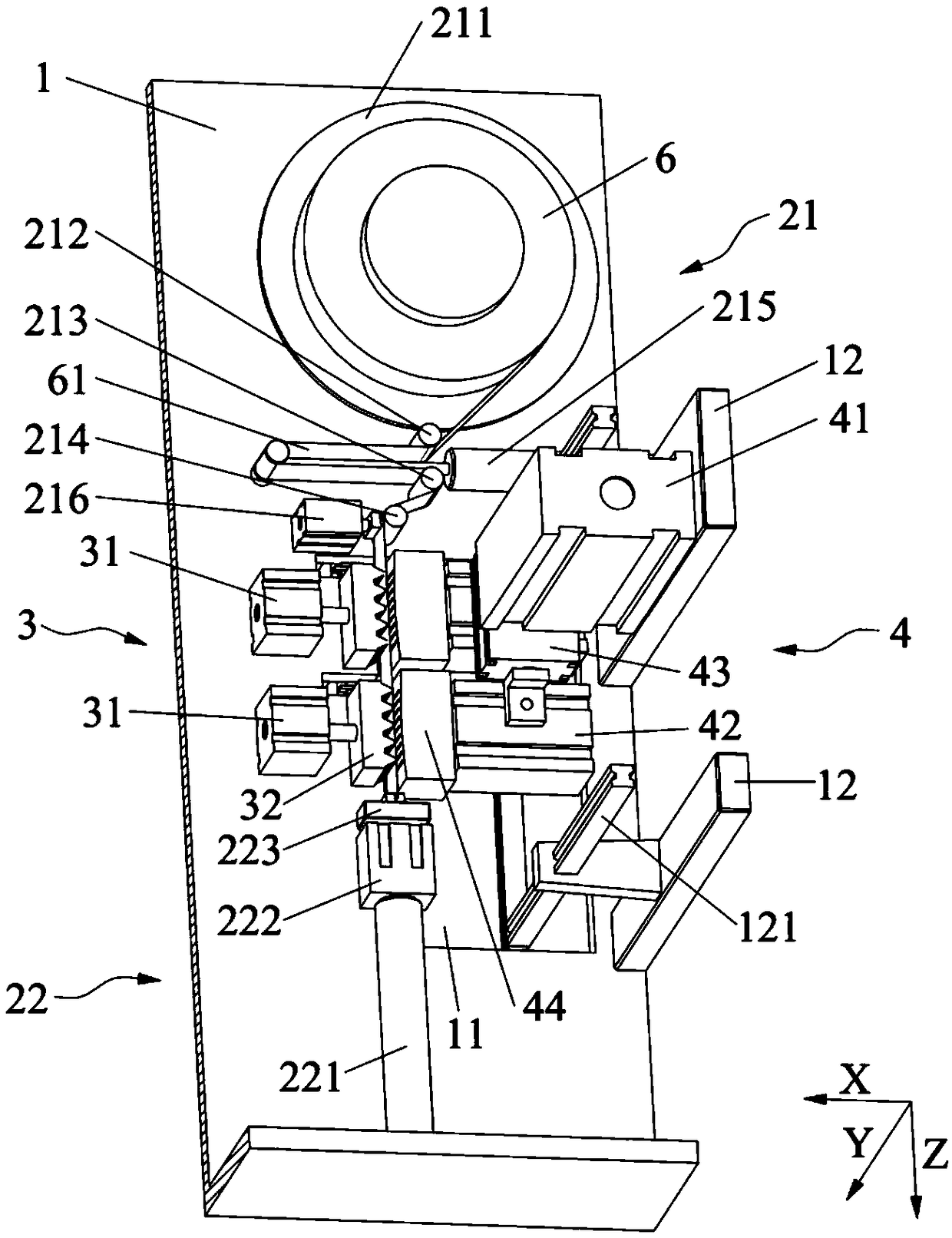

The invention relates to the field of automatic equipment, and particularly discloses a fixing device for product label attaching and an automatic labeling device. The fixing device for product label attaching comprises a product jig, an automatic limiting mechanism and an auxiliary pressing mechanism, wherein a product to be subjected to label attaching is placed on the product jig; the automatic limiting mechanism is arranged on the product jig and can conduct limiting on the product located on the product jig in the X-axis direction and the Y-axis direction; and the auxiliary pressing mechanism is arranged above the product jig and can elastically press and hold the product located on the product jig. The fixing device for product label attaching can effectively prevent the product from warping in the label attaching process. The automatic labeling device can achieve automatic product label attaching, and the situation of label attaching wrinkles is effectively improved.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

