SMT chip mounter for circuit board production

A placement machine and circuit board technology, which is applied in the direction of assembling printed circuits, electrical components, electrical components, etc., can solve problems such as gaps and air bubbles, affect the quality of placement, and the circuit board is easy to adhere to dust, etc., to prevent The generation of gaps and air bubbles, the effect of ensuring the adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

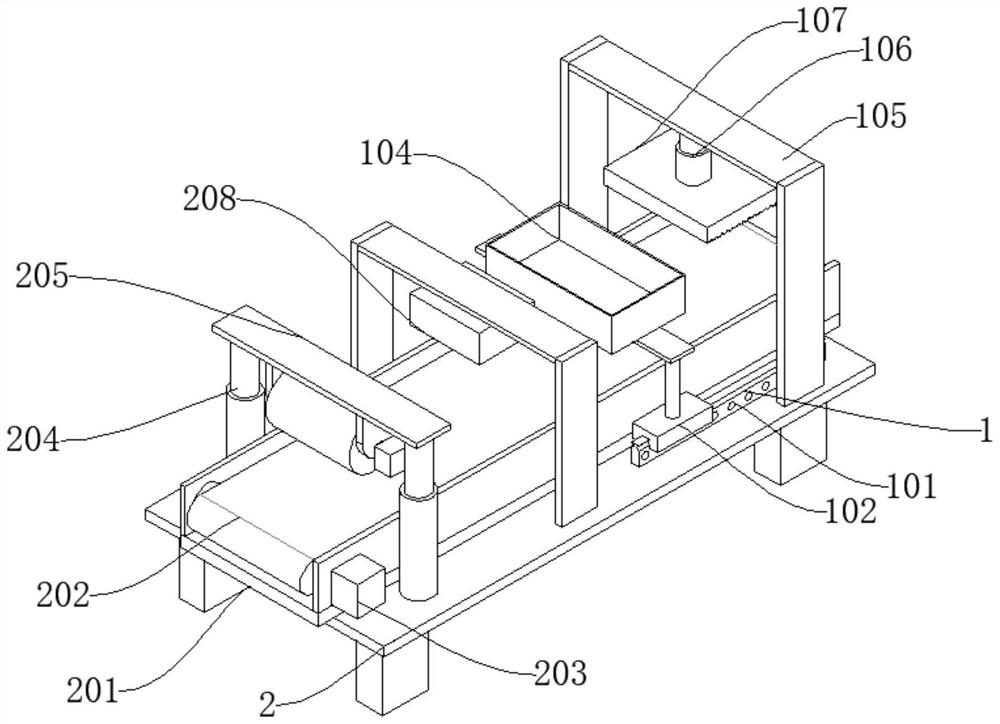

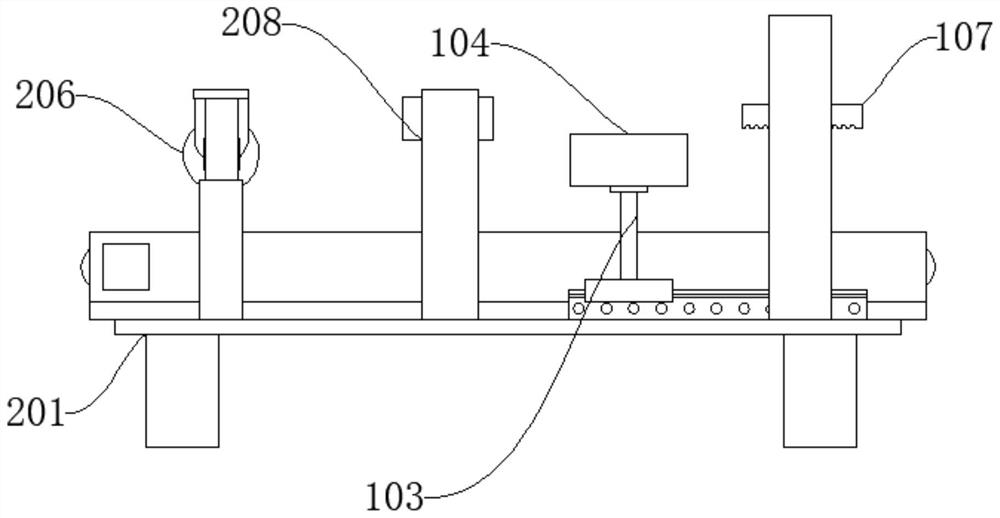

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention provides a technical solution: a SMT placement machine for circuit board production, including a dust removal mechanism 1, a working mechanism 2, and the dust removal mechanism 1 includes a slide rail 101, an electric slider 102, a support frame 103, and a slide rail 101 is equipped with an electric slider 102, the upper end of the electric slider 102 is provided with a support frame 103, the support frame 103 is provided with a collection box 104, the collection box 