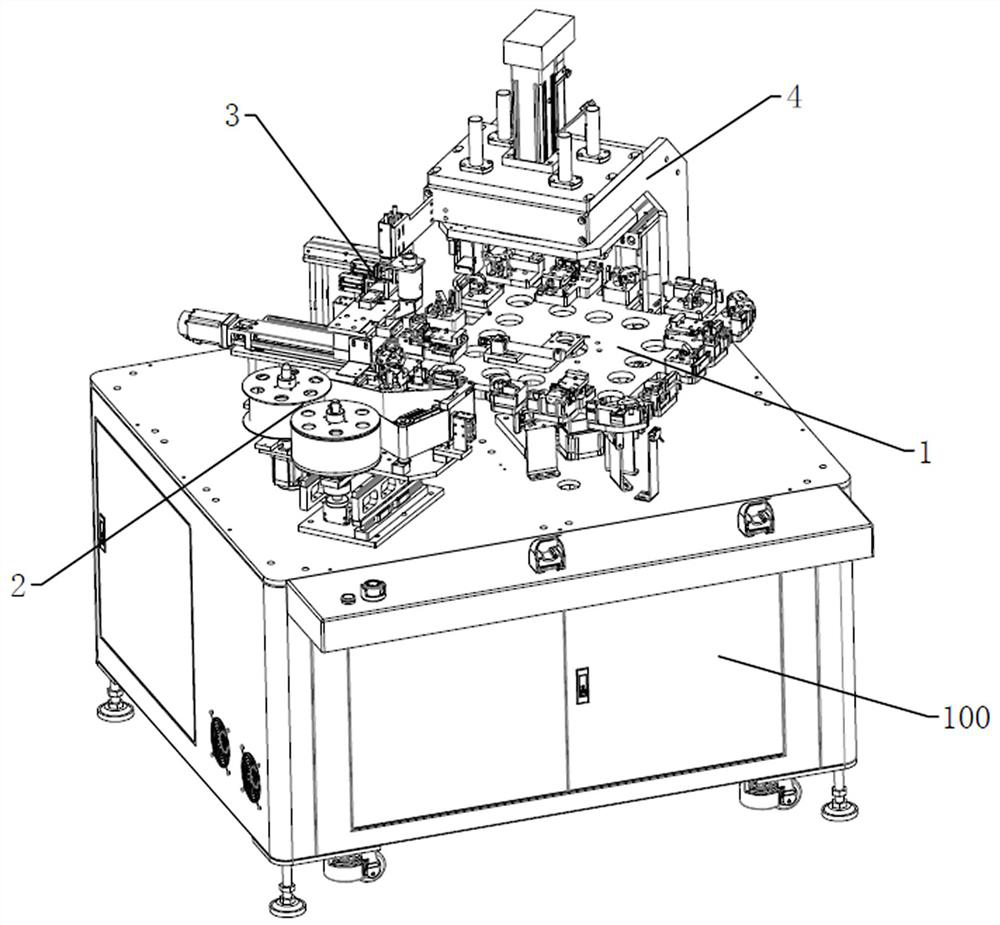

Film pasting equipment

A film sticking equipment and film sticking technology, applied in packaging and other directions, can solve the problems of misalignment, many equipment, and complicated procedures, and achieve the effect of good sticking effect, good flatness and good smoothness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