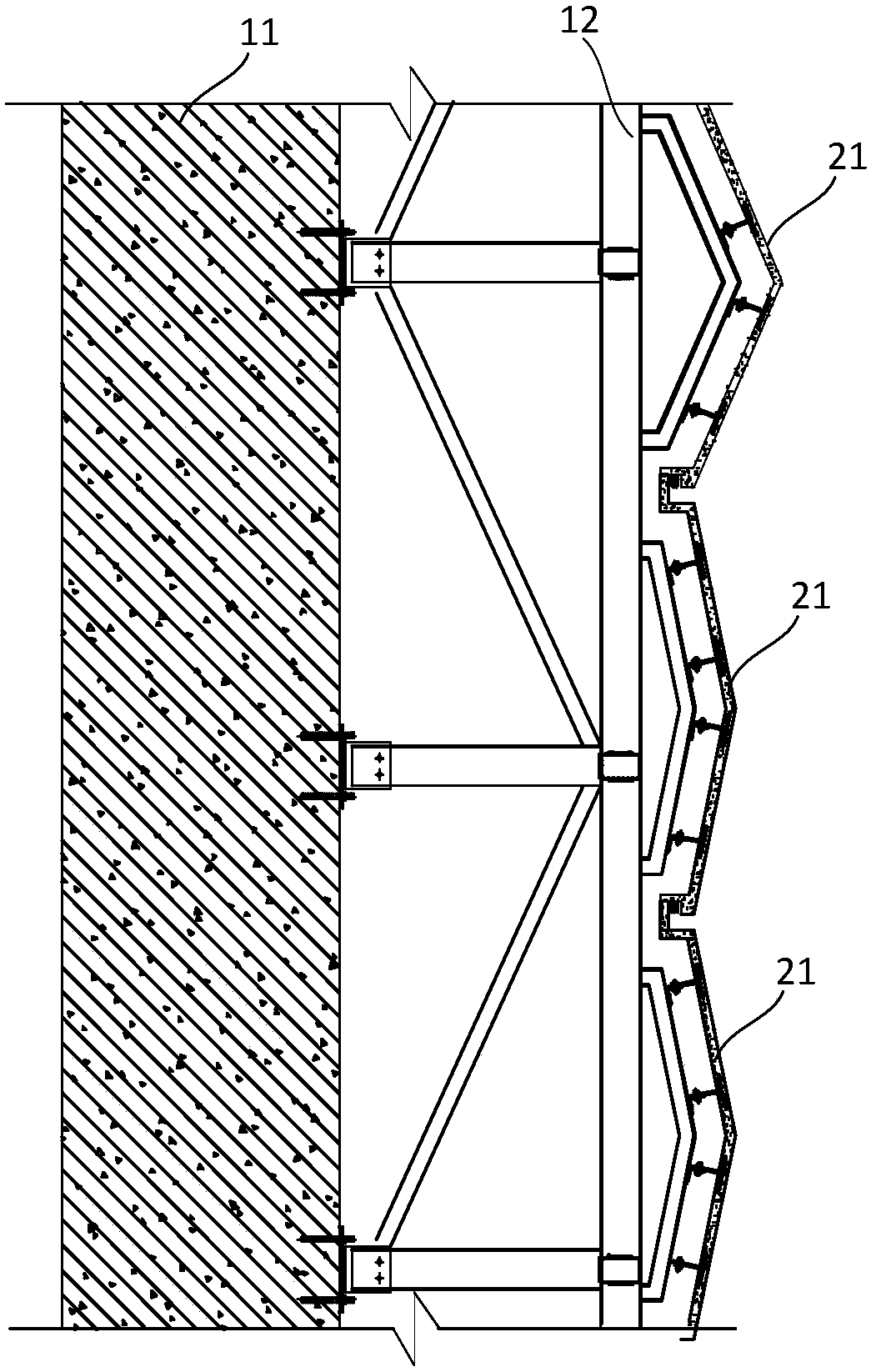

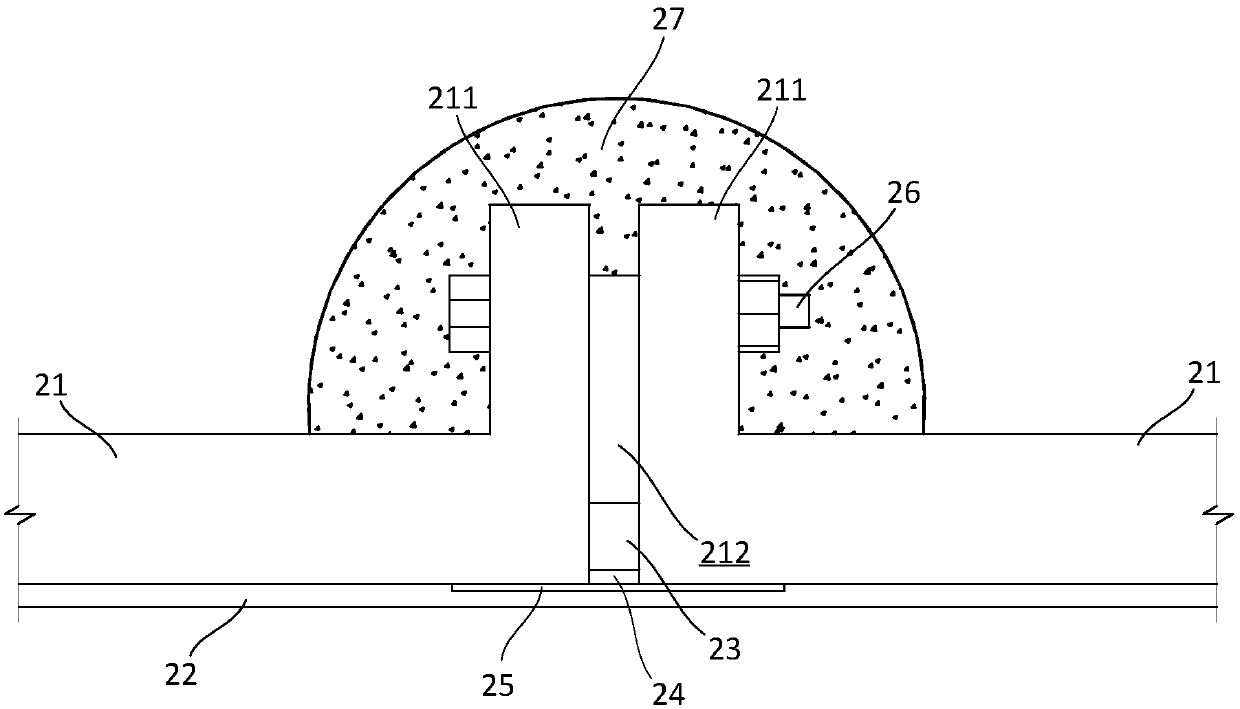

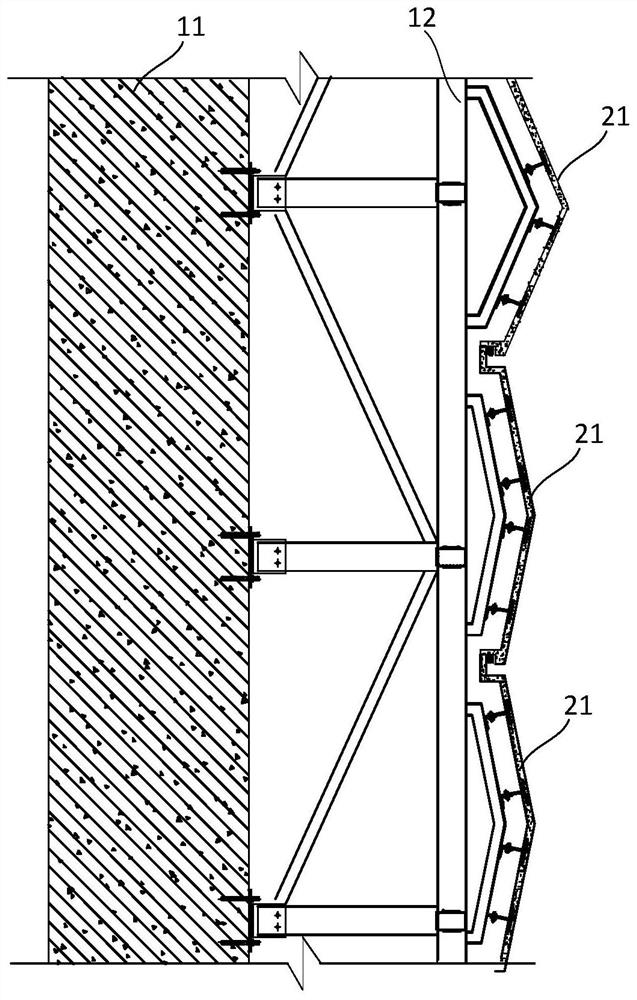

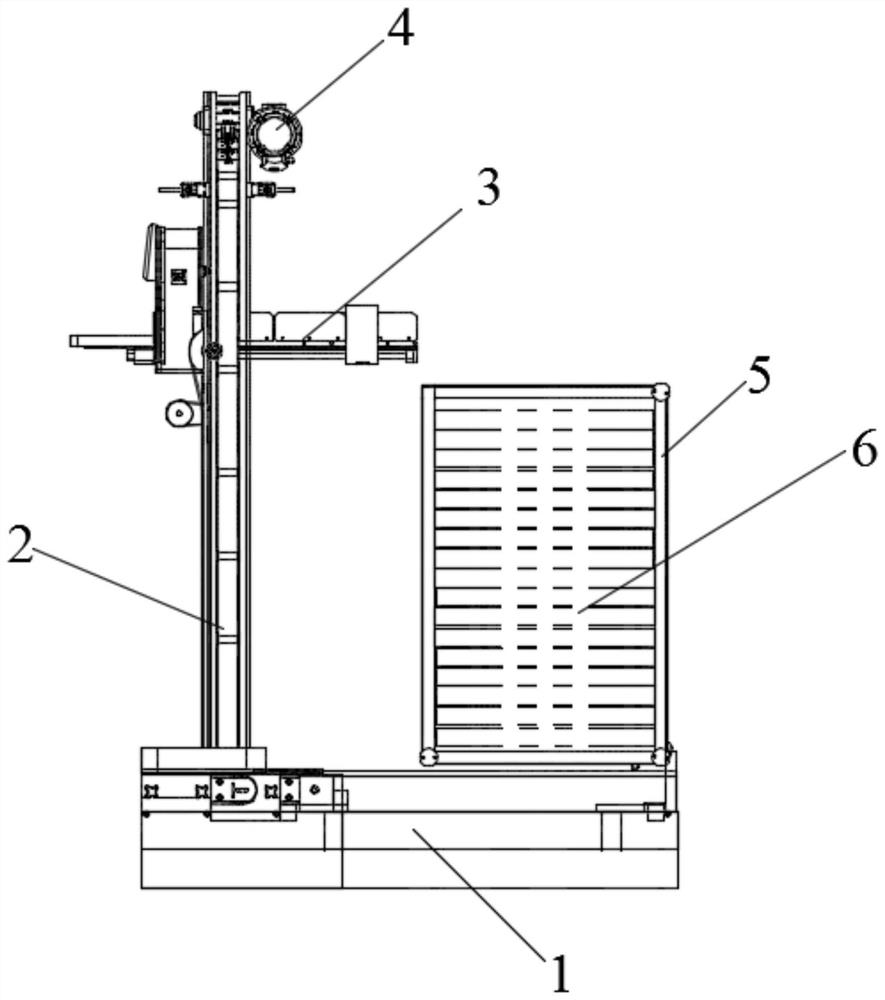

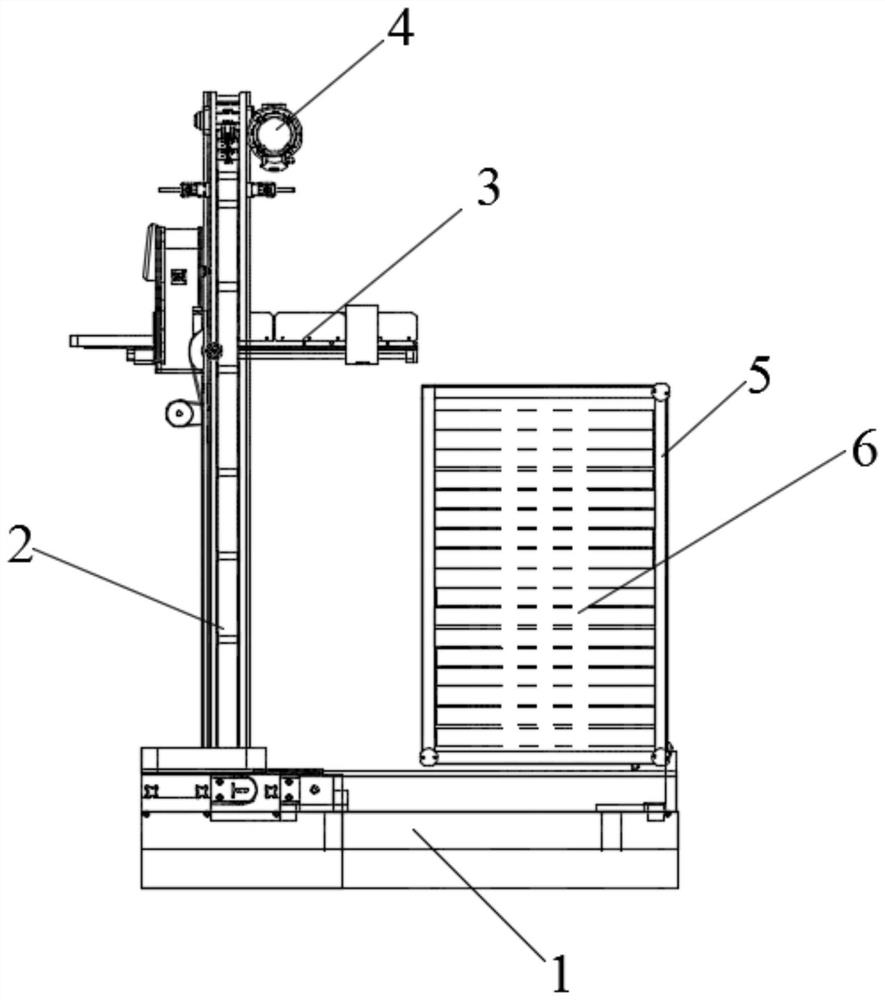

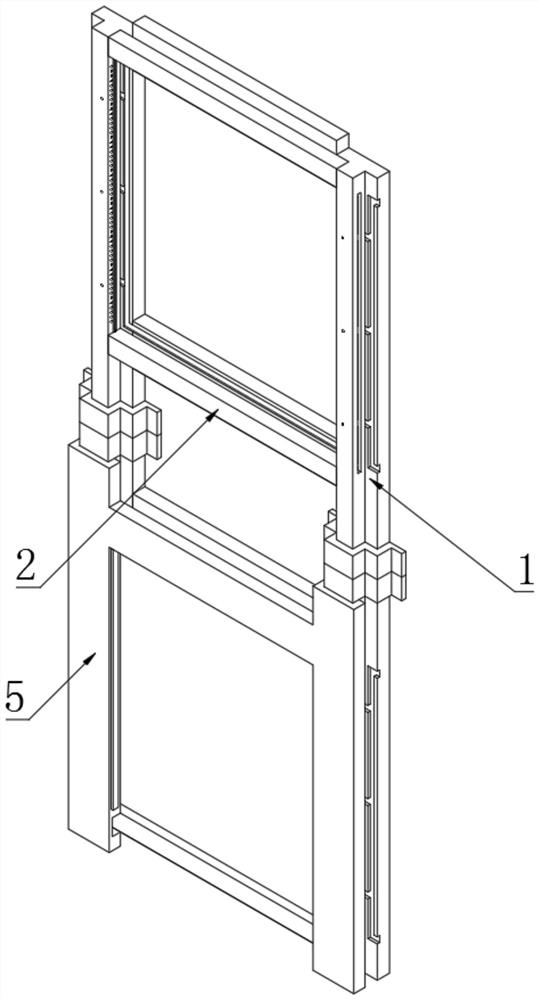

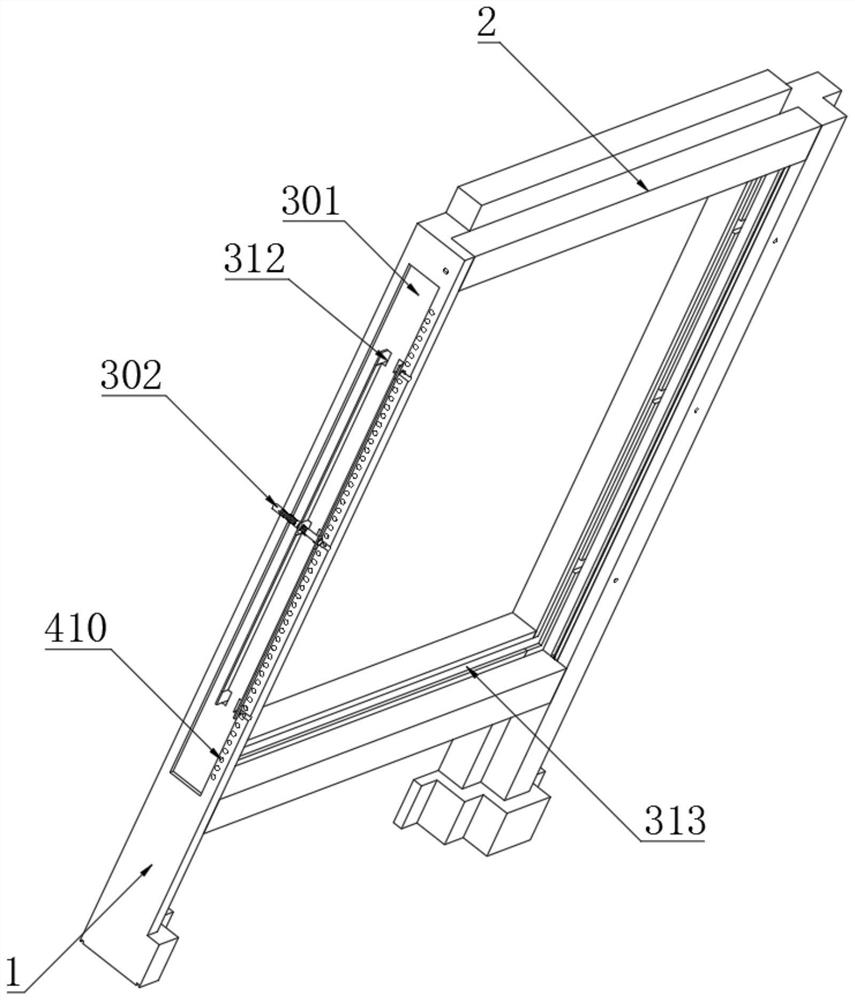

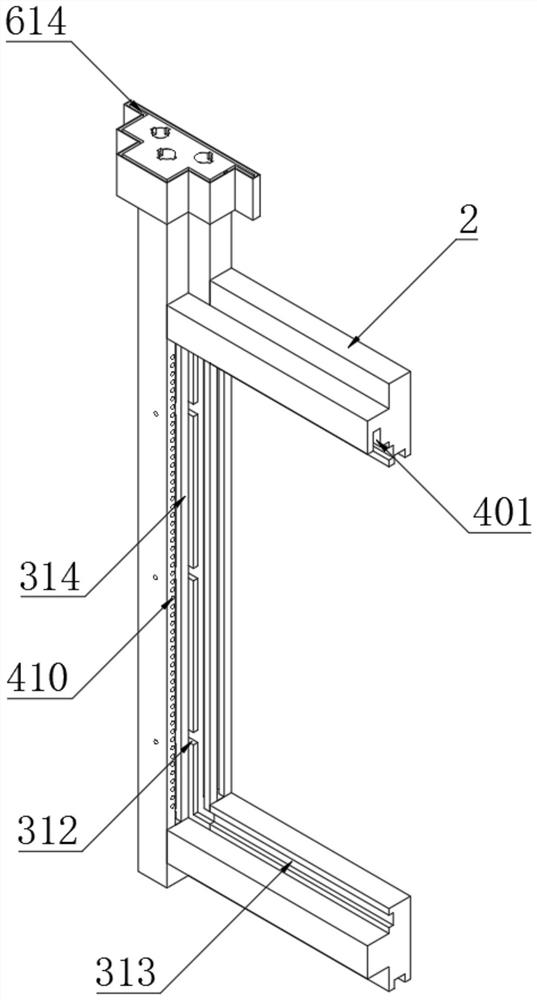

A kind of energy-saving renovation equipment for building front roof

ActiveCN112160512BGuaranteed degree of automationRealize automatic positioningBuilding repairsRoof toolsConstruction engineeringStructural engineering

The invention discloses an energy-saving renovation equipment for the front roof of a building, which can not only realize the lifting operation of the to-be-clad board, but also automatically realize the glue spraying, glue-equalizing and laminating operations, which can effectively ensure the automation degree of the renovation construction and reduce the At the same time, the present invention can also ensure accurate sticking, realize the adjustment of the position through the lifting mechanism, realize the positioning when sticking the board to be sticked by the limit shoulder, ensure the reliability and accuracy of the sticking, and realize automatic Positioning, in the present invention, when the to-be-clad board is taken out, the overturning action of the overturn and the guide seat can be used to facilitate the removal of the to-be-clad plate in the storage board warehouse, and at the same time, when the to-be-clad plate is pushed by the pushing mechanism, the The glue spraying mechanism automatically sprays glue, and through the structure of the main body of the return frame and the glue-equalizing operation of the glue-equalizing brush, it can ensure the uniformity of the glue and the coating effect and ability, and the automatic turning and coating of the flip-coating mechanism , which can effectively reduce the construction difficulty and ensure the construction effect.