104 is used to collect dust conveniently, and a dust removal mechanism is installed on one side of the collection box 104; Working mechanism 2 comprises conveying frame 201, conveying belt 202, No. 1 motor 203, and conveying frame 201 inner side is equipped with conveying belt 202, and conveying belt 202 is in order to convey circuit board, conveying frame 201 front portion is installed No. 1 motor 203, No. 1 motor 203 sid...

Embodiment 2

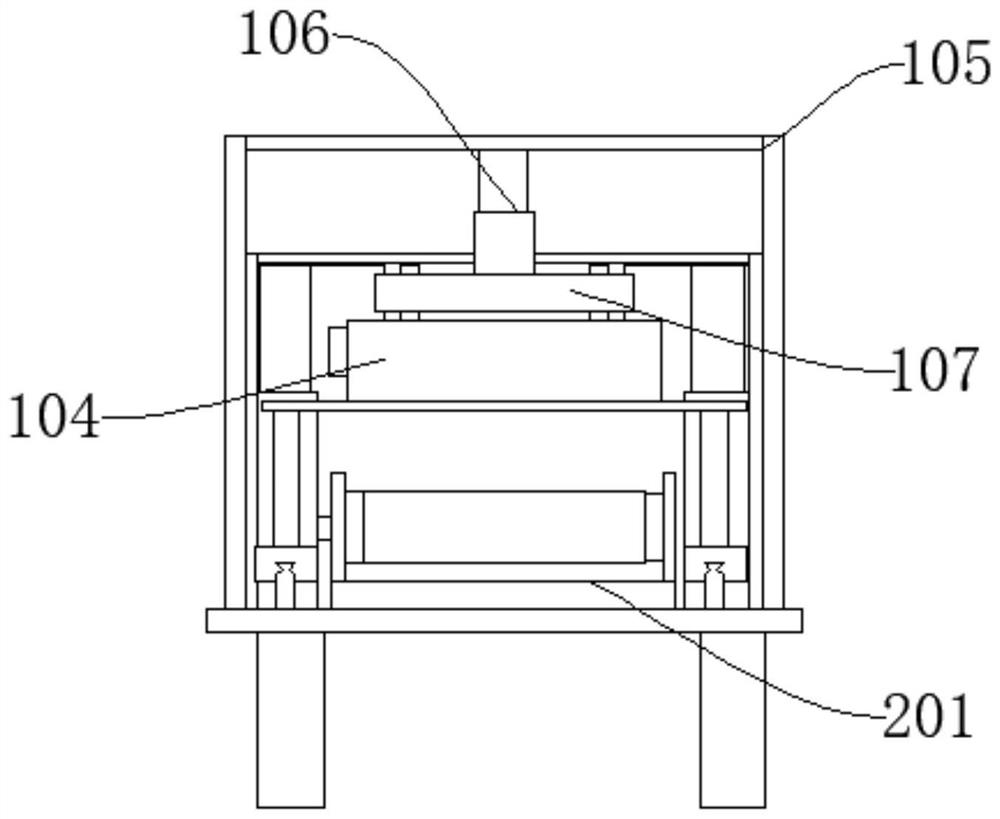

[0030] Such as Figure 5 As shown, the difference between Embodiment 2 and Embodiment 1 is that the dust removal mechanism includes a support 105, a No. 1 electric telescopic column 106, and an electrostatic adsorption rod 108. A No. 1 electric telescopic column 106 is installed inside the support 105, and the lower end of the No. 1 electric telescopic column 106 is An electrostatic adsorption bar 108 is installed.

[0031] The electrostatic precipitator net 107 is replaced by an electrostatic adsorption rod 108, which also plays the role of dust removal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com