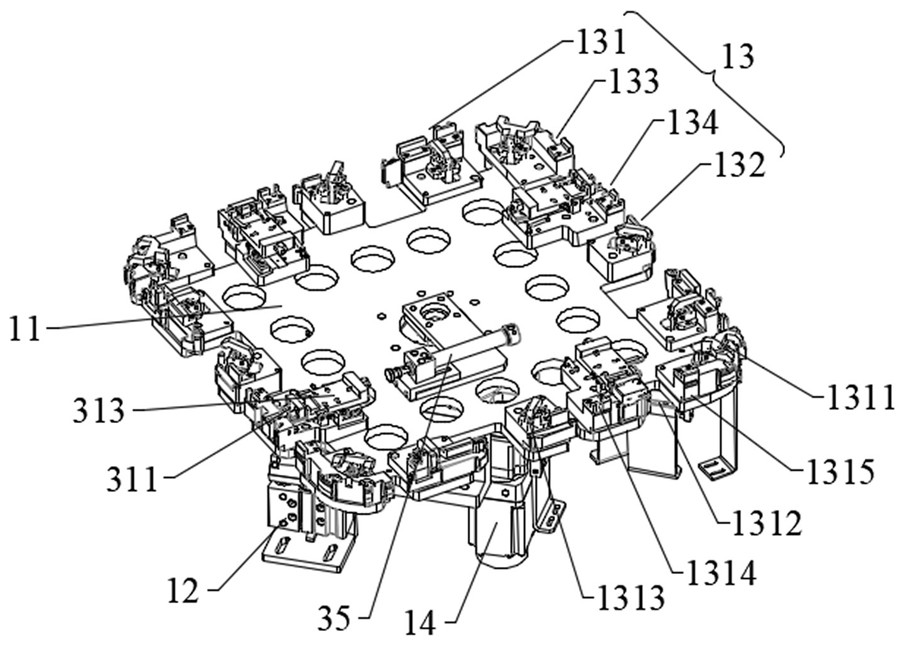

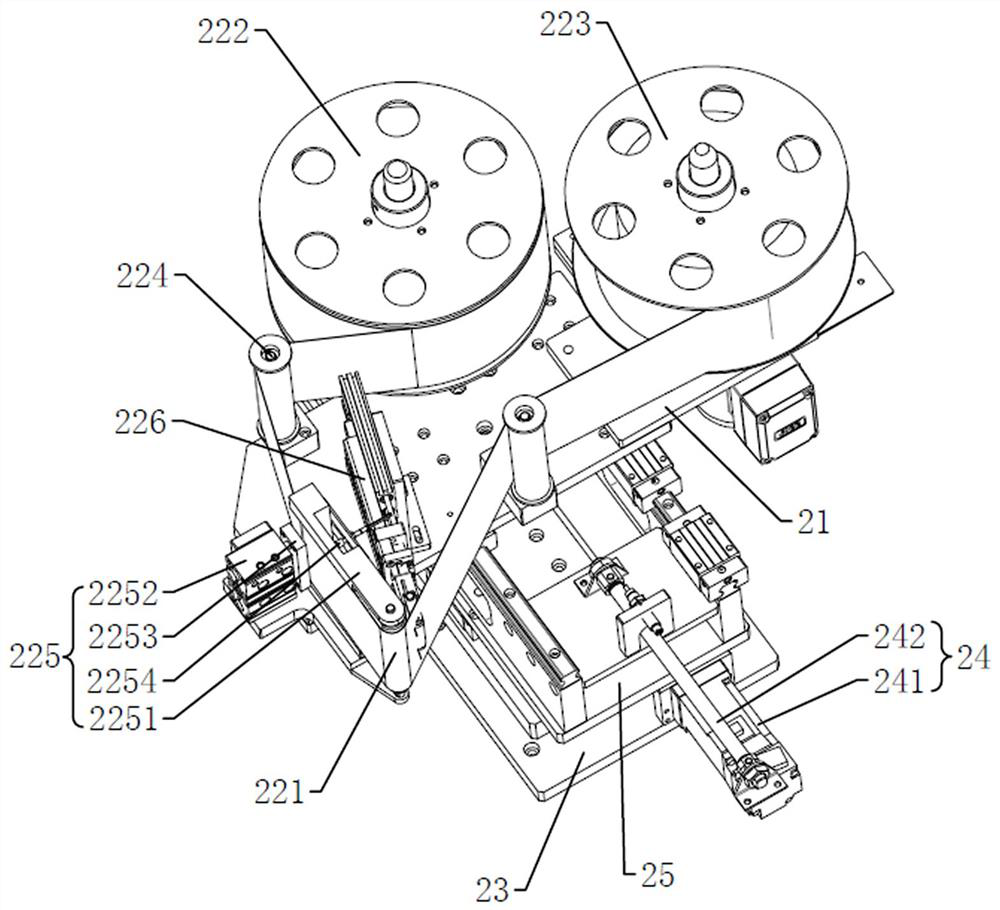

[0036] Specifically, the floating module 24 includes a first floating assembly 241, the first floating assembly 241 is arranged on the film base 23, and the first floating assembly 241 is configured to drive the film mounting plate 21 to float with respect to the distance between the workbench 11; the floating module 24 Also includes a second floating assembly 242, the second floating assembly 242 is arranged on the first floating assembly 241, the film mounting plate 21 is arranged on the second floating assembly 242, the second floating assembly 242 is configured to drive the film mounting plate 21 relative to the working The pitch of the stage 11 is floating. By setting the first floating assembly 241 and the second floating assembly 242, it is used to realize the floating of a larger distance between the attaching roller 221 and the workpiece with a curved surface to be attached, thereby improving the adaptability of the film attaching device 2 .

[0037] Exemplarily, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com