Owner:TONGLING UNIV

A ballpoint pen head automatic rolling film sticking mechanism

Owner:BOZHON PRECISION IND TECH CO LTD

Composite foam, flexible OLED display panel and display device

ActiveCN111179756BQuality assuranceNo interferenceSolid-state devicesIdentification meansDisplay deviceEngineering

Owner:BOE TECH GRP CO LTD +1

A clamping device

InactiveCN106252705BWon't hurtNo shape changeAssembling battery machinesFinal product manufactureSolenoid valveClosed chamber

The invention discloses a clamping device. The end of the upper air claw of the air claw and the adhesive film is provided with a cavity and an air intake channel. One end of the cavity cooperates with the adhesive film, and the other end communicates with the air intake channel. The channel is connected with the intake device through a pipeline, and the solenoid valve on the pipeline controls the intake device to supply air to the intake channel. The solenoid valve is closed, the air claw is closed, the air intake device does not supply air to the air intake channel, the first jaw and the second jaw cooperate to clamp the film, and the film cooperates with the cavity on the first jaw to form a closed cavity body, to realize the effective gripping of the film by the jaws; the air claw moves to the position of the debonded film, the air claw opens, the solenoid valve opens, the air intake device supplies air to the air intake channel, and the gas enters the cavity through the air intake channel. Blow the adhesive film adhering to the first jaw away from the jaws. In the sandwiching device provided by this solution, the detachment of the adhesive film is achieved by blowing air, which will not damage the adhesive film, and will not change the shape of the adhesive film, ensuring the bonding effect of the battery cell and the adhesive film.

Owner:DONGGUAN ALI AUTOMATION CO LTD

Energy-saving reconstruction equipment for front roof of building

ActiveCN112160512AGuaranteed degree of automationRealize automatic positioningBuilding repairsRoof toolsConstruction engineeringStructural engineering

The invention discloses energy-saving reconstruction equipment for a front roof of a building. The energy-saving reconstruction equipment for the front roof of the building not only can realize lifting operation of a to-be-pasted plate, but also can automatically realize glue spraying, glue uniformizing and pasting operation, effectively guarantees the automation degree of reconstruction construction, reduces the labor intensity; and meanwhile, the energy-saving reconstruction equipment for the front roof of the building can also guarantee accurate pasting; by realizing position adjustment through a lifting mechanism and achieving positioning during pasting of the to-be-pasted plate through a limiting shoulder, pasting reliability and accuracy are guaranteed, and automatic positioning is achieved; when the to-be-pasted plate is taken out, the to-be-pasted plate in a plate storage bin can be conveniently taken out through the turnover effect of a turnover and guide seat; and meanwhile,when a pushing mechanism is used for pushing the to-be-pasted plate, automatic glue spraying of a glue spraying mechanism is achieved; through the structure of a concentric-square-shaped frame body and glue uniformizing operation of a glue uniformizing brush, uniformity of glue pulp can be guaranteed, and the pasting effect and capacity are guaranteed; and through automatic overturning and pastingof an overturning pasting mechanism, the construction difficulty can be effectively reduced, and the construction effect is guaranteed.

Owner:TONGLING UNIV

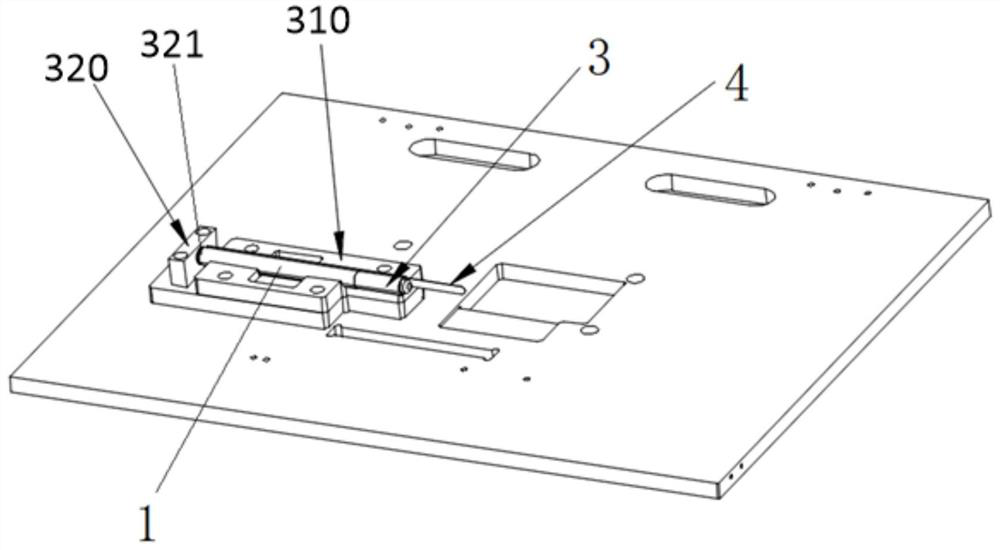

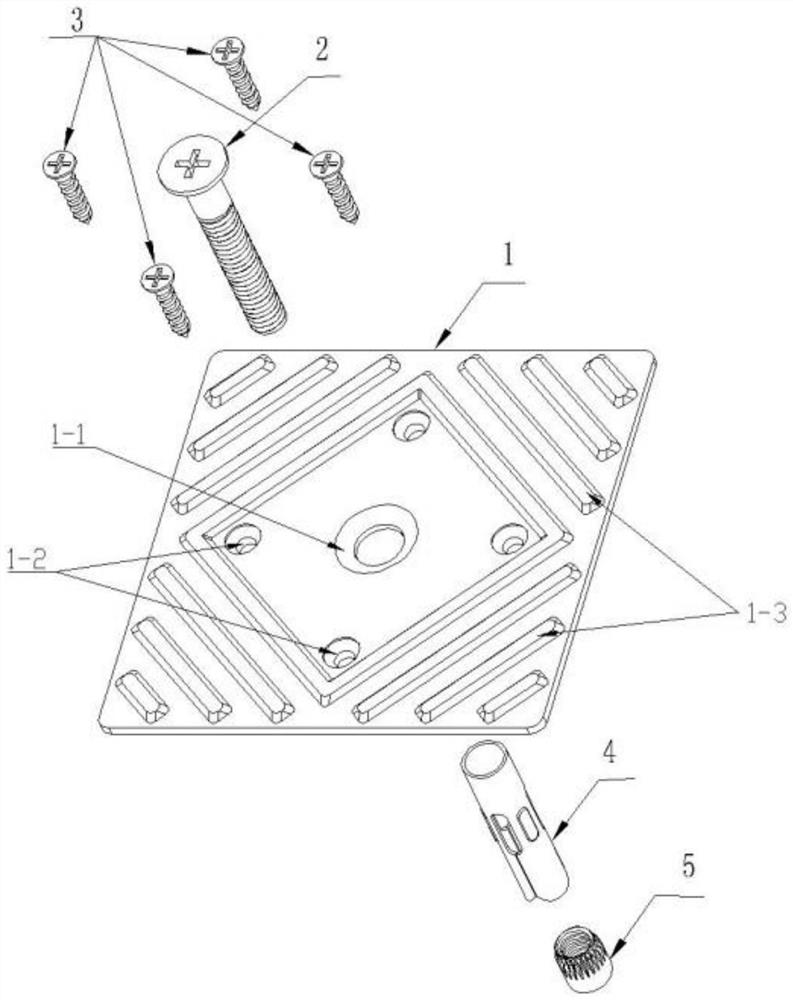

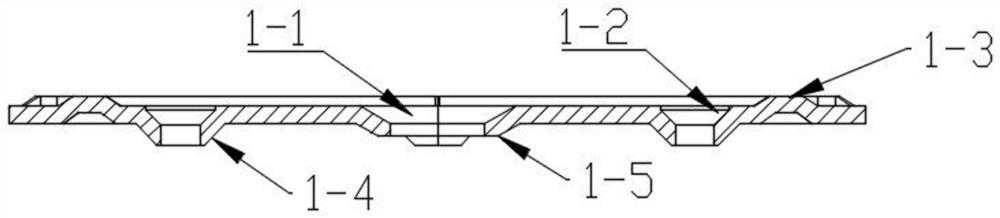

Touch bar pressing tooling

ActiveCN108518394BSave installation timeImprove installation efficiencyMaterial gluingNon-linear opticsEngineeringMechanical engineering

The invention belongs to the technical field of assembly tooling, and in particular relates to a touch bar pressing tooling. The present invention aims to solve the problems of poor pressing effect and low efficiency when the existing touch bar pressing method is used to press the touch bar. The touch bar pressing tool of the present invention includes a support table and a pressing assembly movably connected to the support table. The pressing assembly is configured to move relative to the support table when the touch bar is pressed, so that the pressing assembly presses the touch bar. Tightly attached to the part to be installed. Through the above arrangement, the touch bar can be closely attached to the display screen by pressing it only once, and the operator does not need to press different positions of the touch bar multiple times, which greatly shortens the fixing time of the touch bar. Moreover, the pressing component can apply force on the touch bar more comprehensively and evenly, effectively avoiding the problem of air bubbles between the compressed touch bar and the display screen, and ensuring the touch effect of the display screen.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

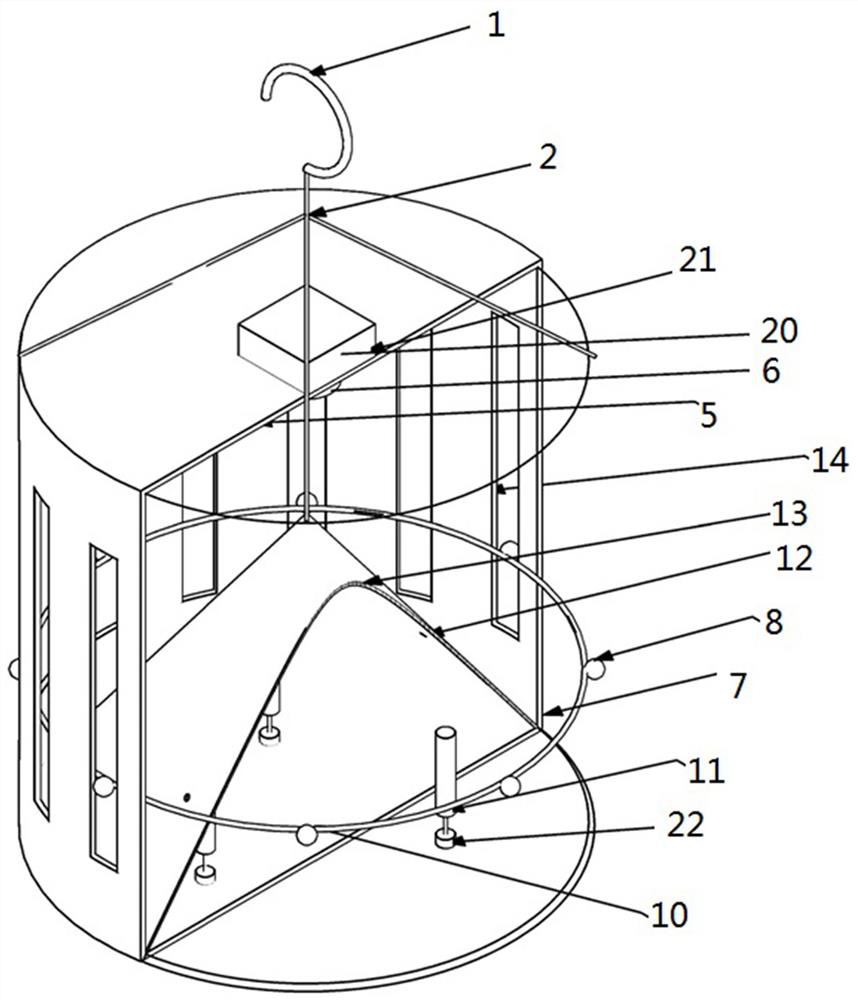

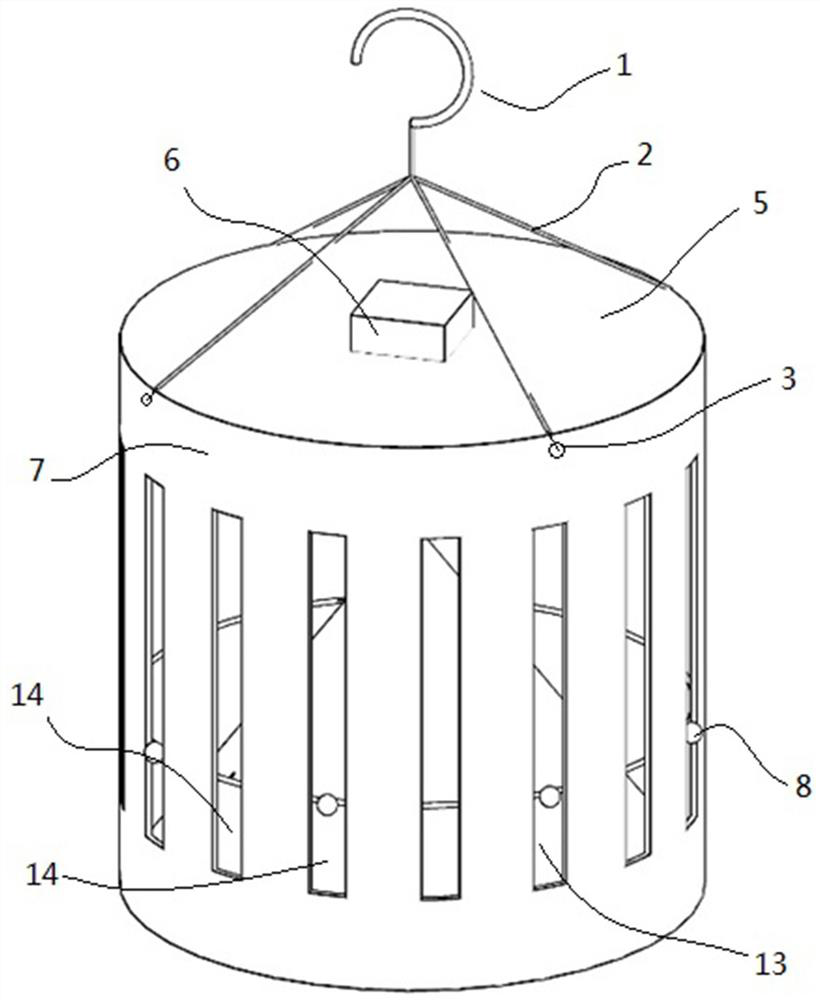

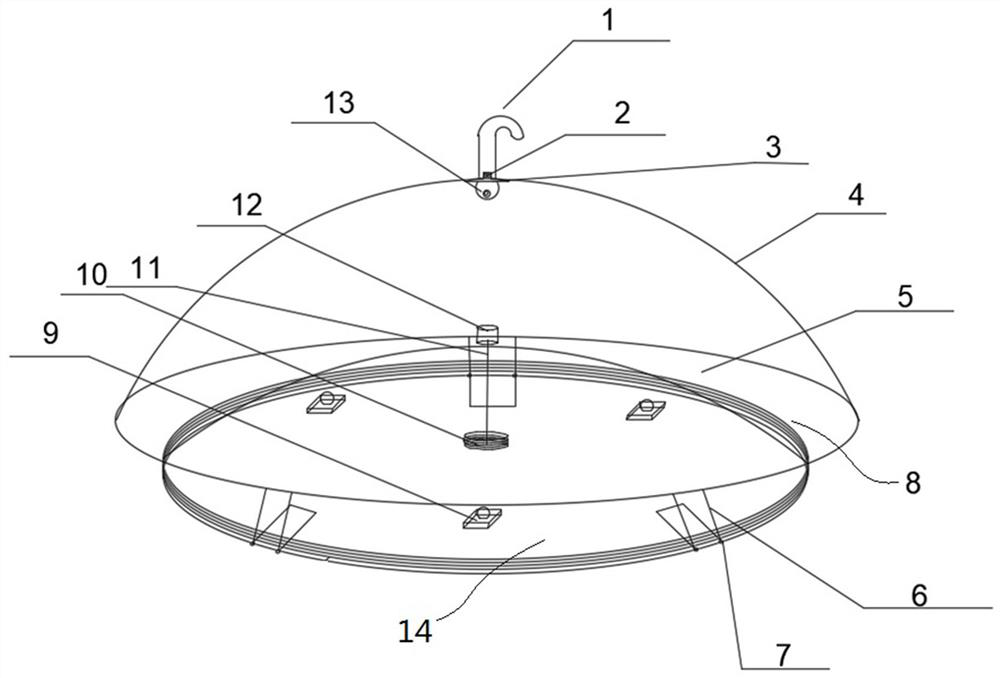

Stored grain insect on-line monitoring device

PendingCN111903636APlay a role in dustAvoid pollutionTelevision system detailsColor television detailsTrappingZoology

The invention relates to a stored grain insect on-line monitoring device which comprises a trapping device. The trapping device comprises a spherical viscose plate with a small upper part and a largelower part, the outer spherical surface of the spherical viscose plate is used for sticking and trapping insects, and the stored grain insect on-line monitoring device further comprises a spherical protective cover which is arranged at the upper side of the spherical viscose plate and has a small upper part and a large lower part. An annular insect inlet allowing insects to fly in from outside toinside is formed between the spherical protective cover and the spherical viscose plate, and a camera used for shooting the outer spherical surface of the spherical adhesive plate downwards is arranged at the position, over the spherical viscose plate, of the spherical protective cover. The invention provides the stored grain insect on-line monitoring device capable of accurately obtaining the insect catching amount.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

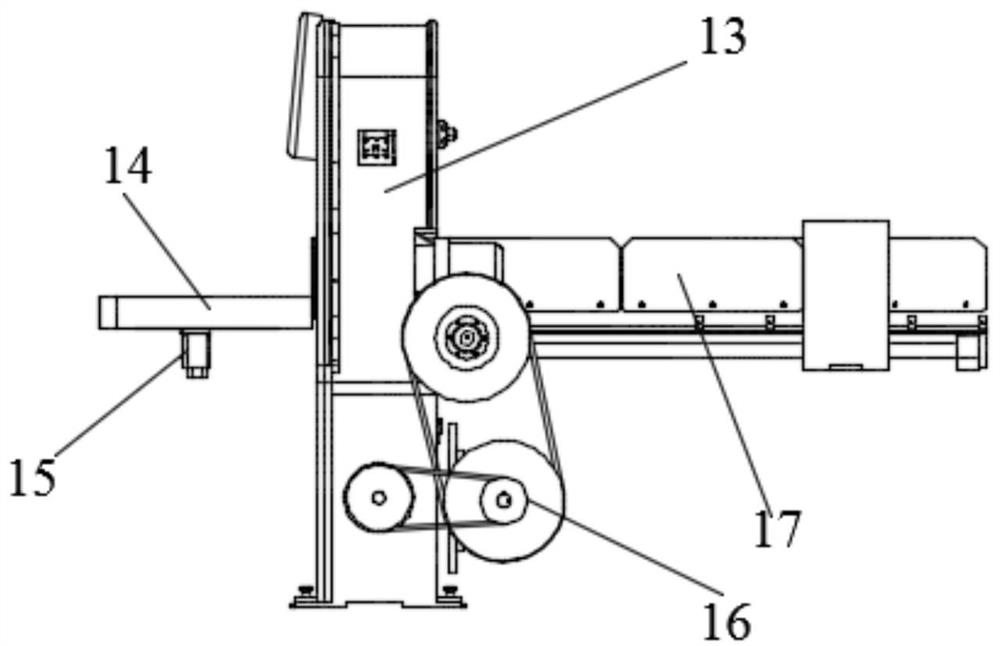

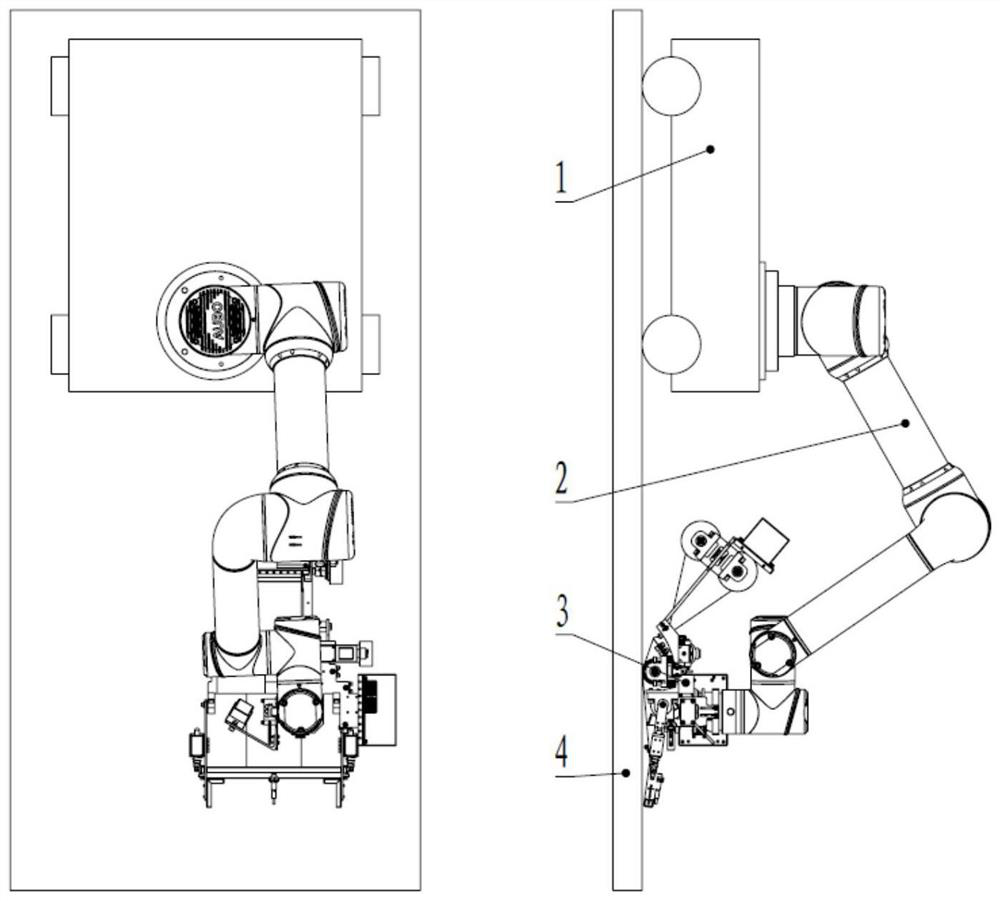

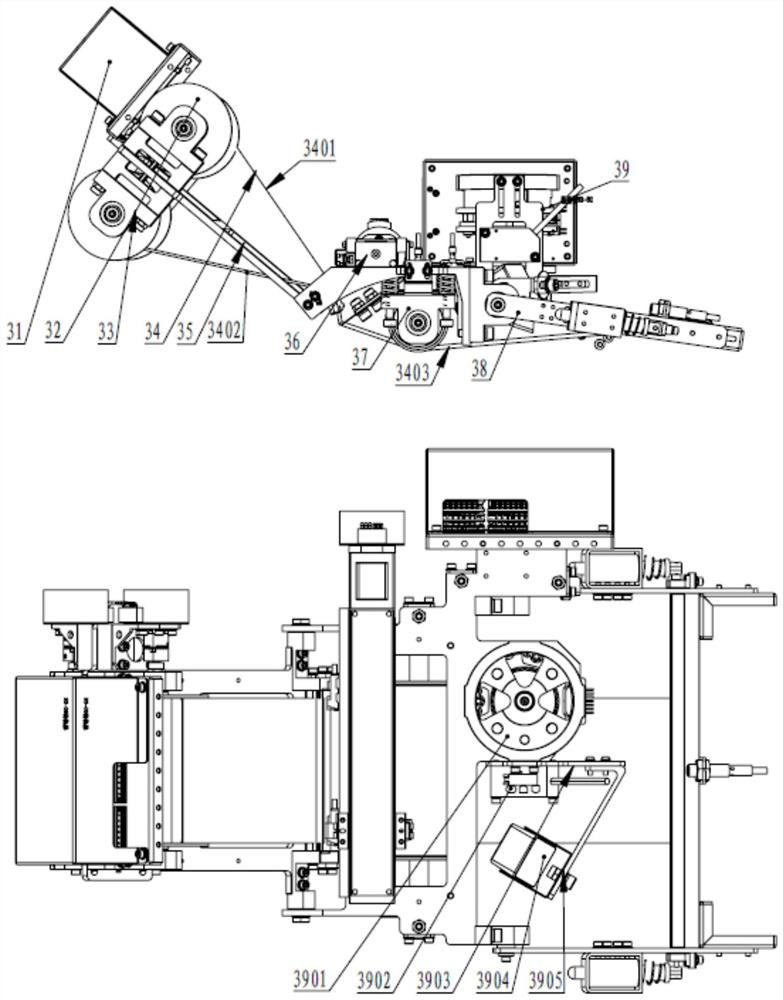

Intelligent pasting robot device and automatic pasting method

ActiveCN114263367APaste firmlyWith visual functionBuilding repairsUsing optical meansAdhesive beltControl engineering

The embodiment of the invention discloses an intelligent pasting robot device which comprises a robot body, a mechanical arm and an automatic pasting device, the robot body serves as an advancing mechanism to carry the intelligent pasting robot device to advance to an area needing pasting, and the mechanical arm and the automatic pasting device serve as an execution structure. The robot body carries the mechanical arm and the automatic pasting device to advance to an area needing pasting, and pasting operation is carried out through the mechanical arm and the automatic pasting device; the automatic pasting device comprises a controller, an upper winding assembly, a lower winding assembly, an adhesive tape, a guide assembly, a cutting assembly, a compression roller assembly, a tensioning assembly and a mounting flange assembly. The mechanical arm base is fixed to the robot body, and the automatic pasting device is installed at the tail end of the mechanical arm through an installation flange assembly. The intelligent attaching robot device is simple in structure, light in weight and capable of meeting the requirement of an intelligent robot, and an operator can complete construction of high-altitude operation on the ground.

Owner:北京克莱明科技有限公司

An environmentally friendly building curtain wall

ActiveCN112095871BEasy to fixImprove securityWallsBuilding repairsArchitectural engineeringScrew thread

Owner:深圳市瑞玮工程有限公司

Ceramic tile attaching method and spacer

PendingCN111980342AGuaranteed sticking effectGood installation effectCovering/liningsAdhesive glueComposite material

The invention discloses a ceramic tile attaching method. The ceramic tile attaching method is characterized in that the method includes the steps that (1) according to the different sizes of to-be-attached ceramic tiles, the attaching positions of a plurality of spacers are determined on a building main body; (2) the spacers are fixed to the corresponding positions on the building main body with anchor bolts; and (3) an structural adhesive is put on the spacers, and then the ceramic tiles and the spacers are bonded and fixed together. The invention also provides the spacer using the ceramic tile attaching method. When the ceramic tiles are attached and tightly pressed, the coated adhesive is squeezed and left in holding grooves by arranging a plurality of convex structures or concave structures on the connection surfaces between the ceramic tiles and the spacers, which can effectively improve the adhesion between the ceramic tiles and the spacers and ensure the attaching effect.

Owner:广东三力锁业有限公司

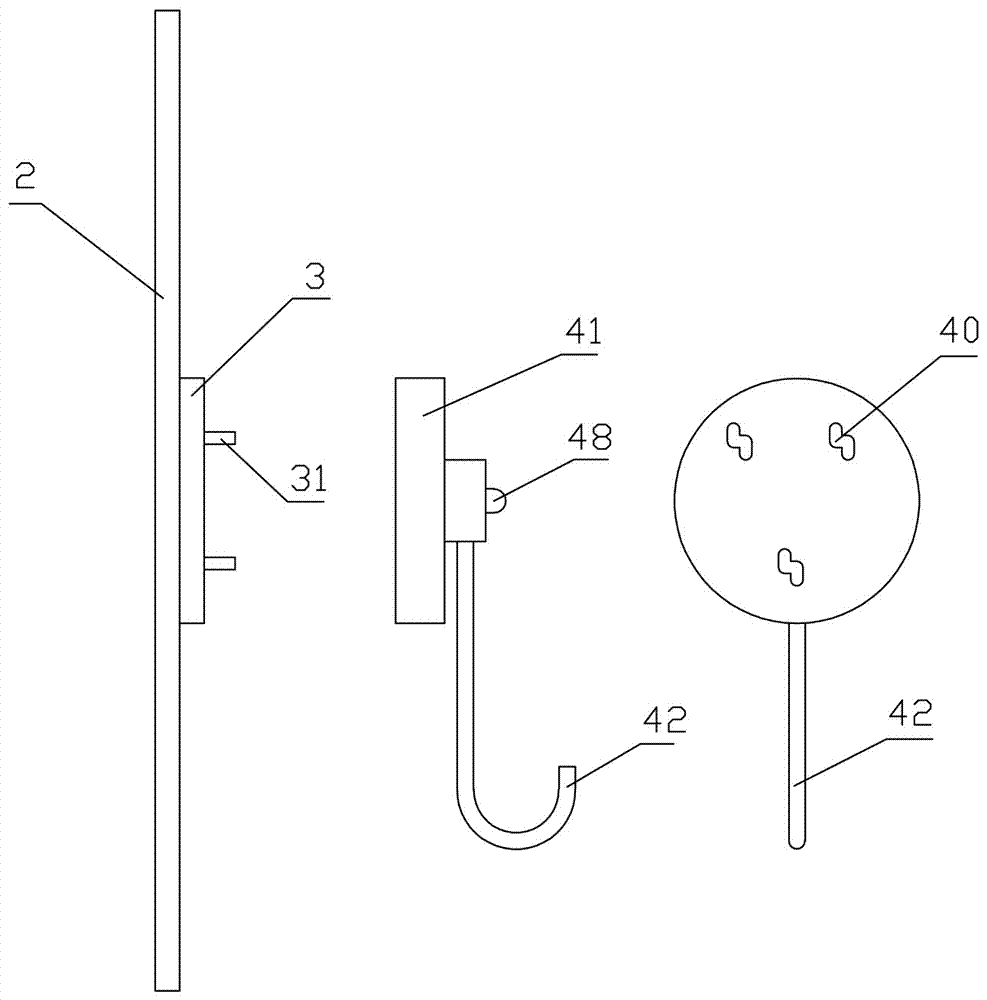

Intelligent hook on basis of pressures-sensitive imaging sensing absorption states

InactiveCN107374290AGuaranteed sticking effectExcellent adhesionKitchen equipmentDomestic articlesPressure sensitiveAbsorption effect

The invention relates to an intelligent hook based on pressure-sensitive imaging induction adsorption state, which includes a protective film, a silica gel suction cup, a support seat and a pendant. The silica gel suction cup includes a substrate layer of transparent material, and one surface of the substrate layer The pressure-sensitive imaging material layer, the isolation film and the silica gel film are covered sequentially from the inside to the outside, the protective film is attached to the surface of the silica gel film, the support base is fixed on the other side of the substrate layer, and the pendant installed on the support base. The invention is based on the fact that the pressure-sensitive imaging material layer will change color under a certain pressure, so that it is convenient for users to judge whether the silica gel suction cup has been fully and comprehensively applied pressure, and ensure that the silica gel suction cup achieves the best adsorption effect.

Owner:洪君扬

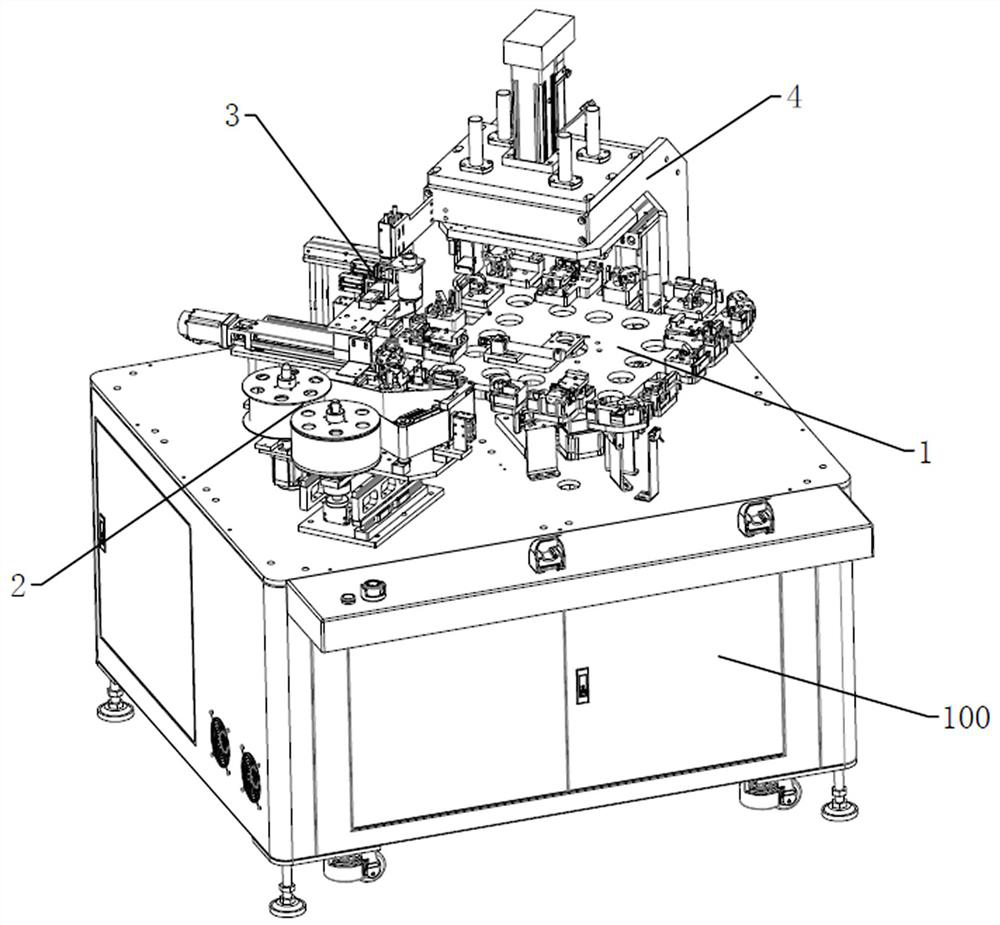

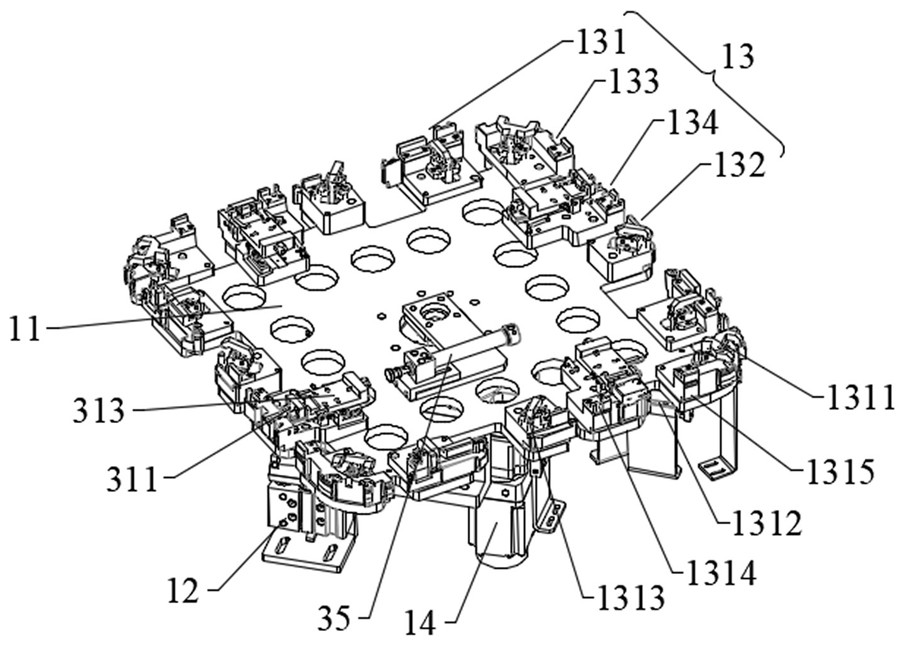

Film pasting equipment

The invention relates to the technical field of automatic equipment, and discloses film pasting equipment. The film pasting equipment comprises a rotating disc device, a film pasting device, a punching device and a sprue blanking device, the rotating disc device comprises a workbench, and the film pasting device, the punching device and the sprue blanking device are sequentially arranged on the outer side of the periphery of the workbench; the workbench is used for bearing a curved surface workpiece to be subjected to film pasting, and the workbench can rotate so as to sequentially convey the curved surface workpiece to be subjected to film pasting to the film pasting device, the punching device and the sprue blanking device. The film pasting device is used for pasting a protective film on the rotating curved surface workpiece to be pasted with the film; the punching device is used for punching the protective film of the curved-surface workpiece which is pasted with the film and is opposite to the punching device, so that the protective film is matched with the curved-surface workpiece; and the sprue blanking device is used for cutting the sprue of the curved-surface workpiece which is punched and directly faces the sprue blanking device. The curved surface workpiece subjected to film pasting is good in smoothness, the protective film cannot cover the functional hole, meanwhile, the protective film subjected to film pasting is good in flatness, and the pasting effect is good.

Owner:JIANGSU COWAIN AUTOMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com